motor OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 4500 of 6000

6A–4

ENGINE MECHANICAL

Engine Diagnosis

Hard Starting

1. Starting Motor Does Not Turn Over

Troubleshooting Procedure

Turn on headlights and starter switch.

Condition

Possible causeCorrection

Headlights go out or dim

considerably

Battery run down or under chargedRecharge or replace battery

considerablyTerminals poorly connectedClean battery posts and terminals

and connect properly

Starting motor coil circuit shortedOverhaul or replace

Starting motor defectiveOverhaul or replace

2. Ignition Trouble — Starting Motor Turns Over But Engine Does Not Start

Spark Test

Disconnect an igniton coil from any spark plug. Connect

the spark plug tester 5–8840–0607–0, start the engine,

a n d c h e c k i f a s p a r k i s g e n e r a t e d in t h e s p a r k p l u g t e s t e r.

Before starting the engine, make sure that the spark plugtester is properly grounded. To avoid electrical shock, do

not touch the part where insulation of the igniton coil is

broken while the engine is running.

Condition

Possible causeCorrection

Spark jumps across gapSpark plug defectiveClean, adjust spark gap or replace

Ignition timing incorrectRefer to Ignition System

Fuel not reaching fuel injector(s) or

engineRefer to item 3 (Trouble in fuel

system)

Valve timing incorrectAdjust

Engine lacks compressionRefer to item 4 (Engine lacks

compression)

No sparking takes placeIgnition coil disconnected or brokenConnect properly or replace

Electronic Ignition System with

moduleReplace

Poor connections in engine harnessCorrect

Powertrain Control Module cable

disconnected or defectiveCorrect or replace

3. Trouble In Fuel System

Condition

Possible causeCorrection

Starting motor turns over and spark

occurs but engine does not start

Fuel tank emptyFill

occurs but engine does not start.Water in fuel systemClean

Fuel filter cloggedReplace filter

Fuel pipe cloggedClean or replace

Fuel pump defectiveReplace

Fuel pump circuit openCorrect or replace

Evaporative Emission Control

System circuit cloggedCorrect or replace

Multiport Fuel Injection System faultyRefer to “Electronic Fuel Injection”

section

Page 4549 of 6000

6A–53

ENGINE MECHANICAL

2. Remove camshaft bracket fixing bolt (5), camshaft

bracket (6), then camshaft exhaust (7), and intake

side (8).

3. Remove tappet with shim (11).

4. Use the 5–8840–2446–0 valve spring compressor

and 5–8840–2547–0 valve spring compressor

adapter to remove the split collar (12), valve spring

with upper seat (13) and valve (14).

014RW042

5. Remove spark plug (1).

CAUTION: Do not remove the spark plugs when the

head and plugs are hot. Clean dirt and debris from

spark plug recess areas before removal.

Clean

Cylinder head

Carefully remove all varnish, soot and carbon from the

bare metal. Do not use a motorized wire brush on any

gasket sealing surface.

Inspection and Repair

1. Cylinder head gasket and mating surfaces for leaks,

corrosion and blow–by. If the gasket has failed,

determine the cause.

– Insufficient torque on head bolts.

– Improper installation

– Loose or warped cylinder head

– Missing dowel pins

– Warped case surface

2. Cylinder head for cracks, especially between valve

seats and in the exhaust ports.3. Cylinder head deck for corrosion, sand particles in

head and porosity.

CAUTION:

Do not attempt to weld the cylinder head. Replace

it.

Do not reuse cylinder head bolts.

4. Cylinder head deck, common chamber and exhaust

manifold mating surfaces for flatness. These

surfaces may be reconditioned by milling. If the

surfaces are “out of flat” by more than specification,

the surface should be ground to within specifications.

Replace the head if it requires machining beyond the

repairable limit.

Head surface and manifold surface

Standard: 0.05 mm (0.002 in) or less

Warpage limit: 0.2 mm (0.0079 in)

Maximum Repairable limit: 0.2 mm (0.0079 in)

Head height

Standard height : 133.2 mm (5.2441 in)

Warpage limit : 0.2 mm (0.0079 in)

Maximum Repairable limit : 133.0 mm (5.2362 in)

011RW019

5. Water jacket sealing plugs seating surfaces.

Reassembly

1. Install Spark plug and tighten all the spark plugs to

specified torque.

