motor OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 5460 of 6000

6E–31 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

060RW120

Menu

The following table shows, which functions are used

the available equipment versions.

F0: Diagnostic Trouble Codes

F0: Read DTC Info Ordered By Priority

F1: Read DTC Info As Stored By ECU

F2: Clear DTC Information

F3: Freeze Frame / Failure Records

F1: Data Display

F2: Snapshot

F3: Actuator Tests

F0: Checklight

F1: Glow Time Lamp

F2: EGR Switching Valve

F3: Exhaust Switching Valve 1

F4: Exhaust Switching Valve 2

F4: Miscellaneous Tests

F0: Throttle Motor Control

F1: Rail Pressure Control

F2: EGR Regulating Valve Control

F3: Rail Pressure Control Valve

F4: Injector Balance Test

F5: Programming

F0: Injector Calibration

(F1: Rail Pressure Calibration)

Page 5469 of 6000

6E–40

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

MAP Sensor

CMP Sensor

CKP Sensor

EGR Pressure Sensor

EGR VSV

RPCV

IAT Sensor

Intake Throttle Motor

Fuel Temperature Sensor

Oil Temperature Sensor

Rail Pressure Sensor

Multiple ECM Information Sensor DTCs Set

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

21. Turn the ignition “OFF,” disconnect the ECM.

2. Turn the ignition “ON,” check the 5 volt reference D

circuit for the following conditions:

D poor connection at the ECM.

An open between the ECM connector and the

splice.

D short to ground.

D short to voltage.

Is there an open or short?

—Go to Step 3Go to Step 4

3Repair the open or short.

Is the action complete?

—Verify repair—

4Check the sensor ground circuit for the following

conditions:

A poor connection at the ECM or the affected

sensors.

An open between the ECM connector and the

affected sensors.

Is there an open or a poor connection?

—Go to Step 5Go to Step 6

5Repair the open or the poor connection.

Is the action complete?

—Verify repairGo to Step 6

6Replace the ECM (Refer to the Data Programming in

Case of ECM change).

Is the action complete?

—

Go to OBD

System

Check

—

Page 5471 of 6000

6E–42

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

4JX1-TC Engine (Automatic and Manual Transmission)

