service OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 3494 of 6000

9J1–7

RESTRAINT CONTROL SYSTEM

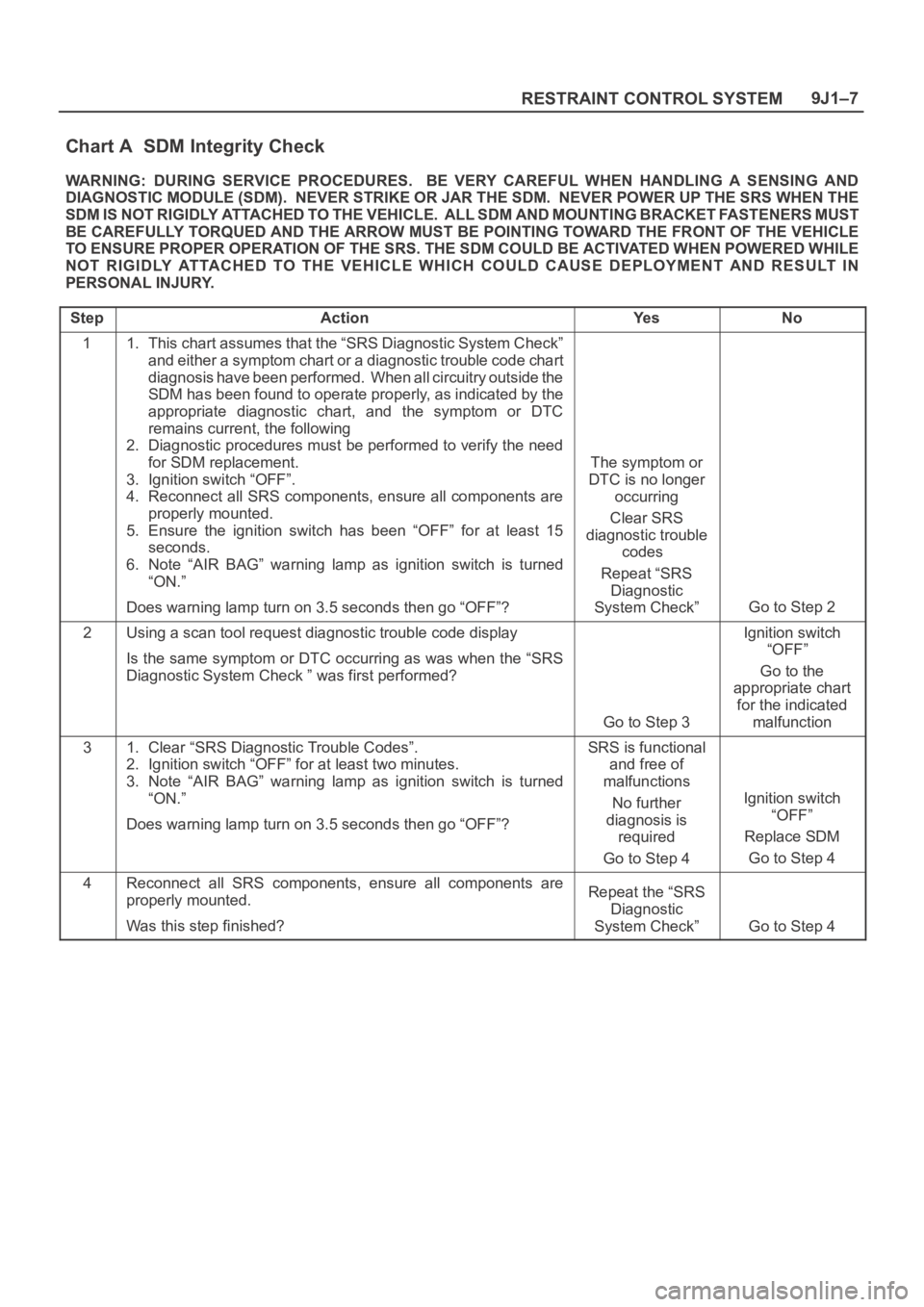

Chart A SDM Integrity Check

WARNING: DURING SERVICE PROCEDURES. BE VERY CAREFUL WHEN HANDLING A SENSING AND

DIAGNOSTIC MODULE (SDM). NEVER STRIKE OR JAR THE SDM. NEVER POWER UP THE SRS WHEN THE

S D M I S N O T R I G I D LY AT TA C H E D T O T H E V E H I C L E . A L L S D M A N D M O U N T ING BRACKET FASTENERS MUST