Torque: 18 Nꞏm (1.8 Kgꞏm/13 lb ft)

2. Tighten sub gear setting bolt.

1. Use 5–8840–2443–0 gear spring lever to turn sub

gear to right direction until the M5 bolt aligns with

the hole between camshaft driven gear and sub

gear.

Page 4633 of 6000

6D3–2STARTING AND CHARGING SYSTEM

Starting System

General Description

Cranking Circuit

The cranking system consists of a battery, starter, starter

switch, starter relay, etc. These main components are

connected.

Starter

The cranking system employs a magnetic type reduction

starter in which the motor shaft is also used as a pinion

shaft. When the starter switch is turned on, the contacts of

magnetic switch are closed, and the armature rotates. At

the same time, the plunger is attracted, and the pinion is

pushed forward by the shift lever to mesh with the ring

gear.

Then, the ring gear runs to start the engine. When the

engine starts and the starter switch is turned off, the

plunger returns, the pinion is disengaged from the ring

gear, and the armature stops rotation. When the engine

speed is higher than the pinion, the pinion idles, so that

the armature is not driven.

Page 4696 of 6000

6E–39 ENGINE DRIVEABILITY AND EMISSIONS

The data displayed on the other Tech 2 will appear the

same, with some exceptions. Some Tech 2s will only be

able to display certain vehicle parameters as values that

are a coded representation of the true or actual value. For

more information on this system of coding, refer to

Decimal/Binary/Hexadecimal Conversions. On this

vehicle Tech 2 displays the actual values for vehicle

parameters. It will not be necessary to perform any

conversions from coded values to actual values.

On-Board Diagnostic (OBD)

On-Board Diagnostic Tests

A diagnostic test is a series of steps, the result of which is

a pass or fail reported to the diagnostic executive. When

a diagnostic test reports a pass result, the diagnostic

executive records the following data:

The diagnostic test has been completed since the last

ignition cycle.

The diagnostic test has passed during the current

ignition cycle.

The fault identified by the diagnostic test is not

currently active.

W h e n a d i a g n o s t i c t e s t r e p o r t s a fail result, the diagnostic

executive records the following data:

The diagnostic test has been completed since the last

ignition cycle.

The fault identified by the diagnostic test is currently

active.

The fault has been active during this ignition cycle.

The operating conditions at the time of the failure.

Remember, a fuel trim DTC may be triggered by a list of

vehicle faults. Make use of all information available (other

DTCs stored, rich or lean condition, etc.) when

diagnosing a fuel trim fault.

Comprehensive Component Monitor

Diagnostic Operation

Input Components:

Input components are monitored for circuit continuity and

out-of-range values. This includes rationality checking.

Rationality checking refers to indicating a fault when the

signal from a sensor does not seem reasonable, i.e.

Throttle Position (TP) sensor that indicates high throttle

position at low engine loads or MAP voltage. Input

components may include, but are not limited to the

following sensors:

Vehicle Speed Sensor (VSS)

Crankshaft Position (CKP) sensor

Knock Sensor (KS)

Throttle Position (TP) sensor

Engine Coolant Temperature (ECT) sensor

Camshaft Position (CMP) sensor

Manifold Absolute Pressure (MAP) sensor

Mass Air Flow (MAF) sensorIn addition to the circuit continuity and rationality check,

the ECT sensor is monitored for its ability to achieve a

steady state temperature to enable closed loop fuel

control.

Output Components:

Output components are diagnosed for proper response to

control module commands. Components where

functional monitoring is not feasible will be monitored for

circuit continuity and out-of-range values if applicable.

Output components to be monitored include, but are not

limited to, the following circuits:

Idle Air Control (IAC) Motor

Electronic Transmission controls

A/C relays

Cooling fan relay

VSS output

MIL control

Cruise control inhibit

Refer to PCM and Sensors in General Descriptions.

