oil type OPEL FRONTERA 1998 User Guide

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 722 of 6000

TRANSFER CASE (STANDARD TYPE)

4D1–1

DRIVELINE/AXLE

TRANSFER CASE (STANDARD TYPE)

CONTENTS

Service Precaution 4D1–1. . . . . . . . . . . . . . . . . . . . . .

General Description 4D1–2. . . . . . . . . . . . . . . . . . . . .

Transfer Rear Oil Seal 4D1–8. . . . . . . . . . . . . . . . . . .

Removal 4D1–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 4D1–8. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transfer Case Assembly 4D1–9. . . . . . . . . . . . . . . . .

Removal 4D1–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 4D1–10. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transfer Rear Cover Assembly

(4WD Switch Model) 4D1–11. . . . . . . . . . . . . . . . . . . .

Transfer Rear Cover Assembly and

Associated Parts 4D1–11. . . . . . . . . . . . . . . . . . . . . .

Removal 4D1–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 4D1–13. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disassembly 4D1–16. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 4D1–17. . . . . . . . . . . . . . . . . .

Reassembly 4D1–17. . . . . . . . . . . . . . . . . . . . . . . . . .

Transfer Rear Cover Assembly

(Except 4WD Switch Model) 4D1–19. . . . . . . . . . . . . . Transfer Rear Cover Assembly and

Associated Parts 4D1–19. . . . . . . . . . . . . . . . . . . . . .

Removal 4D1–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 4D1–20. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disassembly 4D1–23. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 4D1–24. . . . . . . . . . . . . . . . . .

Reassembly 4D1–24. . . . . . . . . . . . . . . . . . . . . . . . . .

Detent, Shift Arm, and Interlock Pin 4D1–26. . . . . . . .

Disassembled View 4D1–26. . . . . . . . . . . . . . . . . . . .

Disassembly 4D1–26. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 4D1–28. . . . . . . . . . . . . . . . . .

Reassembly 4D1–28. . . . . . . . . . . . . . . . . . . . . . . . . .

Transfer Case Assembly 4D1–30. . . . . . . . . . . . . . . . .

Disassembled View 4D1–30. . . . . . . . . . . . . . . . . . . .

Disassembly 4D1–31. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 4D1–33. . . . . . . . . . . . . . . . . .

Reassembly 4D1–37. . . . . . . . . . . . . . . . . . . . . . . . . .

Main Data and Specifications 4D1–43. . . . . . . . . . . . .

Special Tools 4D1–46. . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Precaution

WARNING: THIS VEHICLE HAS A SUPPLEMENTAL

RESTRAINT SYSTEM (SRS). REFER TO THE SRS

COMPONENT AND WIRING LOCATION VIEW IN

ORDER TO DETERMINE WHETHER YOU ARE

PERFORMING SERVICE ON OR NEAR THE SRS

COMPONENTS OR THE SRS WIRING. WHEN YOU

ARE PERFORMING SERVICE ON OR NEAR THE SRS

COMPONENTS OR THE SRS WIRING, REFER TO

THE SRS SERVICE INFORMATION. FAILURE TO

FOLLOW WARNINGS COULD RESULT IN POSSIBLE

AIR BAG DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU will call out those fasteners that require a

replacement after removal. ISUZU will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED, do not

use supplemental coatings (Paints, greases, or other

corrosion inhibitors) on threaded fasteners or

fastener joint interfaces. Generally, such coatings

adversely affect the fastener torque and the joint

clamping force, and may damage the fastener. When

you install fasteners, use the correct tightening

sequence and specifications. Following these

instructions can help you avoid damage to parts and

systems.

Page 729 of 6000

4D1–8

TRANSFER CASE (STANDARD TYPE)

Transfer Rear Oil Seal

Removal

1. Disconnect the rear propeller shaft from the transfer

case side.