BE CAREFULLY TORQUED AND THE ARROW MUST BE POINTING TOWARD THE FRONT OF THE VEHICLE

TO ENSURE PROPER OPERATION OF THE SRS. THE SDM COULD BE ACTIVATED WHEN POWERED WHILE

NOT RIGIDLY ATTACHED TO THE VEHICLE WHICH COULD CAUSE DEPLOYMENT AND RESULT IN

PERSONAL INJURY.

Step

ActionYe sNo

11. This chart assumes that the “SRS Diagnostic System Check”

and either a symptom chart or a diagnostic trouble code chart

diagnosis have been performed. When all circuitry outside the

SDM has been found to operate properly, as indicated by the

appropriate diagnostic chart, and the symptom or DTC

remains current, the following

2. Diagnostic procedures must be performed to verify the need

for SDM replacement.

3. Ignition switch “OFF”.

4. Reconnect all SRS components, ensure all components are

properly mounted.

5. Ensure the ignition switch has been “OFF” for at least 15

seconds.

6. Note “AIR BAG” warning lamp as ignition switch is turned

“ON.”

Does warning lamp turn on 3.5 seconds then go “OFF”?

The symptom or

DTC is no longer

occurring

Clear SRS

diagnostic trouble

codes

Repeat “SRS

Diagnostic

System Check”

Go to Step 2

2Using a scan tool request diagnostic trouble code display

Is the same symptom or DTC occurring as was when the “SRS

Diagnostic System Check ” was first performed?

Go to Step 3

Ignition switch

“OFF”

Go to the

appropriate chart

for the indicated

malfunction

31. Clear “SRS Diagnostic Trouble Codes”.

2. Ignition switch “OFF” for at least two minutes.

3. Note “AIR BAG” warning lamp as ignition switch is turned

“ON.”

Does warning lamp turn on 3.5 seconds then go “OFF”?SRS is functional

and free of

malfunctions

No further

diagnosis is

required

Go to Step 4

Ignition switch

“OFF”

Replace SDM

Go to Step 4

4Reconnect all SRS components, ensure all components are

properly mounted.

Was this step finished?Repeat the “SRS

Diagnostic

System Check”

