service OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 3438 of 6000

SUPPLEMENTAL RESTRAINT SYSTEM9J–1

RESTRAINTS

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

CONTENTS

Service Precaution 9J–1. . . . . . . . . . . . . . . . . . . . . .

General Description 9J–2. . . . . . . . . . . . . . . . . . . . .

SRS Component And Wiring Location View 9J–4.

Component Description 9J–4. . . . . . . . . . . . . . . . . .

Definitions 9J–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagnosis 9J–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SRS Connector Body Face Views 9J–9. . . . . . . . .

Repairs And Inspections Required After

An Accident 9J–9. . . . . . . . . . . . . . . . . . . . . . . . . . . .

On–Vehicle Service 9J–10. . . . . . . . . . . . . . . . . . . . . .

Air Bag Assembly Handling / Shipping

/ Scrapping 9J–11. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pretensioner Seat Belt Handling / Shipping

/ Scrapping. 9J–11. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Special Tools 9J–26. . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Precautions for SRS Component

Service 9J–30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SRS Connectors 9J–31. . . . . . . . . . . . . . . . . . . . . . . .

Sensing And Diagnostic Module (SDM) 9J–33. . . .

Service Precautions 9J–33. . . . . . . . . . . . . . . . . . .

Removal 9J–33. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 9J–33. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Driver Air Bag Assembly 9J–35. . . . . . . . . . . . . . . . .

Service Precautions 9J–35. . . . . . . . . . . . . . . . . . .

Removal 9J–35. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 9J–36. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Steering Wheel 9J–37. . . . . . . . . . . . . . . . . . . . . . . . . Service Precautions 9J–37. . . . . . . . . . . . . . . . . . .

Removal 9J–37. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 9J–38. . . . . . . . . . . . . . . . . . . . . . . . . . . .

SRS Coil Assembly 9J–39. . . . . . . . . . . . . . . . . . . . . .

Service Precautions 9J–39. . . . . . . . . . . . . . . . . . .

Removal 9J–39. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 9J–41. . . . . . . . . . . . . . . . . . . . . . . . . . . .

SRS Coil Replacement Procedure 9J–42. . . . . . . . .

Removal 9J–42. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

How to Disconnect the horn terminal 9J–43. . . . .

How to Connect Horn Terminal 9J–43. . . . . . . . . .

Installation 9J–44. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Steering Column 9J–44. . . . . . . . . . . . . . . . . . . . . . . .

Service Precautions 9J–44. . . . . . . . . . . . . . . . . . .

Removal 9J–44. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 9J–46. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Passenger Air Bag Assembly 9J–48. . . . . . . . . . . . .

Service Precautions 9J–48. . . . . . . . . . . . . . . . . . .

Removal 9J–48. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 9J–48. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pretensioner Seat Belt (If so equipped) 9J–49. . . .

Service Precaution 9J–49. . . . . . . . . . . . . . . . . . . .

Parts Location 9J–49. . . . . . . . . . . . . . . . . . . . . . . .

Removal 9J–49. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 9J–49. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Main Data and Specifications 9J–50. . . . . . . . . . . . .

Service Precaution

WARNING: IF SO EQUIPPED WITH A

SUPPLEMENTAL RESTRAINT SYSTEM (SRS),

REFER TO THE SRS COMPONENT AND WIRING

LOCATION VIEW IN ORDER TO DETERMINE

WHETHER YOU ARE PERFORMING SERVICE ON OR

NEAR THE SRS COMPONENTS OR THE SRS

WIRING. WHEN YOU ARE PERFORMING SERVICE

ON OR NEAR THE SRS COMPONENTS OR THE SRS

WIRING, REFER TO THE SRS SERVICE

INFORMATION. FAILURE TO FOLLOW WARNINGS

COULD RESULT IN POSSIBLE AIR BAG

DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU will call out those fasteners that require a

replacement after removal. ISUZU will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED, do not

use supplemental coatings (Paints, greases, or other

corrosion inhibitors) on threaded fasteners or

fastener joint interfaces. Generally, such coatings

adversely affect the fastener torque and the joint

clamping force, and may damage the fastener. When

you install fasteners, use the correct tightening

sequence and specifications. Following these

instructions can help you avoid damage to parts and

systems.

Page 3441 of 6000

SUPPLEMENTAL RESTRAINT SYSTEM 9J–4

SRS Component And Wiring Location View

810RW298

Legend

(1) Battery

(2) Relay & Fuse Box

(3) Passenger Air Bag Assembly

(4) SDM

(5) Meter Assembly

(6) SRS Coil Assembly

(7) Driver Air Bag Assembly(8) Starter Switch

(9) Fuse Box, C–21

(10) SRS Body Earth

(11) Body Harness Connector

(12) Instrument Harness Connector

(13) Engine Haness Connector

(14) Pretensioner, LH (If so equipped)

(15) Pretensioner, RH (If so equipped)

Component Description

SDM (Sensing and Diagnostic Module)

WARNING: DURING SERVICE PROCEDURES, BE

VERY CAREFUL WHEN HANDLING A SENSING AND

DIAGNOSTIC MODULE (SDM). NEVER STRIKE OR

JAR THE SDM. NEVER POWER UP THE SRS WHEN

THE SDM IS NOT RIGIDLY ATTACHED TO THE

VEHICLE. ALL SDM AND MOUNTING BRACKETFASTENERS MUST BE CAREFULLY TORQUED AND

THE ARROW MUST BE POINTED TOWARD THE

FRONT OF THE VEHICLE TO ENSURE PROPER

OPERATION OF THE SRS. THE SDM COULD BE

ACTIVATED WHEN POWERED WHILE NOT RIGIDLY

ATTACHED TO THE VEHICLE WHICH COULD CAUSE

DEPLOYMENT AND RESULT IN PERSONAL INJURY.