Te c h 2

Parameter

Data ListUnits

DisplayedTy p i c a l D a t a

Values (IDLE)Typical Data

Va l u e s

(2500 RPM)Refer To

Battery VoltageEngineVo l t s12.5 14.513 15General Description

Ignition StatusEngineOn/OffOnOnGeneral Description

Ignition Relay2EngineOn/OffOnOnGeneral Description

Idle SwitchEngineInactive/

Active——DTC P0510, P1510

Manifold

Absolute

PressureEngineKPa96 106110 150General Description

DTC P0107, P0108

Rail Oil

PressureEngineMPa3.5 54.5 10General Description

DTC P0192, P0193

Desired Rail Oil

PressureEngineMPa4 55 9General Description

DTC P0192, P0193

Fuel

TemperatureEngineC (F)75 8575 85DTC P0182, P0183

Quick Warming

SwitchEngineOn/OffOffOffDTC P0380

Thermo RelayEngineOn/Off——DTC P1655

Actual EGR

PressureEngineKPa58 60M/T 63 66

A/T 95

105

DTC P0405, P0406

Barometric

PressureEngineKPa98 10298 102General Description

Relative EGR

PressureEngineKPa–38 –45M/T –34 –37

A/T 0General Description

Desired EGR

PressureEngineKPa–43 –40M/T 36

A/T 0General Description

Brake SwitchEngineInactive/

Active——DTC P1588

GearEngine————

Vehicle SpeedEngineKm/h00Transmission Diagnosis

Rail Pressure

Control ValveEngine%17 2218 27DTC P1193

EGR StatusEngineDisable/

EnableEnableM/T Enable

A/T DisableGeneral Description

EGR Switching

Va l v eEngineOn/Off——General Description

Throttle Motor

Position SensorEngineVo l t s3.1 3.90.2 0.9DTC P1485, P1486,

P1487

Throttle Motor

PositionEngineSteps

0 1.00 1.0

DTC P1488

Delirered Fuel

QuantityEnginemm 3/st

6 106 12

General Description

Injector StatusEngineDisable/

EnableEnableEnableDTC P0201, P0202,

P0203, P0204, General

Description

Injector Pulse

WidthEnginems0.9 1.250.7 1.1General Description

Injector Start

OffsetEngineCA——General Description

Page 5472 of 6000

6E–43 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Te c h 2

ParameterData ListUnits

DisplayedTy p i c a l D a t a

Values (IDLE)Typical Data

Va l u e s

(2500 RPM)Refer To

Exhaust VSV1EngineOn/OffOffOffDTC P0475

Exhaust VSV2EngineOn/OffOffOffDTC P1475

Decelevation

Fuel Cut OffEngineInactive/

Active——General Description

Glow Time

LampEngineOn/OffOffOffDTC P0381

Glow Time

RelayEngineOn/OffOffOffDTC P0380

Diagnostic

RequestEngineInactive

12V/

Active 0V——General Description

A/C ClutchEngineOn/OffOffOffGeneral Description

Desired IdleEngineRPM720—General Description

ECT (Engine

Coolant Temp)EngineC (F)80 9080 90General Description

ECT

Engine SpeedEngineRPM7202500DTC P0219

MAT (Intake Air

Te m p )EngineC (F)65 8065 80DTC P0112, P0113

MAP KPa

(Manifold

Absolute

Pressure)EngineKilopascals——General Description

