battery location OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 588 of 6000

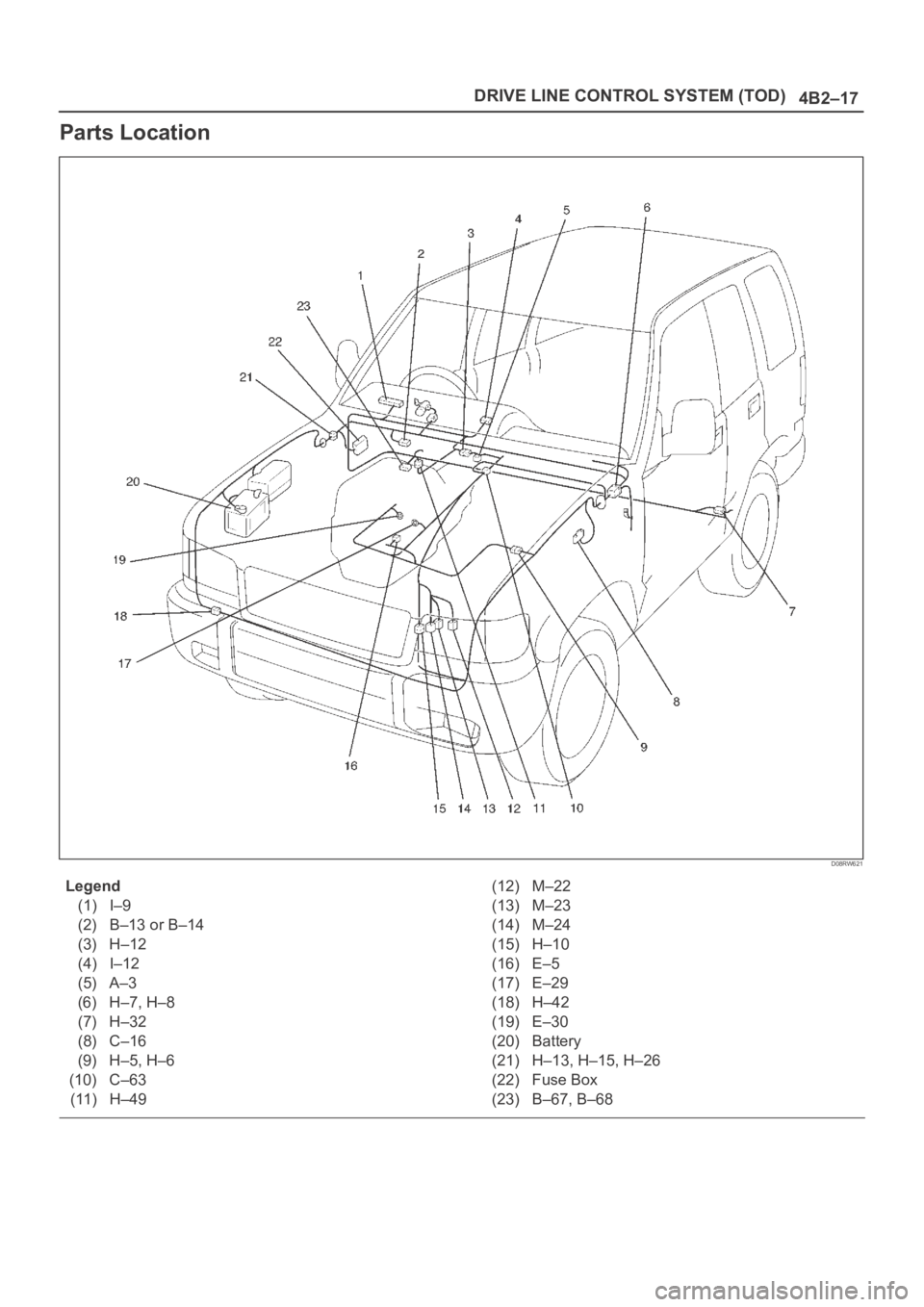

4B2–17 DRIVE LINE CONTROL SYSTEM (TOD)