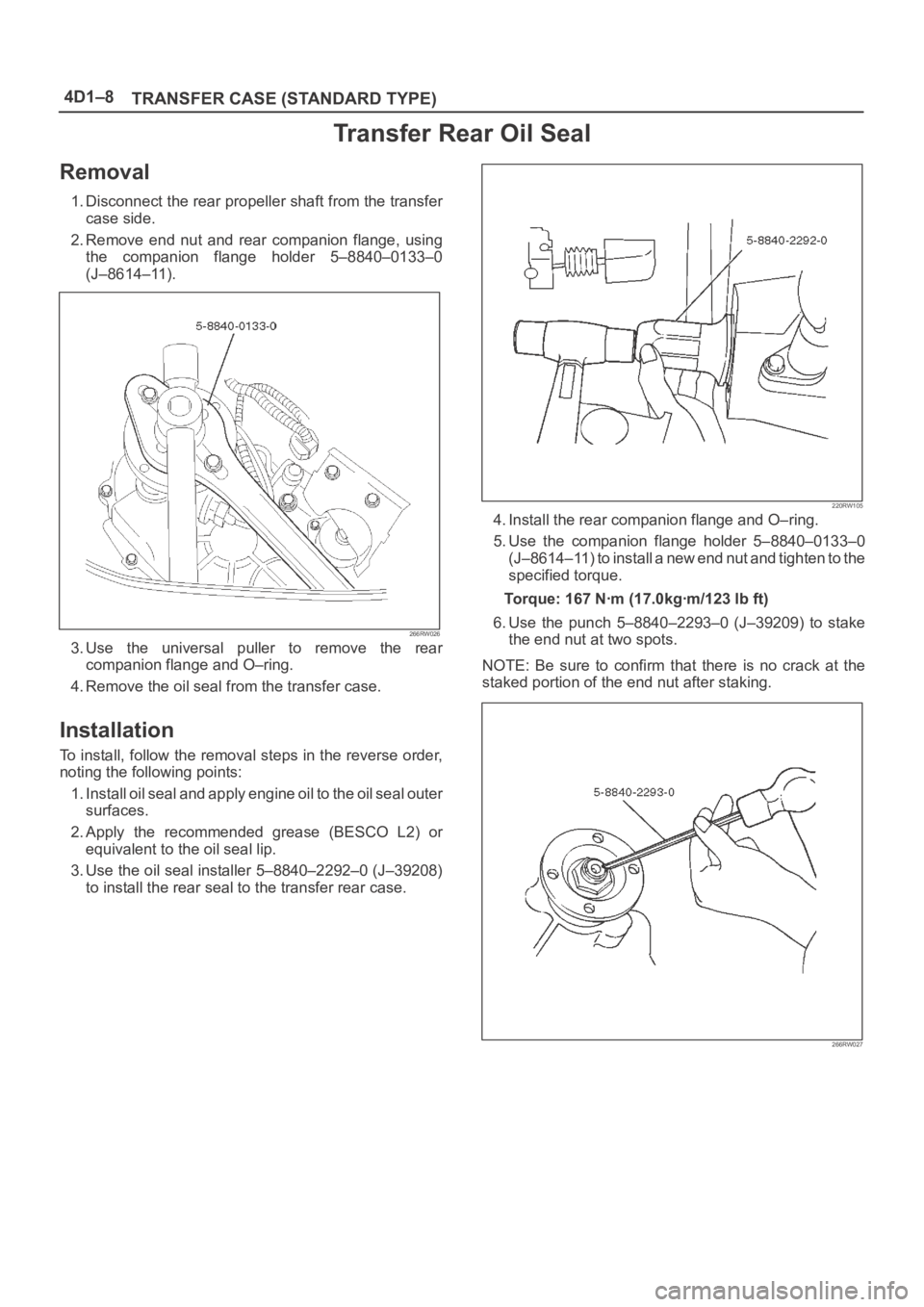

2. Remove end nut and rear companion flange, using

the companion flange holder 5–8840–0133–0

(J–8614–11).

