ECU OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 2581 of 6000

8B–12WIPER/WASHER SYSTEM

Headlight Wiper and Washer Switch

Removal

1. Disconnect the battery ground cable.

2. Remove the front console assembly(1).

Refer to the Instrument Panel Assembly in Body

Structure section.

3. Remove the lower cluster assembly(2).

Refer to the Instrument Panel Assembly in Body

Structure section.

4. Remove the instrument panel driver lower cover(3).

Refer to the Instrument Panel Assembly in Body

Structure section.

821RW024

5. Remove the instrument panel cluster assembly(4).

Refer to the Instrument Panel Assembly in Body

Structure section.

6. Disconnect the connector and push the lock from the

back side of the instrument panel cluster assembly to

remove the headlight wiper switch(5).

825RW245

Installation

To install, follow the removal steps in the reverse order,

noting the following point:

1. Push the switch with your fingers until it locks

securely.

Page 2586 of 6000

ENTERTAINMENT8C–3

Digital Clock

Removal

1. Disconnect the battery ground cable.

2. Remove the front console assembly(1).

Refer to the Instrument Panel Assembly in Body

Structure section.

3. Remove the lower cluster assembly(2).

Refer to the Instrument Panel Assembly in Body

Structure section.

4. Remove the instrument panel driver lower cover

assembly(3).

Refer to the Instrument Panel Assembly in Body

Structure section.

821RW024

5. Remove the instrument panel cluster assembly(4).

Refer to the Instrument Panel Assembly in Body

Structure section.

6. Disconnect the connector and push the lock from the

back side of the instrument panel cluster assembly to

remove the digital clock(5).

821RW034

Installation

To install, follow the removal steps in the reverse order,

noting the following point.

1. Push in the switch with your fingers until it locks

securely.

