ECU OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 1445 of 6000

6E–328

ENGINE DRIVEABILITY AND EMISSIONS

3. Connect the vacuum hoses to the EVAP canister

purge solenoid.

014RW137

4. Connect the electrical connector to the EVAP canister

purge solenoid.

014RW138

Fuel Tank Vent Valve

Removal and Installation Procedure

Refer to Fuel Pump

Linear Exhaust Gas

Recirculation (EGR) Valve

Removal Procedure

1. Disconnect the negative battery cable.2. Disconnect the electrical connector at the EGR valve.

014RW139

3. Remove the bolt and the nut from the upper intake

manifold.

014RW098

4. Remove the EGR valve from the upper intake

manifold.

5. Remove the gasket from the upper intake manifold.

Installation Procedure

1. Install the gasket on the upper intake manifold.

2. Install the EGR valve on the upper intake manifold.

3. Secure the EGR valve and the gasket with the bolt

and the nut.

Page 1446 of 6000

6E–329 ENGINE DRIVEABILITY AND EMISSIONS

NOTE: It is possible to install the EGR valve rotated 180

from the correct position. Make sure that the base of the

valve is placed so that it aligns with the mounting flange.

014RW098

4. Connect the electrical connector at the EGR valve.

014RW139

5. Connect the negative battery cable.

Positive Crankcase Ventilation

(PCV) Valve

Removal Procedure

1. Remove the vacuum hose at the PCV valve.

Slide the clamp back to release the hose.2. Pull the PCV valve from the rubber grommet in the

right valve cover.

014RW097

Inspection Procedure

1. Shake the valve and listen for the rattle of the needle

inside the valve.

2. If the valve does not rattle, replace the valve.

Installation Procedure

1. Push the PCV valve into the rubber grommet in the

left valve cover.

2. Install the vacuum hose on the PCV valve and secure

the vacuum hose with the clamp.

014RW097

Page 1448 of 6000

6E–331 ENGINE DRIVEABILITY AND EMISSIONS

Installation Procedure

1. Splice the wires using splice clips and rosin core

solder.

2. Wrap each splice to insulate.

3. Wrap the splice with mylar and with the drain

(uninsulated) wire.

049

4. Tape over the whole bundle to secure.

050

Twisted Leads

Removal Procedure

1. Locate the damaged wire.

2. Remove the insulation as required.

051

Installation Procedure

1. Use splice clips and rosin core solder in order to splice

the two wires together.

052

Page 1454 of 6000

6E–337 ENGINE DRIVEABILITY AND EMISSIONS

0018

Knock Sensor

Insufficient gasoline octane levels may cause detonation

in some engines. Detonation is an uncontrolled explosion

(burn) in the combustion chamber. This uncontrolled

explosion results from a flame front opposite that of the

normal flame front produced by the spark plug. The

rattling sound normally associated with detonation is the

result of two or more opposing pressures (flame fronts)

colliding within the combustion chamber. Light

detonation is sometimes considered normal, but heavy

detonation could result in engine damage.

A knock sensor system is used to control detonation. This

system is designed to retard spark timing up to 20

degrees to reduce detonation in the engine. This allows

the engine to use maximum spark advance to improve

driveability and fuel economy.

The knock sensor system has two major components:

The knock sensor (KS) module.

The knock sensor.

The knock sensor, mounted in the engine block near the

cylinders, detects abnormal vibration in the engine. The

sensor produces an AC output signal of about 10

millivolts. The signal amplitude and frequency are

dependent on the amount of knock being experienced.

The signal voltage increases with the severity of the

knock. This signal voltage is input to the PCM. The PCM

then retards the ignition control (IC) spark timing based

on the KS signal being received.

The PCM determines whether knock is occurring by

comparing the signal level on the KS circuit with the

voltage level on the noise channel. The noise channel

allows the PCM to reject any false knock signal by

indicating the amount of normal engine mechanical noise

present. Normal engine noise varies depending on the

engine speed and load. If the voltage level on the KS

noise channel circuit is below the range considered

normal, DTC P0327 will set, indicating a fault in the KScircuit or the knock sensor. If the PCM determines that an

abnormal minimum or maximum noise level is being

experienced, DTC P0325 will set.

