tow OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 279 of 6000

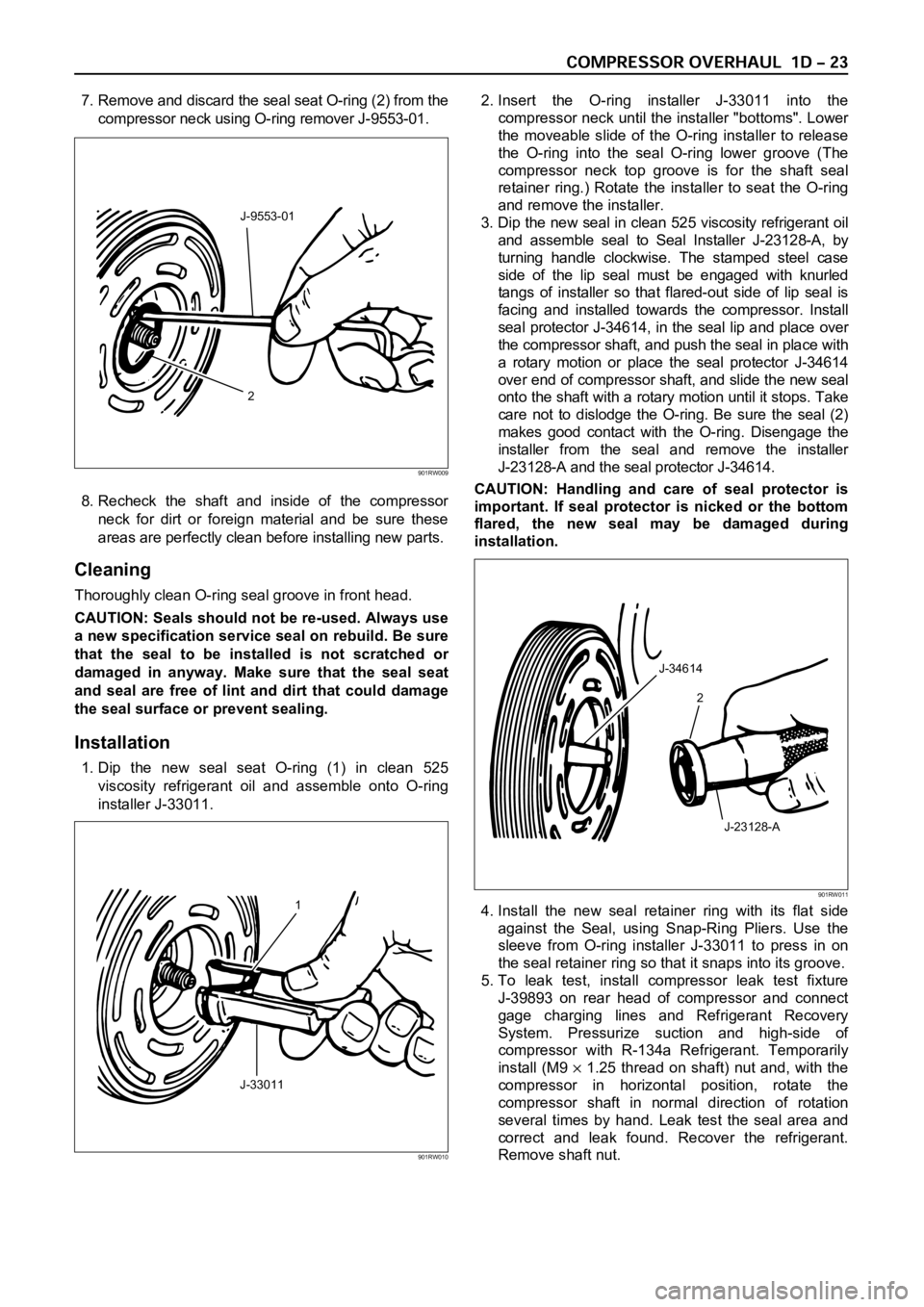

7. Remove and discard the seal seat O-ring (2) from the

compressor neck using O-ring remover J-9553-01.

8. Recheck the shaft and inside of the compressor

neck for dirt or foreign material and be sure these

areas are perfectly clean before installing new parts.

Cleaning

Thoroughly clean O-ring seal groove in front head.

CAUTION: Seals should not be re-used. Always use

a new specification service seal on rebuild. Be sure

that the seal to be installed is not scratched or

damaged in anyway. Make sure that the seal seat

and seal are free of lint and dirt that could damage

the seal surface or prevent sealing.

Installation

1. Dip the new seal seat O-ring (1) in clean 525

viscosity refrigerant oil and assemble onto O-ring

installer J-33011.2. Insert the O-ring installer J-33011 into the

compressor neck until the installer "bottoms". Lower

the moveable slide of the O-ring installer to release

the O-ring into the seal O-ring lower groove (The

compressor neck top groove is for the shaft seal

retainer ring.) Rotate the installer to seat the O-ring

and remove the installer.