Go to Step 4

Page 3498 of 6000

9J1–11

RESTRAINT CONTROL SYSTEM

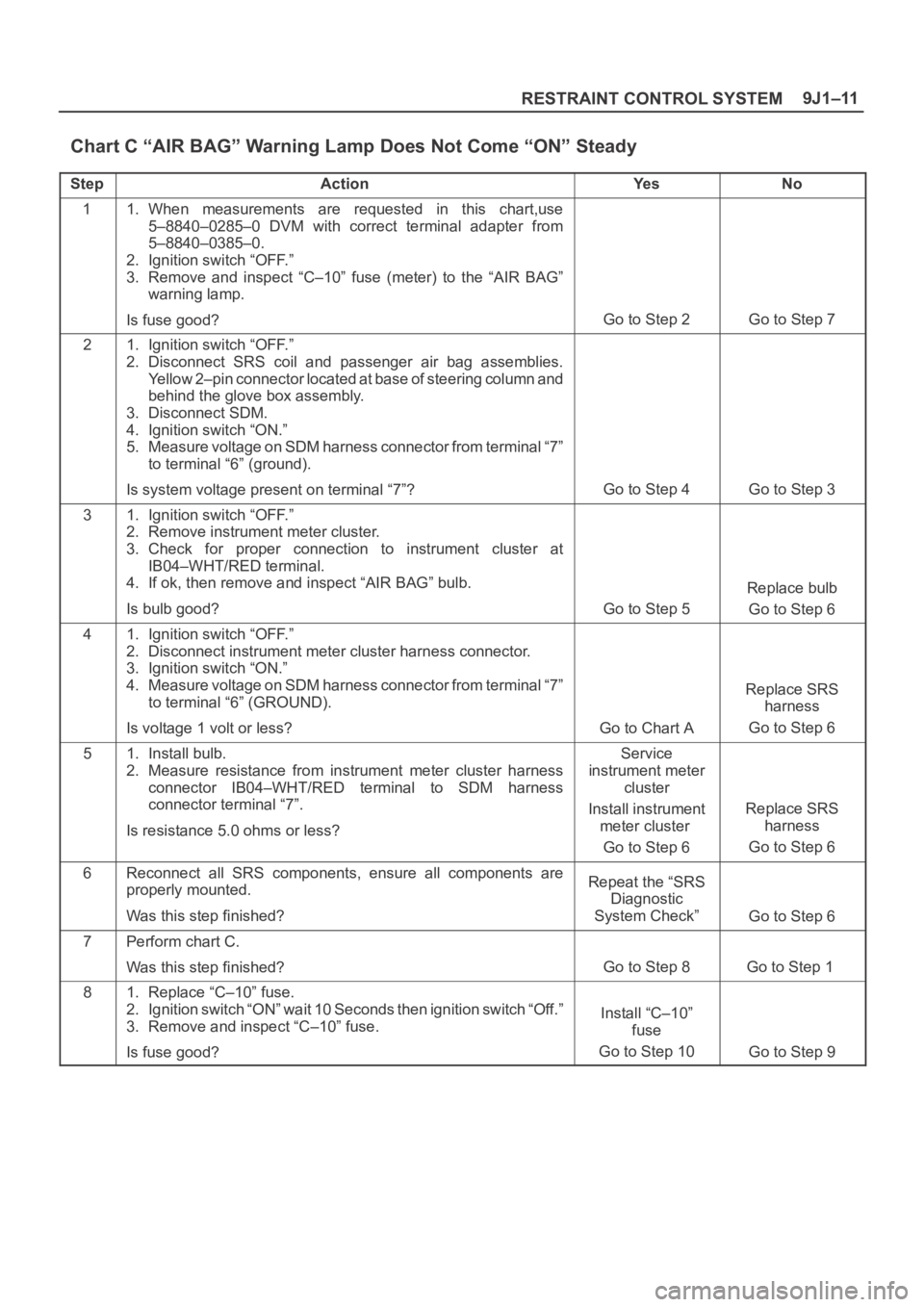

Chart C “AIR BAG” Warning Lamp Does Not Come “ON” Steady

StepActionYe sNo

11. When measurements are requested in this chart,use

5–8840–0285–0 DVM with correct terminal adapter from

5–8840–0385–0.

2. Ignition switch “OFF.”

3. Remove and inspect “C–10” fuse (meter) to the “AIR BAG”

warning lamp.

Is fuse good?

Go to Step 2Go to Step 7

21. Ignition switch “OFF.”

2. Disconnect SRS coil and passenger air bag assemblies.

Yellow 2–pin connector located at base of steering column and

behind the glove box assembly.

3. Disconnect SDM.

4. Ignition switch “ON.”

5. Measure voltage on SDM harness connector from terminal “7”

to terminal “6” (ground).

Is system voltage present on terminal “7”?

Go to Step 4Go to Step 3

31. Ignition switch “OFF.”

2. Remove instrument meter cluster.

3. Check for proper connection to instrument cluster at

IB04–WHT/RED terminal.

4. If ok, then remove and inspect “AIR BAG” bulb.

Is bulb good?