Parts Location

D08RW621

Legend

(1) I–9

(2) B–13 or B–14

(3) H–12

(4) I–12

(5) A–3

(6) H–7, H–8

(7) H–32

(8) C–16

(9) H–5, H–6

(10) C–63

(11) H–49(12) M–22

(13) M–23

(14) M–24

(15) H–10

(16) E–5

(17) E–29

(18) H–42

(19) E–30

(20) Battery

(21) H–13, H–15, H–26

(22) Fuse Box

(23) B–67, B–68

Page 959 of 6000

6A–3

ENGINE MECHANICAL

General Description

Engine Cleanliness And Care

An automobile engine is a combination of many

machined, honed, polished and lapped surfaces with

tolerances that are measured in the thousandths of a

millimeter (ten thousandths of an inch). Accordingly,

when any internal engine parts are serviced, care and

cleanliness are important. Throughout this section, it

should be understood that proper cleaning and protection

of machined surfaces and friction areas is part of the

repair procedure. This is considered standard shop

practice even if not specifically stated.

A liberal coating of engine oil should be applied to all

friction areas during assembly to protect and lubricate

the surfaces on initial operation.

Whenever valve train components, pistons, piston

rings, connecting rods, rod bearings, and crankshaft

journal bearings are removed for service, they should

be retained in order.

At the time of installation, they should be installed in

the same locations and with the same mating

surfaces as when removed.

Battery cables should be disconnected before any

major work is performed on the engine. Failure to

disconnect cables may result in damage to wire

harness or other electrical parts.

The six cylinders of this engine are identified by

numbers; Right side cylinders 1, 3 and 5, Left side

cylinders 2, 4 and 6, as counted from crankshaft

pulley side to flywheel side.

General Information on Engine Service

The following information on engine service should be

noted carefully, as it is important in preventing damage

and contributing to reliable engine performance:

When raising or supporting the engine for any reason,

do not use a jack under the oil pan. Due to the small

clearance between the oil pan and the oil pump

strainer, jacking against the oil pan may cause

damage to the oil pick–up unit.

The 12–volt electrical system is capable of damaging

circuits. When performing any work where electrical

terminals could possibly be grounded, the ground

cable of the battery should be disconnected at the

battery.

Any time the intake air duct or air cleaner is removed,

the intake opening should be covered. This will

protect against accidental entrance of foreign

material into the cylinder which could cause extensive

damage when the engine is started.

Cylinder Block

The cylinder block is made of aluminum die–cast casting

for 75

V–type six cylinders. It has a rear plate integrated

structure and employs a deep skint. The cylinder liner is

cast and the liner inner diameter and crankshaft journal

diameter are classified into grades. The crankshaft is

supported by four bearings of which width of No.3 bearing

on the body side is different in order to support the thrust

bearing. The bearing cap is made of nodular cast iron and

each bearing cap uses four bolts and two side bolts.

Cylinder Head

The cylinder head, made of aluminum alloy casting

employs a pent–roof type combustion chamber with a

spark plug in the center. The intake and exhaust valves

are placed in V–type design. The ports are cross–flow

type.

Va l v e Tr a i n

Intake and exhaust camshaft on the both side of banks

are driven through an camshaft drive gear by timing belt.

The valves are operated by the camshaft and the valve

clearance is adjusted to select suitable thickness shim.

Intake Manifold

The intake manifold system is composed of the aluminum

cast common chamber and intake manifold attached with

six fuel injectors.

Exhaust Manifold

The exhaust manifold is made of nodular cast iron.

Pistons and Connecting Rods

Aluminum pistons are used after selecting the grade that

meets the cylinder bore diameter. Each piston has two

compression rings and one oil ring. The piston pin is made

of chromium steel is offset 1mm toward the thrust side,

and the thrust pressure of piston to the cylinder wall varies

gradually as the piston travels. The connecting rods are

made of forged steel. The connecting rod bearings are

graded for correct seze selection.

Crankshaft and Bearings

The crankshaft is made of Ductile cast–iron. Pins and

journals are graded for correct size selection for their

bearing.