Passive and Active Diagnostic Tests

A passive test is a diagnostic test which simply monitors a

vehicle system or component. Conversely, an active test,

actually takes some sort of action when performing

diagnostic functions, often in response to a failed passive

test. For example, the EGR diagnostic active test will

force the EGR valve open during closed throttle decel

and/or force the EGR valve closed during a steady state.

Either action should result in a change in manifold

pressure.

Intrusive Diagnostic Tests

This is any on-board test run by the Diagnostic

Management System which may have an effect on

vehicle performance or emission levels.

Warm-Up Cycle

A warm-up cycle means that engine at temperature must

reach a minimum of 70

C (160F) and rise at least 22C

(40

F) over the course of a trip.

Freeze Frame

Freeze Frame is an element of the Diagnostic

Management System which stores various vehicle

information at the moment an emissions-related fault is

stored in memory and when the MIL is commanded on.

These data can help to identify the cause of a fault. Refer

to

Storing And Erasing Freeze Fame Data for more

detailed information.

Failure Records

Failure Records data is an enhancement of the OBD

Freeze Frame feature. Failure Records store the same

vehicle information as does Freeze Frame, but it will store

that information for any fault which is stored in on-board

memory, while Freeze Frame stores information only for

emission-related faults that command the MIL on.

Page 4768 of 6000

6E–111 ENGINE DRIVEABILITY AND EMISSIONS

DTC P0103 – MAF Sensor Circuit High Frequency

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

21. Ignition “ON,” engine “OFF.”

2. Review and record Tech 2 Failure Records data.

3. Operate the vehicle within Failure Records

conditions as noted.

4. Using a Tech 2, monitor “DTC” info for DTC P0103.

Does the Tech 2 indicate DTC P0103 failed this

ignition?

—Go to Step 3

Refer to

Diagnostic

Aids

31. Start the engine.

2. With the engine idling, monitor “MAF Frequency”

display on the Tech 2.

Is “MAF Frequency” above the specified value?

219 g/SecGo to Step 4Go to Step 7

41. Ignition “OFF.”

2. Disconnect the MAF sensor connector.

3. Ignition “ON,” engine idling.

4. Using a Tech 2, monitor “MAF Frequency.”

Does the Tech 2 indicate a “MAF Frequency” at the

specified value?

0.0 g/SecGo to Step 5Go to Step 6

5Replace the MAF sensor.

Is the action complete?

—Verify repairGo to Step 8

61. Check the MAF harness for incorrect routing near

high voltage components (solenoids, relays,

motors).

2. If incorrect routing is found, correct the harness

routing.

Was a problem found?

—Verify repairGo to Step 7

71. With the engine idling, monitor “MAF Frequency”

display on the Tech 2.

2. Quickly snap open throttle to wide open throttle

while under a road load and record value.

Does the Tech 2 indicate “MAF Frequency” above the

specified value?

219 g/SecGo to Step 5Go to Step 8

8Replace the PCM.

IMPORTANT:The replacement PCM must be

programmed. Refer to

UBS 98model year Immobilizer

Workshop Manual.

Is the action complete?—Verify repair—

Page 4908 of 6000

6E–251 ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P1508 IAC System Low RPM

T321115

Circuit Description

The powertrain control module (PCM) controls engine

idle speed by adjusting the position of the idle air control

(IAC) motor pintle. The IAC is a bi-directional stepper

motor driven by two coils. The PCM applies current to the

IAC coils in steps (counts) to extend the IAC pintle into a

passage in the throttle body to decrease air flow. The

PCM reverses the current to retract the pintle, increasing

air flow. This method allows highly accurate control of idle

speed and quick response to changes in engine load. If

the PCM detects a condition where too low of an idle

speed is present and the PCM is unable to adjust idle

speed by increasing the IAC counts, DTC P1508 will set,

indicating a problem with the idle control system.

Conditions for Setting the DTC

No Tech 2 test is being run.

None of these DTCs are set: TP sensor, VSS, ECT,

EGR, fuel system, MAF, MAP, IAT, canister purge,

injector control or ignition control.

Barometric pressure is above 75 kPa.

Engine coolant temperature (ECT) is above 50C

(120

F).