266RW026

3. Use the universal puller to remove the rear

companion flange and O–ring.

4. Remove the oil seal from the transfer case.

Installation

To install, follow the removal steps in the reverse order,

noting the following points:

1. Install oil seal and apply engine oil to the oil seal outer

surfaces.

2. Apply the recommended grease (BESCO L2) or

equivalent to the oil seal lip.

3. Use the oil seal installer 5–8840–2292–0 (J–39208)

to install the rear seal to the transfer rear case.

220RW105

4. Install the rear companion flange and O–ring.

5. Use the companion flange holder 5–8840–0133–0

(J–8614–11) to install a new end nut and tighten to the

specified torque.

Torque: 167 Nꞏm (17.0kgꞏm/123 lb ft)

6. Use the punch 5–8840–2293–0 (J–39209) to stake

the end nut at two spots.

NOTE: Be sure to confirm that there is no crack at the

staked portion of the end nut after staking.

266RW027

Page 737 of 6000

4D1–16

TRANSFER CASE (STANDARD TYPE)

Disassembly

226RW154

Legend

(1) Rear Output Shaft Assembly

(2) Rear Output Shaft

(3) Bearing Snap Ring

(4) Ball Bearing(5) Bearing Snap Ring

(6) Ball

(7) Speedometer Drive Gear

(8) Ball Bearing

(9) Transfer Rear Cover (with oil seal)

1. Remove the bearing snap ring (3), using a pair of snap

ring pliers.

226RS060

Page 738 of 6000

TRANSFER CASE (STANDARD TYPE)

