Electrical OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 2209 of 6000

7A–55 AUTOMATIC TRANSMISSION (4L30–E)

242RW008

46. Install two check balls (44).

244RW002

47. Inspect main case electrical connector and seal,

replace if necessary.

Install electrical 4 pin connector/main case and

wiring harness.

48. Install two 5–8840–0022–0 (J–25025–B) guide pins

into main case.

Install main case valve body complete assembly

(45) and manual valve link.NOTE: Valve must be extended as the short end of

manual valve link is connected to the range selector lever.

Long end of link goes into valve.

Install seven 13 mm screws.

To r q u e : 2 0 N

m (2.0 kgꞏm/15 lb ft)

Pass ground wire of adapter case wiring harness

assembly through the hole joining adapter fluid area

and main case fluid area.

Assemble 8.5 mm connector of ground wire under

the head of this valve body bolt and reinstall it.

Remove two guide pins.

244RW001

49. Install servo cover gasket, cover (46) and four 13 mm

screws.

To r q u e : 2 5 N

m (2.6 kgꞏm/18 lb ft)

50. Connect wiring harness (47) to band control, shift

solenoids, and main case 4 pin connector.

51. Install manual detent roller and spring assembly (48)

with clip.

Install two 13 mm screws.

To r q u e : 2 0 N

m (2.0 kgꞏm/15 lb ft)

52. Install oil filter (49), and three 13 mm screws.

To r q u e : 2 0 N

m (2.0 kgꞏm/15 lb ft)

53. Install oil pan gasket, magnet, main oil pan (50), and

sixteen 10 mm screws.

To r q u e : 11 N

m (1.1 kgꞏm/96 lb in)

54. Inspect adapter case electrical connector and seal.

Replace if necessary.

Install electrical five pin connector and harness

assembly (52) in bottom of adapter case.

55. Install gasket, transfer plate, and gasket.

Install adapter case valve body (51) and seven 13

mm screws.

Torque: 20 N

m (2.0 kgꞏm/15 lb ft)

Page 2238 of 6000

7A–84

AUTOMATIC TRANSMISSION (4L30–E)

4L30–E Parts List

Case And Associated Parts

241RW014

Legend

(1) Torque Converter

(2) Screw, Seal Ring Assembly

(3) Seal Ring Assembly, Converter Housing

(4) Screw, Converter Housing/Main Case

(5) Screw, Converter Housing/Oil Pump

(6) Housing, Converter

(7) Plug, Converter Housing

(8) Seal, O–Ring

(9) Wear Plate, Oil Pump Body

(10) Pump Assembly, Oil

(11) Gasket

(12) Washer, Thrust Selective

(13) Ring, Snap

(14) Cover, 3–4 Accumulator Piston

(15) Seal, O–Ring, 3–4 Accumulator

(16) Spring, 3–4 Accumulator Piston(17) Pin, 3–4 Accumulator Piston

(18) Piston, 3–4 Accumulator

(19) Ring, 3–4, Accumulator Piston

(20) Case, Adapter

(22) Connector, Electrical/Adapter Case

(23) Screw, Pan

(27) Restrictor, Oil

(28) Gasket, Transfer Plate/Adapter

(29) Plate, Transfer Adapter/Center Support

(30) Support Assembly, Center

(31) Screw, Center Support

(32) Ring, Oil Seal

(33) Seal, O–Ring Main Case

(34) Fitting, Cooler

(35) Fitting Assembly, Cooler

(36) Case, Main

(37) Breather, Pipe

Page 2239 of 6000

7A–85 AUTOMATIC TRANSMISSION (4L30–E)