Engine Lubrication

The oil discharged by a trochoid–type oil pump driven by

the crankshaft is fed through full–flow oil filter and to the oil

gallery provided under the crankshaft bearing cap. The oil

is then led to the crankshaft journals and cylinder head.

The crank pins are lubricated with oil from crankshaft

journals through oil holes. Also, an oil jet is fed to each

cylinder from crankshaft juornals on the connecting rod

for piston cleaning. The oil pan flange is dealed with liquid

packing only; do not deform or damage the flange surface

during removal or installation.

Page 1080 of 6000

ENGINE ELECTRICAL6D1–1

ENGINE

ENGINE ELECTRICAL

CONTENTS

Service Precaution 6D1–1. . . . . . . . . . . . . . . . . . . . . .

Battery 6D1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Description 6D1–2. . . . . . . . . . . . . . . . . . . .

Diagnosis 6D1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Battery Charging 6D1–3. . . . . . . . . . . . . . . . . . . . . . Jump Starting 6D1–3. . . . . . . . . . . . . . . . . . . . . . . . .

Battery Removal 6D1–4. . . . . . . . . . . . . . . . . . . . . .

Battery Installation 6D1–4. . . . . . . . . . . . . . . . . . . . .

Main Data and Specifications 6D1–5. . . . . . . . . . .

Service Precaution

WARNING: IF SO EQUIPPED WITH A

SUPPLEMENTAL RESTRAINT SYSTEM (SRS),

REFER TO THE SRS COMPONENT AND WIRING

LOCATION VIEW IN ORDER TO DETERMINE

WHETHER YOU ARE PERFORMING SERVICE ON OR

NEAR THE SRS COMPONENTS OR THE SRS

WIRING. WHEN YOU ARE PERFORMING SERVICE

ON OR NEAR THE SRS COMPONENTS OR THE SRS

WIRING, REFER TO THE SRS SERVICE

INFORMATION. FAILURE TO FOLLOW WARNINGS

COULD RESULT IN POSSIBLE AIR BAG

DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU will call out those fasteners that require a

replacement after removal. ISUZU will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED, do not

use supplemental coatings (Paints, greases, or other

corrosion inhibitors) on threaded fasteners or

fastener joint interfaces. Generally, such coatings

adversely affect the fastener torque and the joint

clamping force, and may damage the fastener. When

you install fasteners, use the correct tightening

sequence and specifications. Following these

instructions can help you avoid damage to parts and

systems.

Page 1191 of 6000

6E–74

ENGINE DRIVEABILITY AND EMISSIONS

No Malfunction Indicator Lamp (MIL)

D06RW00006

Circuit Description

The “Check Engine” lamp (MIL) should always be

illuminated and steady with the ignition “ON” and the

engine stopped. Ignition feed voltage is supplied to the

MIL bulb through the meter fuse. The powertrain control

module (PCM) turns the MIL “ON” by grounding the MIL

driver circuit.

Diagnostic Aids

An intermittent MIL may be cased by a poor connection,

rubbed-through wire insulation, or a wire broken inside

the insulation. Check for the following items:

Inspect the PCM harness and connections for

improper mating, broken locks, improperly formed or

damaged terminals, poor terminal-to-wire connection,

and damaged harness.

If the engine runs OK, check for a faulty light bulb, an

open in the MIL driver circuit, or an open in the

instrument cluster ignition feed.

If the engine cranks but will not run, check for an open

PCM ignition or battery feed, or a poor PCM to engine

ground.

Test Description

Number(s) below refer to the step number(s) on the

Diagnostic Chart.

2. A “No MIL” condition accompanied by a no-start

condition suggests a faulty PCM ignition feed or

battery feed circuit.

9. Using a test light connected to B+, probe each of the

PCM ground terminals to ensure that a good ground

is present. Refer to

PCM Terminal End View for

terminal locations of the PCM ground circuits.

12.In this step, temporarily substitute a known good

relay for the PCM relay. The horn relay is nearby,

and it can be verified as “good” simply by honking

the horn. Replace the horn relay after completing

this step.

