motor OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 5040 of 6000

6J–2

INDUCTION

Air Cleaner Element

Removal

1. Remove positive ventilation hose from connector(1).

2. Remove intake air temperature sensor(2).

3. Remove air flow sensor(3).

4. Remove air cleaner duct cover(4).

5. Remove air cleaner element(5).

130RW003

Inspection

Check the air cleaner element for damage or dust

clogging. Replace if it is damaged, or clean if it is clogged.

Cleaning Method

Tap the air cleaner element gently so as not to damage

the paper element, or clean the element by blowing with

compressed air of about 490 kPa (71 psi) from the clean

side if it is extremely dirty.

130RW002

Installation

1. Install air cleaner element(5).

2. Attach the air cleaner duct cover (4) to the body

completely, then clamp it with the clip.

3. Install mass air flow sensor(3).

4. Install air temperature sensor(2).

5. Connect positive crankcase ventilation hose to

connector(1).

For General Export Model

130RW003

For Isuzu General Motors (IGM) Model

130RW006

Page 5286 of 6000

ENGINE MECHANICAL 6A – 13

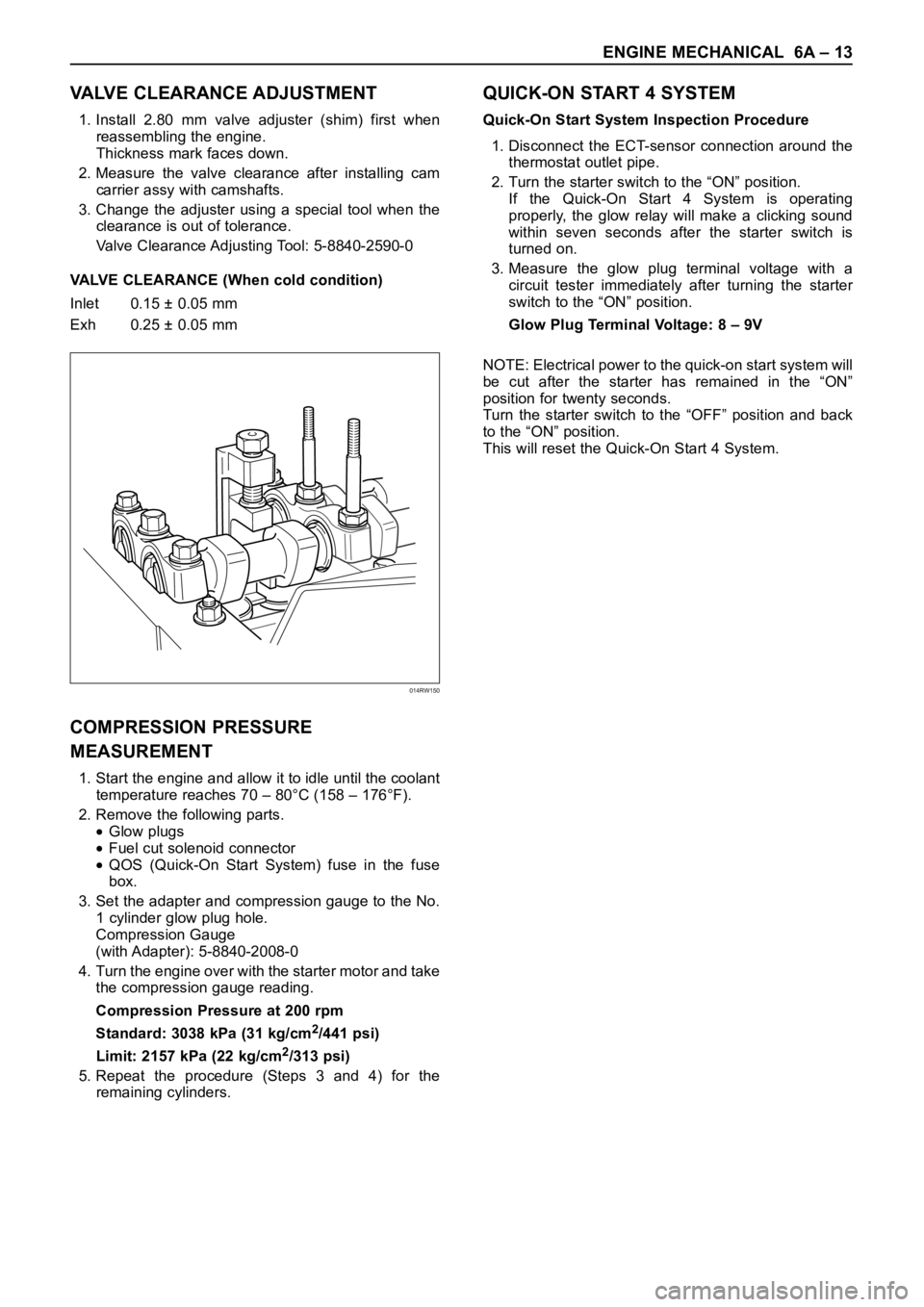

VALVE CLEARANCE ADJUSTMENT

1. Install 2.80 mm valve adjuster (shim) first when

reassembling the engine.

Thickness mark faces down.

2. Measure the valve clearance after installing cam

carrier assy with camshafts.

3. Change the adjuster using a special tool when the

clearance is out of tolerance.

Valve Clearance Adjusting Tool: 5-8840-2590-0

VALVE CLEARANCE (When cold condition)

Inlet 0.15 ± 0.05 mm

Exh 0.25 ± 0.05 mm

COMPRESSION PRESSURE

MEASUREMENT

1. Start the engine and allow it to idle until the coolant

temperature reaches 70 – 80°C (158 – 176°F).

2. Remove the following parts.

Glow plugs

Fuel cut solenoid connector

QOS (Quick-On Start System) fuse in the fuse

box.

3. Set the adapter and compression gauge to the No.

1 cylinder glow plug hole.

Compression Gauge

(with Adapter): 5-8840-2008-0