4D1–17

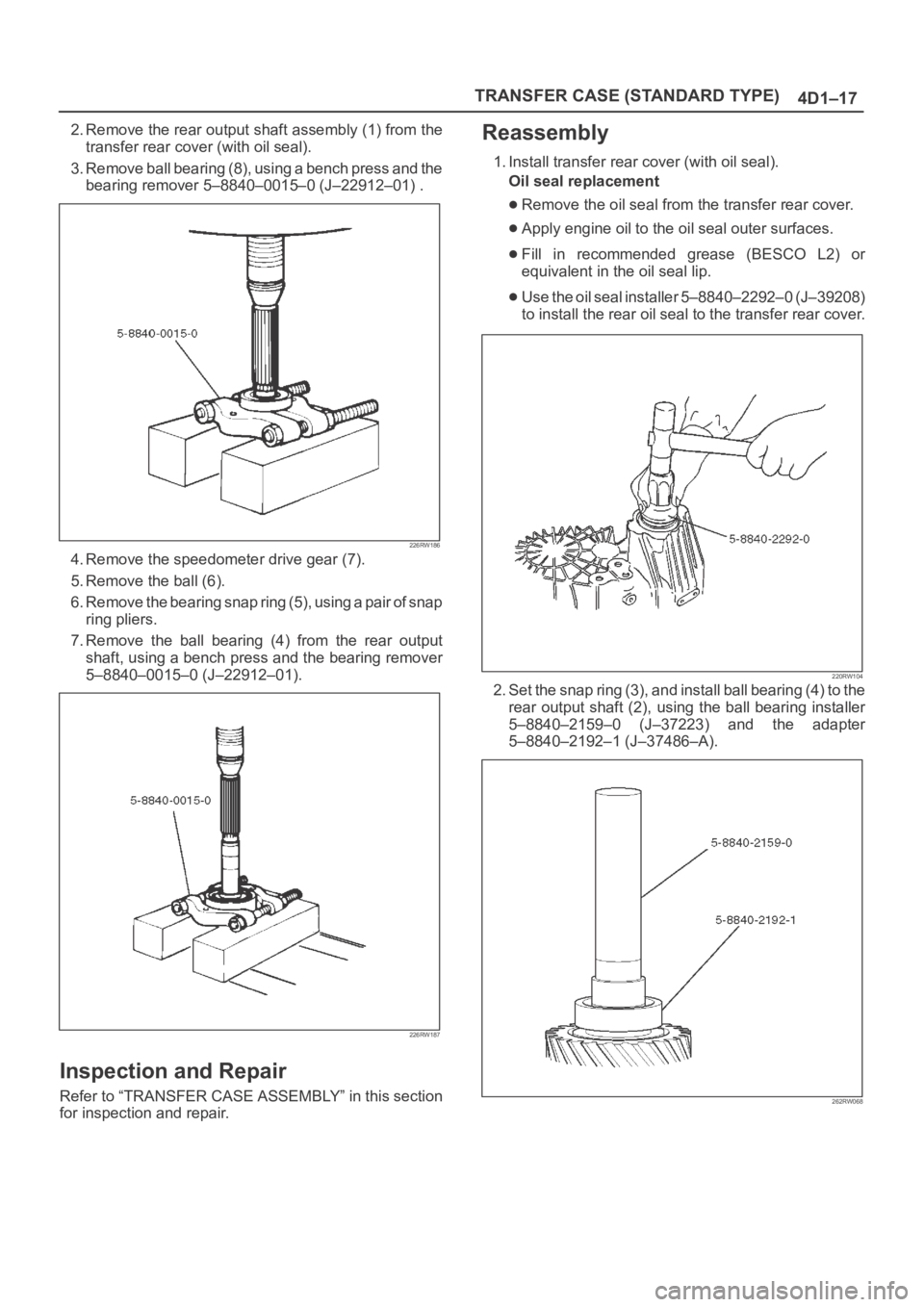

2. Remove the rear output shaft assembly (1) from the

transfer rear cover (with oil seal).

3. Remove ball bearing (8), using a bench press and the

bearing remover 5–8840–0015–0 (J–22912–01) .

226RW186

4. Remove the speedometer drive gear (7).

5. Remove the ball (6).

6. Remove the bearing snap ring (5), using a pair of snap

ring pliers.

7. Remove the ball bearing (4) from the rear output

shaft, using a bench press and the bearing remover

5–8840–0015–0 (J–22912–01).

226RW187

Inspection and Repair

Refer to “TRANSFER CASE ASSEMBLY” in this section

for inspection and repair.

Reassembly

1. Install transfer rear cover (with oil seal).

Oil seal replacement

Remove the oil seal from the transfer rear cover.

Apply engine oil to the oil seal outer surfaces.

Fill in recommended grease (BESCO L2) or

equivalent in the oil seal lip.

Use the oil seal installer 5–8840–2292–0 (J–39208)

to install the rear oil seal to the transfer rear cover.

220RW104

2. Set the snap ring (3), and install ball bearing (4) to the

rear output shaft (2), using the ball bearing installer

5–8840–2159–0 (J–37223) and the adapter

5–8840–2192–1 (J–37486–A).

262RW068

Page 744 of 6000

TRANSFER CASE (STANDARD TYPE)

4D1–23

Disassembly

226RW154

Legend

(1) Rear Output Shaft Assembly

(2) Rear Output Shaft

(3) Bearing Snap Ring

(4) Ball Bearing(5) Bearing Snap Ring

(6) Ball

(7) Speedometer Drive Gear

(8) Ball Bearing

(9) Transfer Rear Cover (with oil seal)

1. Remove the bearing snap ring (3), using a pair of snap

ring pliers.