Page 1224 of 6000

6E–107 ENGINE DRIVEABILITY AND EMISSIONS

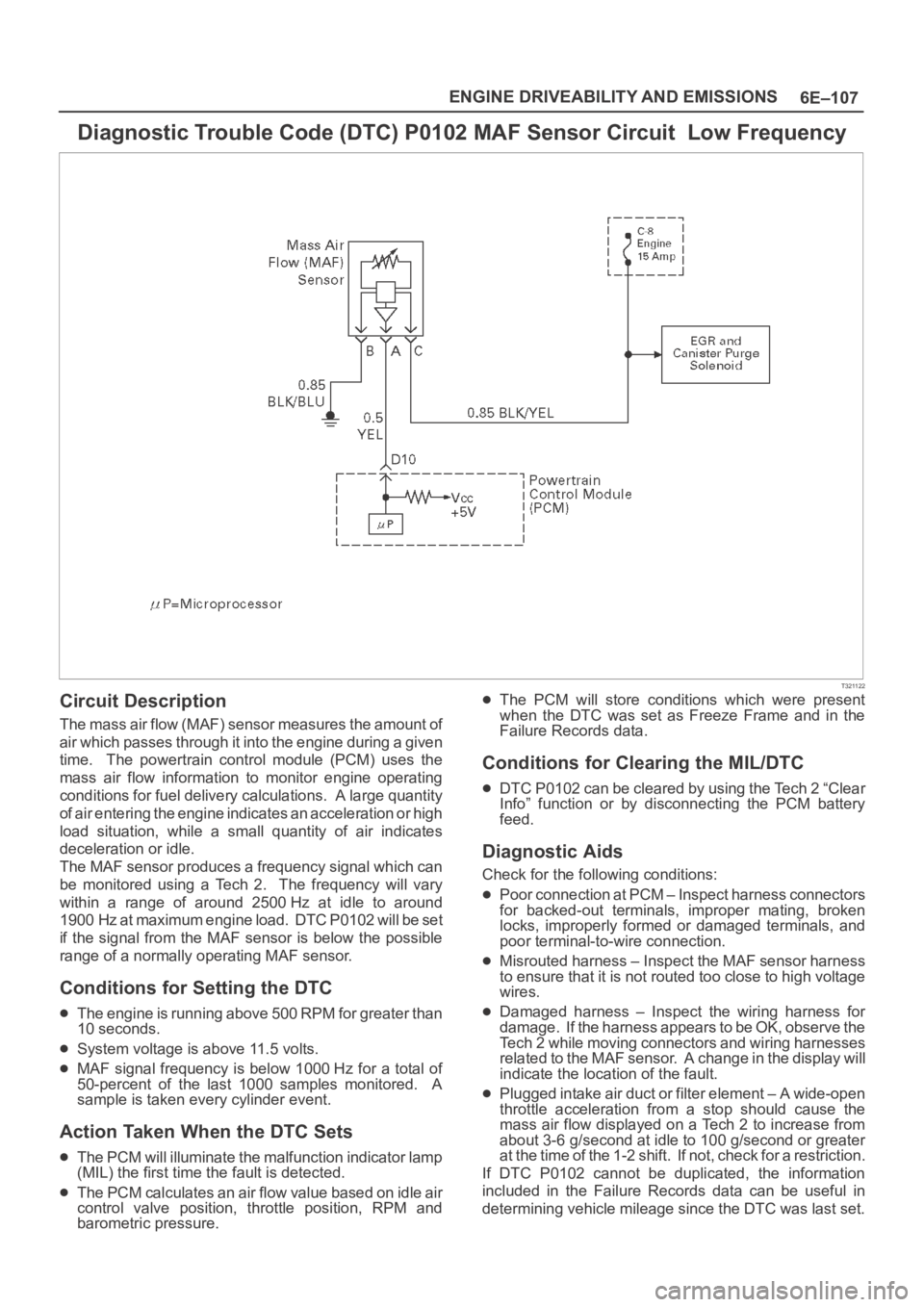

Diagnostic Trouble Code (DTC) P0102 MAF Sensor Circuit Low Frequency

T321122

Circuit Description

The mass air flow (MAF) sensor measures the amount of

air which passes through it into the engine during a given

time. The powertrain control module (PCM) uses the

mass air flow information to monitor engine operating

conditions for fuel delivery calculations. A large quantity

of air entering the engine indicates an acceleration or high

load situation, while a small quantity of air indicates

deceleration or idle.