4. Turn the engine over with the starter motor and take

the compression gauge reading.

Compression Pressure at 200 rpm

Standard: 3038 kPa (31 kg/cm

2/441 psi)

Limit: 2157 kPa (22 kg/cm

2/313 psi)

5. Repeat the procedure (Steps 3 and 4) for the

remaining cylinders.

QUICK-ON START 4 SYSTEM

Quick-On Start System Inspection Procedure

1. Disconnect the ECT-sensor connection around the

thermostat outlet pipe.

2. Turn the starter switch to the “ON” position.

If the Quick-On Start 4 System is operating

properly, the glow relay will make a clicking sound

within seven seconds after the starter switch is

turned on.

3. Measure the glow plug terminal voltage with a

circuit tester immediately after turning the starter

switch to the “ON” position.

Glow Plug Terminal Voltage: 8 – 9V

NOTE: Electrical power to the quick-on start system will

be cut after the starter has remained in the “ON”

position for twenty seconds.

Turn the starter switch to the “OFF” position and back

to the “ON” position.

This will reset the Quick-On Start 4 System.

014RW150

Page 5310 of 6000

ENGINE MECHANICAL 6A – 37

CYLINDER HEAD

3

4

1

2

012RW096

Legend

(1) Glow Plug

(2) Plate

(3) Cylinder Head Bolt

(4) Cylinder Head

NOTE:

During disassembly, be sure that the valve train

components are kept together and identified so that

they can be re-installed in their original locations.

Before removing the cylinder head from the engine

and before disassembling the valve mechanism, do

a compression test and note the results.

DISASSEMBLY

1. Injector Assy

2. Glow Plug and Glow Plug Connector

3. Cylinder Head Assembly

Refer to “Cylinder Head Gasket”

CLEAN

Cylinder head bolts

Cylinder head

Carefully remove all varnish, soot and carbon on

the bare metal. Do not use a motorized wire brush

on any gasket sealing surface.

INSPECTION AND REPAIR

Make the necessary adjustments, repairs, and part

replacements if excessive wear or damage is

discovered during inspection.