Engine speed is more than 100-200 RPM lower than

desired idle, based upon coolant temperature.

The engine has been running for at least 125 seconds.

Vehicle speed is less than 1 mph.

Canister purge duty cycle is above 10%.

Ignition voltage is between 9.5 volts and 16.7 volts.

The throttle is closed.

Engine speed is lower than desired idle.

All of the above conditions are met for 10 seconds.

Action Taken When the DTC Sets

The PCM will illuminate the malfunction indicator lamp

(MIL) after the second consecutive trip in which the

fault is detected.

The PCM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

DTC P1508 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the PCM battery

feed.

Diagnostic Aids

Check for the following conditions:

Poor connection at PCM or IAC motor – Inspect

harness connectors for backed-out terminals,

improper mating, broken locks, improperly formed or

damaged terminals, and poor terminal-to-wire

connection.

Damaged harness – Inspect the wiring for damage.

Restricted air intake system – Check for a possible

collapsed air intake duct, restricted air filter element,

or foreign objects blocking the air intake system.

Throttle body – Check for objects blocking the IAC

passage or throttle bore, excessive deposits in the IAC

Page 4911 of 6000

6E–254

ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P1509 IAC System High RPM

T321115

Circuit Description

The powertrain control module (PCM) controls engine

idle speed by adjusting the position of the idle air control

(IAC) motor pintle. The IAC is a bi-directional stepper

motor driven by two coils. The PCM applies current to the

IAC coils in steps (counts) to extend the IAC pintle into a

passage in the throttle body to decrease air flow. The

PCM reverses the current to retract the pintle, increasing

air flow. This method allows highly accurate control of idle

speed and quick response to changes in engine load. If

the PCM detect a condition where too high of an idle

speed is present and the PCM is unable to adjust idle

speed by increasing the IAC counts, DTC P1509 will set,

indicating a problem with the idle control system.

Conditions for Setting the DTC

No Tech 2 test is being run.

None of these DTCs are set: TP sensor, VSS, ECT,

EGR, fuel system, MAF, MAP, IAT, canister purge,

injector control or ignition control.

Barometric pressure is above 75 kPa.

Engine coolant temperature is above 50C (120F).

Engine speed is more than 100-200 RPM lower than

desired idle, based upon coolant temperature.

The engine has been running for at least 125 seconds.

Vehicle speed is less than 1 mph.

Canister purge duty cycle is above 10%.

Ignition voltage is between 9.5 volts and 16.7 volts.

Engine speed is lower than desired idle.

All of the above conditions are met for 5 seconds.

Action Taken When the DTC Sets

The PCM will illuminate the malfunction indicator lamp

(MIL) after the second consecutive trip in which the

fault is detected.

The PCM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

DTC P1509 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the PCM battery

feed.

Diagnostic Aids

Check for the following conditions:

Poor connection at PCM or IAC motor – Inspect

harness connectors for backed-out terminals,

improper mating, broken locks, improperly formed or

damaged terminals, and poor terminal-to-wire

connection.

Damaged harness – Inspect the wiring for damage.

Vacuum leak – Check for a condition that causes a

vacuum leak, such as disconnected or damaged

h o s e s , l e a k s a t t h e E G R v a l v e a n d t h e E G R p i p e t o t h e

intake manifold, leaks at the throttle body, faulty or

incorrectly installed PCV valve, leaks at the intake

manifold, etc.

Page 4931 of 6000

6E–274

ENGINE DRIVEABILITY AND EMISSIONS

Rough, Unstable, or Incorrect Idle, Stalling Symptom

StepNo Ye s Va l u e ( s ) Action

171. Check ignition coils for cracks or carbon tracking.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 18

18Using Tech 2, monitor the throttle position (TP) angle

with the engine idling.

Is the TP angle at the specified value and steady?

0%Go to Step 19

Refer to DTC

P0123

for

further

diagnosis

191. Check the positive crankcase ventilation (PCV)

valve for proper operation. Refer to

Crankcase

Ventilation System

.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 20

201. Check the transmission range switch circuit. Use

Tech 2 and be sure Tech 2 indicates that the vehicle

is in drive with the gear selector in drive or overdrive.