Go to Step 5

Replace bulb

Go to Step 6

41. Ignition switch “OFF.”

2. Disconnect instrument meter cluster harness connector.

3. Ignition switch “ON.”

4. Measure voltage on SDM harness connector from terminal “7”

to terminal “6” (GROUND).

Is voltage 1 volt or less?

Go to Chart A

Replace SRS

harness

Go to Step 6

51. Install bulb.

2. Measure resistance from instrument meter cluster harness

connector IB04–WHT/RED terminal to SDM harness

connector terminal “7”.

Is resistance 5.0 ohms or less?Service

instrument meter

cluster

Install instrument

meter cluster

Go to Step 6

Replace SRS

harness

Go to Step 6

6Reconnect all SRS components, ensure all components are

properly mounted.

Was this step finished?Repeat the “SRS

Diagnostic

System Check”

Go to Step 6

7Perform chart C.

Was this step finished?

Go to Step 8Go to Step 1

81. Replace “C–10” fuse.

2. Ignition switch “ON” wait 10 Seconds then ignition switch “Off.”

3. Remove and inspect “C–10” fuse.

Is fuse good?

Install “C–10”

fuse

Go to Step 10

Go to Step 9

Page 3523 of 6000

RESTRAINT CONTROL SYSTEM 9J1–36

DTC 51 Air Bag Deployment Event Commanded

WARNING: DURING SERVICE PROCEDURES. BE VERY CAREFUL WHEN HANDLING A SENSING AND

DIAGNOSTIC MODULE (SDM). NEVER STRIKE OR JAR THE SDM. NEVER POWER UP THE SRS WHEN THE

SDM IS NOT RIGIDLY ATTACHED TO THE VEHICLE. ALL SDM AND MOUNTING BRACKET FASTENERS MUST

BE CAREFULLY TORQUED AND THE ARROW MUST BE POINTING TOWARD THE FRONT OF THE VEHICLE

TO ENSURE PROPER OPERATION OF THE SRS. THE SDM COULD BE ACTIVATED WHEN POWERED WHILE

NOT RIGIDLY ATTACHED TO THE VEHICLE WHICH COULD CAUSE DEPLOYMENT AND RESULT IN

PERSONAL INJURY.

Step

ActionYe sNo

1Was the “SRS Diagnostic System Check” performed?

Go to Step 2

Go to the “SRS

Diagnostic

System Check”

2Ignition switch “OFF.”

Have air bag assemblies deployed?Replace

components and

perform

inspections as

directed in

“repairs and

inspections

required after an

accident” in this

section

Clear diagnostic

trouble codes

Repeat “SRS

Diagnostic

System Check”

Go to Step 3

3Inspect front of vehicle and undercarriage for sings of impact.

Were signs of impact found?Replace

components and

perform

inspections as

directed in

“Repairs and

Inspections

Required After An

Accident” in this

section

Clear diagnostic

trouble codes

Repeat “SRS

Diagnostic

System Check”

Ignition switch

“OFF”

Replace SDM

Reconnect all

SRS system

components,

ensure all

components are

properly mounted

Repeat “SRS

Diagnostic

System Check”

Page 3525 of 6000

RESTRAINT CONTROL SYSTEM 9J1–38

DTC 53 Deployment Commanded WITH Deployment Loop Fault Or Energy Reserves Out

Of Range

WARNING: DURING SERVICE PROCEDURES. BE VERY CAREFUL WHEN HANDLING A SENSING AND

DIAGNOSTIC MODULE (SDM). NEVER STRIKE OR JAR THE SDM. NEVER POWER UP THE SRS WHEN THE

SDM IS NOT RIGIDLY ATTACHED TO THE VEHICLE. ALL SDM AND MOUNTING BRACKET FASTENERS MUST

BE CAREFULLY TORQUED AND THE ARROW MUST BE POINTING TOWARD THE FRONT OF THE VEHICLE

TO ENSURE PROPER OPERATION OF THE SRS. THE SDM COULD BE ACTIVATED WHEN POWERED WHILE

NOT RIGIDLY ATTACHED TO THE VEHICLE WHICH COULD CAUSE DEPLOYMENT AND RESULT IN

PERSONAL INJURY.