Cylinder head gasket and mating surfaces for

leaks, corrosion and blow-by. If the gasket has

failed, determine the cause;

– Improper installation

– Loosen or warped cylinder head

– Insufficient torque on head bolts

– Warped cylinder block surface

Page 5329 of 6000

6A – 56 ENGINE MECHANICAL

VALVE STEM SEAL, VALVE SPRING AND ADJUSTER

REMOVAL

1. Disconnect battery ground cable.

2. Drain engine coolant.

3. Remove the air duct from between air cleaner and

turbocharger.

4. Remove intercooler assembly.

Refer to “Intercooler” in this manual.

5. Remove oil level gauge guide assembly.

6. Disconnect PCV hose.

7. Disconnect EGR vacuum hose.

8. Disconnect harness connectors around the cylinder

head such as the injector, CMP sensor, MAP

sensor, EGR sensor, EVRV, IAT sensor, A/C

compressor, TP stepping motor, TP sensor and fuel

temperature sensor etc.

9. Remove A/C compressor assembly.

10. Remove A/C compressor bracket.

11. Remove generator assembly and take out drivebelt.

12. Remove heat protector, remove exhaust valve

assembly.

13. Remove water cooling hose and lubrication pipe for

turbocharger.

14. Remove turbocharger assembly.

15. Remove hose between thermostat and radiator.

16. Remove noise insulator cover of cylinder head.

NOTE: Do not damage injector harness.

17. Remove high pressure oil pipe.

18. Remove timing belt cover.

19. Remove CMP sensor bracket.

20. Remove timing belt tensioner then remove timing

belt.

21. Remove camshaft pulley.

22. Remove front plate.

23. Remove engine coolant pipe between cylinder

head and water pump.

1

2

3

4

5

6

9

10

7

8

011RW031

Legend

(1) Adjuster

(2) Tappet

(3) Split Collar

(4) Spring Seat Upper

(5) Valve Spring(6) Spring Seat Lower

(7) Valve Stem Seal

(8) Valve Guide

(9) Valve Seat

(10) Valve

Page 5408 of 6000

ENGINE ELECTRICAL 6D – 5

STARTING SYTEM

GENERAL DESCRIPTION

STARTING CIRCUIT

The cranking system consists of a battery, starter, starter switch, starter relay, etc. and these main

components are connected as shown in the illustration.

“S”

“B”

“M”

5

4

32 IG1ST

B2

B1

1

76

P

NN

Legend

(1) Inhibitor Switch

(2) Starter Switch

(3) Battery(4) Magnetic Switch

(5) Pinion Clutch

(6) Starter Motor

(7) Starter Relay

065RW039

STARTER

The starting system employs a magnetic type reduction

starter in which the motor shaft is also used as a pinion

shaft. When the starter switch is turned on, the contacts

of the magnetic switch are closed, and the armature

rotates. At the same time, the plunger is activated, and

the pinion is pushed forward by the shift lever to mesh

with ring gear.Then, the ring gear runs to start the engine. When the

engine starts and the starter switch is turned off, the

plunger returns, the pinion is disengaged from the ring

gear, and the armature stops rotation. When the engine

speed is higher than the pinion, the pinion idles, so that

the armature is not driven.

Page 5410 of 6000

ENGINE ELECTRICAL 6D – 7

ON-VEHICLE SERVICE

STARTER

REMOVAL

1 Battery ground cable

2 Remove the slave cylinder and bind with wire it to

the frame.

3 Disconnect the connector from terminals “B” and

“S”.

4. Remove mounting bolts

5. Remove starter assembly

INSTALLATION

1. Install starter assembly, tighten the fixing bolt and

nut to the specified torque.

Torque: 94 Nꞏm (9.6 kgꞏm/69 lb ft)

2. Reconnect the starter terminals.

CAUTION: When installing the starter motor wiring,

do not allow the S-circuit wiring to obstruct the B-

circuit terminal.

Install the wiring exactly as shown on the attached

illustration.

If S-circuit wiring obstructs the B-circuit terminal,

harness cover breakage and short circuiting may

occur.2-1. Install the wire harness from the battery to the

terminal “B” with tightening torque 8.6 Nꞏm

(0.88 kgꞏm/6.4 lbꞏft).

2-2. Cover the terminal “B” together with wire

harness.

2-3. Connect the wire harness from starter relay to

the terminal “S”.

3. Install the clutch slave cylinder, tighten the fixing

bolt and nut to the specified torque.