The Sensing and Diagnostic Module (SDM) is designed

to perform the following functions in the SRS:

Page 3446 of 6000

SUPPLEMENTAL RESTRAINT SYSTEM9J–9

SRS Connector Body Face Views

D09RW016

Legend

(1) SDM

(2) Driver Air Bag Assembly

(3) Passenger Air Bag Assembly

(4) “Air Bag” Warning Lamp

(5) SRS Coil Assembly

(6) DLC

(7) Connector between Chassis Harness and

Pretensioner Harness for Driver Seat Belt (If so

equipped)(8) Connector between Chassis Harness and

Pretensioner Harness for Passenger Seat Belt

(If so equipped)

(9) Connector between Pretensioner Harness and

driver side Pretensioner Seat Belt (If so

equipped)

(10) Connector between Pretensioner Harness and

passenger side Pretensioner Seat Belt (If so

equipped)

Repairs And Inspections Required

After An Accident

NOTE: If any SRS components are damaged, they must

be replaced. If SRS component mounting points are

damaged, they must be replaced.

Never use SRS parts from another vehicle. This does

not include remanufactured parts purchased from an

a u t h o r i z e d d e a l e r ; t h e y m a y b e u s e d f o r S R S r e p a i r s .

Do not attempt to service the SDM, the SRS coil

assembly, or the air bag assembly. Service of these

items is by replacement only.

Verify the part number of replacement air bag

assembly.CAUTION: Never use the air bag assembly from

another vehicle. Use only the air bag assembly for

Trooper.

CAUTION: Proper operation of the sensors and

supplemental restraint system (SRS) requires that

any repairs to the vehicle structure return it to the

original production configuration. Deployment

requires, at a minimum, replacement of the SDM, air

bag assembly and dimensional inspection of the

steering column. Any visible damage to the SDM

mounting bracket (s) requires replacement, and the

steering column must be dimensionally inspected,

whether deployment occurred or not.

Page 3447 of 6000

SUPPLEMENTAL RESTRAINT SYSTEM 9J–10

Accident With Deployment – Component

Replacement And Inspections

Certain SRS components must be replaced or inspected

for damage after a frontal crash involving air bag

deployment. Those components are:

Air bag assembly

SDM

CAUTION: Refer to “SDM Replacement Guidelines”

below for important information on SDM

replacement in both deployment and non

deployment crashes.

SRS coil assembly — Inspect wiring and connector

for any signs of scorching, melting, or damage due to

excessive heat. Replace if damaged. Refer to

section “SRS Coil Assembly” in this manual.

Accident With or Without Deployment –

Component Inspection

Certain SRS system components and rotation parts must

be inspected after any crash, whether the air bag

deployed or not. Those components are:

Steering column — Refer to Inspection Required

“After an Accident” in this manual.

Knee bolsters and mounting points — Inspect for any

distortion, bending, cracking, or other damage.

I/P steering column reinforcement plate — Inspect for

any distortion, bending, cracking, or other damage.

I/P braces — Inspect for any distortion, bending,

cracking, or other damage.

Seat belts and mounting points — Refer to “Seat

Belts” in Section “Seat Belt” of this workshop manual.

SDM Replacement Guidelines

SDM replacement policy requires replacement of SDM,

after crash involving air bag deployment when “SRS

Warning Lamp” turn “ON”, “SRS Diagnosis” should be

done according to Section “Restraint Control System.”

If accident without deployment air bag, it is not necessary

replacement of SDM when do not indicate to replace the

SDM by scan tool after SRS system check.

Wiring Damage

If any SRS wire harness is damaged, it should be

replaced. Don’t repair SRS harness. It is replace only.

SRS Connector (Plastic Body And

Terminal Metal Pin) Damage

If any connector or terminal in the SRS wire harness

(except pigtails) is damaged, it should be replaced.

SRS Wire Pigtail Damage

If the wiring pigtail (a wire or wires attached directly to the

device, not by a connector) is damaged, the entire

component (with pigtail) must be replaced. Examples of

“pigtail” components are the driver air bag assembly, the

passenger air bag assembly, and the SRS coil assembly.

On–Vehicle Service

Service Precaution

WARNING: WHEN PERFORMING SERVICE ON OR

AROUND SRS COMPONENTS OR SRS WIRING,

FOLLOW THE PROCEDURES LISTED BELOW TO

TEMPORARILY DISABLE THE SRS. FAILURE TO

FOLLOW PROCEDURES COULD RESULT IN

POSSIBLE AIR BAG DEPLOYMENT, PERSONAL

INJURY OR OTHERWISE UNNEEDED SRS REPAIRS.

The SDM in Driver–Passenger SRS can maintain

sufficient voltage to cause a deployment for up to 15

seconds after the ignition switch is turned “OFF,” the

battery is disconnected, or the fuse powering the SDM is

removed.

Many of the service procedures require removal of the

“C–21” fuse, and disconnection of the air bag assembly

from the deployment loop to avoid an accidental

deployment. If the air bag assembly is disconnected from

the deployment loop as noted in the “Disabling the SRS”

procedure that follows, service can begin immediately

without waiting for the 15 second time period to expire.