The MAF sensor produces a frequency signal which can

be monitored using a Tech 2. The frequency will vary

within a range of around 2500 Hz at idle to around

1900 Hz at maximum engine load. DTC P0102 will be set

if the signal from the MAF sensor is below the possible

range of a normally operating MAF sensor.

Conditions for Setting the DTC

The engine is running above 500 RPM for greater than

10 seconds.

System voltage is above 11.5 volts.

MAF signal frequency is below 1000 Hz for a total of

50-percent of the last 1000 samples monitored. A

sample is taken every cylinder event.

Action Taken When the DTC Sets

The PCM will illuminate the malfunction indicator lamp

(MIL) the first time the fault is detected.

The PCM calculates an air flow value based on idle air

control valve position, throttle position, RPM and

barometric pressure.

The PCM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

DTC P0102 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the PCM battery

feed.

Diagnostic Aids

Check for the following conditions:

Poor connection at PCM – Inspect harness connectors

for backed-out terminals, improper mating, broken

locks, improperly formed or damaged terminals, and

poor terminal-to-wire connection.

Misrouted harness – Inspect the MAF sensor harness

to ensure that it is not routed too close to high voltage

wires.

Damaged harness – Inspect the wiring harness for

damage. If the harness appears to be OK, observe the

Tech 2 while moving connectors and wiring harnesses

related to the MAF sensor. A change in the display will

indicate the location of the fault.

Plugged intake air duct or filter element – A wide-open

throttle acceleration from a stop should cause the

mass air flow displayed on a Tech 2 to increase from

about 3-6 g/second at idle to 100 g/second or greater

at the time of the 1-2 shift. If not, check for a restriction.

If DTC P0102 cannot be duplicated, the information

included in the Failure Records data can be useful in

determining vehicle mileage since the DTC was last set.

Page 1232 of 6000

6E–115 ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0108 MAP Sensor Circuit High Voltage

D06RW102

Circuit Description

The manifold absolute pressure (MAP) sensor responds

to changes in intake manifold pressure (vacuum). The

MAP sensor signal voltage to the powertrain control

module (PCM) varies from below 2 volts at idle (high

vacuum) to above 4 volts with the key “ON,” engine not

running or at wide-open throttle (low vacuum).

The MAP sensor is used to determine manifold pressure

changes while the linear EGR flow test diagnostic is being

run (refer to

DTC P0401), to determine engine vacuum

level for some other diagnostics and to determine

barometric pressure (BARO). The PCM monitors the

MAP signals for voltages outside the normal range of the

MAP sensor. If the PCM detects a MAP signal voltage

that is excessively high, DTC P0108 will be set.

Conditions for Setting the DTC

No TP sensor DTCs present.

Engine is running for more than 10 seconds.

Throttle position is below 3% if engine speed is below

1000 RPM.

Throttle position is below 10% if engine speed is above

1000 RPM.

The MAP sensor indicates an intermittent manifold

absolute pressure above 80kPa for a total of

approximately 10 seconds over a 16-second period.

Action Taken When the DTC Sets

The PCM will illuminate the malfunction indicator lamp

(MIL) the first time the fault is detected.

The PCM will default to a BARO value of 79.3 kPa.

The PCM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

DTC P0108 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the PCM battery

feed.

Diagnostic Aids

Check for the following conditions:

Poor connection at PCM – Inspect harness connectors

for backed-out terminals, improper mating, broken

locks, improperly formed or damaged terminals, and

poor terminal-to-wire connection.

Damaged harness – Inspect the wiring harness for

damage. If the harness appears to be OK, observe the

MAP display on the Tech 2 while moving connectors

and wiring harnesses related to the sensor. A change

in the display will indicate the location of the fault.