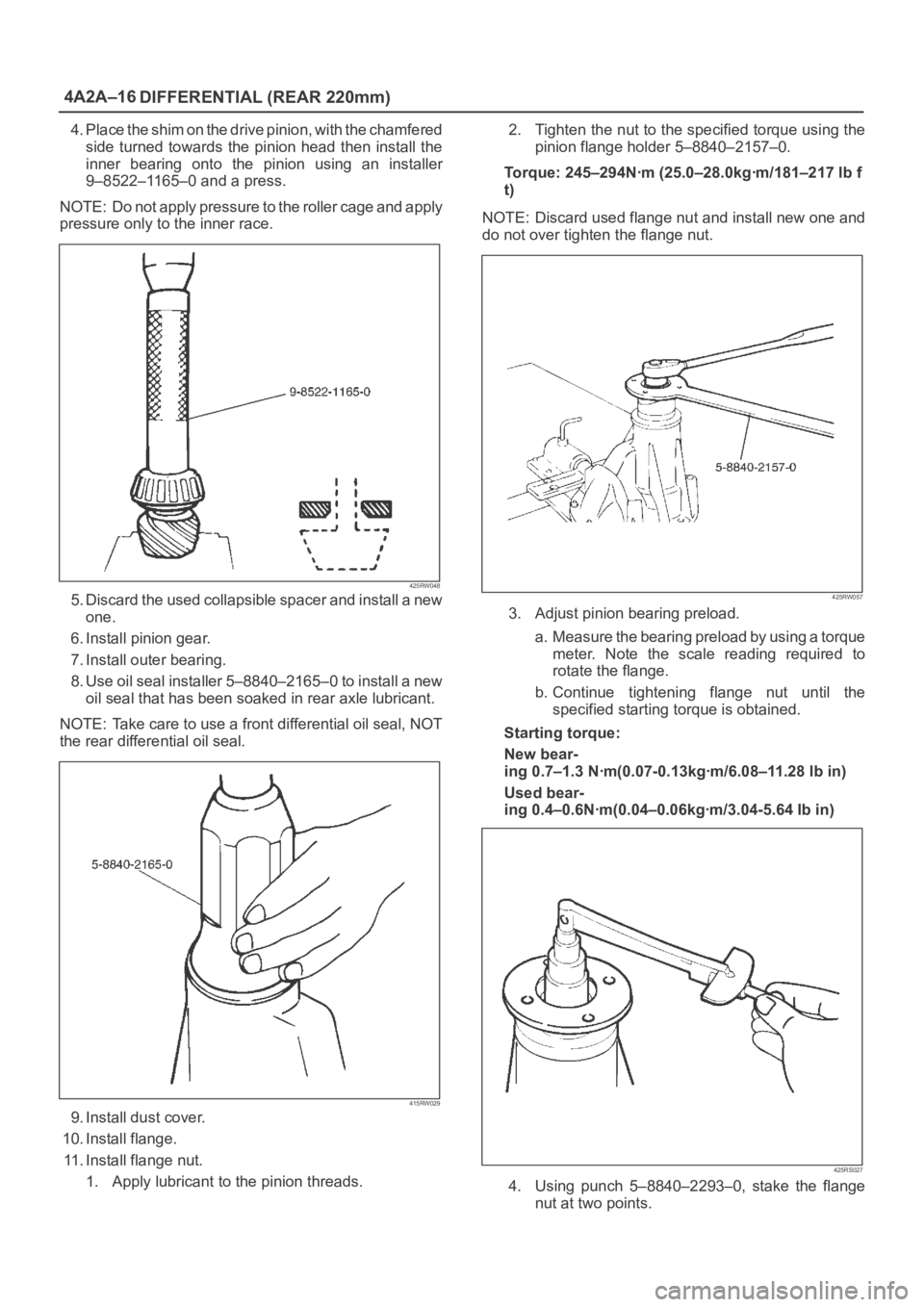

3. Dip the new seal in clean 525 viscosity refrigerant oil

and assemble seal to Seal Installer J-23128-A, by

turning handle clockwise. The stamped steel case

side of the lip seal must be engaged with knurled

tangs of installer so that flared-out side of lip seal is

facing and installed towards the compressor. Install

seal protector J-34614, in the seal lip and place over

the compressor shaft, and push the seal in place with

a rotary motion or place the seal protector J-34614

over end of compressor shaft, and slide the new seal

onto the shaft with a rotary motion until it stops. Take

care not to dislodge the O-ring. Be sure the seal (2)

makes good contact with the O-ring. Disengage the

installer from the seal and remove the installer

J-23128-A and the seal protector J-34614.

CAUTION: Handling and care of seal protector is

important. If seal protector is nicked or the bottom

flared, the new seal may be damaged during

installation.

4. Install the new seal retainer ring with its flat side

against the Seal, using Snap-Ring Pliers. Use the

sleeve from O-ring installer J-33011 to press in on

the seal retainer ring so that it snaps into its groove.

5. To leak test, install compressor leak test fixture

J-39893 on rear head of compressor and connect

gage charging lines and Refrigerant Recovery

System. Pressurize suction and high-side of

compressor with R-134a Refrigerant. Temporarily

install (M9

1.25 thread on shaft) nut and, with the

compressor in horizontal position, rotate the

compressor shaft in normal direction of rotation

several times by hand. Leak test the seal area and

correct and leak found. Recover the refrigerant.

Remove shaft nut.

2 J-9553-01

901RW009

1

J-33011

901RW010

J-34614

2

J-23128-A

901RW011

Page 452 of 6000

4A1–15 DIFFERENTIAL (FRONT)

8. Select the shim using the chart;

Pinion marking+10+8+6+4+20–2–4–6–8–10

Dial indicator

reading

(Inches)mm

(Inches)mm

(Inches)mm

(Inches)mm

(Inches)mm

(Inches)mm

(Inches)mm

(Inches)mm

(Inches)mm

(Inches)mm

(Inches)mm

(Inches)

0.0812.18

(0.0858)

0.0822.18

(0.0858)2.20

(0.0866)

0.0832.18

(0.0858)2.20

(0.0866)2.23

(0.0882)

0.0842.18

(0.0858)2.20

(0.0866)2.24

(0.0882)2.26

(0.0890)

0.0852.18

(0.0858)2.20

(0.0866)2.24

(0.0882)2.26

(0.0890)2.28

(0.0898)

0.0862.18

(0.0858)2.20

(0.0866)2.24

(0.0882)2.26

(0.0890)2.28

(0.0898)2.32

(0.0914)

0.0872.18

(0.0858)2.20

(0.0866)2.24

(0.0882)2.26

(0.0890)2.28

(0.0898)2.32

(0.0914)2.34

(0.0921)

0.0882.18

(0.0858)2.20

(0.0866)2.24

(0.0882)2.26

(0.0890)2.28

(0.0898)2.32

(0.0914)2.34

(0.0921)2.36

(0.0929)

0.0892.18

(0.0858)2.20

(0.0866)2.24

(0.0882)2.26

(0.0890)2.28

(0.0898)2.32

(0.0914)2.34

(0.0921)2.36

(0.0929)2.38

(0.0937)

0.0902.18

(0.0858)2.20

(0.0866)2.24

(0.0882)2.26

(0.0890)2.28

(0.0898)2.32

(0.0914)2.34

(0.0921)2.36

(0.0929)2.38

(0.0937)2.42

(0.0953)