Page 2601 of 6000

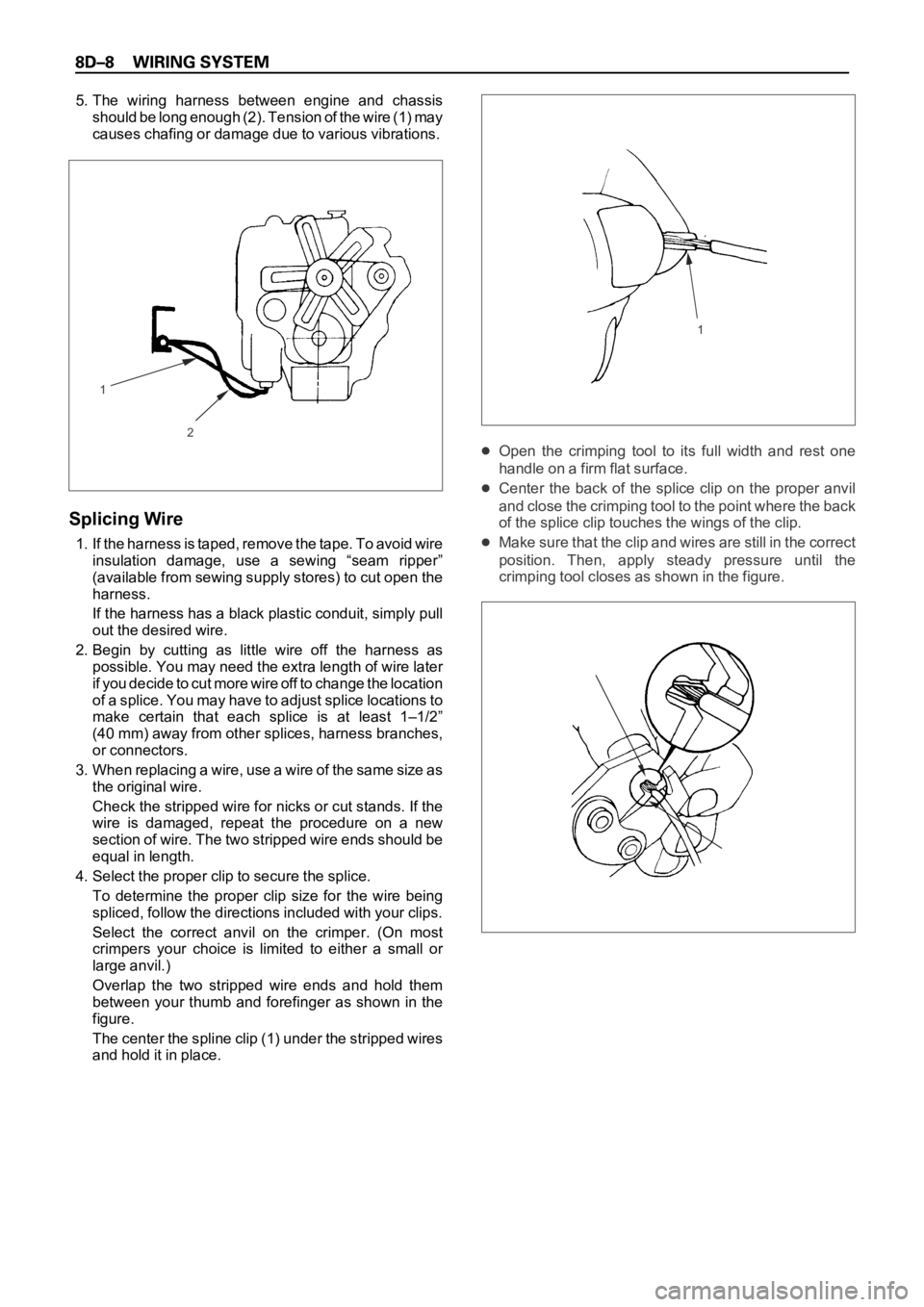

5. The wiring harness between engine and chassis

should be long enough (2). Tension of the wire (1) may

causes chafing or damage due to various vibrations.

Splicing Wire

1. If the harness is taped, remove the tape. To avoid wire

insulation damage, use a sewing “seam ripper”

(available from sewing supply stores) to cut open the

harness.

If the harness has a black plastic conduit, simply pull

out the desired wire.

2. Begin by cutting as little wire off the harness as

possible. You may need the extra length of wire later

if you decide to cut more wire off to change the location

of a splice. You may have to adjust splice locations to

make certain that each splice is at least 1–1/2”

(40 mm) away from other splices, harness branches,

or connectors.

3 . W h e n r e p l a c i n g a w i r e , u s e a w i r e o f t h e s a m e s i z e a s

the original wire.

Check the stripped wire for nicks or cut stands. If the

wire is damaged, repeat the procedure on a new

section of wire. The two stripped wire ends should be

equal in length.

4. Select the proper clip to secure the splice.

To determine the proper clip size for the wire being

spliced, follow the directions included with your clips.

Select the correct anvil on the crimper. (On most

crimpers your choice is limited to either a small or

large anvil.)

Overlap the two stripped wire ends and hold them

between your thumb and forefinger as shown in the

figure.

The center the spline clip (1) under the stripped wires

and hold it in place.

Open the crimping tool to its full width and rest one

handle on a firm flat surface.

Center the back of the splice clip on the proper anvil

and close the crimping tool to the point where the back

of the splice clip touches the wings of the clip.

Make sure that the clip and wires are still in the correct

position. Then, apply steady pressure until the

crimping tool closes as shown in the figure.

2

11

Page 2859 of 6000

STEP ACTION VALUE(S) YES NO

Is the fuse C–4 normal?

Is the circuit breaker C/B–2 normal?

Is B–19 grounded securely?

Disconnect the power window relay connector B–37.

Is the battery voltage applied between harness side

connector B–37 terminal 2 and the ground?

Repair an open circuit between the circuit breaker C/B–2 and

connector B–37 terminal 2.

Is the action complete?

