4WD OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 4361 of 6000

5A–11 BRAKE CONTROL SYSTEM

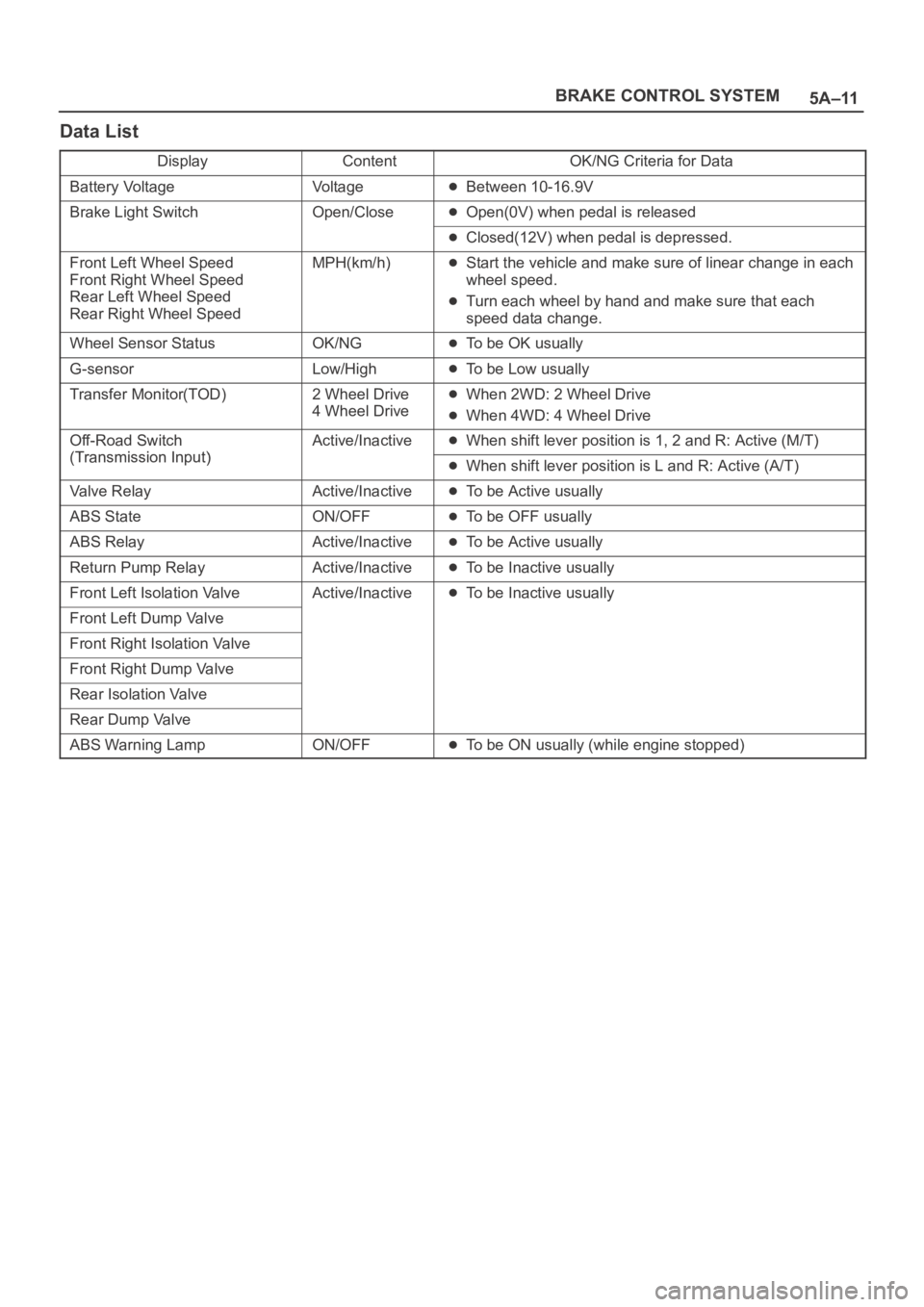

Data List

DisplayContentOK/NG Criteria for Data

Battery VoltageVo l t a g eBetween 10-16.9V

Brake Light SwitchOpen/CloseOpen(0V) when pedal is released

Closed(12V) when pedal is depressed.