Disabling The SRS

Removal

Turn the ignition switch to “LOCK” and remove key.

1. Remove SRS fuse C–21, from left dash side lower

fuse block or disconnect battery.

2. Disconnect yellow 2–pin connector at the base of

steering column.

3. Remove glove box assembly, refer to “Passenger Air

Bag Assembly Replacement” in this manual.

4. Disconnect yellow 2–pin connector behind the glove

box assembly.

CAUTION: With the “C–21” fuse removed and

ignition switch “ON”, the “AIR BAG” warning lamp

will be “ON”. This is normal operation and does not

indicate an SRS malfunction.

Enabling The SRS

Installation

CAUTION: Never use the air bag assembly from

another vehicle. Use only the air bag assembly for

Trooper.

Turn ignition switch to “LOCK” and remove key.

1. Connect yellow 2–pin connector passenger air bag

assembly.

2. Install glove box assembly. Refer to “Passenger air

bag assembly replacement” in this manual.

3. Connect yellow 2–pin connector at the base of

steering column.

4. Install “AIR BAG” fuse C–21 to left dash side lower

fuse block or connect battery.

Turn ignition switch to “ON” and verify that the “AIR BAG”

warning lamp turn on 3.5 seconds and then turns “OFF.” If

it does not operate as described, perform the “SRS

Diagnostic System Check” in this manual.

Page 3448 of 6000

SUPPLEMENTAL RESTRAINT SYSTEM9J–11

Handling / Installation / Diagnosis

1. Air bag assembly should not be subjected to

temperatures above 93

C (200F).

2. Air bag assembly, and SDM should not be used if they

have been dropped from a height of 100 centimeters

(3.28 feet) or more.

3. When a SDM is replaced, it must be oriented with the

arrow on the sensor pointing toward the front of the

vehicle. It is very important for the SDM to be located

flat on the mounting surface, parallel to the vehicle

datum line. It is important that the SDM mounting

surface is free of any dirt or other foreign material.

4. Do not apply power to the SRS unless all components

are connected or a diagnostic chart requests it, as this

will set a diagnostic trouble code.

5. The “SRS Diagnostic System Check” must be the

starting point of any SRS diagnostics. The “SRS

Diagnostic System Check” will verify proper “AIR

BAG” warning lamp operation and will lead you to the

correct chart to diagnose any SRS malfunctions.

Bypassing these procedures may result in extended

diagnostic time, incorrect diagnosis, and incorrect

parts replacement.

Air Bag Assembly Handling /

Shipping / Scrapping

Live (Undeployed) Air Bag Assembly

Special care is necessary when handling and storing a

live (undeployed) air bag assembly. The rapid gas

generation produced during deployment of the air bag

could cause the air bag assembly, or an object in front of

the air bag assembly, to be thrown through the air in the

unlikely event of an accidental deployment.

827RV004

WARNING: WHEN CARRYING A LIVE AIR BAG

ASSEMBLY, MAKE SURE THE BAG OPENING IS

POINTED AWAY FROM YOU. IN CASE OF AN

ACCIDENTAL DEPLOYMENT, THE BAG WILL THEN

DEPLOY WITH MINIMAL CHANCE OF INJURY.

NEVER CARRY THE AIR BAG ASSEMBLY BY THEWIRES OR CONNECTOR ON THE UNDERSIDE OF

THE MODULE.

Pretensioner Seat Belt Handling /

Shipping / Scrapping.

Live (undeployed) pretensioner seat belt.

Special care is necessary when handling and storing a

live (undeployed) pretensioner seat belt.

The rapid gas generation produced during deployment of

the pretensioner seat belt (could cause the pretensioner

seat belt), or an object around of pretensioner seat belt, to

be thrown through the air in the unlikely event of an

accidental deployment.

WARNING: WHEN CARRYING A LIVE

PRETENSIONER SEAT BELT, MAKE SURE THE

PRETENSIONER SEAT BELT CYLINDER IS POINTED

AWAY FROM YOU. IN CASE OF AN ACCIDENTAL

DEPLOYMENT, THE PRETENSIONER SEAT BELT

WILL THEN DEPLOY WITH MINIMAL CHANCE OF

INJURY. NEVER CARRY THE PRETENSIONER SEAT

BELT BY THE CYLINDER OR WIRES ON THE

UNDERSIDE OF THE MODULE.

827RS044

Air Bag Assembly and/or Pretensioner

Seat Belt Shipping Procedure For

Live(Undeployed) Them.

Service personnel should refer to the Service Bulletins for

proper SRS composition parts shipping procedures.

Page 3449 of 6000

SUPPLEMENTAL RESTRAINT SYSTEM 9J–12

Deployed Air Bag Assembly (Driver Side)

“You should wear gloves and glasses. After the air bag

assembly has been deployed, the surface of the air bag

may contain solid particulate. This solid particulate

c o n s i s t s p r i m a r i l y o f b y p r oducts of the chemical reaction,

Potassium Chloride and copper metal dust. Compounds

of Potassium Borate, Strontium Chloride, Copper

Chloride, and Ammonium Chloride may be found in

amounts of about 1% (each) of the total particulate.”

Deployed Pretensioner Seat Belt.

You should wear gloves and safety glasses. After the

pretensioner seat belt has been deployed, the surface of

the pretensioner seat belt cylinder may heating up.