0.0912.18

(0.0858)2.20

(0.0866)2.24

(0.0882)2.26

(0.0890)2.28

(0.0898)2.32

(0.0914)2.34

(0.0921)2.36

(0.0929)2.38

(0.0937)2.42

(0.0953)2.44

(0.0961)

0.0922.20

(0.0866)2.24

(0.0882)2.26

(0.0890)2.28

(0.0898)2.32

(0.0914)2.34

(0.0921)2.36

(0.0929)2.38

(0.0937)2.42

(0.0953)2.44

(0.0961)2.46

(0.0969)

0.0932.24

(0.0882)2.26

(0.0890)2.28

(0.0898)2.32

(0.0914)2.34

(0.0921)2.36

(0.0929)2.38

(0.0937)2.42

(0.0953)2.44

(0.0961)2.46

(0.0969)2.48

(0.0977)

0.0942.26

(0.0890)2.28

(0.0898)2.32

(0.0914)2.34

(0.0921)2.36

(0.0929)2.38

(0.0937)2.42

(0.0953)2.44

(0.0961)2.46

(0.0969)2.48

(0.0977)2.52

(0.0992)

0.0952.28

(0.0898)2.32

(0.0914)2.34

(0.0921)2.36

(0.0929)2.38

(0.0937)2.42

(0.0953)2.44

(0.0961)2.46

(0.0969)2.48

(0.0977)2.52

(0.0992)2.54

(0.1000)

0.0962.32

(0.0914)2.34

(0.0921)2.36

(0.0929)2.38

(0.0937)2.42

(0.0953)2.44

(0.0961)2.46

(0.0969)2.48

(0.0977)2.52

(0.0992)2.54

(0.1000)2.56

(0.1008)

0.0972.34

(0.0921)2.36

(0.0929)2.38

(0.0937)2.42

(0.0953)2.44

(0.0961)2.46

(0.0969)2.48

(0.0977)2.52

(0.0992)2.54

(0.1000)2.56

(0.1008)

0.0982.36

(0.0929)2.38

(0.0937)2.42

(0.0953)2.44

(0.0961)2.46

(0.0969)2.48

(0.0977)2.52

(0.0992)2.54

(0.1000)2.56

(0.1008)

0.0992.38

(0.0937)2.42

(0.0953)2.44

(0.0961)2.46

(0.0969)2.48

(0.0977)2.52

(0.0992)2.54

(0.1000)2.56

(0.1008)

02.42

(0.0953)2.44

(0.0961)2.46

(0.0969)2.48

(0.0977)2.52

(0.0992)2.54

(0.1000)2.56

(0.1008)

0.0012.44

(0.0961)2.46

(0.0969)2.48

(0.0977)2.52

(0.0992)2.54

(0.1000)2.56

(0.1008)

0.0022.46

(0.0969)2.48

(0.0977)2.52

(0.0992)2.54

(0.1000)2.56

(0.1008)

0.0032.48

(0.0977)2.52

(0.0992)2.54

(0.1000)2.56

(0.1008)

0.0042.52

(0.0992)2.54

(0.1000)2.56

(0.1008)

0.0052.54

(0.1000)2.56

(0.1008)

0.0062.56

(0.1008)

NOTE: When ordering shims, find the part number in the

parts catalog by using the thickness of shims listed in the

above table.4. Place the shim on the drive pinion, with the chamfered

side turned towards the pinion head then install the

inner bearing onto the pinion using an installer

9–8522–1165–0 and a press.

Page 483 of 6000

4A2A–16

DIFFERENTIAL (REAR 220mm)