Front Left Wheel Speed

Front Right Wheel Speed

Rear Left Wheel Speed

Rear Right Wheel SpeedMPH(km/h)Start the vehicle and make sure of linear change in each

wheel speed.

Turn each wheel by hand and make sure that each

speed data change.

Wheel Sensor StatusOK/NGTo be OK usually

G-sensorLow/HighTo be Low usually

Transfer Monitor(TOD)2 Wheel Drive

4 Wheel DriveWhen 2WD: 2 Wheel Drive

When 4WD: 4 Wheel Drive

Off-Road Switch

(Transmission Input)

Active/InactiveWhen shift lever position is 1, 2 and R: Active (M/T)

(Transmission Input)When shift lever position is L and R: Active (A/T)

Valve RelayActive/InactiveTo be Active usually

ABS StateON/OFFTo be OFF usually

ABS RelayActive/InactiveTo be Active usually

Return Pump RelayActive/InactiveTo be Inactive usually

Front Left Isolation ValveActive/InactiveTo be Inactive usually

Front Left Dump Valve

Front Right Isolation Valve

Front Right Dump Valve

Rear Isolation Valve

Rear Dump Valve

ABS Warning LampON/OFFTo be ON usually (while engine stopped)

Page 4386 of 6000

5A–36

BRAKE CONTROL SYSTEM

StepNo Ye s

Action

10Is the input of 4WD controller normal?

Go to Step 11

Replace

controller or

repair harness.

Go to Step 11

11Reconnect all components and ensure all components are

properly mounted.

Was this step finished?Repeat the “Basic

diagnostic flow

chart.”

Go to Step 11

Chart TA-1 ABS Works Frequently But Vehicle Does Not Decelerate (Use TECH 2)

StepActionYe sNo

11. Connect TECH 2.

2. Make sure of the output conditions of each wheel speed

sensor by mode “F1: Data Display”.

Is the output of each sensor normal?

Go to Step 2

Replace wheel

speed sensor.

Go to Step 3

2Return to Chart A-1.

Was the Chart A-1 finished?

Go to Step 3Go to Step 2

3Reconnect all components, ensure all components are properly

mounted.

Was this step finished?Repeat the “Basic

diagnostic flow

chart.”

Go to Step 3

Chart A-2 Uneven Braking Occurs While ABS Works

StepActionYe sNo

1Is there play in each sensor?Repair.

Go to Step 5

Go to Step 2

2Is there damage or powdered iron sticking to each sensor/sensor

ring?Repair.

Go to Step 5

Go to Step 3

3Is the output of each sensor normal? (Refer to chart C-1 or TC-1)

Go to Step 4

Replace sensor

or repair harness.

Go to Step 5

4Is brake pipe connecting order correct?

Replace EHCU.

Go to Step 5

Reconnect brake

pipe correctly.

Go to Step 5

5Reconnect all components, ensure all components are properly

mounted.

Was this step finished?Repeat the “Basic

diagnostic flow

chart.”