Step

ActionYe sNo

1Was the “SRS Diagnostic System Check” performed?

Go to Step 2

Go to the “SRS

Diagnostic

System Check”

2Ignition switch “OFF.”

Have air bag assembles deployed?Replace

components and

perform

inspections as

directed in

“Repairs And

Inspections

Required After An

Accident” in this

section

Clear diagnostic

trouble codes

Repeat the “SRS

Diagnostic

System Check”

Go to Step 3

3Inspect front of vehicle and undercarriage for signs of impact.

Were signs of impact found?Replace

components and

perform

inspections as

directed in

“Repairs And

Inspections

Required After An

Accident” in this

section

Clear diagnostic

trouble codes

Repeat “SRS

Diagnostic

System Check”

Ignition switch

“OFF”

Replace SDM

Reconnect all

SRS system

components,

ensure all

components are

properly mounted

Repeat the “SRS

Diagnostic

System Check”

Page 3529 of 6000

RESTRAINT CONTROL SYSTEM 9J1–42

DTC 71 Internal SDM Fault

WARNING: DURING SERVICE PROCEDURES. BE VERY CAREFUL WHEN HANDLING A SENSING AND

DIAGNOSTIC MODULE (SDM). NEVER STRIKE OR JAR THE SDM. NEVER POWER UP THE SRS WHEN THE

SDM IS NOT RIGIDLY ATTACHED TO THE VEHICLE. ALL SDM AND MOUNTING BRACKET FASTENERS MUST

BE CAREFULLY TORQUED AND THE ARROW MUST BE POINTING TOWARD THE FRONT OF THE VEHICLE

TO ENSURE PROPER OPERATION OF THE SRS. THE SDM COULD BE ACTIVATED WHEN POWERED WHILE

NOT RIGIDLY ATTACHED TO THE VEHICLE WHICH COULD CAUSE DEPLOYMENT AND RESULT IN

PERSONAL INJURY.

CAUTION: When DTC 19 or 25 has been set, it is necessary to replace the SDM. Setting DTC 19 and 25 or 51

or 53 will also cause DTC 71 to set. When a scan tool “CLEAR CODES” command is issued and the

malfunction is no longer present, DTC 51 or 53 and DTC 71 will remain current. Ensure that the short to voltage

condition DTC 19, 25 is repaired prior to installing a replacement SDM to avoid damaging the SDM.

Step

ActionYe sNo

1Was the “SRS Diagnostic System Check” performed?

Go to Step 2

Go to the “SRS

Diagnostic

System Check”

2Note SRS “Diagnostic System Check.”

IS DTC 19 OR 25 OR 51 OR 53 ALSO SET (CURRENT OR

HISTORY)? (REFER TO NOTICE ABOVE.)Go to DTC 19 if

DTC 19 is set

Go to DTC 25 if

DTC 25 is set

Go to DTC 51 if

DTC 51 is set

Go to DTC 53 if

DTC 53 is set

Ignition switch

“OFF”

Replace SDM

Repeat the “SRS

Diagnostic

System Check”

Page 3551 of 6000

RESTRAINT CONTROL SYSTEM 9J1–64

DTC 52 Deployment Event Commanded

WARNING: DURING SERVICE PROCEDURES. BE VERY CAREFUL WHEN HANDLING A SENSING AND

DIAGNOSTIC MODULE (SDM). NEVER STRIKE OR JAR THE SDM. NEVER POWER UP THE PRETENSIONER

WHEN THE SDM IS NOT RIGIDLY ATTACHED TO THE VEHICLE. ALL SDM AND MOUNTING BRACKET

FASTENERS MUST BE CAREFULLY TORQUED AND THE ARROW MUST BE POINTING TOWARD THE FRONT

OF THE VEHICLE TO ENSURE PROPER OPERATION OF THE PRETENSIONER. THE SDM COULD BE

ACTIVATED WHEN POWERED WHILE NOT RIGIDLY ATTACHED TO THE VEHICLE WHICH COULD CAUSE

DEPLOYMENT AND RESULT IN PERSONAL INJURY.