226RS060

Page 745 of 6000

4D1–24

TRANSFER CASE (STANDARD TYPE)

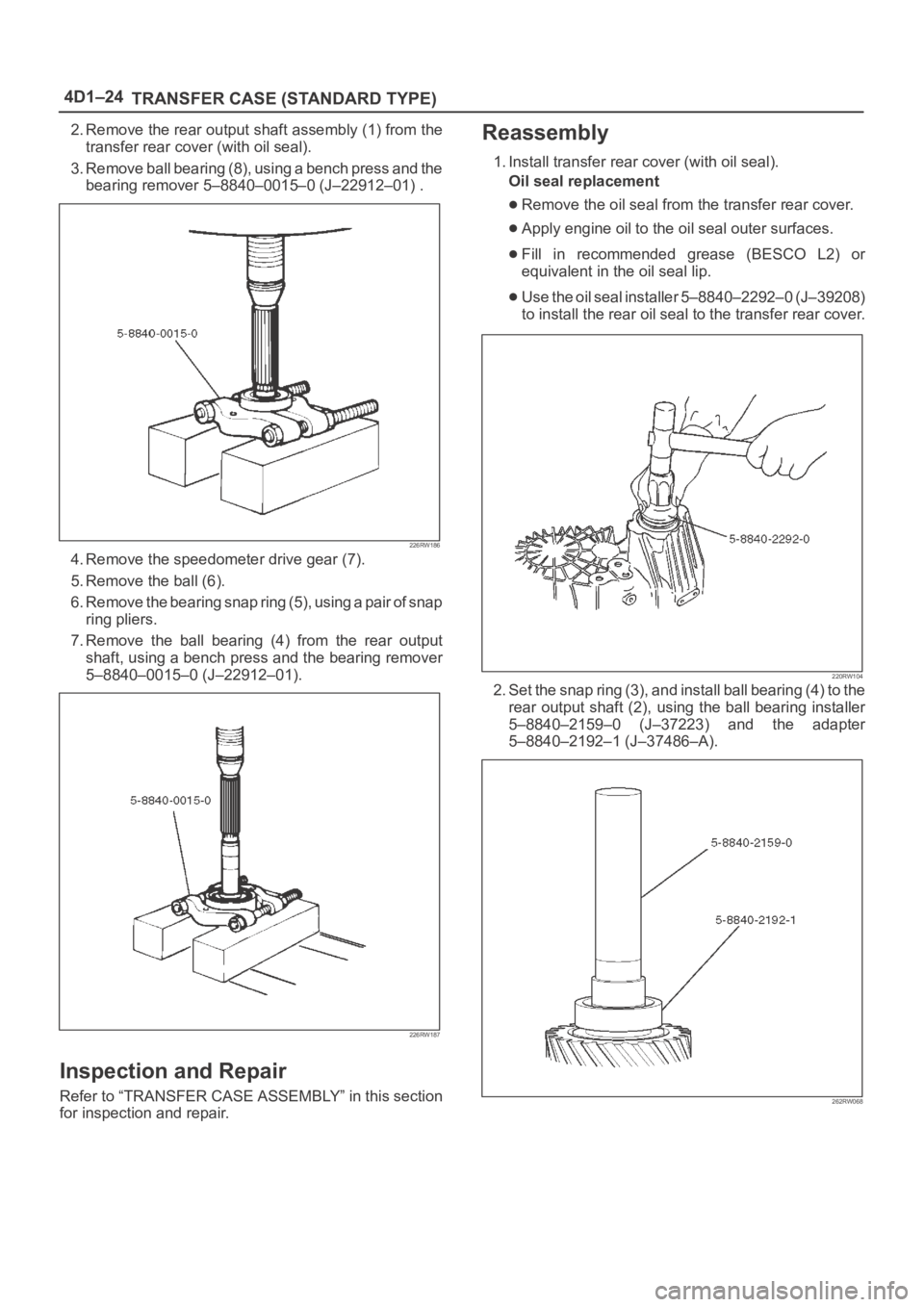

2. Remove the rear output shaft assembly (1) from the

transfer rear cover (with oil seal).

3. Remove ball bearing (8), using a bench press and the

bearing remover 5–8840–0015–0 (J–22912–01) .