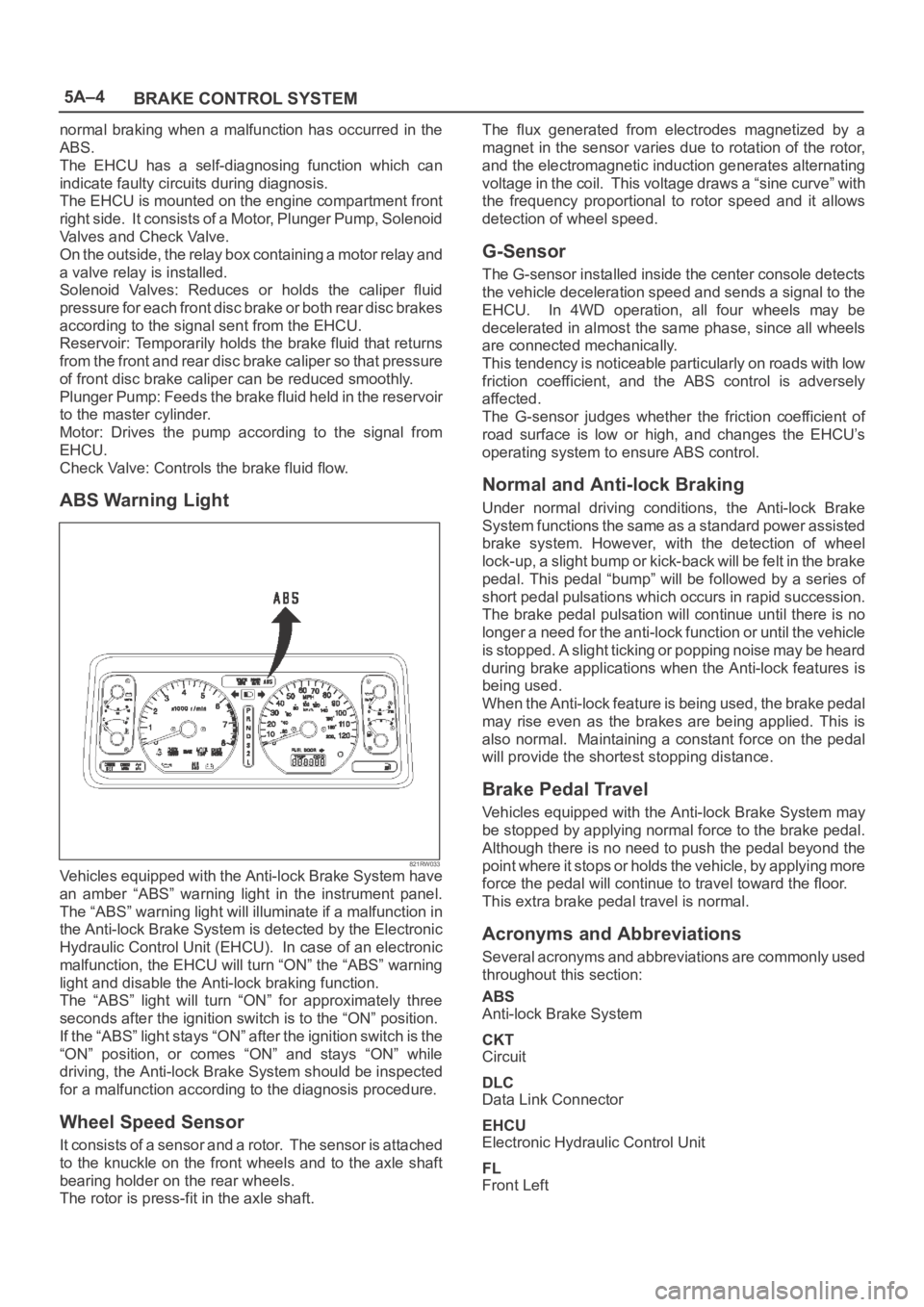

4. Place the shim on the drive pinion, with the chamfered

side turned towards the pinion head then install the

inner bearing onto the pinion using an installer

9–8522–1165–0 and a press.

NOTE: Do not apply pressure to the roller cage and apply

pressure only to the inner race.

425RW048

5. Discard the used collapsible spacer and install a new

one.

6. Install pinion gear.

7. Install outer bearing.

8. Use oil seal installer 5–8840–2165–0 to install a new

oil seal that has been soaked in rear axle lubricant.

NOTE: Take care to use a front differential oil seal, NOT

the rear differential oil seal.

415RW029

9. Install dust cover.

10. Install flange.

11. Install flange nut.

1. Apply lubricant to the pinion threads.2. Tighten the nut to the specified torque using the

pinion flange holder 5–8840–2157–0.

Torque: 245–294Nꞏm (25.0–28.0kgꞏm/181–217 lb f

t)

NOTE: Discard used flange nut and install new one and

do not over tighten the flange nut.

425RW057

3. Adjust pinion bearing preload.

a. Measure the bearing preload by using a torque

meter. Note the scale reading required to

rotate the flange.

b. Continue tightening flange nut until the

specified starting torque is obtained.

Starting torque:

New bear-

ing 0.7–1.3 Nꞏm(0.07-0.13kgꞏm/6.08–11.28 lb in)

Used bear-

ing 0.4–0.6Nꞏm(0.04–0.06kgꞏm/3.04-5.64 Ib in)

425RS027

4. Using punch 5–8840–2293–0, stake the flange

nut at two points.

Page 527 of 6000

4A2B–24DIFFERENTIAL (REAR 244mm)

4. Remove Differential shaft (2) using hammer and

punch.

Place shop towel behind case to prevent differential

shaft from dropping out of case.

425RW005

5. Assemble clutch pack unloading tool

5–8840–2586–0 .

a. Install cap (1) to the bottom differential side gear.

b. Install threaded screw cap (2) to top differential

side gear. Thread forcing screws (3) into threaded

screw cap until it becomes centered into the

bottom cap.

425RW064

c. Tighten forcing screw until tight enough to collapse

dished spacers and allow looseness between side

and pinion mate gears.6. Both pinion mate gear thrust washers using a shim

stock (1) of 0.51 mm (0.020 in.) or equivalent tool to

push out washers.

425RW007

7. Relieve tension of dished spacers by loosening

forcing screw.

NOTE:

You may have to adjust the forcing screw slightly to

allow the case to rotate.

8. Insert differential shaft into its hole of case. Pull on

shaft and rotate case until pinion mate gears can be

removed.

9. Remove pinion mate gears.

10. Hold side gear top clutch pack (1) with one hand and

remove positraction unloading tools.

425RW008

Page 683 of 6000

4C–17 DRIVE SHAFT SYSTEM

11. Install follower to clutch so that follower nails (large)

(1) will come closer to the bent portion of retaining

spring by aligning follower stopper nail with outer

teeth of clutch. Then, fit in with follower’s nails (small)

(2) caught in spring.

411RW016

12. Install compression ring.

Turn the smaller diameter side toward follower and fit

spring in clutch.

13. Align follower nail (1) to handle groove (2). and then

assemble clutch with knob by pushing and turning

clutch counterclockwise to knob.

411RW017

14. Install gasket.

Make sure that there is no breakage, etc.

15. Install outer bearing outer race by driving it into the

hub, by using installer 5–8522–2118–0 and grip

5–8840–0007–0.

411RW007

16. Install inner bearing outer race by driving it into the

hub, by using installer 5–8840–2119–0 and grip

5–8840–0007–0.

411RW006

Page 814 of 6000

5A–4

BRAKE CONTROL SYSTEM

normal braking when a malfunction has occurred in the

ABS.

The EHCU has a self-diagnosing function which can

indicate faulty circuits during diagnosis.

The EHCU is mounted on the engine compartment front

right side. It consists of a Motor, Plunger Pump, Solenoid

Valves and Check Valve.

On the outside, the relay box containing a motor relay and

a valve relay is installed.

Solenoid Valves: Reduces or holds the caliper fluid

pressure for each front disc brake or both rear disc brakes

according to the signal sent from the EHCU.

Reservoir: Temporarily holds the brake fluid that returns

from the front and rear disc brake caliper so that pressure

of front disc brake caliper can be reduced smoothly.

Plunger Pump: Feeds the brake fluid held in the reservoir

to the master cylinder.

Motor: Drives the pump according to the signal from

EHCU.

Check Valve: Controls the brake fluid flow.