(38) Seal, O–Ring

(39) Reservoir

(42) Gasket, Extension Case

(43) Extension Assembly

(44) Seal, O–Ring/Speed Sensor

(45) Sensor Assembly, Speed

(46) Screw, Speed Sensor

(50) Seal, Extension Assembly

(52) Screw, Extension/Main Case

(53) Spring, Parking Pawl Lock

(54) Pawl, Parking Lock

(55) Connector, Electrical/Main Case

(56) Actuator Assembly, Parking Lock

(57) Nut, Parking Lock Lever

(58) Link, Manual Valve

(59) Pin, Spring

(60) Lever, Parking Lock and Range Selector

(61) Shaft, Selector

(62) Seal, Selector Shaft

(63) Mode Switch Assembly

(64) Screw and Conical Washer Assembly

(65) Shield, Mode Switch

(67) Pan, Bottom/Adapter Case

(68) Gasket, Bottom Pan/Adapter Case

(69) Harness Assembly, Adapter Case

(70) Screw, Valve Body

(71) Valve Body Assembly, Adapter Case

(72) Gasket, Adapter Valve Body

(73) Plate, Adapter Valve Body/Transfer

(74) Pan, Bottom/Main Case(75) Gasket, Bottom Pan/Main Case

(76) Gasket, Oil Drain or Overfill Screw

(77) Screw, Oil Drain or Overfill

(78) Magnet, Chip Collector

(79) Filter Oil

(80) Harness Assembly, Main Case

(82) Roller and Spring Assembly, Manual Detent

(84) Valve Body Assembly, Main Case

(85) Ball, Check

(86) Gasket, Main V.B./Transfer Plate

(87) Plate, Main V.B./Transfer

(88) Gasket, Transfer/Main Case

(89) Screw, Transfer Plate on V.B.

(90) Screw, Servo Cover

(91) Cover, Servo Piston

(92) Gasket, Cover/Servo Piston

(93) Ring, Retaining Servo Piston

(94) Clip, Servo Piston

(95) Nut, Servo Screw

(96) Screw, Servo Piston

(97) Piston, Servo

(98) Seal, Ring/Servo Piston

(99) Spring, Cushion/Servo Piston

(100) Seat, Cushion Spring

(101) Sleeve, Servo Piston Adjust

(102) Rod, Apply/Servo Piston

(103) Spring, Return/Servo Piston

(104) Gasket, Adapter Case/Transfer Plate

(105) Powertrain Control Module

(106) Servo Piston Assembly

Page 2246 of 6000

TRANSMISSION CONTROL SYSTEM (4L30–E)7A1–1

TRANSMISSION

TRANSMISSION CONTROL SYSTEM (4L30–E)

CONTENTS

Service Precaution 7A1–2. . . . . . . . . . . . . . . . . . . . . .

General Description 7A1–2. . . . . . . . . . . . . . . . . . . . .

Shift Control 7A1–6. . . . . . . . . . . . . . . . . . . . . . . . . .

Band Apply Control 7A1–6. . . . . . . . . . . . . . . . . . . .

Torque Converter Clutch Control 7A1–6. . . . . . . . .

Line Pressure Control 7A1–6. . . . . . . . . . . . . . . . . .

On–Board Diagnostic System 7A1–6. . . . . . . . . . .

Fail Safe Mechanism 7A1–6. . . . . . . . . . . . . . . . . . .

Torque Management Control 7A1–6. . . . . . . . . . . .

ATF Warning Control 7A1–6. . . . . . . . . . . . . . . . . . .

ABS Control (If equipped) 7A1–6. . . . . . . . . . . . . .

Winter Drive Mode 7A1–9. . . . . . . . . . . . . . . . . . . . .

Backup Mode 7A1–9. . . . . . . . . . . . . . . . . . . . . . . . .

Functions of Input / Output Components 7A1–10. .

Diagnosis 7A1–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Check Trans Indicator 7A1–11. . . . . . . . . . . . . . . . . .

Diagnostic Check 7A1–11. . . . . . . . . . . . . . . . . . . . . .

“Check Trans” Check 7A1–12. . . . . . . . . . . . . . . . . .

Tech2 OBD II Connection 7A1–13. . . . . . . . . . . . . . .

OBD II Diagnostic Management System 7A1–18. .

16 – Terminal Data Link Connector (DLC) 7A1–19.

Malfunction Indicator Lamp (MIL) 7A1–20. . . . . . . .

Types Of Diagnostic Trouble Codes

(DTCs) 7A1–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Clear DTC 7A1–20. . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC Check 7A1–21. . . . . . . . . . . . . . . . . . . . . . . . . . .

PCM Precaution 7A1–21. . . . . . . . . . . . . . . . . . . . . . .

Information On PCM 7A1–21. . . . . . . . . . . . . . . . . . .

Intermittent Conditions 7A1–21. . . . . . . . . . . . . . . . .

Transmission And PCM Identification 7A1–22. . . . .