Air Bag Assembly and/or Pretensioner

Seat Belt Scrapping Procedure.

During the cause of vehicle’s useful life, certain situations

may arise which will necessitate the disposal of a live air

bag and/or pretensioner seat belt. (This information

covers proper procedures for disposing of a live air bag

assembly and/or pretensioner seat belt.)

Before a live air bag assembly can be dispose off, it must

be deployed.

A live air bag assembly and/or pretensioner seat belt

must not be disposed of though normal refuse channels.

WARNING: FAILURE TO FOLLOW PROPER

SUPPLEMENTAL RESTRAINT SYSTEM (SRS) AIR

BAG ASSEMBLY DISPOSAL PROCEDURES CAN

RESULT IN AIR BAG DEPLOYMENT WHICH MAY

CAUSE PERSONAL INJURY. AN UNDPLOYED AIR

BAG ASSEMBLY MUST NOT BE DISPOSED OF

THROUGH NORMAL REFUSE CHANNELS. THE

UNDEPLOYED AIR BAG ASSEMBLY CONTAINS

SUBSTANCES THAT CAN CAUSE SEVERE ILLNESS

OR PERSONAL INJURY IF THE SEALED CONTAINER

IS DAMAGED DURING DISPOSAL. DISPOSAL IN

ANY MANNER INCONSISTENT WITH PROPER

PROCEDURES MAY BE A VIOLATION OF LOCAL

LAW.

In situations which require deployment of a live air bag

assembly, deployment may be accomplished inside or

outside the vehicle. The method employed depends

upon the final disposition of the particular vehicle, as

noted in “Deployment Outside Vehicle” and “Deployment

Inside Vehicle” in this section.

Cautions About Air Bag Deployment And

Disposal

Failure to follow proper procedures could result in

erroneous air bag deployment which may cause personal

injury be sure to follow proper procedures.

1. Turn off (Lock) the ignition switch and disconnect the

minus terminal of the battery, then start the work 15 or

more sec later. (Air bag is designed to work by the

back-up power source even if the battery power

source is cut off at vehicle collision).

2. Be sure not to disassemble the air bag.

3. Do not give an impact to the air bag and bring the air

bag close to magnet. (The air bag could deploy

unexpectedly).4. Place the air bag with its trim cover up.

5. Do not let the air bag deploy directly on the floor. (The

air bag may be blown off 2

3 m (6.5 or 10 feet)).

6. Be sure to install the air bag firmly to a deployment

tool (fixing tool).

7. Set a battery 10 m (33 feet) or more away from the air

bag.

8. Before disconnecting air bag harness, ground the

worker by touching the vehicle outer panel with bare

hand.

9. When connecting or disconnecting the harness, do

not work just in front of the air bag.

10. As deployment gives rise to big sound, warn the

people around against it. Further, try to reduce the

sound by covering the steering wheel or tires, and

shut the vehicle windows in case of deployment

inside the vehicle.

11. As deployment generates smoke, select a well

ventilated place. (In case of deployment indoors,

avoid deployment just under a fire alarm, smoke

sensor, and fluorescent lamps).

12. Be careful not to inhale the smoke after deployment.

13. If part of the vehicle glass is damaged, cover the

vehicle with a car cover to prevent the glass from

braking at the time of deployment.

14. Do not touch the air bag immediately after

deployment, since it remains hot for 30 minutes.

15. Do not water the air bag immediately after

deployment.

16. Wear safety glasses and gloves throughout the work

and wash the glasses and gloves after the work.

17. Do not reuse the removed air bag for another vehicle.

(Deployment characteristic is different with vehicle

types).

Deployment Outside Vehicle (Driver Air

Bag Assembly)

Deployment outside the vehicle is proper when the

vehicle is to be returned to service. This includes, for

example, situations in which the vehicle will be returned to

useful service after a functionally or cosmetically deficient

air bag assembly is replaced. Deployment and disposal

of a malfunctioning air bag assembly is, of course, subject

to any required retention period.

For deployment of a live (undeployed) air bag assembly

outside the vehicle, the deployment procedure must be

followed exactly. Always wear safety glasses during this

deployment procedure until a deployed air bag assembly

is scrapped or until an undeployed air bag assembly is

shipped. Before performing the procedures you should

be familiar with servicing the SRS and with proper

handling of the air bag assembly. Procedures should be

read fully before they are performed.

The following procedure requires use of 5–8840–2468–0

SRS deployment harness with appropriate pigtail

adapter. Do not attempt procedure without

5–8840–2468–0 adapter.

WARNING: FAILURE TO FOLLOW PROCEDURES IN

THE ORDER LISTED MAY RESULT IN PERSONAL

INJURY. NEVER CONNECT DEPLOYMENT

Page 3452 of 6000

SUPPLEMENTAL RESTRAINT SYSTEM9J–15

SURFACE, ALWAYS FACE THE BAG AND TRIM

COVER UP AND AWAY FROM THE SURFACE. THIS

IS NECESSARY SO THAT A FREE SPACE IS

PROVIDED TO ALLOW THE AIR BAG TO EXPAND IN

THE UNLIKELY EVENT OF ACCIDENTAL

DEPLOYMENT. FAILURE TO FOLLOW

PROCEDURES MAY RESULT IN PERSONAL INJURY.

26. Temporarily store the driver air bag assembly with its

trim cover facing up, away from the surface upon

which it rests.