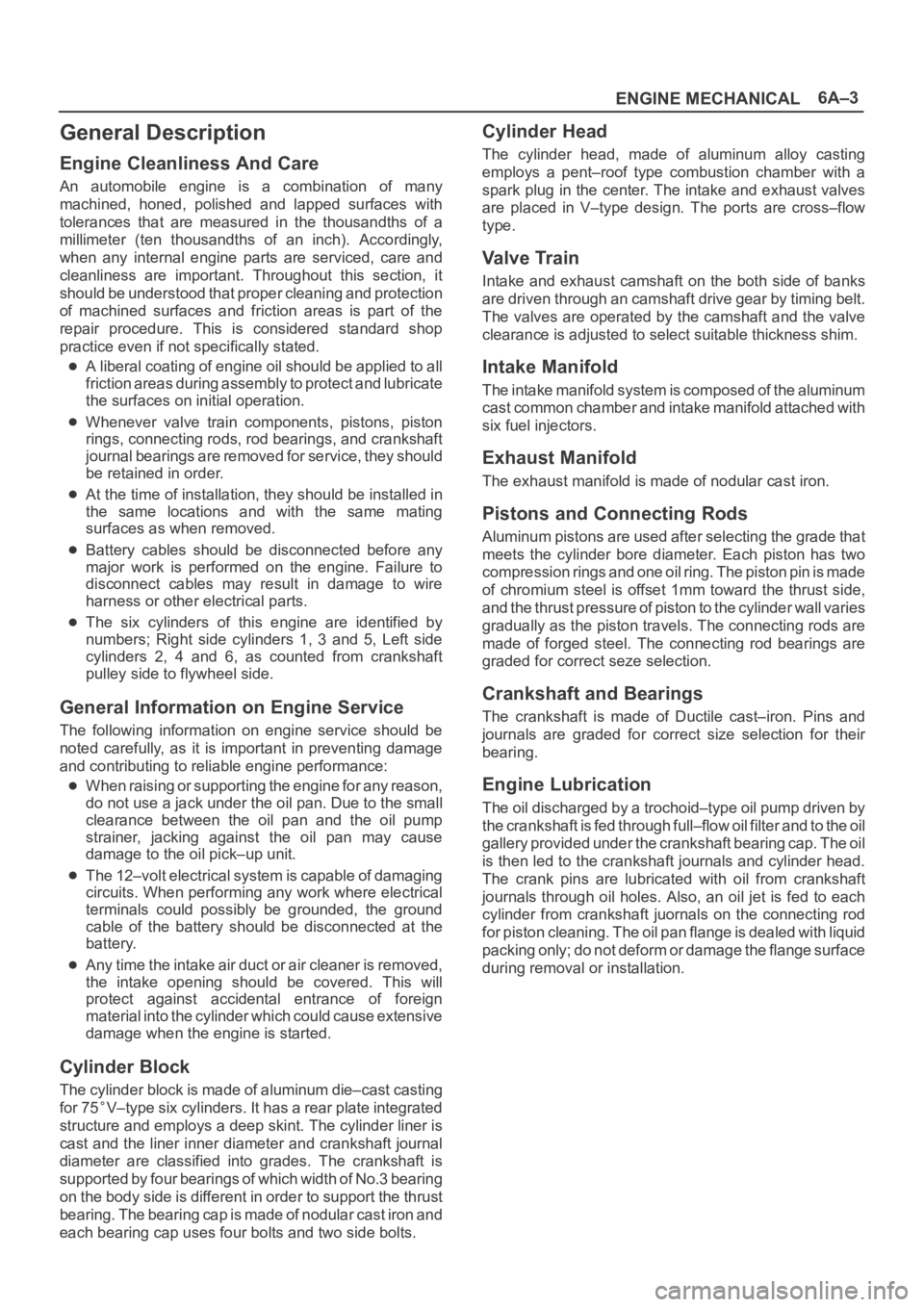

ABS Warning Light

821RW033Vehicles equipped with the Anti-lock Brake System have

an amber “ABS” warning light in the instrument panel.

The “ABS” warning light will illuminate if a malfunction in

the Anti-lock Brake System is detected by the Electronic

Hydraulic Control Unit (EHCU). In case of an electronic

malfunction, the EHCU will turn “ON” the “ABS” warning

light and disable the Anti-lock braking function.

The “ABS” light will turn “ON” for approximately three

seconds after the ignition switch is to the “ON” position.

If the “ABS” light stays “ON” after the ignition switch is the

“ON” position, or comes “ON” and stays “ON” while

driving, the Anti-lock Brake System should be inspected

for a malfunction according to the diagnosis procedure.

Wheel Speed Sensor

It consists of a sensor and a rotor. The sensor is attached

to the knuckle on the front wheels and to the axle shaft

bearing holder on the rear wheels.

The rotor is press-fit in the axle shaft.The flux generated from electrodes magnetized by a

magnet in the sensor varies due to rotation of the rotor,

and the electromagnetic induction generates alternating

voltage in the coil. This voltage draws a “sine curve” with

the frequency proportional to rotor speed and it allows

detection of wheel speed.

G-Sensor

The G-sensor installed inside the center console detects

the vehicle deceleration speed and sends a signal to the

EHCU. In 4WD operation, all four wheels may be

decelerated in almost the same phase, since all wheels

are connected mechanically.

This tendency is noticeable particularly on roads with low

friction coefficient, and the ABS control is adversely

affected.

The G-sensor judges whether the friction coefficient of

road surface is low or high, and changes the EHCU’s

operating system to ensure ABS control.

Normal and Anti-lock Braking

Under normal driving conditions, the Anti-lock Brake

System functions the same as a standard power assisted

brake system. However, with the detection of wheel

lock-up, a slight bump or kick-back will be felt in the brake

pedal. This pedal “bump” will be followed by a series of

short pedal pulsations which occurs in rapid succession.

The brake pedal pulsation will continue until there is no

longer a need for the anti-lock function or until the vehicle

is stopped. A slight ticking or popping noise may be heard

during brake applications when the Anti-lock features is

being used.

When the Anti-lock feature is being used, the brake pedal

may rise even as the brakes are being applied. This is

also normal. Maintaining a constant force on the pedal

will provide the shortest stopping distance.

Brake Pedal Travel

Vehicles equipped with the Anti-lock Brake System may

be stopped by applying normal force to the brake pedal.

Although there is no need to push the pedal beyond the

point where it stops or holds the vehicle, by applying more

force the pedal will continue to travel toward the floor.

This extra brake pedal travel is normal.