Go to Step 5

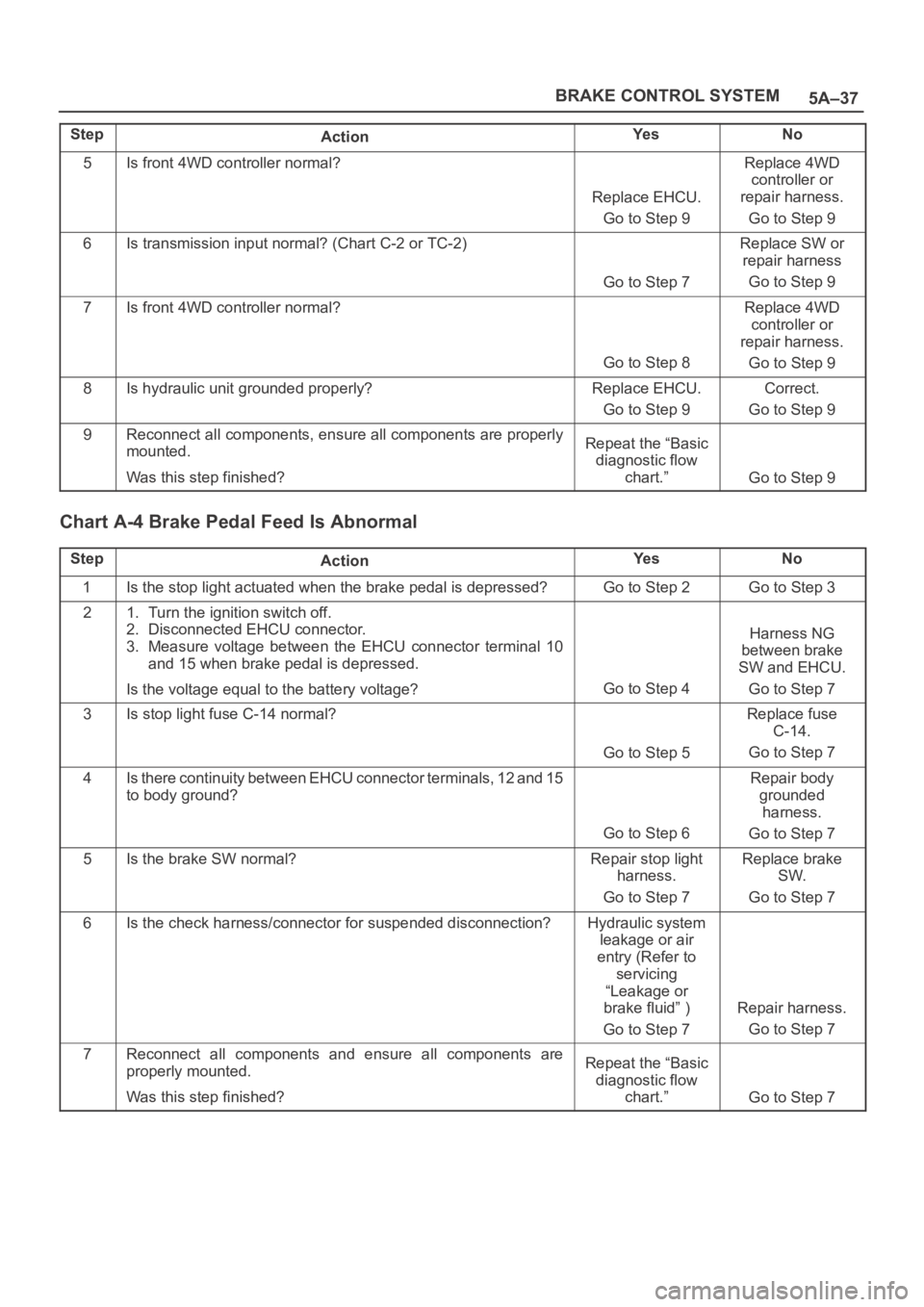

Chart A-3, TA-3 The Wheels Are Locked

StepActionYe sNo

1Is ABS working?Go to Step 2Go to Step 6

2Is vehicle speed under 10 km/h (6mph)?Normal.Go to Step 3

3Is sensor output normal? (Chart C-1 or TC-1)

Go to Step 4

Replace sensor

or repair harness.

Go to Step 9

4Is transmission input normal? (Chart C-2 or TC-2)

Go to Step 5

Replace SW or

repair harness.

Go to Step 9

Page 4387 of 6000

5A–37 BRAKE CONTROL SYSTEM

StepNo Ye s

Action

5Is front 4WD controller normal?

Replace EHCU.

Go to Step 9

Replace 4WD

controller or

repair harness.

Go to Step 9

6Is transmission input normal? (Chart C-2 or TC-2)

Go to Step 7

Replace SW or

repair harness

Go to Step 9

7Is front 4WD controller normal?