The PCM contains a knock sensor (KS) module. The KS

module contains the circuitry which allows the PCM to

utilize the KS signal and diagnose the KS sensor and the

KS circuitry. If the KS module is missing or faulty, a

continuous knock condition will be indicated, and the

PCM will set DTC P0325.

Although it is a plug-in device, the KS module is not

replaceable. If the KS module is faulty, the entire PCM

must be replaced.

0009

Linear Exhaust Gas Recirculation (EGR)

Control

The PCM monitors the exhaust gas recirculation (EGR)

actual position and adjusts the pintle position accordingly.

The PCM uses information from the following sensors to

control the pintle position:

Engine coolant temperature (ECT) sensor.

Throttle position (TP) sensor.

Mass air flow (MAF) sensor.

Mass Air Flow (MAF) Sensor

The mass air flow (MAF) sensor measures the difference

between the volume and the quantity of air that enters the

engine. “Volume” means the size of the space to be filled.

“Quantity” means the number of air molecules that will fit

into the space. This information is important to the PCM

because heavier, denser air will hold more fuel than

lighter, thinner air. The PCM adjusts the air/fuel ratio as

needed depending on the MAF value. Tech 2 reads the

MAF value and displays it in terms of grams per second

(gm/s). At idle, Tech 2 should read between 4-7 gm/s on a

fully warmed up engine. Values should change quickly on

acceleration. Values should remain stable at any given

Page 1791 of 6000

6A – 58 ENGINE MECHANICAL

14. Camshaft pulley

1) Align TDC mark with crankshaft pulley and gear

case cover.

2) Set camshaft stopper on the end of intake and

exhaust camshaft.

Camshaft Stopper: 5-8840-2592-0

3) Install key to camshaft and install camshaft

pulley.

4) Apply engine oil to camshaft pulley fixing bolt

and tighten bolt with angular tightening method.

First step: 40 Nꞏm (4.0 kgꞏm / 29 lb ft)

Second step: 60° to 90°

15. Timing belt

1) Install tensioner and tighten the bolt temporarily.

2) Align timing mark with camshaft pulley timing

mark and timing gear case timing mark.

3) Set No.1 cylinder TDC position.4) Install the timing belt in the following order

camshaft pulley, oil pump pulley, tensioner.

NOTE:

1) It is recommended for easy installation that the belt

be secured with a double clip after it is installed to

each pulley.

2) The “ISUZU” mark should be read from the front of

the engine when installing the timing belt.

5) Install the belt tensioner.

6) Conform not phase difference each pulley.

7) Tension the timing belt with two turns of the

crankshaft.

8) Tighten the tensioner bolt in order A to B to the

specified torque.

Torque: Bolt A 5 Nꞏm (0.5 kgꞏm/3.6 lb ft)

Bolt B 2 Nꞏm (0.2 kgꞏm/1.4 lb ft)

Legend

(1) Align Mark

(2) Camshaft Pulley

(3) Timing Belt

(4) Oil Pump Pulley

(5) Bolt B

(6) Tensioner Assy

(7) Tensioner Bolt A

(8) Tensioner Spring

16. CMP sensor bracket

1) Install CMP sensor bracket and tighten bolt to

the specified torque.

Torque: 20 Nꞏm (2.0 kgꞏm / 14.5 lb ft)

17. Timing belt cover

1) Install timing belt cover and tighten bolt to the

specified torque.

Torque: 9 Nꞏm (0.9 kgꞏm / 6.5 lb ft)

2) Tighten CMP sensor to the specified torque.

Torque: 9 Nꞏm (0.9 kgꞏm / 6.5 lb ft)