Turn the starter switch on

Is the battery voltage applied between harness side

connector B–37 terminal 1 and the ground?

Repair an open circuit between the fuse C–4 and connector

B–37 terminal 1.

Is the action complete?

Is there continuity between harness side connector B–37

terminal 3 and the ground B–19?

Repair an open circuit between connector B–37 terminal 3

and the ground B–19.

Is the action complete?–

–

–

Approx. 12V

–

Approx. 12V

–

–

–Go to

step 2

Go to

step 3

Go to

step 4

Go to

step 6

Go to

step 4

Go to

step 8

Go to

step 6

Replace

the relay

Verify

repairReplace

the fuse

Replace

the circuit

breaker

Ground it

securely

Go to

step 5

–

Go to

step 7

–

Go to

step 9

– 1

2

3

4

5

6

7

8

9

Page 2860 of 6000

STEP ACTION VALUE(S) YES NO

Is B–18 grounded securely?

Is there continuity between harness side connector D–5

terminal 1 and the ground B–18?

Repair an open circuit between connector D–5 terminal 1

and the ground B–18.

Is the action complete?

Turn the starter switch on.

Is the battery voltage applied between harness side

connector D–5 terminal 7 and the ground?

Repair an open circuit between connector B–37 terminal 4

and connector D–5 terminal 7.

Is the action complete?

Connect the battery positive terminal with harness side

connector D–5 terminal 5 or 6, and the negative terminal with

harness side connector D–5 terminal 6 or 5.

Does the motor operate?

1. Disconnect the front power window motor–RH connector

D–2.

2. Connect the battery positive terminal with the motor side

connector D–2 terminal 1 or 2, and connect the battery

negative terminal with the motor side connector D–2

terminal 2 or 1.

Does the motor operate?

Repair an open circuit between the front power window &

door lock switch–RH and the front power window motor–RH.

Is the action complete?–

–

–

Approx. 12V

–

–

–

–Go to

step 2

Go to

step 4

Go to

step 2

Go to

step 6

Go to

step 4

Replace

the front

power

window &

door lock

switch–RH

Go to

step 8

Verify

repairGround it

securely

Go to

step 3

–

Go to

step 5

–

Go to

step 7

Replace

the motor

– 1

2

3

4

5

6

7

8

Page 2861 of 6000

STEP ACTION VALUE(S) YES NO

Is B–1 grounded securely?

Disconnect the front power window & door lock switch–LH

connector D–14.

Is there continuity between harness side connector D–14

terminal 7 and the ground B–1?

Repair an open circuit between connector D–14 terminal 7

and the ground B–1.

Is the action complete?

Turn the starter switch on.

Is the battery voltage applied between harness side

connector D–14 terminal 5 and the ground?

Repair an open circuit between connector B–37 terminal 4

and connector D–14 terminal 5.

Is the action complete?

Connect the battery positive terminal with harness side

connector D–14 terminal 10 or 1, and connect the battery

negative terminal with harness side connector D–14 terminal

1 or 10.

Does the motor operate?

1. Disconnect the front power window motor–LH connector

D–11.

2. Connect the battery positive terminal with the motor side

connector D–11 terminal 1 or 2, and connect the battery

negative terminal with the motor side connector D–11

terminal 2 or 1.

Does the motor operate?

Repair an open circuit between the front power window &

door lock switch–LH and the front power window motor–LH.

Is the action complete?–

–

–

Approx. 12V

–

–

–

–Go to

step 2

Go to

step 4

Go to

step 2

Go to

step 6

Go to

step 4

Replace

the front

power

window &

door lock

switch–LH

Go to

step 8

Verify

repairGround it

securely

Go to

step 3

–

Go to

step 5

–

Go to

step 7

Replace

the motor

– 1

2

3

4

5

6

7

8

Page 2992 of 6000

WIRING SYSTEM 8D–399

1. Check to see if the battery voltage is normal.

2. Check to see if the fuse is normal.

3. Replace the anti–theft & keyless entry control unit with one reserved for test. If a trouble recurs even after replacing

the control unit, find out the cause of the trouble by referring to “System check procedure” and the following list.