If DTC P0108 cannot be duplicated, the information

included in the Failure Records data can be useful in

determining vehicle mileage since the DTC was last set. If

it is determined that the DTC occurs intermittently,

performing the DTC P1108 Diagnostic Chart may isolate

the cause of the fault.

Page 1235 of 6000

6E–118

ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0112 IAT Sensor Circuit Low Voltage

D06RW026

Circuit Description

The intake air temperature (IAT) sensor is a thermistor

which measures the temperature of the air entering the

engine. The powertrain control module (PCM) applies 5

volts through a pull-up resistor to the IAT sensor. When

the intake air is cold, the sensor resistance is high and the

PCM will monitor a high signal voltage on the IAT signal

circuit. If the intake air is warm, the sensor resistance is

lower, causing the PCM to monitor a lower voltage. DTC

P0112 will set when the PCM detects an excessively low

signal voltage on the intake air temperature sensor signal

circuit.

Conditions for Setting the DTC

The engine has been running for over 2 minutes.

Vehicle speed is greater than 30 mph (48 km/h) .

IAT signal voltage indicates and intake air temperature

greater than 148C (298F) (about 5 volts) for a total

of 12.5 seconds over a 25-second period of time.

Action Taken When the DTC Sets

The PCM will illuminate the malfunction indicator lamp

(MIL) the first time the fault is detected.

The PCM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

DTC P0112 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the PCM battery

feed.

Diagnostic Aids

Check for the following conditions:

Poor connection at PCM – Inspect harness connectors

for backed-bout terminals, improper mating, broken

locks, improperly formed or damaged terminals, and

poor terminal-to-wire connection.

Damaged harness – Inspect the wiring harness for

damage. If the harness appears to be OK, observe the

IAT display on the Tech 2 while moving connectors and

wiring harnesses related to the IAT sensor. A change

in the IAT display will indicate the location of the fault.

If DTC P0112 cannot be duplicated, the information

included in the Failure Records data can be useful in

determining vehicle mileage since the DTC was last set.

Test Description

Number(s) below refer to the step number(s) on the

Diagnostic Chart:

2. Verifies that the fault is present.

Page 1238 of 6000

6E–121 ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0113 IAT Sensor Circuit High Voltage

D06RW026

Circuit Description

The intake air temperature (IAT) sensor is a thermistor

which measures the temperature of the air entering the

engine. The powertrain control module (PCM) applies 5

volts through a pull-up resistor to the IAT sensor. When

the intake air is cold, the sensor resistance is high and the

PCM will monitor a high signal voltage on the IAT signal

circuit. If the intake air is warm, the sensor resistance is

lower causing the PCM to monitor a lower voltage. DTC

P0113 will set when the PCM detects an excessively high

signal voltage on the intake air temperature sensor signal

circuit.

Conditions for Setting the DTC

The engine has been running for over 4 minutes.

Vehicle speed is less than 20 mph (32 km/h).

ECT signal temperature is above 60C (140F).

Mass air flow is less then 20 g/second.

IAT signal voltage indicates an intake air temperature

less than –39C (–38F) for total of 12.5 seconds over

a 25-second period.

Action Taken When the DTC Sets

The PCM will illuminate the malfunction indicator lamp

(MIL) the first time the fault is detected.

The PCM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

DTC P0113 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the PCM battery

feed.

Diagnostic Aids

Check for the following conditions:

The IAT sensor shares a ground with the EGR position

sensor and the TP sensor. Check the ground if these

DTC’s are set.

Poor connection at PCM – Inspect harness connectors

for backed-out terminals, improper mating, broken

locks, improperly formed or damaged terminals, and

poor terminal-to-wire connection.

Damaged harness – Inspect the wiring harness for

damage. If the harness appears to be OK, observe the

IAT display on the Tech 2 while moving connectors and

wiring harnesses related to the IAT sensor. A change

in the IAT display will indicate the location of the fault.

If DTC P0113 cannot be duplicated, the information

included in the Failure Records data can be useful in

determining vehicle mileage since the DTC was last set.