012RW036

012RW099

1

2

3

8

67

4 5

F06RW055

Page 1853 of 6000

6C – 8 ENGINE FUEL

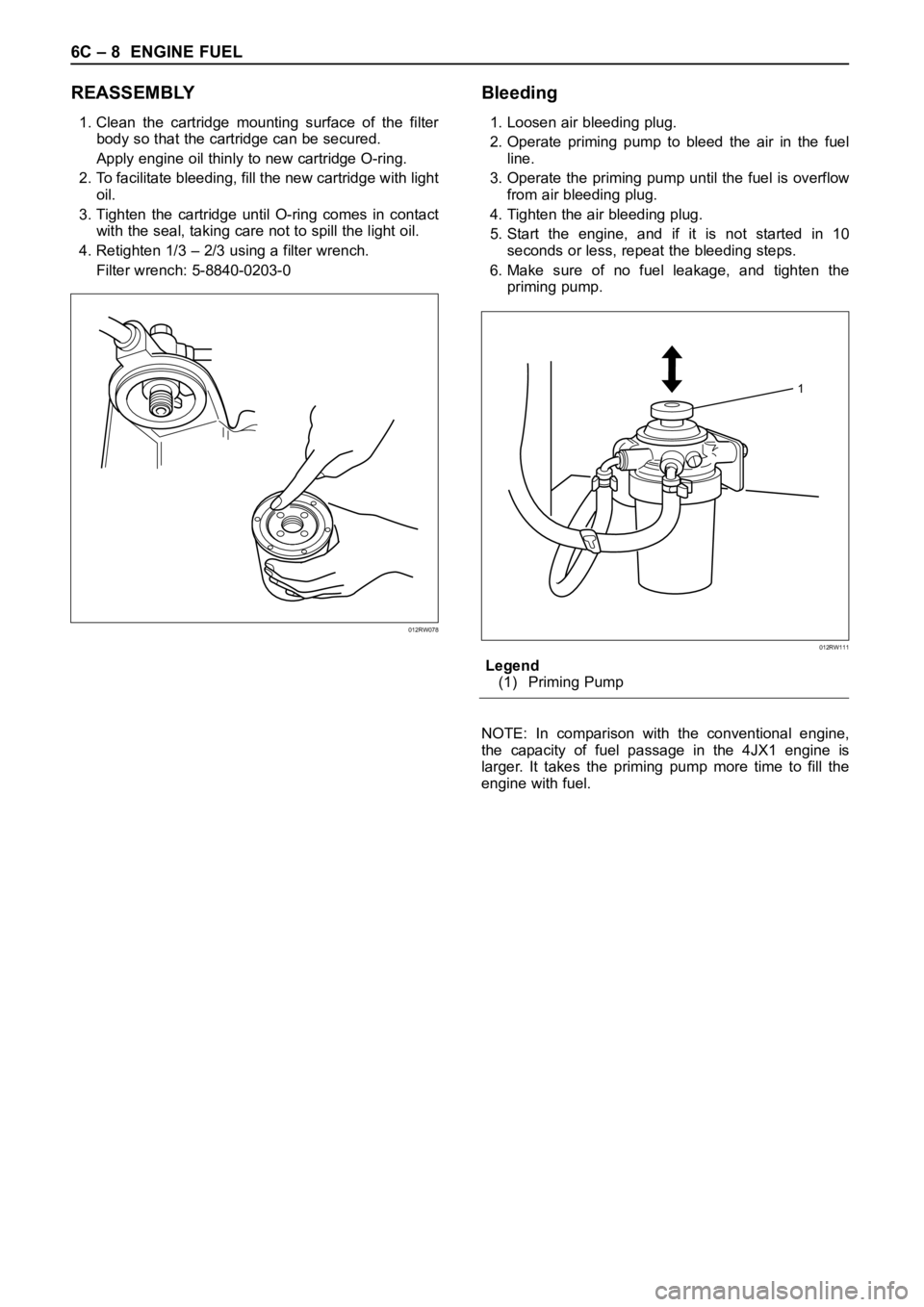

REASSEMBLY

1. Clean the cartridge mounting surface of the filter

body so that the cartridge can be secured.

Apply engine oil thinly to new cartridge O-ring.

2. To facilitate bleeding, fill the new cartridge with light

oil.

3. Tighten the cartridge until O-ring comes in contact

with the seal, taking care not to spill the light oil.

4. Retighten 1/3 – 2/3 using a filter wrench.

Filter wrench: 5-8840-0203-0

Bleeding

1. Loosen air bleeding plug.

2. Operate priming pump to bleed the air in the fuel

line.

3. Operate the priming pump until the fuel is overflow

from air bleeding plug.

4. Tighten the air bleeding plug.

5. Start the engine, and if it is not started in 10

seconds or less, repeat the bleeding steps.

6. Make sure of no fuel leakage, and tighten the

priming pump.