ITEM MALFUNCTION POSSIBLE CAUSE DETECTING METHOD REMARKS

ANTI–THEFT

indicator light

does not flash

ANTI–THEFT

indicator light

does not turn off.

(Steadily on)

When door is

opened by pulling

up locking knob,

alarm does not

operate

Alarm does not

stop. Indicator light

does not change

to fully ON

condition, or does

not come on at

all.Burnt out indicator

light bulb possible.

Refer to “Connector

check table” in this

system.

Refer to “Connector

check table” in this

system.

Refer to “Connector

check table” in this

system.

Refer to “Connector

check table” in this

system.

Refer to “Connector

check table” in this

system.

Refer to “Connector

check table” in this

system. Defective contact of door switch,

or open circuit in door switch

wiring.

Short circuit in the detect switch.

Engine hood, doors and tailgate

are not fully closed and locked.

Defective door switch, or short

circuit in switch wiring.

Defective tamper switch, or short

circuit in wiring.

Defective lock switch, or short

circuit in wiring.

Defective engine hood switch, or

short circuit in wiring.

Defective tailgate switch, or short

circuit in wiring.

Defective control unit.

Poor contact of lock switch, or

open circuit in wiring.

Broken wire in wiring to headlight

and horn, or a blown fuse.

Defective contact of detect

switch, or damaged switch wiring.With door open, dome light and

courtesy light do not come on.

Check the control unit connector.

Check to see if doors are closed

and locked.

Dome light and courtesy light

remain lit on after closing doors.

Check the control unit connector.

Check the control unit connector.

Check the control unit connector.

Luggage room light remains lit

after closing tailgate.

Check alarm operation (See No.

46 of “System check procedure”),

possible cause is a poor contact

of lock switch of an open circuit in

wiring.

Check to see if headlights go out.

Check the control unit connector.

Check the control unit connector. A

C

D

E B

Page 3280 of 6000

8F–85 BODY STRUCTURE

Tailgate Sash Trim Cover

Parts Location

684RS012

Legend

(1) Tailgate Sash Trim Cover

Removal

1. Remove tailgate sash trim cover (1).

Pry the tailgate trim cover retainers free from the

tailgate panel.

684RS013

Installation

1. Install the tailgate sash trim cover (1).

Insert the trim cover retainers into the tailgate hole

securely so that there are no gaps between them.

Page 3281 of 6000

8F–86BODY STRUCTURE

Tailgate Outer Weatherstrip

Parts Location

682RW001

Legend

(1) Tailgate Outer Weatherstrip

Removal

1. Disconnect the battery ground cable.

2. Remove tailgate outer weatherstrip (1).

Pry the tailgate outer weatherstrip clips (2) free from

the body panel.

682RS002

Installation

1. Install the tailgate weatherstrip.

Insert the tailgate outer weatherstrip clip into the

body panel hole securely in order to install the

tailgate outer weatherstrip with the gap between the

body panel and the weatherstrip.

Page 3290 of 6000

8F–95 BODY STRUCTURE

Installation

1. Install the moulding roof clips (1).

Install the clips on roof panel flange (2) to refer the

illustration.

645RW003

2. Install the roof end moulding (3).

Clean the body panel where the roof end moulding

is installed.

Install the roof end moulding and the rear air

deflector (2) so that the installation clearance

between them is within the specified values.

Securely fix it with the adhesive tape (4) and sealing

adhesive (5).

645RW001

3. Install the roof moulding (9).

Assemble the windshield side moulding upper clip

(8) to the roof panel with the clip positioning rib (6)

(oblique lines portion) attached to the roof panel

flange (7). Assemble the roof moulding (9) while

you attach the front edge portion of the roof molding

to the windshield side moulding (10).

645RW005