2. If a problem is found, diagnose and repair the

transmission range switch as necessary (refer to

4L30-E Automatic Transmission Diagnosis).

Was a problem found?

—Verify repairGo to Step 21

211. Check for the following engine mechanical items.

Refer to

Engine Mechanical for diagnosis

procedures:

EGR valve mounted backward. Compare with

a known-good vehicle.

Low compression

Sticking or leaking valves

Worn camshaft lobe(s)

Camshaft drive belt slipped or stripped

Incorrect valve timing

Worn rocker arms

Broken valve springs

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 22

221. Check for faulty motor mounts. Refer to Engine

Mechanical

for inspection of mounts.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 23

231. Review all diagnostic procedures within this table.

2. If all procedures have been completed and no

malfunctions have been found, review/inspect the

following:

Visual/physical inspection

Te c h 2 d a t a

Freeze Frame data/Failure Records buffer

All electrical connections within a suspected

circuit and/or system.

3. If a problem is found, repair as necessary.

Was a problem found?

—Verify repair

Contact

Te c h n i c a l

Assistance

Page 4941 of 6000

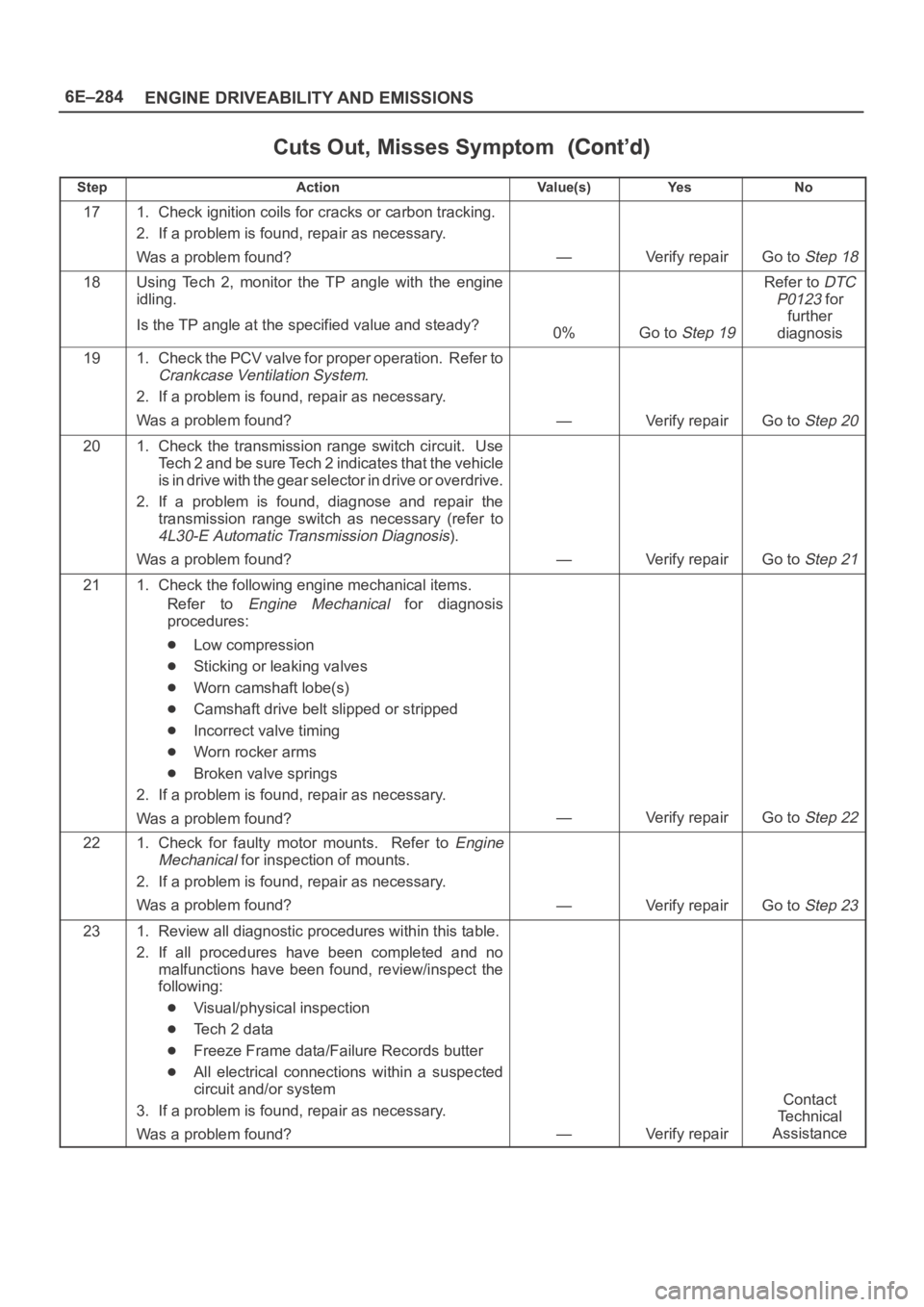

6E–284

ENGINE DRIVEABILITY AND EMISSIONS

Cuts Out, Misses Symptom

StepNo Ye s Va l u e ( s ) Action

171. Check ignition coils for cracks or carbon tracking.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 18

18Using Tech 2, monitor the TP angle with the engine