Legend

(1) Priming Pump

NOTE: In comparison with the conventional engine,

the capacity of fuel passage in the 4JX1 engine is

larger. It takes the priming pump more time to fill the

engine with fuel.

012RW078

1

012RW111

Page 1886 of 6000

ENGINE ELECTRICAL 6D – 19

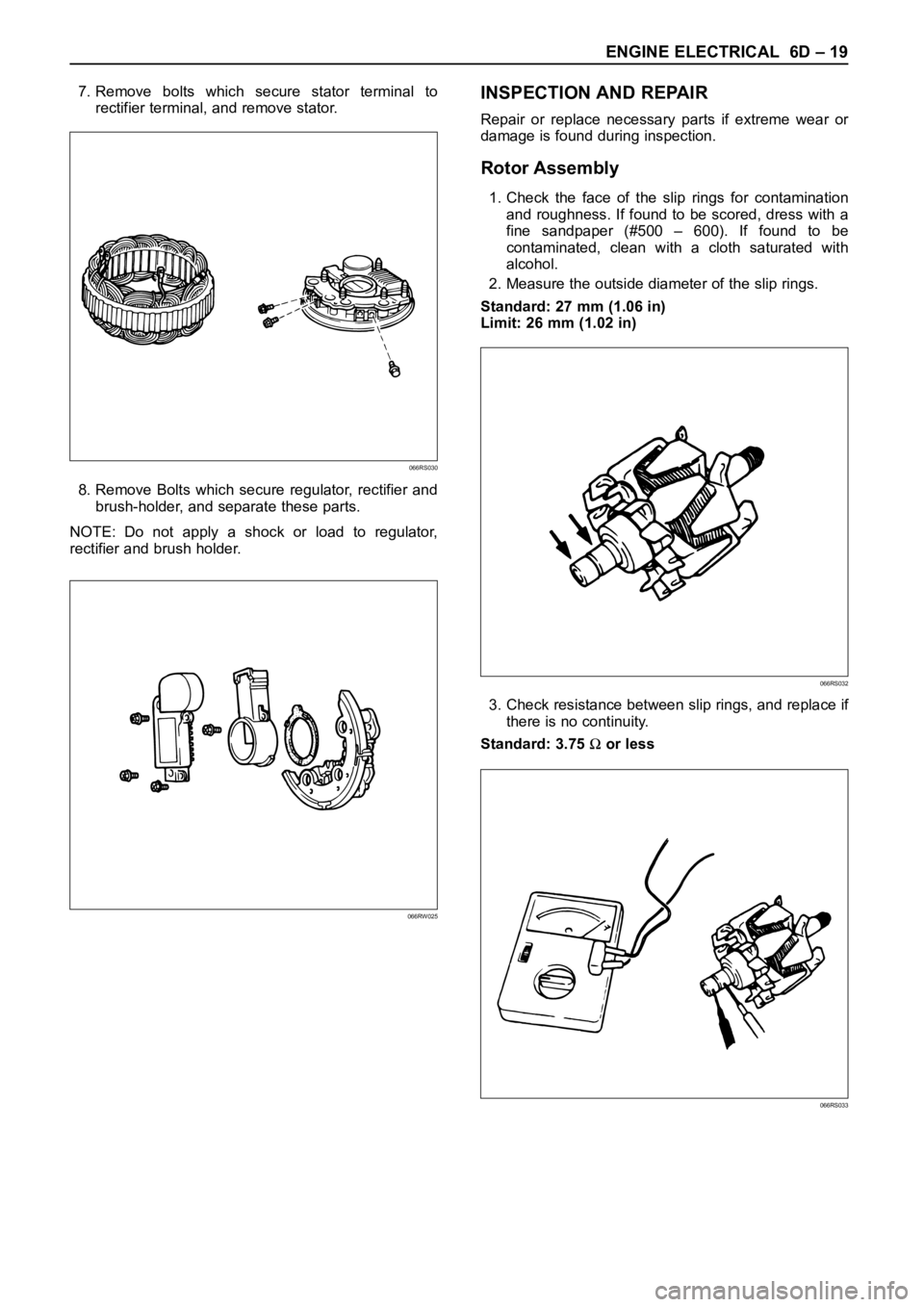

7. Remove bolts which secure stator terminal to

rectifier terminal, and remove stator.