226RW186

4. Remove the speedometer drive gear (7).

5. Remove the ball (6).

6. Remove the bearing snap ring (5), using a pair of snap

ring pliers.

7. Remove the ball bearing (4) from the rear output

shaft, using a bench press and the bearing remover

5–8840–0015–0 (J–22912–01).

226RW187

Inspection and Repair

Refer to “TRANSFER CASE ASSEMBLY” in this section

for inspection and repair.

Reassembly

1. Install transfer rear cover (with oil seal).

Oil seal replacement

Remove the oil seal from the transfer rear cover.

Apply engine oil to the oil seal outer surfaces.

Fill in recommended grease (BESCO L2) or

equivalent in the oil seal lip.

Use the oil seal installer 5–8840–2292–0 (J–39208)

to install the rear oil seal to the transfer rear cover.

220RW104

2. Set the snap ring (3), and install ball bearing (4) to the

rear output shaft (2), using the ball bearing installer

5–8840–2159–0 (J–37223) and the adapter

5–8840–2192–1 (J–37486–A).

262RW068

Page 751 of 6000

4D1–30

TRANSFER CASE (STANDARD TYPE)

Transfer Case Assembly

Disassembled View

226RW132

Legend

(1) Transfer Case (with oil seal)

(2) Bearing Snap Ring

(3) Front Output Gear Assembly

(4) Ball Bearing

(5) Front Output Shaft

(6) Stopper Plate (Shift On The Fly model)

(7) 2WD–4WD Clutch Hub and Sleeve Assembly

(8) Block Ring (Shift On The Fly model)

(9) Outside Ring (Shift On The Fly model)

(10) Inside Ring (Shift On The Fly model)

(11) Front Output Gear

(12) Needle Bearing

(13) Sub–Gear (anti–lash plate) (M/T)

(14) Belleville Spring (M/T)

(15) Spacer (M/T)

(16) Sub–Gear Snap Ring (M/T)

(17) Bearing Collar

(18) Ball Bearing

(19) Bearing Snap Ring

(20) Snap Ring

(21) Ball Bearing(22) Counter Gear

(23) Sub–Gear (anti–lash plate)

(24) Belleville Spring

(25) Spacer

(26) Ball Bearing

(27) Snap Ring

(28) Counter Gear Assembly

(29) Bearing Snap Ring

(30) Input Shaft Assembly

(31) Input Shaft

(32) Ball Bearing

(33) Snap Ring

(34) Plate

(35) Ball

(36) Bearing Collar

(37) Needle Bearing

(38) Transfer Input Gear

(39) High–Low Clutch Hub and Sleeve Assembly

(40) Lock Nut

(41) Ball Bearing

(42) Bearing Snap Ring

Page 754 of 6000

TRANSFER CASE (STANDARD TYPE)

4D1–33

NOTE: Do not reuse the stopper plate. (Shift On The Fly

model)

24. Disassemble the 2WD–4WD clutch hub and sleeve

assembly.

Springs (1) (Shift On The Fly model)

Inserts (2) (Shift On The Fly model)

Clutch Hub (3)

Sleeve (4)

226RW133

25. Use a bench press and the ball bearing remover

5–8840–0015–0 (J–22912–01) to remove the ball

bearing (4) from front output shaft (5).

262RW071

26. Remove bearing snap ring (29) from transfer case.

27. Remove the counter gear assembly (28) from the

transfer case (1).

28. Use a pair of snap ring pliers to remove the snap ring

(20).29. Use a bench press and the bearing remover

5–8840–0015–0 (J–22912–01) to remove the ball

bearing (21).

30. Use a pair of snap ring pliers to remove the snap ring

(27).

31. Use a bench press and the bearing remover

5–8840–0015–0 (J–22912–01) to remove the ball

bearing (26).

226RW191

32. Remove the spacer (25).

33. Remove the belleville spring (24).

34. Remove the sub–gear (anti–lash plate) (23) from the

counter gear (22).