Deployment Outside Vehicle (Passenger

Air Bag Assembly)

WARNING: FAILURE TO FOLLOW PROPER SRS AIR

BAG ASSEMBLY DISPOSAL PROCEDURES CAN

RESULT IN AIR BAG DEPLOYMENT WHICH MAY

CAUSE PERSONAL INJURY. UNDEPLOYED AIR

BAG ASSEMBLIES MUST NOT BE DISPOSED OF

THROUGH NORMAL REFUSE CHANNELS. THE

UNDEPLOYED AIR BAG ASSEMBLY CONTAINS

SUBSTANCES THAT CAN CAUSE SEVERE ILLNESS

OR PERSONAL INJURY IF THE SEALED CONTAINER

IS DAMAGED DURING DISPOSAL. DISPOSAL IN

ANY MANNER INCONSISTENT WITH PROPER

PROCEDURES MAY BE A VIOLATION OF FEDERAL,

STATE AND/OR LOCAL LAWS.

Deployment out of the vehicle is proper when the vehicle

is to be returned to service. This includes, for example,

situations in which a functionally or cosmetically deficient

air bag assembly is replaced. Deployment and disposal

of an air bag assembly is, of course, subject to any

required retention period.

For deployment of a live air bag assembly out of the

vehicle, the deployment procedure must be followed

exactly. Always wear safety glasses during this

deployment procedure until the deployed air bag

assembly is scrapped. Before performing the

procedures, you should be familiar with servicing the SRS

system and with proper handling of the air bag assembly.

Procedures should be read fully before they are

performed.

The following procedure requires use of 5–8840–2468–0

SRS Deployment Harness with the appropriate pigtail

adapter. The procedure also requires the use of

5–8840–2420–0 Passenger Side SRS Module

Deployment Fixture. Do not attempt this procedure

without 5–8840–2468–0 and adapter, and

5–8840–2420–0.

WARNING: FAILURE TO FOLLOW PROCEDURES IN

THE ORDER LISTED MAY RESULT IN PERSONAL

INJURY. NEVER CONNECT DEPLOYMENT

HARNESS TO ANY POWER SOURCE BEFORE

CONNECTING DEPLOYMENT HARNESS TO THE AIR

BAG ASSEMBLY. DEPLOYMENT HARNESS SHALL

REMAIN SHORTED AND NOT BE CONNECTED TO A

POWER SOURCE UNTIL THE AIR BAG IS TO BE

DEPLOYED. THE AIR BAG ASSEMBLY WILL

IMMEDIATELY DEPLOY THE AIR BAG WHEN A

POWER SOURCE IS CONNECTED TO IT. WEARSAFETY GLASSES THROUGHOUT THIS ENTIRE

DEPLOYMENT AND DISPOSAL PROCEDURE.

NOTE: This information applies only to passenger air bag

assembly. Information for disposing of a live driver air bag

assembly can be found in “Deployment Outside Vehicle”

(Driver Air Bag Assembly) in this section.

1. Turn ignition switch to “LOCK” remove key, and put on

safety glasses.

2. Inspect 5–8840–2468–0 SRS Deployment Harness

and appropriate pigtail adapter for damage. If

harness or pigtail is damaged, discard and obtain a

replacement.

3. Short the two SRS Deployment Harness leads

together by fully seating one banana plug into the

other. The SRS Deployment Harness shall remain

shorted and not be connected to a power source until

the air bag is to be deployed.

827RS003

4. Connect the appropriate pigtail adapter to the SRS

Deployment Harness

827RS004

Page 3460 of 6000

SUPPLEMENTAL RESTRAINT SYSTEM9J–23

carbonate and sodium bicarbonate (baking soda).

Therefore, it is unlikely that sodium hydroxide will be

present after deployment.

(Driver air bag assembly)

After the air bag assembly has been deployed, the

surface of the air bag may contain solid particulate. This

solid particulate consists primarily of by products of the

chemical reaction, Potassium Chloride and copper metal

dust. Compounds of Potassium Borate, Strontium

Chloride, Copper Chloride, and Ammonium Chloride may

be found in amounts of about 1 % (each) of the total

particulate.

Deployment Outside Vehicle (Pretensioner

Seat Belt Assembly)

Deployment outside the vehicle is proper when the

vehicle is to be returned to service. This includes, for

example, situations in which the vehicle will be returned to

useful service after a functionally or cosmetically deficient

pretensioner seat belt assembly is replaced. Deployment

and disposal of a malfunctioning pretensioner seat belt

assembly is, of course, subject to any required retention

period.

For deployment of a live (undeployed) pretensioner seat

belt assembly outside the vehicle, the deployment

procedure must be followed exactly. Always wear gloves

and safety glasses during this deployment procedure until

a deployed pretensioner seat belt assembly is scrapped

or until an undeployed pretensioner seat belt assembly is

shipped. Before performing the procedures you should

be familiar with servicing the system and with proper

handling of the pretensioner seat belt assembly.

Procedures should be read fully before they are

performed.

The following procedure requires use of SRS deployment

harness with appropriate pigtail adapter. Do not attempt

procedure without adapter.

WARNING: FAILURE TO FOLLOW PROCEDURES IN

THE ORDER LISTED MAY RESULT IN PERSONAL

INJURY. NEVER CONNECT DEPLOYMENT

HARNESS TO ANY POWER SOURCE BEFORE

CONNECTING DEPLOYMENT HARNESS TO THE

PRETENSIONER SEAT BELT ASSEMBLY.