8. Remove Bolts which secure regulator, rectifier and

brush-holder, and separate these parts.

NOTE: Do not apply a shock or load to regulator,

rectifier and brush holder.INSPECTION AND REPAIR

Repair or replace necessary parts if extreme wear or

damage is found during inspection.

Rotor Assembly

1. Check the face of the slip rings for contamination

and roughness. If found to be scored, dress with a

fine sandpaper (#500 – 600). If found to be

contaminated, clean with a cloth saturated with

alcohol.

2. Measure the outside diameter of the slip rings.

Standard: 27 mm (1.06 in)

Limit: 26 mm (1.02 in)

3. Check resistance between slip rings, and replace if

there is no continuity.

Standard: 3.75

or less

066RS030

066RW025

066RS032

066RS033

Page 1889 of 6000

6D – 22 ENGINE ELECTRICAL

1. Using a press with a socket wrench attached,

reassemble rotor and rear end cover assembly in

the front cover.2. Install pulley on the rotor.

Secure the pulley directly in the vise between two

copper plates, and tighten nut to the specified

torque.

Torque: 111 Nꞏm (82 lb ft)

066RS022

066RS010

MAIN DATA AND SPECIFICATIONS

General Specifications

Model LR190-750B LR-1100-731

Battery voltage V 12

Rated output A 90 100

Direction of rotation Clockwise

(as viewed from pulley side)

Rated rotation speed rpm 5,000

Maximum speed rpm 18,000

Page 1894 of 6000

6E–1 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

4JX1–TC 3.0L ENGINE

DRIVEABILITY AND EMISSIONS

CONTENTS

Specification 6E–7. . . . . . . . . . . . . . . . . . . . . . . . . .

Tightening Specifications 6E–7. . . . . . . . . . . . . . .

Diagrams and Schematics 6E–8. . . . . . . . . . . . . . . .

ECM Wiring Diagram (1 of 6) 6E–8. . . . . . . . . . . .

ECM Wiring Diagram (2 of 6) 6E–9. . . . . . . . . . . .

ECM Wiring Diagram (3 of 6) 6E–10. . . . . . . . . . . .

ECM Wiring Diagram (4 of 6) 6E–11. . . . . . . . . . . .

ECM Wiring Diagram (5 of 6) 6E–12. . . . . . . . . . . .

ECM Wiring Diagram (6 of 6) 6E–13. . . . . . . . . . . .

ECM Pinouts 6E–14. . . . . . . . . . . . . . . . . . . . . . . . . . .

ECM Pinout Table, 32-Way Connector – J1

RED – Upper 6E–14. . . . . . . . . . . . . . . . . . . . . . . . .

ECM Pinout Table, 32-Way Connector – J1

RED – Lower 6E–15. . . . . . . . . . . . . . . . . . . . . . . . .

ECM Pinout Table, 32-Way Connector – J2

BLUE – Upper 6E–16. . . . . . . . . . . . . . . . . . . . . . . .

ECM Pinout Table, 32-Way Connector – J2

BLUE – Lower 6E–17. . . . . . . . . . . . . . . . . . . . . . . .

ECM Pinout Table, 5-Way Connector – J3 6E–18

Component Locator 6E–19. . . . . . . . . . . . . . . . . . . . .

Sensors and Miscellaneous Component

Locators 6E–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Abbreviations Charts 6E–23. . . . . . . . . . . . . . . . . . . .

Diagnosis 6E–24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Strategy-Based Diagnostics 6E–24. . . . . . . . . . . . .

Strategy-Based Diagnostics 6E–24. . . . . . . . . . . . .

DTC Stored 6E–24. . . . . . . . . . . . . . . . . . . . . . . . . . .

No DTC 6E–24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

No Matching Symptom 6E–24. . . . . . . . . . . . . . . . .

Intermittents 6E–24. . . . . . . . . . . . . . . . . . . . . . . . . .

No Trouble Found 6E–24. . . . . . . . . . . . . . . . . . . . .

Verifying Vehicle Repair 6E–24. . . . . . . . . . . . . . . .

General Service Information 6E–25. . . . . . . . . . . . . .