Inspection and Repair

1. Make the necessary repair or parts replacement if

wear, damage or any other abnormal conditions are

found during inspection.

2. Wash all parts thoroughly in clean solvent. Be sure all

old lubricant, metallic particles, dirt, or foreign

material are removed from the surfaces of every part.

Apply compressed air to each oil feed port and

channel in each case half to remove any obstructions

or cleaning solvent residue.

Gears

1. Inspect all the gear teeth for signs of excessive wear

or damage and check all the gear splines for burrs,

nicks, wear or damage. Remove the minor nicks or

scratches on an oil stone. Replace any part exhibiting

excessive wear or damage.

Front Output Gear Inside Diameter

1. Use an inside dial indicator to measure the gear inside

diameter.

Page 755 of 6000

4D1–34

TRANSFER CASE (STANDARD TYPE)

2. If the measured value exceeds the specified limit, the

gear must be replaced.

Gear inside diameter

Standard : 48.000–48.013 mm (1.8898–1.8903 in)

Limit : 48.10 mm (1.894 in)

226RS040

Clutch Hub Spline Play

1. Set a dial indicator to the clutch hub to measured.

2. Move the clutch hub as far as possible to both the right

and the left.

Note the dial indicator reading.

3. If the measured value exceeds the specified limit, the

clutch hub must be replaced.

Clutch hub spline play

Standard : 0–0.1 mm (0–0.004 in)

Limit : 0.2 mm (0.008 in)

226RS042

Bearings

1. Inspect the condition of all the needles and ball

bearings. Wash bearings thoroughly in a cleaning

solvent. Apply compressed air to the bearings.

NOTE: Do not allow the bearings to spin. Turn them

slowly by hand. Spinning bearings may damage the

rollers.

2. Lubricate the bearings with a light oil and check them

for roughness by slowly turning the race by hand.

Ball Bearing Play

1. Use a dial indicator to measure the ball bearing play.

2. If the measured value exceeds the specified limit, the

ball bearing must be replaced.

Limit : 0.2 mm (0.008 in)

226RS043

Synchronizers

The synchronizer hubs and sliding sleeves are a selected

assembly and should be kept together as originally

assembled.

Clean synchronizer components with clean solvent and

air dry.

Inspect the components for the following:

Teeth for wear, scuffs, nicks, burrs or breaks.

Keys and springs for wear, cracks or distortion,

replace if these conditions are present.

If scuffed, nicked or burred conditions cannot be

corrected with a soft stone or crocus cloth, replace the

component.

Block Ring and Insert Clearance

1. Use a vernier caliper to measure the clearance

between the block ring and the insert.

2. If the measured value exceeds the specified limit, the

block ring and the insert must be replaced.

Block ring and insert clearance

Standard : 2.46–2.74 mm (0.097–0.108 in)

Page 758 of 6000

TRANSFER CASE (STANDARD TYPE)