DEPLOYMENT HARNESS SHALL REMAIN

SHORTED AND NOT BE CONNECTED TO A POWER

SOURCE UNTIL THE PRETENSIONER SEAT BELT IS

TO BE DEPLOYED. THE PRETENSIONER SEAT

BELT ASSEMBLY WILL IMMEDIATELY DEPLOY THE

PRETENSIONER SEAT BELT WHEN A POWER

SOURCE IS CONNECTED TO IT. WEAR GLOVES

AND SAFETY GLASSES THROUGHOUT THIS

ENTIRE DEPLOYMENT AND DISPOSAL

PROCEDURE.

1. Turn ignition switch to “LOCK”, remove key.

2. Remove the pretensioner seat belt assembly from

vehicle. Refer to “Pretensioner Seat Belt Removal” in

this manual.

3. Prepare SRS deployment harness.

901HV009

4. Short the two SRS deployment harness leads

together by fully seating one banana plug into the

other. SRS deployment harness shall remain shorted

and not be connected to a power source until the

pretensioner seat belt is to be deployed.

5. Place the pretensioner seat belt assembly on a work

bench or other surface away from all loose or

flammable objects.

WARNING: WHEN FIXING THE DEPLOYMENT

DEVICE OF PRETENSIONER SEAT BELT, THE

DEPLOYMENT DEVICE SHOULD BE FIXED AWAY

FROM OTHER PERSON

6. Clear a space on the ground about 183 cm (six feet) in

diameter where the pretensioner seat belt assembly

is to be deployed. A paved, outdoor location where

there is no activity is preferred. If an outdoor location

is not available, a space on the shop floor where there

is no activity and sufficient ventilation is

recommended. Ensure no loose or flammable

objects are within the deployment area.

7. Stretch the SRS deployment harness and pigtail

adapter from the pretensioner seat belt assembly to

its full length.

8. Place a power source near the shorted end of the

SRS deployment harness. Recommended

application: 12 volts minimum, 2 amps minimum. A

vehicle battery is suggested.

9. Deployment harness shall remain shorted and not be

connected to a power source until the pretensioner

seat belt is to be deployed. The pretensioner seat belt

assembly will immediately deploy the pretensioner

seat belt when a power source is connected to it.

10. Verify that the area around the pretensioner seat belt

assembly is clear of all people and loose or flammable

objects.

11. Notify all people in the immediate area that you intend

to deploy the driver air bag. The deployment will be

accompanied by a substantial noise which may

startle the uninformed.

12. Connect the pretensioner seat belt to the pigtail

adapter on the SRS deployment harness.