DTC P0107, P0108

MILEngineOn/OffOffOffGeneral Description

AP (Accel

Position)EnginePercent08 14DTC P0121, P0122,

P0123

AP (Accel

Position)EngineVo l t s0.25 0.450.8 1.0DTC P0121, P0122,

P0123

Rail Oil

TemperatureEngineC (F)——DTC P0197, P0198

Desired Throttle

Motor PositionEngineSteps———

Learned Idle

Fuel QuantityEnginemm 3/st———

Page 5484 of 6000

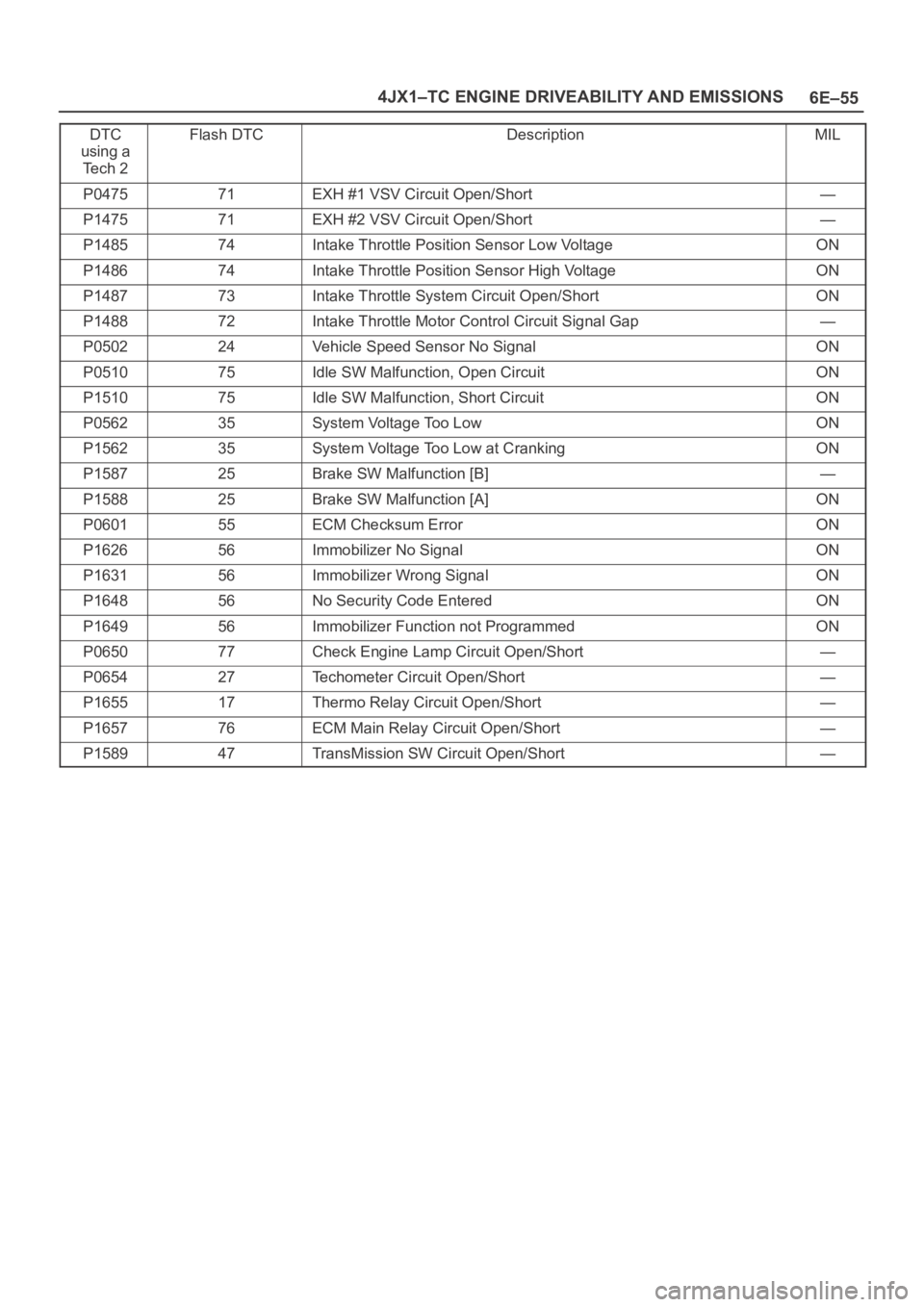

6E–55 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

DTC

using a

Te c h 2Flash DTCDescriptionMIL

P047571EXH #1 VSV Circuit Open/Short—

P147571EXH #2 VSV Circuit Open/Short—

P148574Intake Throttle Position Sensor Low VoltageON

P148674Intake Throttle Position Sensor High VoltageON

P148773Intake Throttle System Circuit Open/ShortON

P148872Intake Throttle Motor Control Circuit Signal Gap—

P050224Vehicle Speed Sensor No SignalON

P051075Idle SW Malfunction, Open CircuitON

P151075Idle SW Malfunction, Short CircuitON

P056235System Voltage Too LowON

P156235System Voltage Too Low at CrankingON

P158725Brake SW Malfunction [B]—

P158825Brake SW Malfunction [A]ON

P060155ECM Checksum ErrorON

P162656Immobilizer No SignalON

P163156Immobilizer Wrong SignalON

P164856No Security Code EnteredON

P164956Immobilizer Function not ProgrammedON

P065077Check Engine Lamp Circuit Open/Short—

P065427Techometer Circuit Open/Short—

P165517Thermo Relay Circuit Open/Short—

P165776ECM Main Relay Circuit Open/Short—

P158947TransMission SW Circuit Open/Short—

Page 5559 of 6000

6E–130

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P1403 (Flash DTC 32)

EGR EVRV Fault

060RW135

Circuit Description

EGR EVRV Circuit has a common power source in

parallel with EGR, VSV, RPCV, and Intake Throttle Motor.

This may cause multiple DTCs. On such occasion, refer

to “Multiple ECM Information sensor DTCs Set”.

Diagnostic Aids

Check for the following conditions:

Poor connection or damaged EVRV – Inspect the

wiring harness for damage.

Ensure EVRV is correctly mounted. See On-Vehicle

Service.

Reviewing the Failure Records vehicle mileage since the

diagnostic test last failed may help determine how often

the condition that caused the DTC to be set occurs. This

may assist in diagnosing the condition.

Test Description

Number(s) below refer to the step number(s) on the

Diagnostic Chart

3. A malfunctioning MAP sensor can set an EGR DTC.

The MAP sensor could send a constant signal which

is not low enough to set a low MAP DTC. The

constant signal from the MAP sensor also may not

be high enough to set a high MAP DTC. This step

verifies that the MAP sensor is responding.