idling.

Is the TP angle at the specified value and steady?

0%Go to Step 19

Refer to DTC

P0123

for

further

diagnosis

191. Check the PCV valve for proper operation. Refer to

Crankcase Ventilation System.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 20

201. Check the transmission range switch circuit. Use

Tech 2 and be sure Tech 2 indicates that the vehicle

is in drive with the gear selector in drive or overdrive.

2. If a problem is found, diagnose and repair the

transmission range switch as necessary (refer to

4L30-E Automatic Transmission Diagnosis).

Was a problem found?

—Verify repairGo to Step 21

211. Check the following engine mechanical items.

Refer to

Engine Mechanical for diagnosis

procedures:

Low compression

Sticking or leaking valves

Worn camshaft lobe(s)

Camshaft drive belt slipped or stripped

Incorrect valve timing

Worn rocker arms

Broken valve springs

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 22

221. Check for faulty motor mounts. Refer to Engine

Mechanical

for inspection of mounts.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 23

231. Review all diagnostic procedures within this table.

2. If all procedures have been completed and no

malfunctions have been found, review/inspect the

following:

Visual/physical inspection

Te c h 2 d a t a

Freeze Frame data/Failure Records butter

All electrical connections within a suspected

circuit and/or system

3. If a problem is found, repair as necessary.

Was a problem found?