Torque: 78 Nꞏm (8.0 kgꞏm/58 lbꞏft)

1

32

4

Legend

(1) Clutch Slave Cylinder

(2) Magnetic Switch(3) Bolt

(4) Starter Assembly

065RW00003

Do not recommend

wiring route.

Recommend wiring route

from S terminal.From

battery

From

starter relay Terminal B

Terminal MTerminal SIn this area,

Scratch to break the wire

cover and make shortage.

065RW00002

Page 5411 of 6000

6D – 8 ENGINE ELECTRICAL

UNIT REPAIR

8

241 3

23

25

2

14

15 21222019181716

109

11

13

127

6

5

4

Legend

(1) Terminal

(2) Bolt

(3) Magnetic Switch

(4) Torsion Spring

(5) Plunger

(6) Shim

(7) Magnetic Switch

(8) Through Bolt

(9) Rear Cover

(10) Motor Assembly

(11) Brush Holder

(12) Armature(13) Yoke Assembly

(14) Bearing Retainer

(15) Pinion Assembly

(16) Bearing Holder

(17) Bearing

(18) Clip

(19) Stopper

(20) Spring

(21) Pinion Shaft

(22) Clutch

(23) Dust Cover

(24) Shift Lever

(25) Gear Case

065RW040

Page 5412 of 6000

ENGINE ELECTRICAL 6D – 9

DISASSEMBLY

1. Terminal Nut

1) Loosen the nut on terminal “M” of magnetic

switch and disconnect the connector cable.

2. Bolt (2 pcs)

3. Magnetic Switch Assembly

4. Torsion Spring

1) Remove torsion spring from magnetic switch

assembly.

5. Plunger

6. Shim

7. Magnetic Switch

8. Through Bolt

9. Rear Cover

1) Remove the through bolts, then remove the rear

cover.10. Motor Assembly

11. Brush Holder

1) Raise a brush spring to detach the negative side

of the brushes (2 pcs) from the commutator face

and remove the positive side of brushes (2 pcs)

from the positive side of brushes (2 pcs) from

the brush holder.

12. Armature

13. Yoke Assembly

14. Bearing Retainer

15. Pinion Assembly

16. Bearing Holder

17. Bearing

18. Pinion Stopper Clip

1) Remove the stopper clip using a screw driver of

equivalent size.

19. Pinion Stopper

20. Return Spring

21. Pinion Shaft

22. Clutch

23. Dust Cover

24. Shift Lever

25. Gear Case

065RW044

065RW043

065RW042

Page 5433 of 6000

6E–4

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Aids 6E–122. . . . . . . . . . . . . . . . . . . . . . . .

Test Description 6E–122. . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0380

(Flash DTC 66) Glow Relay Circuit

Open/Short 6E–126. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Description 6E–126. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–126. . . . . . .

Conditions for Clearing the MIL/DTC 6E–126. . . . .

Diagnostic Aids 6E–126. . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0381

(Flash DTC 67) Glow Lamp Circuit

Open/Short 6E–128. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Description 6E–128. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–128. . . . . . .

Conditions for Clearing the MIL/DTC 6E–128. . . . .

Diagnostic Aids 6E–128. . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P1403

(Flash DTC 32) EGR EVRV Fault 6E–130. . . . . . . . .

Circuit Description 6E–130. . . . . . . . . . . . . . . . . . . . .

Diagnostic Aids 6E–130. . . . . . . . . . . . . . . . . . . . . . . .

Test Description 6E–130. . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P1404

(Flash DTC 31) EGR VSV Circuit 6E–132. . . . . . . . .

Circuit Description 6E–132. . . . . . . . . . . . . . . . . . . . .

Diagnostic Aids 6E–132. . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0405

(Flash DTC 26) EGR Pressure Sensor

Low Voltage 6E–134. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–134. . . . . . .

Conditions for Clearing the MIL/DTC 6E–134. . . . .

Diagnostic Aids 6E–134. . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P1405

(Flash DTC 37) EGR EVRV Circuit

Open/Short 6E–136. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Description 6E–136. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–136. . . . . . .