Page 3465 of 6000

SUPPLEMENTAL RESTRAINT SYSTEM 9J–28

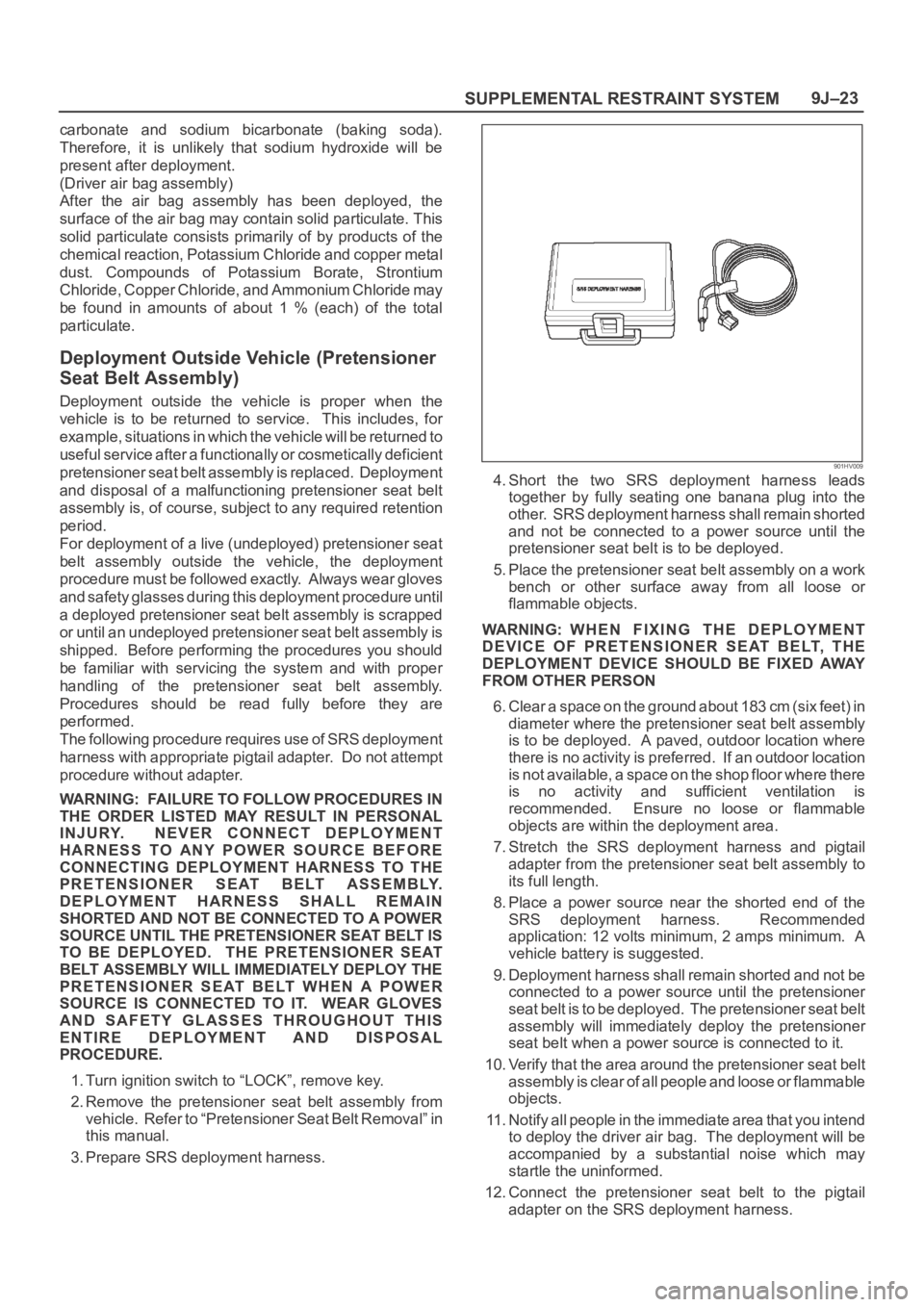

Tech 2 Scan Tool

From 98 MY, Isuzu dealer service departments are

recommended to use Tech 2. Please refer to Tech 2 scan

tool user guide.

901RW200

Legend

(1) PCMCIA Card

(2) RS 232 Loop Back Connector

(3) SAE 16/19 Adaptor

(4) DLC Cable

(5) Tech–2

Getting Started

Before operating the Isuzu PCMCIA card with the

Tech 2, the following steps must be performed:

1. Insert the Isuzu 98 System PCMCIA card (1) into the

Tech 2 (5).

2. Connect the SAE 16/19 adapter (3) to the DLC cable

(4).3. Connect the DLC cable to the Tech 2 (5)

4. Make sure of the vehicle ignition is off.

5. Connect the Tech 2 SAE 16/19 adapter to the vehicle

ALDL/DLC connector.

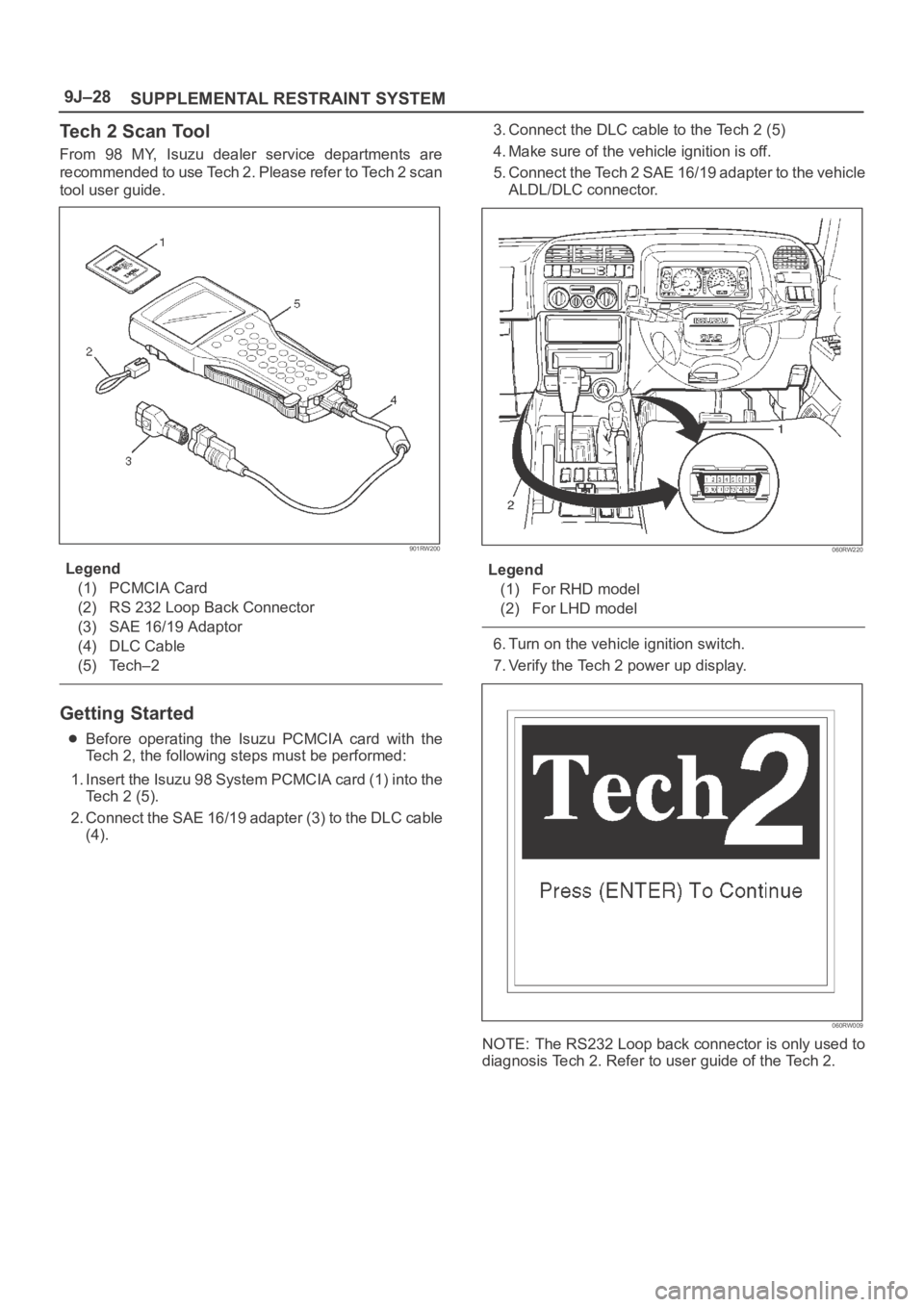

060RW220

Legend

(1) For RHD model

(2) For LHD model

6. Turn on the vehicle ignition switch.

7. Verify the Tech 2 power up display.

060RW009

NOTE: The RS232 Loop back connector is only used to

diagnosis Tech 2. Refer to user guide of the Tech 2.