—Verify repair

Contact

Te c h n i c a l

Assistance

Page 5014 of 6000

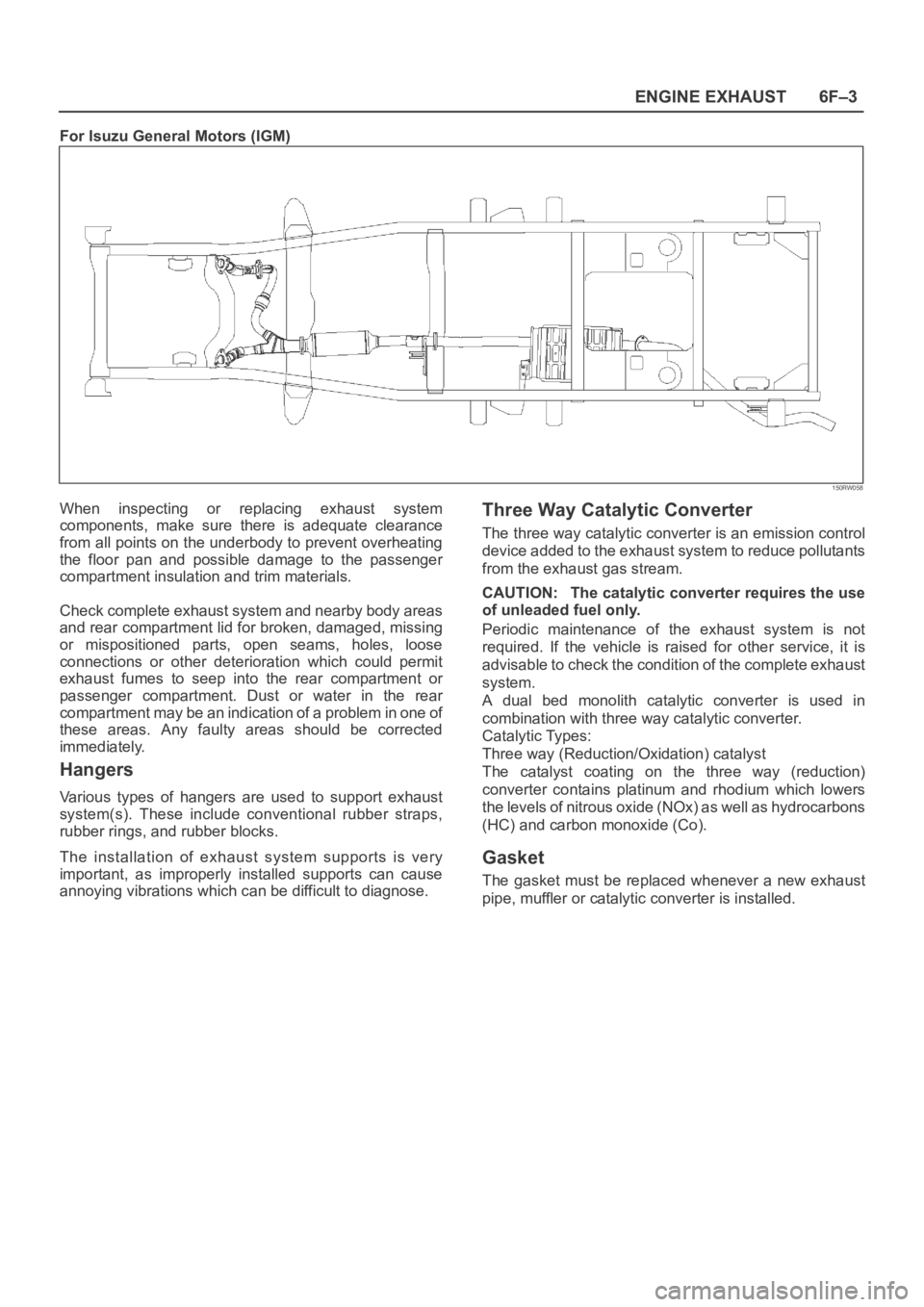

6F–3 ENGINE EXHAUST

For Isuzu General Motors (IGM)

150RW058

When inspecting or replacing exhaust system

components, make sure there is adequate clearance

from all points on the underbody to prevent overheating

the floor pan and possible damage to the passenger

compartment insulation and trim materials.

Check complete exhaust system and nearby body areas

and rear compartment lid for broken, damaged, missing

or mispositioned parts, open seams, holes, loose

connections or other deterioration which could permit

exhaust fumes to seep into the rear compartment or

passenger compartment. Dust or water in the rear

compartment may be an indication of a problem in one of

these areas. Any faulty areas should be corrected

immediately.

Hangers

Various types of hangers are used to support exhaust

system(s). These include conventional rubber straps,

rubber rings, and rubber blocks.

The installation of exhaust system supports is very

important, as improperly installed supports can cause

annoying vibrations which can be difficult to diagnose.

Three Way Catalytic Converter

The three way catalytic converter is an emission control

device added to the exhaust system to reduce pollutants

from the exhaust gas stream.

CAUTION: The catalytic converter requires the use

of unleaded fuel only.

Periodic maintenance of the exhaust system is not

required. If the vehicle is raised for other service, it is

advisable to check the condition of the complete exhaust

system.

A dual bed monolith catalytic converter is used in

combination with three way catalytic converter.

Catalytic Types:

Three way (Reduction/Oxidation) catalyst

The catalyst coating on the three way (reduction)

converter contains platinum and rhodium which lowers

the levels of nitrous oxide (NOx) as well as hydrocarbons

(HC) and carbon monoxide (Co).

Gasket

The gasket must be replaced whenever a new exhaust

pipe, muffler or catalytic converter is installed.