Go to Step 8

Replace 4WD

controller or

repair harness.

Go to Step 9

8Is hydraulic unit grounded properly?Replace EHCU.

Go to Step 9Correct.

Go to Step 9

9Reconnect all components, ensure all components are properly

mounted.

Was this step finished?Repeat the “Basic

diagnostic flow

chart.”

Go to Step 9

Chart A-4 Brake Pedal Feed Is Abnormal

StepActionYe sNo

1Is the stop light actuated when the brake pedal is depressed?Go to Step 2Go to Step 3

21. Turn the ignition switch off.

2. Disconnected EHCU connector.

3. Measure voltage between the EHCU connector terminal 10

and 15 when brake pedal is depressed.

Is the voltage equal to the battery voltage?

Go to Step 4

Harness NG

between brake

SW and EHCU.

Go to Step 7

3Is stop light fuse C-14 normal?

Go to Step 5

Replace fuse

C-14.

Go to Step 7

4Is there continuity between EHCU connector terminals, 12 and 15

to body ground?

Go to Step 6

Repair body

grounded

harness.

Go to Step 7

5Is the brake SW normal?Repair stop light

harness.

Go to Step 7Replace brake

SW.

Go to Step 7

6Is the check harness/connector for suspended disconnection?Hydraulic system

leakage or air

entry (Refer to

servicing

“Leakage or

brake fluid” )

Go to Step 7

Repair harness.

Go to Step 7

7Reconnect all components and ensure all components are

properly mounted.

Was this step finished?Repeat the “Basic

diagnostic flow

chart.”