Step

ActionYe sNo

1Was the “SRS Diagnostic System Check” performed?

Go to Step 2.

Go to the “SRS

Diagnostic

System Check”

2Ignition switch “OFF.”

Have pretensioner assemblies deployed?Replace

components and

perform

inspections as

directed in

“repairs and

inspections

required after an

accident” in this

section

clear diagnostic

trouble codes

Repeat “SRS

Diagnostic

System Check”

Go to Step 3

3Inspect front of vehicle and undercarriage for sings of impact.

Were signs of impact found?Replace

components and

perform

inspections as

directed in

“Repairs and

Inspections

Required After An

Accident” in this

section

Clear diagnostic

trouble codes

Repeat “SRS

Diagnostic

System Check”

Ignition switch

“OFF”

Replace SDM

Reconnect all

SRS system

components,

ensure all

components are

properly mounted

Repeat “SRS

Diagnostic

System Check”

Page 3552 of 6000

10A–1

CRUISE CONTROL SYSTEM

CONTROL SYSTEM

CRUISE CONTROL SYSTEM

CONTENTS

Service Precaution 10A–1. . . . . . . . . . . . . . . . . . . . . .

General Description 10A–1. . . . . . . . . . . . . . . . . . . . .

Diagnosis 10A–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Brake Switch 10A–2. . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 10A–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 10A–2. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjustment 10A–3. . . . . . . . . . . . . . . . . . . . . . . . . . .

Clutch Switch 10A–3. . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal and Installation 10A–3. . . . . . . . . . . . . . .

Adjustment 10A–3. . . . . . . . . . . . . . . . . . . . . . . . . . .

Starter Switch 10A–4. . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 10A–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 10A–4. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cruise Control Main Switch 10A–5. . . . . . . . . . . . . . . Removal 10A–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 10A–5. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cruise Control Switch (Combination Switch) 10A–5

Removal and Installation 10A–5. . . . . . . . . . . . . . .

Cruise Control Unit 10A–6. . . . . . . . . . . . . . . . . . . . . .

Removal 10A–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 10A–6. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cruise Actuator 10A–7. . . . . . . . . . . . . . . . . . . . . . . . .

Actuator Cable Diagram (LHD) 10A–7. . . . . . . . . .

Actuator Cable Diagram (RHD) 10A–7. . . . . . . . . .

Removal 10A–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 10A–8. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mode Switch 10A–8. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal and Installation 10A–8. . . . . . . . . . . . . . .

Service Precaution

WARNING: IF SO EQUIPPED WITH A

SUPPLEMENTAL RESTRAINT SYSTEM (SRS),

REFER TO THE SRS COMPONENT AND WIRING

LOCATION VIEW IN ORDER TO DETERMINE

WHETHER YOU ARE PERFORMING SERVICE ON OR

NEAR THE SRS COMPONENTS OR THE SRS

WIRING. WHEN YOU ARE PERFORMING SERVICE

ON OR NEAR THE SRS COMPONENTS OR THE SRS

WIRING, REFER TO THE SRS SERVICE

INFORMATION. FAILURE TO FOLLOW WARNINGS

COULD RESULT IN POSSIBLE AIR BAG

DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU will call out those fasteners that require a

replacement after removal. ISUZU will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED, do not

use supplemental coatings (Paints, greases, or other

corrosion inhibitors) on threaded fasteners or

fastener joint interfaces. Generally, such coatings

adversely affect the fastener torque and the joint

clamping force, and may damage the fastener. When

you install fasteners, use the correct tightening

sequence and specifications. Following these

instructions can help you avoid damage to parts and

systems.