4D1–37

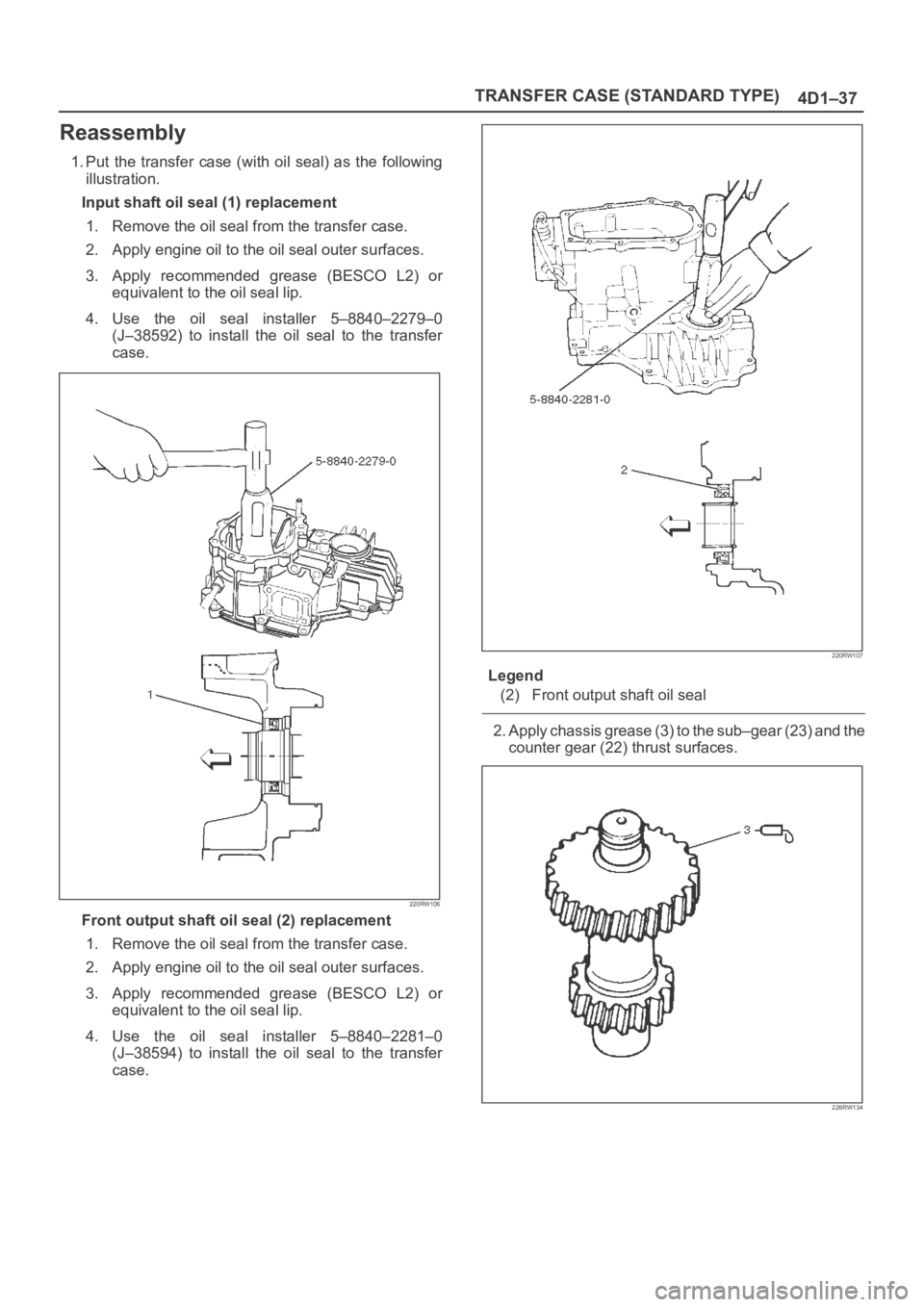

Reassembly

1. Put the transfer case (with oil seal) as the following

illustration.

Input shaft oil seal (1) replacement

1. Remove the oil seal from the transfer case.

2. Apply engine oil to the oil seal outer surfaces.

3. Apply recommended grease (BESCO L2) or

equivalent to the oil seal lip.

4. Use the oil seal installer 5–8840–2279–0

(J–38592) to install the oil seal to the transfer

case.

220RW106

Front output shaft oil seal (2) replacement

1. Remove the oil seal from the transfer case.

2. Apply engine oil to the oil seal outer surfaces.

3. Apply recommended grease (BESCO L2) or

equivalent to the oil seal lip.

4. Use the oil seal installer 5–8840–2281–0

(J–38594) to install the oil seal to the transfer

case.

220RW107

Legend

(2) Front output shaft oil seal

2. Apply chassis grease (3) to the sub–gear (23) and the

counter gear (22) thrust surfaces.

226RW134