Go to Step 7

Page 4397 of 6000

5A–47 BRAKE CONTROL SYSTEM

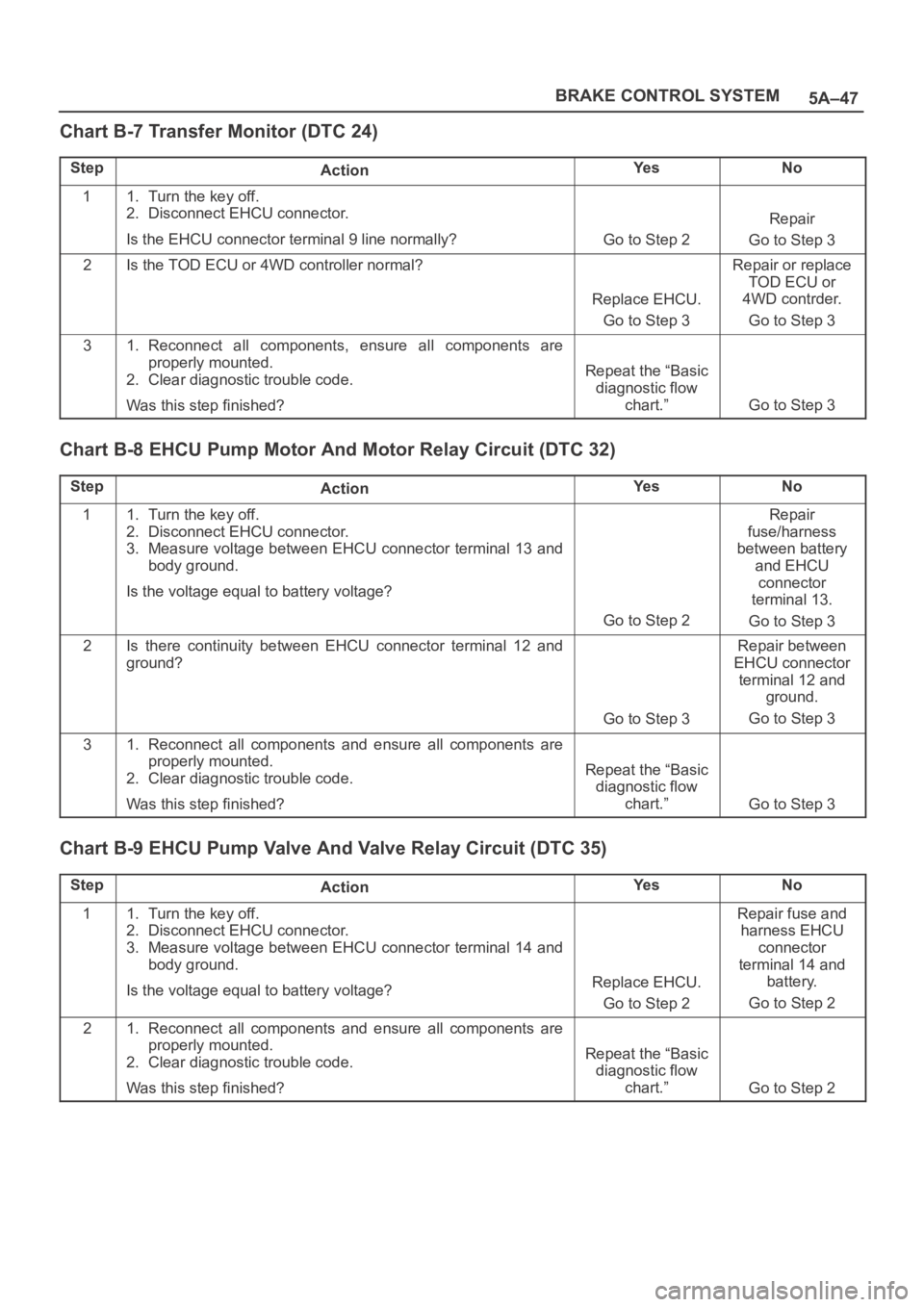

Chart B-7 Transfer Monitor (DTC 24)

StepActionYe sNo

11. Turn the key off.

2. Disconnect EHCU connector.

Is the EHCU connector terminal 9 line normally?

Go to Step 2

Repair

Go to Step 3

2Is the TOD ECU or 4WD controller normal?

Replace EHCU.

Go to Step 3

Repair or replace

TOD ECU or

4WD contrder.

Go to Step 3

31. Reconnect all components, ensure all components are

properly mounted.

2. Clear diagnostic trouble code.

Was this step finished?

Repeat the “Basic

diagnostic flow

chart.”

Go to Step 3

Chart B-8 EHCU Pump Motor And Motor Relay Circuit (DTC 32)

StepActionYe sNo

11. Turn the key off.

2. Disconnect EHCU connector.

3. Measure voltage between EHCU connector terminal 13 and

body ground.

Is the voltage equal to battery voltage?

Go to Step 2

Repair

fuse/harness

between battery

and EHCU

connector

terminal 13.

Go to Step 3

2Is there continuity between EHCU connector terminal 12 and

ground?

Go to Step 3

Repair between

EHCU connector

terminal 12 and

ground.

Go to Step 3

31. Reconnect all components and ensure all components are

properly mounted.

2. Clear diagnostic trouble code.

Was this step finished?

Repeat the “Basic

diagnostic flow

chart.”

Go to Step 3

Chart B-9 EHCU Pump Valve And Valve Relay Circuit (DTC 35)

StepActionYe sNo

11. Turn the key off.

2. Disconnect EHCU connector.

3. Measure voltage between EHCU connector terminal 14 and

body ground.

Is the voltage equal to battery voltage?

Replace EHCU.

Go to Step 2

Repair fuse and

harness EHCU

connector

terminal 14 and

battery.

Go to Step 2

21. Reconnect all components and ensure all components are

properly mounted.

2. Clear diagnostic trouble code.

Was this step finished?

Repeat the “Basic

diagnostic flow

chart.”

Go to Step 2

Page 4689 of 6000

6E–32

ENGINE DRIVEABILITY AND EMISSIONS

Undercarriage Component Locator

F00RW040

Undercarriage Component Locator Table (Automatic Transmission)

Number

NameLocation

1Fuel Pump AssemblyInstalled in the top of the fuel tank

2Fuel Gauge UnitInstalled in the front edge of the fuel tank, on

the right side

3Fuel FilterLocated along the inside of the right frame rail,

ahead of the rear axle

4Vehicle Speed Sensor (VSS)2WD: Protrudes from the transmission

housing, just ahead of the propeller shaft.