General Description

The cruise control keeps the vehicle running at a fixed

speed until a signal canceling this fixed speed is received .

When the main switch “AUTO CRUISE” is turned on with

the vehicle in the running mode, the battery voltage is

applied to the control unit. When a signal from the control

switch is input to the control unit while the vehicle is in this

state, the cruise control actuator is activated to operate

the system. Also, while the system is operating, the

“AUTO CRUISE” indicator light in the meter assembly

lights up.

1. SET/COAST Switch Function

1.Set Function: When the SET/COAST switch is

pressed and released with the main switch on, the

speed at which the vehicle is running at that moment

is stored in the memory, and the vehicle automatically

runs at the stored speed.

2.Coast-down Function: When the SET/COAST

switch is kept on while the vehicle in running, the

vehicle decelerates during that time. The speed at

which vehicle is running when the control switch is

turned off is stored in the memory, and the vehicle

automatically returns to the stored speed.

3.Tap-down Function: When the SET/COAST switch

is turned on and off instantaneously while the vehicle

is running, the vehicle decelerates a mile for each

on/off operation. The vehicle speed at which the

vehicle was running when the SET/COAST was

turned off last is stored in the memory, and the vehicle

automatically returns to this stored speed.

Page 3562 of 6000

PAGE BACK PAGE NEXT

THIS MALUAL INCLUDES THE FOLLOWING SECTIONS:

SECTION No. CONTRNTS

00 SERVICE INFORMATION

2A FRONT END ALIGNMENT

HOME

00

2A

Page 3567 of 6000

PAGE BACK PAGE NEXT

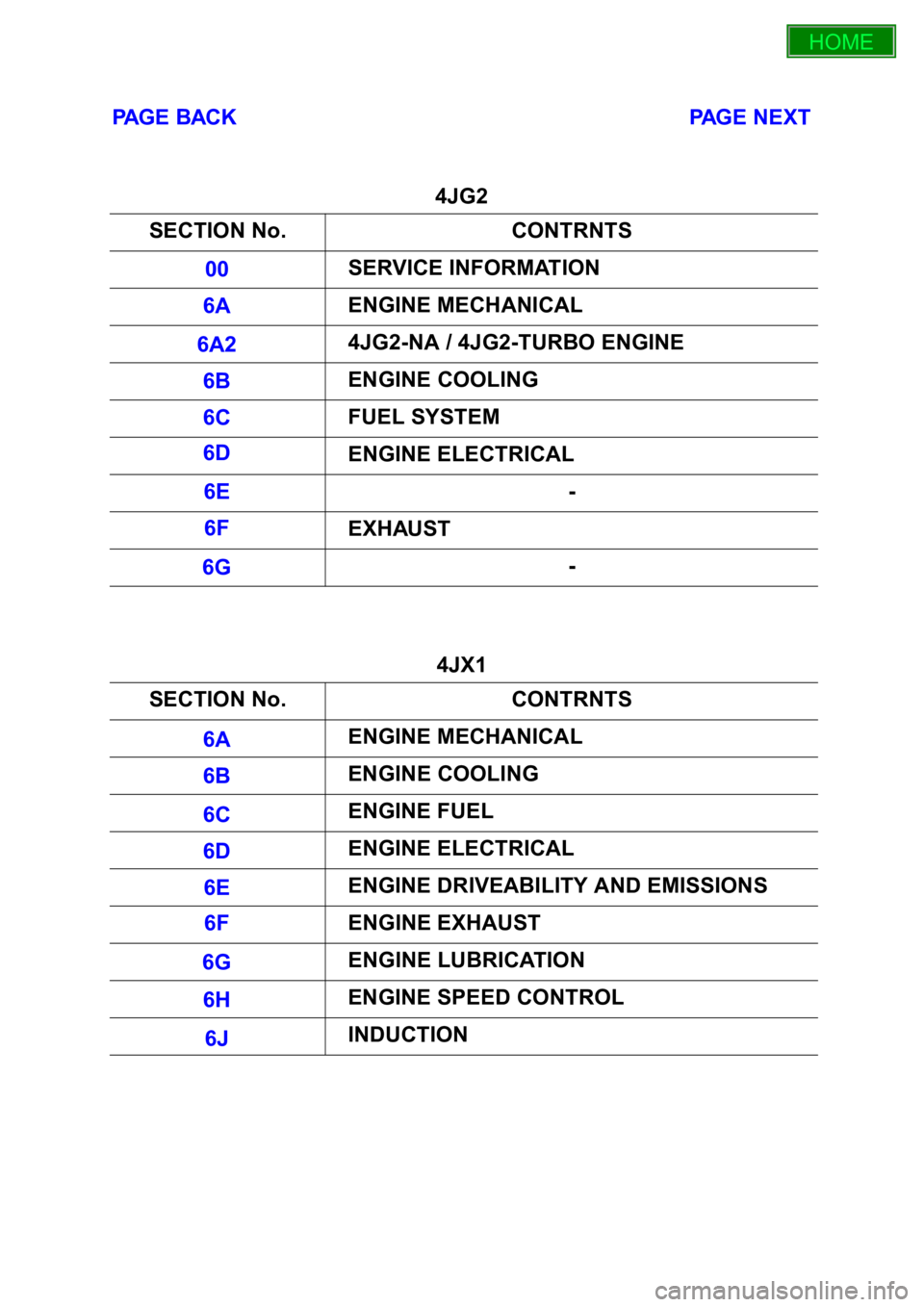

4JG2

4JX1 SECTION No. CONTRNTS

00 SERVICE INFORMATION

6A ENGINE MECHANICAL

6A2 4JG2-NA / 4JG2-TURBO ENGINE

6B ENGINE COOLING

6C FUEL SYSTEM

6D ENGINE ELECTRICAL

6E -

6F EXHAUST

6G -

SECTION No. CONTRNTS

6A ENGINE MECHANICAL

6B ENGINE COOLING

6C ENGINE FUEL

6D ENGINE ELECTRICAL

6E ENGINE DRIVEABILITY AND EMISSIONS

6F ENGINE EXHAUST

6G ENGINE LUBRICATION

6H ENGINE SPEED CONTROL

6J INDUCTION

HOME

00

6A

6A2

6B

6C

6D

6E

6F

6G

6A

6B

6C

6D

6E

6F

6G

6H

6J

Page 3573 of 6000

Service Precaution

WARNING: THIS VEHICLE HAS A SUPPLEMENTAL

RESTRAINT SYSTEM (SRS). REFER TO THE SRS

COMPONENT AND WIRING LOCATION VIEW IN

ORDER TO DETERMINE WHETHER YOU ARE

PERFORMING SERVICE ON OR NEAR THE SRS

COMPONENTS OR THE SRS WIRING. WHEN YOU

ARE PERFORMING SERVICE ON OR NEAR THE

SRS COMPONENTS OR THE SRS WIRING, REFER

TO THE SRS SERVICE INFORMATION. FAILURE

TO FOLLOW WARNINGS COULD RESULT IN

POSSIBLE AIR BAG DEPLOYMENT, PERSONAL

INJURY, OR OTHERWISE UNNEEDED SRS

SYSTEM REPAIRS.CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU will call out those fasteners that require a

replacement after removal. ISUZU will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED, do not

use supplemental coatings (Paints, greases, or

other corrosion inhibitors) on threaded fasteners

or fasteners joint interfaces. Generally, such

coatings adversely affect the fastener torque and

the joint clamping force, and may damage the

fastener. When you install fasteners, use the

correct tightening sequence and specification.

Following these instructions can help you avoid

damage to parts and systems.