Conditions for Clearing the MIL/DTC 6E–136. . . . .

Diagnostic Aids 6E–136. . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0406

(Flash DTC 26) EGR Pressure Sensor

High Voltage 6E–138. . . . . . . . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–138. . . . . . .

Conditions for Clearing the MIL/DTC 6E–138. . . . .

Diagnostic Aids 6E–138. . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0475

(Flash DTC 71) EXH #1 VSV Circuit 6E–140. . . . . . .

Circuit Description 6E–140. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–140. . . . . . .

Conditions for Clearing the MIL/DTC 6E–140. . . . .

Diagnostic Aids 6E–140. . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P1475

(Flash DTC 71) EXH #2 VSV Circuit

Open/Short 6E–142. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Description 6E–142. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–142. . . . . . . Conditions for Clearing the MIL/DTC 6E–142. . . . .

Diagnostic Aids 6E–142. . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P1485

(Flash DTC 74) ITP (Intake Thorottle Position)

Sensor Low Voltage 6E–144. . . . . . . . . . . . . . . . . . . . .

Circuit Description 6E–144. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–144. . . . . . .

Conditions for Clearing the MIL/DTC 6E–144. . . . .

Diagnostic Aids 6E–144. . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P1486

(Flash DTC 74) ITP (Intake Throttle Position)

Sensor High Voltage 6E–146. . . . . . . . . . . . . . . . . . . .

Circuit Description 6E–146. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–146. . . . . . .

Conditions for Clearing the MIL/DTC 6E–146. . . . .

Diagnostic Aids 6E–146. . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P1487

(Flash DTC 73) Intake Throttle System

Circuit Open/Start 6E–148. . . . . . . . . . . . . . . . . . . . . . .

Circuit Description 6E–148. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–148. . . . . . .

Conditions for Clearing the MIL/DTC 6E–148. . . . .

Diagnostic Aids 6E–148. . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P1488

(Flash DTC 72) Intake Throttle Motor Control

Circuit Signal Gap 6E–150. . . . . . . . . . . . . . . . . . . . . .

Circuit Description 6E–150. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–150. . . . . . .

Conditions for Clearing the MIL/DTC 6E–150. . . . .

Diagnostic Aids 6E–150. . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0502

(Flash DTC 24) VSS (Vehicle Speed Sensor)

No Signal 6E–152. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Description 6E–152. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–152. . . . . . .

Conditions for Clearing the MIL/DTC 6E–152. . . . .

Test Description 6E–153. . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0510

(Flash DTC 75) Idle SW Malfunction, Open

Circuit 6E–155. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Description 6E–155. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–155. . . . . . .

Conditions for Clearing the MIL/DTC 6E–155. . . . .

Diagnostic Aids 6E–155. . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P1510

(Flash DTC 75) Idle SW Malfunction

Short Circuit 6E–157. . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Description 6E–157. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–157. . . . . . .

Conditions for Clearing the MIL/DTC 6E–157. . . . .

Diagnostic Aids 6E–157. . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0562

(Flash DTC 35) System Voltage Too Low 6E–159. .

Circuit Description 6E–159. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–159. . . . . . .