Diagnostic Trouble Code (DTC)

Identification 7A1–24. . . . . . . . . . . . . . . . . . . . . . . . .

DTC P0218 Transmission Fluid Over

Temperature 7A1–25. . . . . . . . . . . . . . . . . . . . . . . . . . . Conditions For Setting The DTC 7A1–25. . . . . . . . .

Action Taken When The DTC Sets 7A1–25. . . . . . .

Conditions For Clearing The DTC 7A1–25. . . . . . . .

Diagnostic Aids 7A1–25. . . . . . . . . . . . . . . . . . . . . . . .

Test Description 7A1–25. . . . . . . . . . . . . . . . . . . . . . .

DTC P0560 System Voltage Malfunction 7A1–27. . .

DTC P0705 Transmission Range Switch

(Mode Switch) Illegal Position 7A1–30. . . . . . . . . . . .

DTC P0706 Transmission Range Switch

(Mode Switch) Performance 7A1–33. . . . . . . . . . . . . .

DTC P0712 Transmission Fluid Temperature

(TFT) Sensor Circuit Low Input 7A1–36. . . . . . . . . . .

DTC P0713 Transmission Fluid Temperature

(TFT) Sensor Circuit High Input 7A1–39. . . . . . . . . . .

DTC P0719 TCC Brake Switch Circuit High

(Stuck On) 7A1–42. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P0722 Transmission Output Speed

Sensor (OSS) Low Input 7A1–45. . . . . . . . . . . . . . . . .

DTC P0723 Transmission Output Speed

Sensor (OSS) Intermittent 7A1–48. . . . . . . . . . . . . . .

DTC P0730 Transmission Incorrect

Gear Ratio 7A1–51. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P0748 Pressure Control Solenoid

(PCS) (Force Motor) Circuit Electrical 7A1–54. . . . .

DTC P0753 Shift Solenoid A Electrical 7A1–56. . . . .

DTC P0758 Shift Solenoid B Electrical 7A1–59. . . . .

DTC P1790 ROM Transmission Side Bad

Check Sum 7A1–63. . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P1792 EEPROM Transmission Side

Bad Check Sum 7A1–64. . . . . . . . . . . . . . . . . . . . . . . .

DTC P1835 Kickdown Switch Always On 7A1–65. . .

DTC P1850 Brake Band Apply Solenoid

Malfunction 7A1–67. . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P1860 TCC Solenoid Electrical 7A1–71. . . . . . .

Page 2266 of 6000

TRANSMISSION CONTROL SYSTEM (4L30–E)7A1–21

NOTE: To use the DTC again to identify a problem, you

will need to reproduce the fault or the problem. This may

require a new test drive or just turning the ignition on (this

depends on the nature of the fault).

1. IF you have a Tech2:

1. Connect the Tech2 if it is still not connected

GOTHROUGH Tech2 OBD II CONNECTION.

2. Push “F4” and answer “Yes” to the question “Do

you really want to clear the codes?”

a. When a malfunction remains as it is the Tech2

displays “4L30E CODES NOT CLEARED”. This

means that the problem is still there or that the

recovery was not done. Please GOTO DTC

CHECK.

b. When a malfunction has been repaired and the

recovery is done. The Tech2 displays “4L30E

CODES CLEARED”.

2. IF you have no Tech2:

To clear the DTC, remove Fuse “Stop, A/T CONT”

(C–14, 15A) for at least 10 seconds.

DTC Check

1. Diagnostic Trouble Codes (DTC) have been identified

by Tech2.

2. You have written the list of the DTCs. The order of the

malfunctions has no meanings for this PCM. Usually

only one or two malfunctions should be set for a given

problem.

3. Check directly the DTCs you identified. The DTCs are

sorted by number. Refer to Diagnostic Trouble Code

(DTC) Identification in this section.

PCM Precaution

The PCM can be damaged by:

1. Electrostatic discharge

2. The short circuit of some terminals to voltage or to

ground.