Page 5565 of 6000

6E–136

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P1405 (Flash DTC 37)

EGR EVRV Circuit Open/Short

060RW135

Circuit Description

EGR EVRV Circuit has a common power source in

parallel with EGR, VSV, RPCV, and Intake Throttle Motor.

This may cause multiple DTCs. On such occasion, refer

to “Multiple ECM Information Sensor DTCs Set”.

Action Taken When the DTC Sets

The ECM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

DTC P1405 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the ECM battery

feed.

Diagnostic Aids

An intermittent may be caused by a poor connection,

rubbed-through wire insulation or a wire broken inside the

insulation. Check for:

Poor connection – Inspect the ECM harness and

connectors for improper mating, broken locks,

improperly formed or damaged terminals, and poor

terminal-to-wire connection.

Damaged harness – Inspect the wiring harness for

damage.

Page 5579 of 6000

6E–150

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P1488 (Flash DTC 72)

Intake Throttle Motor Control Circuit Signal Gap

060RW135

Circuit Description

The Intake throttle position (ITP) sensor circuit provides a

voltage signal that changes relative to throttle blade

angle.

Action Taken When the DTC Sets

The ECM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

DTC P1488 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the ECM battery

feed.

Diagnostic Aids

Check for the following conditions:

Poor connection at ECM – Inspect harness connectors

for backed-out terminals, improper mating, broken

locks, improperly formed or damaged terminals, and

poor terminal-to-wire connection.

Damaged harness – Inspect the wiring harness for

damage. If the harness appears to be OK, observe the

throttle position display on the Tech 2 while moving

connectors and wiring harnesses related to the ITP

sensor. A change in the display will indicate the

location of the fault.

If DTC P1488 cannot be duplicated, the information

included in the Failure Records data can be useful in

determining vehicle mileage since the DTC was last set.

Page 5580 of 6000

6E–151 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

DTC P1488 – Intake Throttle Motor Control Circuit Signal Gap

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

21. Ignition “ON,” engine “OFF.”

2. With the throttle closed, observe the “ITP Sensor”

display on the Tech 2.

Is the “ITP Sensor” below the specified value?

0.22 VGo to Step 4Go to Step 3

31. Ignition “ON,” engine “OFF.”

2. Review and record Tech 2 Failure Records data.

3. Operate the vehicle within Failure Records

conditions as noted.

4. Using a Tech 2, monitor the “Specific DTC” info for

DTC P1488.

Does the Tech 2 indicate DTC P1488 failed?

—Go to Step 4

Refer to

Diagnostic

Aids

4Check the ITP circuit for a poor connection at the ECM

and replace the terminal if necessary.

Did the terminal require replacement?

—Verify repairGo to Step 5

5Check the Intake throttle motor circuit for a poor

connection and replace the terminal if necessary.

Did the terminal require replacement?

—Verify repairGo to Step 6

6Check the ITP Assembly for a poor connection at the

TP sensor and fasten the ITP Assembly if necessary.

Did the ITP Assembly require repair?

—Verify repairGo to Step 7

7Replace the ECM (Refer to the Data Programming in

Case of ECM change).

Is the action complete?

—Verify repair—

Page 5619 of 6000

6E–190

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Cuts Out, Symptom

StepNo Ye s Va l u e ( s ) Action

91. Injector Test

Operate the each injector by Tech 2 with the

ignition “ON” and check if the working noise

confirm.

2. If a problem is found, check the harness or replace

the injector.

Is the action complete?

—Verify repairGo to Step 10

101. Check the following engine mechanical items.

Refer to

Engine Mechanical for diagnosis

procedures:

Low compression

Sticking or leaking valves

Worn camshaft lobe(s)

Camshaft drive belt slipped or stripped

Incorrect valve timing

Broken valve springs

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 11

111. Check for faulty motor mounts. Refer to Engine

Mechanical

for inspection of mounts.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 12

121. Review all diagnostic procedures within this table.

2. If all procedures have been completed and no

malfunctions have been found, review/inspect the

following:

Visual/physical inspection

Te c h 2 d a t a

Freeze Frame data/Failure Records butter

All electrical connections within a suspected

circuit and/or system

3. If a problem is found, repair as necessary.

Was a problem found?

—Verify repair

Contact

Te c h n i c a l

Assistance