Acronyms and Abbreviations

Several acronyms and abbreviations are commonly used

throughout this section:

ABS

Anti-lock Brake System

CKT

Circuit

DLC

Data Link Connector

EHCU

Electronic Hydraulic Control Unit

FL

Front Left

Page 959 of 6000

6A–3

ENGINE MECHANICAL

General Description

Engine Cleanliness And Care

An automobile engine is a combination of many

machined, honed, polished and lapped surfaces with

tolerances that are measured in the thousandths of a

millimeter (ten thousandths of an inch). Accordingly,

when any internal engine parts are serviced, care and

cleanliness are important. Throughout this section, it

should be understood that proper cleaning and protection

of machined surfaces and friction areas is part of the

repair procedure. This is considered standard shop

practice even if not specifically stated.

A liberal coating of engine oil should be applied to all

friction areas during assembly to protect and lubricate

the surfaces on initial operation.

Whenever valve train components, pistons, piston

rings, connecting rods, rod bearings, and crankshaft

journal bearings are removed for service, they should

be retained in order.

At the time of installation, they should be installed in

the same locations and with the same mating

surfaces as when removed.

Battery cables should be disconnected before any

major work is performed on the engine. Failure to

disconnect cables may result in damage to wire

harness or other electrical parts.

The six cylinders of this engine are identified by

numbers; Right side cylinders 1, 3 and 5, Left side

cylinders 2, 4 and 6, as counted from crankshaft

pulley side to flywheel side.

General Information on Engine Service

The following information on engine service should be

noted carefully, as it is important in preventing damage

and contributing to reliable engine performance:

When raising or supporting the engine for any reason,

do not use a jack under the oil pan. Due to the small

clearance between the oil pan and the oil pump

strainer, jacking against the oil pan may cause

damage to the oil pick–up unit.

The 12–volt electrical system is capable of damaging

circuits. When performing any work where electrical

terminals could possibly be grounded, the ground

cable of the battery should be disconnected at the

battery.

Any time the intake air duct or air cleaner is removed,

the intake opening should be covered. This will

protect against accidental entrance of foreign

material into the cylinder which could cause extensive

damage when the engine is started.

Cylinder Block

The cylinder block is made of aluminum die–cast casting

for 75

V–type six cylinders. It has a rear plate integrated

structure and employs a deep skint. The cylinder liner is

cast and the liner inner diameter and crankshaft journal

diameter are classified into grades. The crankshaft is

supported by four bearings of which width of No.3 bearing

on the body side is different in order to support the thrust

bearing. The bearing cap is made of nodular cast iron and

each bearing cap uses four bolts and two side bolts.

Cylinder Head

The cylinder head, made of aluminum alloy casting

employs a pent–roof type combustion chamber with a

spark plug in the center. The intake and exhaust valves

are placed in V–type design. The ports are cross–flow

type.

Va l v e Tr a i n

Intake and exhaust camshaft on the both side of banks

are driven through an camshaft drive gear by timing belt.

The valves are operated by the camshaft and the valve

clearance is adjusted to select suitable thickness shim.

Intake Manifold

The intake manifold system is composed of the aluminum

cast common chamber and intake manifold attached with

six fuel injectors.

Exhaust Manifold

The exhaust manifold is made of nodular cast iron.

Pistons and Connecting Rods

Aluminum pistons are used after selecting the grade that

meets the cylinder bore diameter. Each piston has two

compression rings and one oil ring. The piston pin is made

of chromium steel is offset 1mm toward the thrust side,

and the thrust pressure of piston to the cylinder wall varies

gradually as the piston travels. The connecting rods are

made of forged steel. The connecting rod bearings are

graded for correct seze selection.

Crankshaft and Bearings

The crankshaft is made of Ductile cast–iron. Pins and

journals are graded for correct size selection for their

bearing.

Engine Lubrication

The oil discharged by a trochoid–type oil pump driven by

the crankshaft is fed through full–flow oil filter and to the oil

gallery provided under the crankshaft bearing cap. The oil

is then led to the crankshaft journals and cylinder head.

The crank pins are lubricated with oil from crankshaft

journals through oil holes. Also, an oil jet is fed to each

cylinder from crankshaft juornals on the connecting rod

for piston cleaning. The oil pan flange is dealed with liquid

packing only; do not deform or damage the flange surface

during removal or installation.

Page 971 of 6000

6A–15

ENGINE MECHANICAL

Condition CorrectionPossible cause

Oil leaking into combustion

chambers due topoor seal in valve

Valve stem oil seal defectiveReplace

chambers due to oor seal in valve

systemValve stem or valve guide wornReplace valve and valve guide

Oil leaking into combustion

chambers due to poor seal in cylinder

t

Cylinders and pistons worn

excessivelyReplace cylinder body assembly and

pistons

partsPiston ring gaps incorrectly

positionedCorrect

Piston rings set with wrong side upCorrect

Piston ring stickingReplace cylinder body assembly and

pistons

Piston ring and ring groove wornReplace pistons and others

Return ports in oil rings cloggedClean piston and replace rings

Positive Crankcase Ventilation

System malfunctioningPositive Crankcase Ventilation Valve

cloggedClean

OthersImproper oil viscosityUse oil of recommended S.A.E.

viscosity

Continuous high speed driving

and/or severe usage such as trailer

towingContinuous high speed operation

and/or severe usage will normally

cause increased oil consumption

Fuel Consumption Excessive

ConditionPossible causeCorrection

Trouble in fuel systemMixture too rich or too lean due to

trouble in fuel injection systemRefer to “Abnormal Combustion”

Fuel cut function does not workRefer to “Abnormal Combustion”

Trouble in ignition systemMisfiring or abnormal combustion

due to trouble in ignition systemRefer to “Hard Start” or “Abnormal

Combustion”

OthersEngine idle speed too highReset Idle Air Control Valve

Returning of accelerator control

sluggishCorrect

Fuel system leakageCorrect or replace

Clutch slippingCorrect

Brake dragCorrect

Selection of transmission gear

incorrectCaution operator of incorrect gear

selection

Excessive Exhaust Gas

Recirculation flow due to trouble in

Exhaust Gas Recirculation systemRefer to “Abnormal Combustion”