Serviceability Issues 6E–25. . . . . . . . . . . . . . . . . . .

Visual/Physical Engine Compartment

Inspection 6E–25. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Basic Knowledge of Tools Required 6E–25. . . . . .

Serial Data Communications 6E–25. . . . . . . . . . . . . .

Class II Serial Data Communications 6E–25. . . . .

On-Board Diagnostic (OBD) 6E–25. . . . . . . . . . . . . .

On-Board Diagnostic Tests 6E–25. . . . . . . . . . . . .

Comprehensive Component Monitor

Diagnostic Operation 6E–25. . . . . . . . . . . . . . . . . .

Common OBD Terms 6E–26. . . . . . . . . . . . . . . . . .

The Diagnostic Executive 6E–26. . . . . . . . . . . . . . .

DTC Types 6E–26. . . . . . . . . . . . . . . . . . . . . . . . . . .

Verifying Vehicle Repair 6E–27. . . . . . . . . . . . . . . . Reading Flash Diagnostic Trouble Codes 6E–27.

Reading Diagnostic Trouble Codes Using

a TECH 2 6E–28. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tech 2 Scan Tool 6E–29. . . . . . . . . . . . . . . . . . . . . .

Getting Started 6E–30. . . . . . . . . . . . . . . . . . . . . . . .

DTC Modes 6E–32. . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC Information Mode 6E–32. . . . . . . . . . . . . . . . .

Injector Test 6E–32. . . . . . . . . . . . . . . . . . . . . . . . . .

EGR Valve Test 6E–32. . . . . . . . . . . . . . . . . . . . . . .

Rail Pressure Control Valve Test 6E–32. . . . . . . . .

Injector Balance Test 6E–32. . . . . . . . . . . . . . . . . . .

Data Programming in Case of ECM Change 6E–32

Rail Pressure Sensor Programming 6E–33. . . . . .

Injector Group Sign Programming

(Injector Change) 6E–33. . . . . . . . . . . . . . . . . . . . .

On-Board Diagnostic (OBD) System Check 6E–35.

Circuit Description 6E–37. . . . . . . . . . . . . . . . . . . . .

Diagnostic Aids 6E–37. . . . . . . . . . . . . . . . . . . . . . . .

Engine Control Module ECM Diagnosis 6E–39. . . .

Multiple ECM Information Sensor DTCS Set 6E–39

Circuit Description 6E–39. . . . . . . . . . . . . . . . . . . . .

Diagnostic Aids 6E–39. . . . . . . . . . . . . . . . . . . . . . . .

EGR (Exhaust Gas Recirculation) Diagnosis 6E–41

Tech 2 Data Definitions and Ranges 6E–41. . . . . . .

Typical Scan Data Values 6E–41. . . . . . . . . . . . . . . .

Test Conditions 6E–41. . . . . . . . . . . . . . . . . . . . . . . .

4JX1-TC Engine (Automatic and Manual

Transmission) 6E–42. . . . . . . . . . . . . . . . . . . . . . . .

No Malfunction Indicator Lamp (MIL) 6E–44. . . . . . .

Circuit Description 6E–44. . . . . . . . . . . . . . . . . . . . .

Diagnostic Aids 6E–44. . . . . . . . . . . . . . . . . . . . . . . .

Malfunction Indicator Lamp (MIL) “ON”

Steady 6E–47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit description 6E–47. . . . . . . . . . . . . . . . . . . . .

Diagnostic Aids 6E–47. . . . . . . . . . . . . . . . . . . . . . . .

Engine Cranks But Will Not Run 6E–49. . . . . . . . . . .

Circuit Description 6E–49. . . . . . . . . . . . . . . . . . . . .

Diagnostic Aids 6E–49. . . . . . . . . . . . . . . . . . . . . . . .

Exhaust Gas Recirculation (EGR) System

Check 6E–52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Description 6E–52. . . . . . . . . . . . . . . . . . . . .

ECM Diagnostic Trouble Codes 6E–54. . . . . . . . . . .

ECM Diagnostic Trouble Codes 6E–54. . . . . . . . .

Diagnostic Trouble Code (DTC) P0107

(Flash DTC 34)

MAP Sensor Circuit Low Voltage 6E–56. . . . . . . . . .