Electrostatic Discharge Damage Description:

1. Electronic components used to control systems are

often designed to carry very low voltage, and are very

susceptible to damage caused by electrostatic

discharge. It is possible for less than 100 volts of

static electricity to cause damage to some electronic

components. By comparison, it takes as much as

4,000 volts for a person to even feel the zap of a static

discharge.2. There are several ways for a person to become

statically charged. The most common methods of

charging are by friction and induction. An example of

charging by friction is a person sliding across a car

seat, in which a charge of as much as 25,000 volts

can build up. Charging by induction occurs when a

person with well insulated shoes stands near a highly

charged object and momentarily touches ground.

Charges for the same polarity are drained off, leaving

the person highly charged with the opposite polarity.

Static charges of either type can cause damage,

therefore, it is important to use care when handling

and testing electronic components.

NOTICE: To prevent possible electrostatic

discharge damage:

1. Do not touch the PCM connector pins or soldered

components on the PCM circuit board.

2. Be sure to follow the guidelines listed below if

servicing any of these electronic components:

3. Do not open the replacement part package until it is

time to install the part.

4. Avoid touching electrical terminals of the part.

5. Before removing the part from its package, ground

the package to a known good ground on the vehicle.

6. Always touch a known good ground before handling

the part. This step should be repeated before

installing the part if the part has been handled while

sliding across the seat, while sitting down from a

standing position or while walking some distance.

Information On PCM

1. The Powertrain Control Module (PCM) is located in

the center console and is the control center of the

electronic transmission control system.

2. The PCM must be maintained at a temperature below

185

F (85C) at all times. This is most essential if the

vehicle is put through a paint baking process. The

PCM will become inoperative if its temperature

exceeds 85

C (185F). Therefore, it is

recommended that the PCM be removed or that

temporary insulation be placed around the PCM

during the time the vehicle is in a paint oven or other

high temperature process.

3. The PCM is designed to process the various inputs

and then respond by sending the appropriate

electrical signals to control transmission upshift,

downshift, shift feel and torque converter clutch

engagement.

4. The PCM constantly interprets information from the

various sensors, and controls the systems that affect

transmission and vehicle performance. By analyzing

operational problems, the PCM is able to perform a

diagnostic function by displaying DTC(s) and aid the

technician in making repairs.

Intermittent Conditions

If the Tech2 displays a diagnostic trouble code as

intermittent, or if after a test drive a DTC does not

reappear though the detection conditions for this DTC are

present, the problem is most likely a faulty electrical

Page 2267 of 6000

7A1–22

TRANSMISSION CONTROL SYSTEM (4L30–E)

connection or loose wiring. Terminals and grounds should

always be the prime suspect. Intermittents rarely occur

inside sophisticated electronic components such as the

PCM.

Use the DTC information to understand which wires and

sensors are involved.

When an intermittent problem is encountered, check

suspect circuits for:

1. Poor terminal to wire connection.

2. Terminals not fully seated in the connector body

(backed out).

3. Improperly formed or damaged terminals.

4. Loose, dirty, or corroded ground connections:

HINT: Any time you have an intermittent in more than

one circuit, check whether the circuits share a

common ground connection.

5. Pinched or damaged wires.

6. Electro–Magnetic Interference (EMI):

HINT: Check that all wires are properly routed away

from spark plug wires, distributor wires, coil, and

generator. Also check for improperly installed

electrical options, such as lights, 2–way radios, etc.Use the F3 SNAPSHOT mode of the Tech2 to help isolate

the cause of an intermittent fault. The snapshot mode will

record information before and after the problem occurs.

Set the snapshot to “trigger” on the suspect DTC. If you

notice the reported symptom during the test drive, trigger

the snapshot manually.

After the snapshot has been triggered, command the

Tech2 to play back the flow of data recorded from each of

the various sensors. Signs of an intermittent fault in a

sensor circuit are sudden unexplainable jump in data

values out of the normal range.

Transmission And PCM Identification

The chart below contains a list of all important information

concerning rear axle ratio, Powertrain Control Module

(PCM), and transmission identification.