Page 1082 of 6000

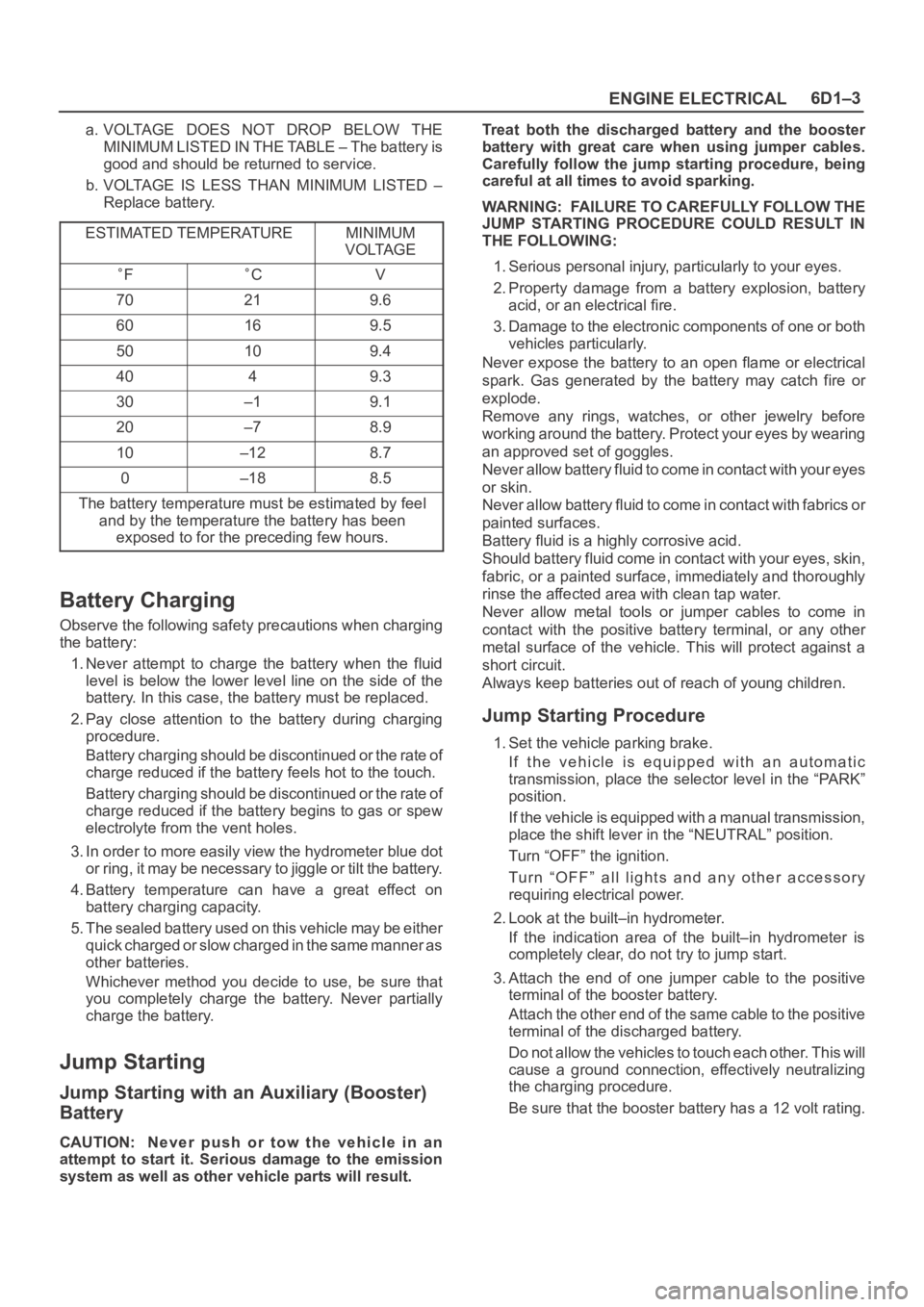

ENGINE ELECTRICAL6D1–3

a. VOLTAGE DOES NOT DROP BELOW THE

MINIMUM LISTED IN THE TABLE – The battery is

good and should be returned to service.

b. VOLTAGE IS LESS THAN MINIMUM LISTED –

Replace battery.

ESTIMATED TEMPERATURE

MINIMUM

VOLTAGE

FCV

70219.6

60169.5

50109.4

4049.3

30–19.1

20–78.9

10–128.7

0–188.5

The battery temperature must be estimated by feel

and by the temperature the battery has been

exposed to for the preceding few hours.

Battery Charging

Observe the following safety precautions when charging

the battery:

1. Never attempt to charge the battery when the fluid

level is below the lower level line on the side of the

battery. In this case, the battery must be replaced.

2. Pay close attention to the battery during charging

procedure.

Battery charging should be discontinued or the rate of

charge reduced if the battery feels hot to the touch.

Battery charging should be discontinued or the rate of

charge reduced if the battery begins to gas or spew

electrolyte from the vent holes.

3. In order to more easily view the hydrometer blue dot

or ring, it may be necessary to jiggle or tilt the battery.

4. Battery temperature can have a great effect on

battery charging capacity.

5. The sealed battery used on this vehicle may be either

quick charged or slow charged in the same manner as

other batteries.

Whichever method you decide to use, be sure that

you completely charge the battery. Never partially

charge the battery.

Jump Starting

Jump Starting with an Auxiliary (Booster)

Battery

CAUTION: Never push or tow the vehicle in an

attempt to start it. Serious damage to the emission

system as well as other vehicle parts will result.Treat both the discharged battery and the booster

battery with great care when using jumper cables.

Carefully follow the jump starting procedure, being

careful at all times to avoid sparking.

WARNING: FAILURE TO CAREFULLY FOLLOW THE

JUMP STARTING PROCEDURE COULD RESULT IN

THE FOLLOWING:

1. Serious personal injury, particularly to your eyes.

2. Property damage from a battery explosion, battery

acid, or an electrical fire.

3. Damage to the electronic components of one or both

vehicles particularly.

Never expose the battery to an open flame or electrical

spark. Gas generated by the battery may catch fire or

explode.

Remove any rings, watches, or other jewelry before

working around the battery. Protect your eyes by wearing

an approved set of goggles.

Never allow battery fluid to come in contact with your eyes

or skin.

Never allow battery fluid to come in contact with fabrics or

painted surfaces.

Battery fluid is a highly corrosive acid.