Page 3467 of 6000

SUPPLEMENTAL RESTRAINT SYSTEM 9J–30

Service Precautions for SRS

Component Service

CAUTION: When fasteners are removed, always

reinstall them at the same location from which they

were removed. If a fastener needs to be replaced, use

the correct part number fastener for that application.

If the correct part number fastener is not available, a

fastener of equal size and strength (or stronger) may

be used. fasteners that are not reused, and those

requiring thread locking compound will be called

out. The correct torque value must be used when

installing fasteners that require it. If the above

conditions are not followed, parts or system damage

could result.

WARNING: WHEN PERFORMING SERVICE ON OR

AROUND SRS COMPONENTS OR SRS WIRING,

FOLLOW THE PROCEDURES LISTED BELOW TO

TEMPORARILY DISABLE THE SRS. FAILURE TO

FOLLOW PROCEDURES COULD RESULT IN

POSSIBLE AIR BAG DEPLOYMENT, PERSONAL

INJURY OR OTHERWISE UNNEEDED SRS REPAIRS.

The SDM in Driver–Passenger SRS can maintain

sufficient voltage to cause a deployment for up to 15

seconds after the ignition switch is turned “OFF,” the

battery is disconnected, or the fuse powering the SDM is

removed.

Many of the service procedures require removal of the

“C–21” fuse, and disconnection of the air bag assembly

from the deployment loop to avoid an accidental

deployment. If the air bag assembly is disconnected from

the deployment loop as noted in the “Disabling the SRS”

procedure that follows, service can begin immediately

without waiting for the 15 second time period to expire.

Disabling The SRS

Removal

Turn the ignition switch to “OFF” and turn the steering

wheel so that the vehicle’s wheels are pointing straight

ahead.

1. Remove SRS fuse “C–21” from left dash side lower

fuse block or disconnect battery.

2. Disconnect yellow 2–pin connector at the base of

steering column.

3 . R e m o v e g l o v e b o x a s s e m b l y ; R e f e r t o “ P a s s e n g e r a i r

bag assembly replacement” in this section.

4. Disconnect passenger air bag assembly yellow 2–pin

connector behind the glove box assembly.

CAUTION: W i t h t h e “ C – 2 1 ” f u s e r e m o v e d a n d

ignition switch “ON,” the “AIR BAG” warning lamp

will be “ON.” This is normal operation and does not

indicate an SRS malfunction.

Enabling The SRS

Installation

Turn ignition switch to “LOCK” and remove key.

1. Connect yellow 2–pin connector passenger air bag

assembly.2. Install glove box assembly. Refer to “Passenger Air

Bag Assembly Replacement” in this section.

3. Connect yellow 2–pin connector at the base of the

steering column.

4. Install “AIR BAG” fuse “C–21” to left dash side lower

fuse block or connect battery.

Turn ignition switch to “ON” and verify that the “AIR BAG”

warning lamp turn on 3.5 seconds and then turns “OFF.” If

it does not operate as described, perform the “SRS

Diagnostic System Check” in this section.

Handling / Installation / Diagnosis

1. Air bag assembly should not be subjected to

temperatures above 93

C (200F).

2. Air bag assembly, and SDM should not be used if they

have been dropped from a height of 100 centimeters

(3.28 feet) or more.

3. When a SDM is replaced, it must be oriented with the

arrow on the SDM pointing toward the front of the

vehicle. It is very important for the SDM to be located

flat on the mounting surface, parallel to the vehicle

datum line. It is important that the SDM mounting

surface is free of any dirt or other foreign material.

4. Do not apply power to the SRS unless all components

are connected or a diagnostic chart requests it, as

this will set a diagnostic trouble code.

5. The “SRS Diagnostic System Check” must be the

starting point of any SRS diagnostics. The “SRS

Diagnostic System Check” will verify proper “AIR

BAG” warning lamp operation and will lead you to the

correct chart to diagnose any SRS malfunctions.

Bypassing these procedures may result in extended

diagnostic time, incorrect diagnosis, and incorrect

parts replacements.

Inspections Required After An Accident

CAUTION: C e r t a i n S R S c o m p o n e n t s m u s t b e

replaced after a frontal crash involving air bag

deployment.

In all types of accidents regardless of “Air Bag”

deployment, visually inspect all of the following

components and replace as required:

— Driver air bag assembly

— Passenger air bag assembly

— Driver pretensioner assembly

— Passenger pretensioner assembly

— Steering wheel

— SRS coil assembly

— Steering column

— Knee bolster and instrument panel mounting

attachments

— Driver seat and belt

— Passenger seat and belt

—SDM

SDM always should be checked according to “SDM

Replacement Guidelines.”