4WD: Protrudes from the rear output shaft

housing of the transfer case.

5Heated Oxygen Sensor (Bank 1, HO2S 1)Threaded into the exhaust pipe ahead of the

right-hand catalytic converter

6Heated Oxygen Sensor (Bank 2, HO2S 1)Threaded into the exhaust pipe ahead the

left-hand catalytic converter

Page 4690 of 6000

6E–33 ENGINE DRIVEABILITY AND EMISSIONS

Undercarriage Component Locator Table (Manual Transmission)

Number

NameLocation

1Fuel Pump AssemblyInstalled in the top of the fuel tank

2Fuel Gauge UnitInstalled in the front edge of the right frame

rail, ahead of the rear axle

3Fuel FilterLocated along the inside of the right frame rail,

ahead of the rear axle

4Vehicle Speed Sensor (VSS)2WD: Protrudes from the transmission

housing, just ahead of the propeller shaft.

4WD: Protrudes from the rear output shaft

housing of the transfer case.

5Heated Oxygen Sensor (Bank 1, HO2S 1)Threaded into the exhaust pipe ahead of the

right-hand catalytic converter

6Heated Oxygen Sensor (Bank 2, HO2S 1)Threaded into the exhaust pipe ahead of the

left-hand catalytic converter

Fuse and Relay Panel (Underhood Electrical Center)

TS23336

Page 5708 of 6000

7A–19 AUTOMATIC TRANSMISSION (4L30–E)

Chart 13: Shudder Only During Torque Converter Clutch (TCC) Applying

StepActionYe sNo

11. TCC shudder is one of the most commonly misdiagnosed

conditions in an automatic transmission. The key to

diagnosing TCC shudder is to note when it happens and under

what conditions. Once the TCC has been fully applied, it is

nearly impossible to make it shudder. TCC shudder (short

burst of noise normally less than 1 second) will only occur

during clutch applying. It is not a steady state condition.

2. Drive until whole drivetrain is at normal operating temperature.

– On 4WD vehicles, the test must be performed with transfer

case selector lever in “2H” position.

– Shudder is a short burst of noise normally less than 1 second

in duration, and can be induced by the following maneuver:

3. From coast condition at 50 mph in “D” range (Normal mode),

depress the throttle to 1/4-1/3 throttle. If present, shudder will

occur within 5 seconds together with TCC application.(The

scan tool may be used to determine the exact time of TCC

applying)

Was the problem found?

Replace

transmission fluid

and filter (remove

both pans) and

flush cooler lines.

Replace

converter

assembly and

O-ring on turbine

shaft

Perform

mechanical

inspection of

other drivetrain

components.

Chart 14: Possible Causes Of Transmission Noise

CAUTION: Before checking transmission for what

is believed to be transmission noise, ensure

presence and positioning of insulating plugs, pads

etc. Also make sure that noise does not come from

other drivetrain components.

Condition

Possible causeCorrection

Whine or BuzzOil level lowFill with ATF, check for external

leaks.

Plugged or restricted oil filterInspect oil filter.

Replace oil filter or ATF as necessary.

Damaged oil filter gasketReplace oil filter gasket.

Knocking noise from front of

transmission

Loose bolts (Converter to flex plate)Tighten to specifications.

transmission.Cracked or broken flex plateReplace flex plate.

Converter damagedReplace converter.

Knocking noise while driving, mostly

on acceleration.Transmission mount loose or brokenTighten mount bolts or replace

transmission mount.

Cooler line mounts loose or brokenTighten or replace cooler line

mounts.

Cooler lines touching body or frameRepair or replace as necessary.

Knocking noise when vehicle is

stationary

Loose flex plate mounting boltsTighten to specifications.

stationary.Cracked or broken flex plateReplace flex plate.

Damaged converterReplace converter.