Test Description

Number(s) below refer to the step number(s) on the

Diagnostic Chart:

2. Verifies that the fault is present.

Page 1241 of 6000

6E–124

ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0117 ECT Sensor Circuit Low Voltage

060RY00304

Circuit Description

The engine coolant temperature (ETC) sensor is a

thermistor mounted on a coolant crossover pipe at the

rear of the engine. The powertrain control module (PCM)

applies a voltage (about 5 volts) through a pull-up resistor

to the ECT signal circuit. When the engine coolant is cold,

the sensor (thermistor) resistance is high, therefore the

PCM will measure a high signal voltage. As the engine

coolant warms, the sensor resistance becomes lower,

and the ECT signal voltage measured at the PCM drops.

With a fully warmed-up engine, the ECT signal voltage

should measure about 1.5 to 2.0 volts.

Conditions for Setting the DTC

Engine running time is longer than one minute.

The ECT sensor signal indicates an engine coolant

temperature greater than 150C (302F) (about 0.10

V) for a total of 50 seconds over a 100–second period.

Action Taken When the DTC Sets

The PCM will illuminate the malfunction indicator lamp

(MIL) the first time the fault is detected.

The PCM will substitute the ECT reading with a default

engine coolant temperature value. The default value

is based on start-up intake air temperature and running

time.

The PCM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

DTC P0117 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the PCM battery

feed.

Diagnostic Aids

Check for the following conditions:

Poor connection at PCM – Inspect harness connectors

for backed-out terminals, improper mating, broken

locks, improperly formed or damaged terminals, and

poor terminal-to-wire connection.

Damaged harness – Inspect the wiring harness for

damage. If the harness appears to be OK, observe the

ECT display on the Tech 2 while moving connectors

and wiring harnesses related to the ECT sensor. A

change in the ECT display will indicate the location of

the fault.

If DTC P0117 cannot be duplicated, the information

included in the Failure Records data can be useful in

determining vehicle mileage since the DTC was last set.

Test Description

Number(s) below refer to the step number(s) on the

Diagnostic Chart.