Should battery fluid come in contact with your eyes, skin,

fabric, or a painted surface, immediately and thoroughly

rinse the affected area with clean tap water.

Never allow metal tools or jumper cables to come in

contact with the positive battery terminal, or any other

metal surface of the vehicle. This will protect against a

short circuit.

Always keep batteries out of reach of young children.

Jump Starting Procedure

1. Set the vehicle parking brake.

If the vehicle is equipped with an automatic

transmission, place the selector level in the “PARK”

position.

If the vehicle is equipped with a manual transmission,

place the shift lever in the “NEUTRAL” position.

Turn “OFF” the ignition.

Turn “OFF” all lights and any other accessory

requiring electrical power.

2. Look at the built–in hydrometer.

If the indication area of the built–in hydrometer is

completely clear, do not try to jump start.

3. Attach the end of one jumper cable to the positive

terminal of the booster battery.

Attach the other end of the same cable to the positive

terminal of the discharged battery.

Do not allow the vehicles to touch each other. This will

cause a ground connection, effectively neutralizing

the charging procedure.

Be sure that the booster battery has a 12 volt rating.

Page 1096 of 6000

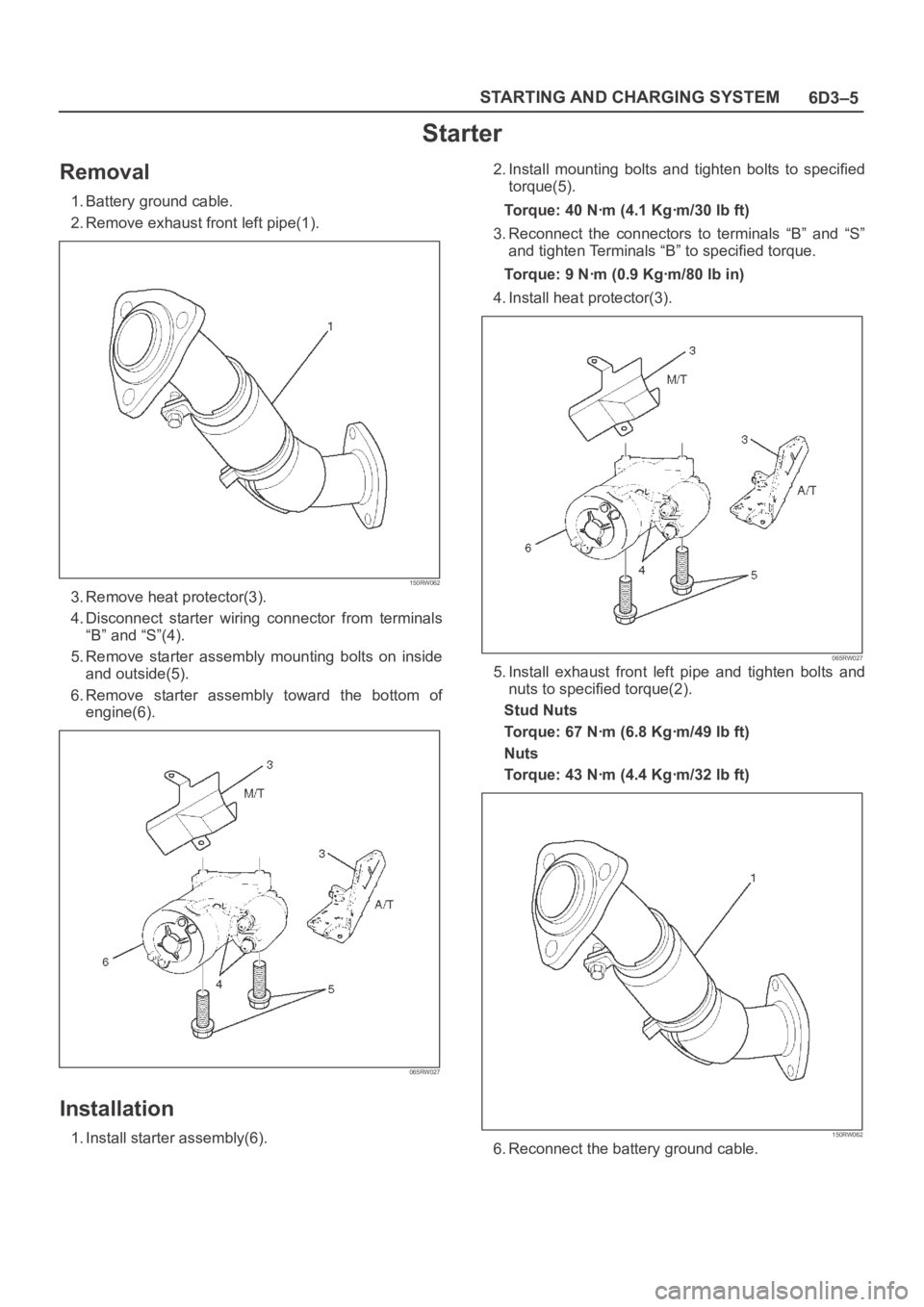

6D3–5 STARTING AND CHARGING SYSTEM

Starter

Removal

1. Battery ground cable.

2. Remove exhaust front left pipe(1).

150RW062

3. Remove heat protector(3).

4. Disconnect starter wiring connector from terminals

“B” and “S”(4).

5. Remove starter assembly mounting bolts on inside

and outside(5).

6. Remove starter assembly toward the bottom of

engine(6).

065RW027

Installation

1. Install starter assembly(6).2. Install mounting bolts and tighten bolts to specified

torque(5).

Torque: 40 Nꞏm (4.1 Kgꞏm/30 lb ft)

3. Reconnect the connectors to terminals “B” and “S”

and tighten Terminals “B” to specified torque.

Torque: 9 Nꞏm (0.9 Kgꞏm/80 lb in)

4. Install heat protector(3).

065RW027

5. Install exhaust front left pipe and tighten bolts and

nuts to specified torque(2).

Stud Nuts

Torque: 67 Nꞏm (6.8 Kgꞏm/49 lb ft)

Nuts

Torque: 43 Nꞏm (4.4 Kgꞏm/32 lb ft)

150RW062

6. Reconnect the battery ground cable.