Page 5448 of 6000

6E–19 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

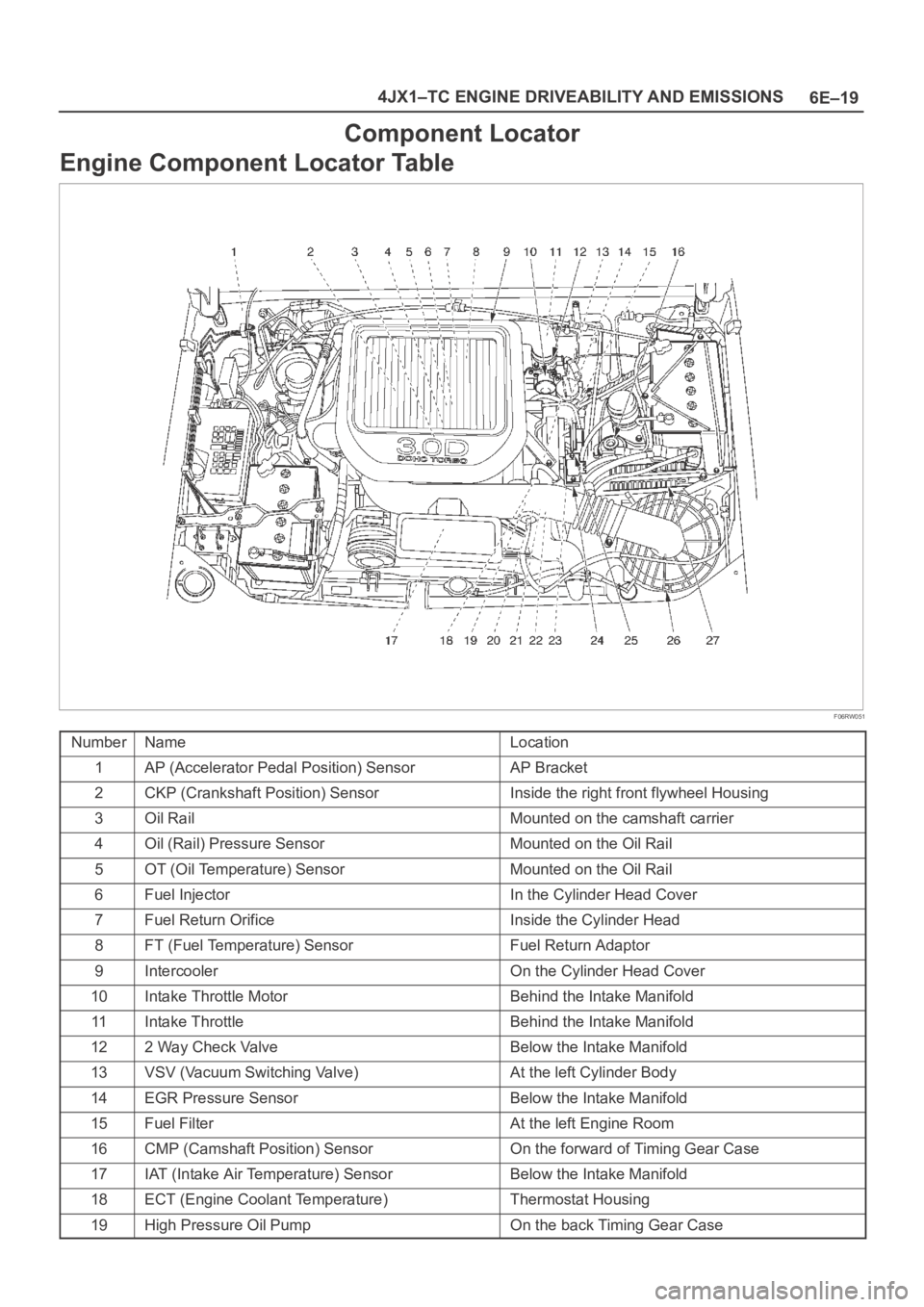

Component Locator

Engine Component Locator Table

F06RW051

NumberNameLocation

1AP (Accelerator Pedal Position) SensorAP Bracket

2CKP (Crankshaft Position) SensorInside the right front flywheel Housing

3Oil RailMounted on the camshaft carrier

4Oil (Rail) Pressure SensorMounted on the Oil Rail

5OT (Oil Temperature) SensorMounted on the Oil Rail

6Fuel InjectorIn the Cylinder Head Cover

7Fuel Return OrificeInside the Cylinder Head

8FT (Fuel Temperature) SensorFuel Return Adaptor

9IntercoolerOn the Cylinder Head Cover

10Intake Throttle MotorBehind the Intake Manifold

11Intake ThrottleBehind the Intake Manifold

122 Way Check ValveBelow the Intake Manifold

13VSV (Vacuum Switching Valve)At the left Cylinder Body

14EGR Pressure SensorBelow the Intake Manifold

15Fuel FilterAt the left Engine Room

16CMP (Camshaft Position) SensorOn the forward of Timing Gear Case

17IAT (Intake Air Temperature) SensorBelow the Intake Manifold

18ECT (Engine Coolant Temperature)Thermostat Housing

19High Pressure Oil PumpOn the back Timing Gear Case