Page 1244 of 6000

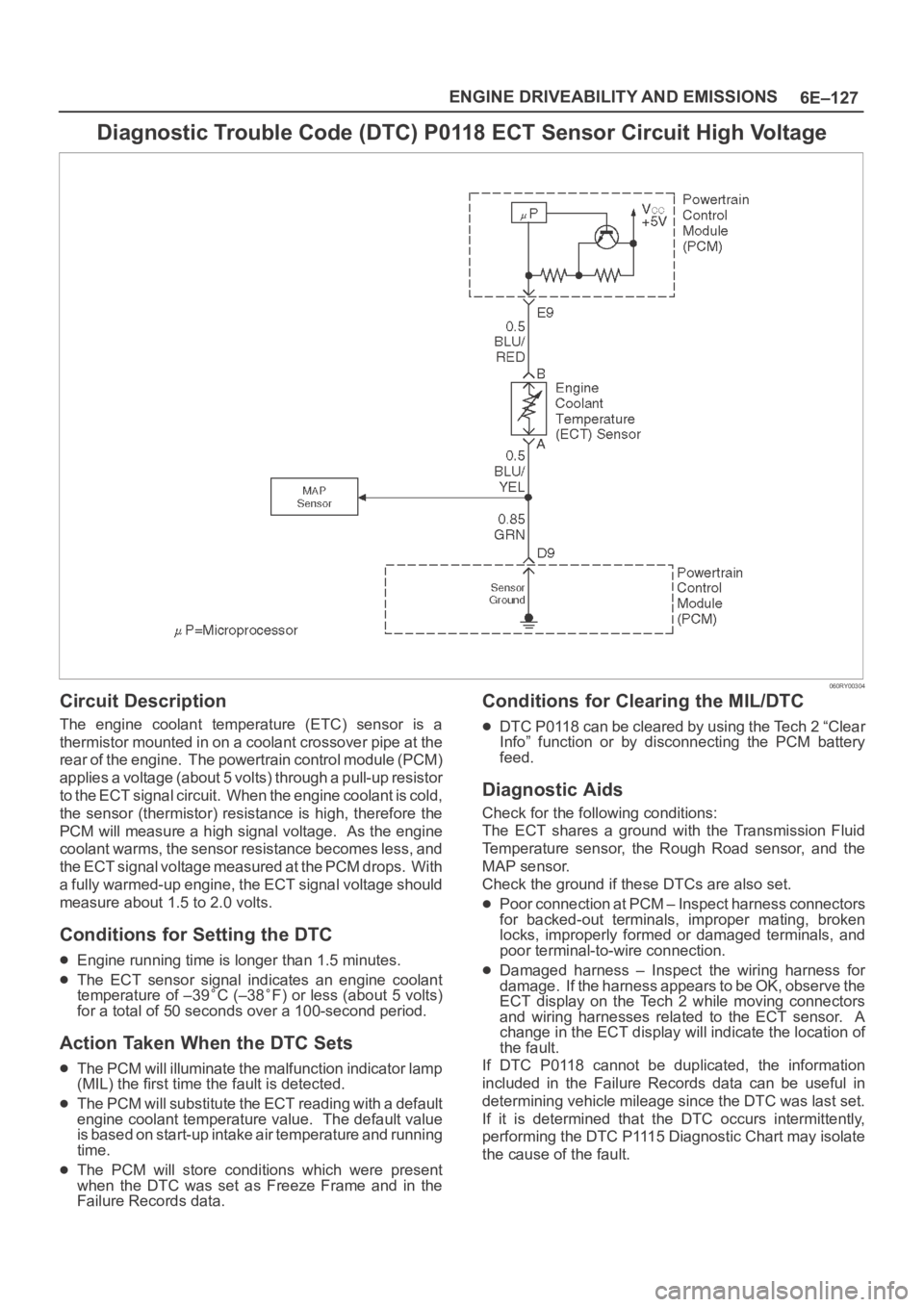

6E–127 ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0118 ECT Sensor Circuit High Voltage

060RY00304

Circuit Description

The engine coolant temperature (ETC) sensor is a

thermistor mounted in on a coolant crossover pipe at the

rear of the engine. The powertrain control module (PCM)

applies a voltage (about 5 volts) through a pull-up resistor

to the ECT signal circuit. When the engine coolant is cold,

the sensor (thermistor) resistance is high, therefore the

PCM will measure a high signal voltage. As the engine

coolant warms, the sensor resistance becomes less, and

the ECT signal voltage measured at the PCM drops. With

a fully warmed-up engine, the ECT signal voltage should

measure about 1.5 to 2.0 volts.

Conditions for Setting the DTC

Engine running time is longer than 1.5 minutes.

The ECT sensor signal indicates an engine coolant

temperature of –39C (–38F) or less (about 5 volts)

for a total of 50 seconds over a 100-second period.

Action Taken When the DTC Sets

The PCM will illuminate the malfunction indicator lamp

(MIL) the first time the fault is detected.

The PCM will substitute the ECT reading with a default

engine coolant temperature value. The default value

is based on start-up intake air temperature and running

time.

The PCM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

DTC P0118 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the PCM battery

feed.

Diagnostic Aids

Check for the following conditions:

The ECT shares a ground with the Transmission Fluid

Temperature sensor, the Rough Road sensor, and the

MAP sensor.

Check the ground if these DTCs are also set.

Poor connection at PCM – Inspect harness connectors

for backed-out terminals, improper mating, broken

locks, improperly formed or damaged terminals, and

poor terminal-to-wire connection.

Damaged harness – Inspect the wiring harness for

damage. If the harness appears to be OK, observe the

ECT display on the Tech 2 while moving connectors

and wiring harnesses related to the ECT sensor. A

change in the ECT display will indicate the location of

the fault.

If DTC P0118 cannot be duplicated, the information

included in the Failure Records data can be useful in

determining vehicle mileage since the DTC was last set.

If it is determined that the DTC occurs intermittently,

performing the DTC P1115 Diagnostic Chart may isolate

the cause of the fault.