Page 1918 of 6000

6E–25 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

General Service Information

Serviceability Issues

Non-OEM Parts

All of the OBD diagnostics have been calibrated to run

with OEM parts. Accordingly, if commercially sold sensor

or switch is installed, it makes a wrong diagnosis and turn

on the MIL (“Check Engine” lamp).

Aftermarket electronics, such as cellular phones,

stereos, and anti-theft devices, may radiate EMI into the

control system if they are improperly installed. This may

cause a false sensor reading and turn on the MIL (“Check

Engine” lamp).

Poor Vehicle Maintenance

The sensitivity of OBD diagnostics will cause the MIL

(“Check Engine” lamp) to turn on if the vehicle is not

maintained properly. Restricted oil filters, fuel filters, and

crankcase deposits due to lack of oil changes or improper

oil viscosity can trigger actual vehicle faults that were not

previously monitored prior to OBD. Poor vehicle

maintenance can not be classified as a “non-vehicle

fault”, but with the sensitivity of OBD diagnostics, vehicle

maintenance schedules must be more closely followed.

Related System Faults

Many of the OBD system diagnostics will not run if the

ECM detects a fault on a related system or component.

Visual/Physical Engine Compartment

Inspection

Perform a careful visual and physical engine

compartment inspection when performing any diagnostic

procedure or diagnosing the cause of an emission test

failure. This can often lead to repairing a problem without

further steps. Use the following guidelines when

performing a visual/physical inspection:

Inspect all vacuum hoses for punches, cuts,

disconnects, and correct routing.

Inspect hoses that are difficult to see behind other

components.

Inspect all wires in the engine compartment for proper

connections, burned or chafed spots, pinched wires,

contact with sharp edges or contact with hot exhaust

manifolds or pipes.

Basic Knowledge of Tools Required

NOTE: Lack of basic knowledge of this powertrain when

performing diagnostic procedures could result in an

incorrect diagnosis or damage to powertrain

components. Do not attempt to diagnose a powertrain

problem without this basic knowledge.

A basic understanding of hand tools is necessary to effec-

tively use this section of the Service Manual.

Serial Data Communications

Class II Serial Data Communications

This vehicle utilizes the “Class II” communication system.

Each bit of information can have one of two lengths: longor short. This allows vehicle wiring to be reduced by

transmitting and receiving multiple signals over a single

wire. The messages carried on Class II data streams are

also prioritized. If two messages attempt to establish

communications on the data line at the same time, only

the message with higher priority will continue. The device

with the lower priority message must wait.

On this vehicle the Tech 2 displays the actual values for

vehicle parameters. It will not be necessary to perform

any conversions from coded values to actual values.

On-Board Diagnostic (OBD)

On-Board Diagnostic Tests

A diagnostic test is a series of steps, the result of which is

a pass or fail reported to the diagnostic executive. When

a diagnostic test reports a pass result, the diagnostic

executive records the following data:

The diagnostic test has been completed since the last

ignition cycle.

The diagnostic test has passed during the current

ignition cycle.

The fault identified by the diagnostic test is not

currently active.

When a diagnostic test reports a fail result, the diagnostic

executive records the following data:

The diagnostic test has been completed since the last

ignition cycle.

The fault identified by the diagnostic test is currently

active.

The fault has been active during this ignition cycle.

The operating conditions at the time of the failure.

Comprehensive Component Monitor

Diagnostic Operation

Comprehensive component monitoring diagnostics are

required to operate engine properly.

Input Components:

Input components are monitored for circuit continuity and

out-of-range values. This includes rationality checking.

Rationality checking refers to indicating a fault when the

signal from a sensor does not seem reasonable. Accel

Position (AP) sensor that indicates high throttle position

at low engine loads or MAP voltage. Input components

may include, but are not limited to the following sensors:

Intake Air Temperature (IAT) Sensor

Crankshaft Position (CKP) Sensor

Intake throttle Position (ITP) Sensor

Engine Coolant Temperature (ECT) Sensor

Camshaft Position (CMP) Sensor

Manifold absolute Pressure (MAP) Sensor

Accel Position Sensor

Fuel Temp Sensor

Rail Pressure Sensor

Oil Temp Sensor

EGR Pressure Sensor

Vehicle Speed Sensor