VEHICLE

Rr axlePCMTRANSMISSION

Ty p eEngine

Rr axle

RatioISUZU Parts No.Calibration

CodeIsuzu Part No.Model Code

Isuzu /

Trooper3.2L V64.555

8–16254–949–0

8–16254–749–0

8–16253–989–0

G208–96018–272–3FP (4X4)

Page 2269 of 6000

7A1–24

TRANSMISSION CONTROL SYSTEM (4L30–E)

Diagnostic Trouble Code (DTC)

Identification

DTC NUM-

BERDTC NAMEDTC TYPE“CHECK

TRANS”

P0218Transmission Fluid Over TemperatureD

P0560System Voltage MalfunctionCFlash

P0705Transmission Range Switch (Mode Switch) Illegal PositionD

P0706Transmission Range Switch (Mode Switch) PerformanceD

P0712Transmission Fluid Temperature Sensor Circuit Low Input

(TFT)D

P0713Transmission Fluid Temperature (TFT) Sensor Circuit High

InputD

P0719TCC Brake Switch Circuit High (Stuck ON)D

P0722Transmission Output Speed Sensor (OSS) Low InputCFlash

P0723Transmission Output Speed Sensor (OSS) IntermittentCFlash

P0730Transmission Incorrect Gear Ratio FlashCFlash

P0748Pressure Control Solenoid (PCS) (FORCE MOTOR) Circuit

ElectricalCFlash

P0753Shift Solenoid A ElectricalCFlash

P0758Shift Solenoid B ElectricalCFlash

P1790ROM Transmission Side Bad Check SumCFlash

P1792EEPROM Transmission Side Bad Check SumCFlash

P1835Kickdown Switch Always OND

P1850Brake Band Apply Solenoid MalfunctionD

P1860TCC Solenoid ElectricalD

DTC TYPEDEFINITION

CFlashing Check Trans on 1st failure

DNo lamps

NOTE: On the following charts, refer to the Powertrain

Control Module (PCM) section for the Wiring System, and

the Body and Accessories section for circuit diagram

details, parts location, and connector configuration.

Page 2270 of 6000

TRANSMISSION CONTROL SYSTEM (4L30–E)7A1–25

DTC P0218 Transmission Fluid Over Temperature

D07RW029

Circuit Description

The Transmission Fluid Temperature (TFT) sensor is a

thermister that controls the signal voltage to the PCM.

The PCM supplies a 5–volt reference to the sensor on

circuit RED/BLK–GRN/RED. When the transmission fluid

is cold, the sensor resistance is high and the PCM will

sense high signal voltage. As the fluid temperature

warms to a normal transmission operating temperature of

100

C (212F), the sensor resistance becomes less and

the voltage decreases to 1.5 to 2.0 volts.

This DTC detects a high transmission temperature for a

long period of time. This is a type “D” DTC.

Conditions For Setting The DTC

No TFT DTCs P0712 or P0713.

TFT is greater than 135C (275F).

All conditions met for 21 seconds.

Action Taken When The DTC Sets

Hot mode TCC Shift Pattern.

The PCM will not illuminate the CHECK TRANS

Lamp.

ATF Lamp ON. (TFT is greater than 145C (293F).)

Disable E–side TCC OFF request.

Conditions For Clearing The DTC

The DTC can be cleared from the PCM history by

using a scan tool.

The DTC will be cleared from history when the vehicle

has achieved 40 warm–up cycles without a failure

reported.

The PCM will cancel the DTC default actions when

the fault no longer exists and the ignition is cycled “off”

long enough to power down the PCM.

Diagnostic Aids

Inspect the wiring for poor electrical connections at

the PCM and at the transmission 16–way connector.

Look for possible bent, backed out, deformed, or

damaged terminals. Check for weak terminal tension

as well.

Also check for a chafed wire that could short to bare

metal or other wiring. Inspect for a broken wire inside

the insulation.

When diagnosing for a possible intermittent short or

open condition, move the wiring harness while

observing test equipment for a change.

Check harness routing for a potential short to ground

in circuit RED/BLK–GRN/RED.

Scan tool TFT sensor temperature should rise

steadily to about 100

C (212F), then stabilize.

Check for a “skewed” (mis–scaled) sensor by

comparing the TFT sensor temperature to the

ambient temperature after a vehicle cold soak. A

“skewed” sensor can cause delayed garage shifts or

TCC complaints.

Check for a possible torque converter stator problem.

Verify customer driving habits, trailer towing, etc.

Test Description

The numbers below refer to the step numbers on the

diagnostic chart.

3. This test checks for a “skewed” sensor or shorted

circuit.

4. This test simulates a TFT DTC P0713.

Page 2273 of 6000

7A1–28

TRANSMISSION CONTROL SYSTEM (4L30–E)

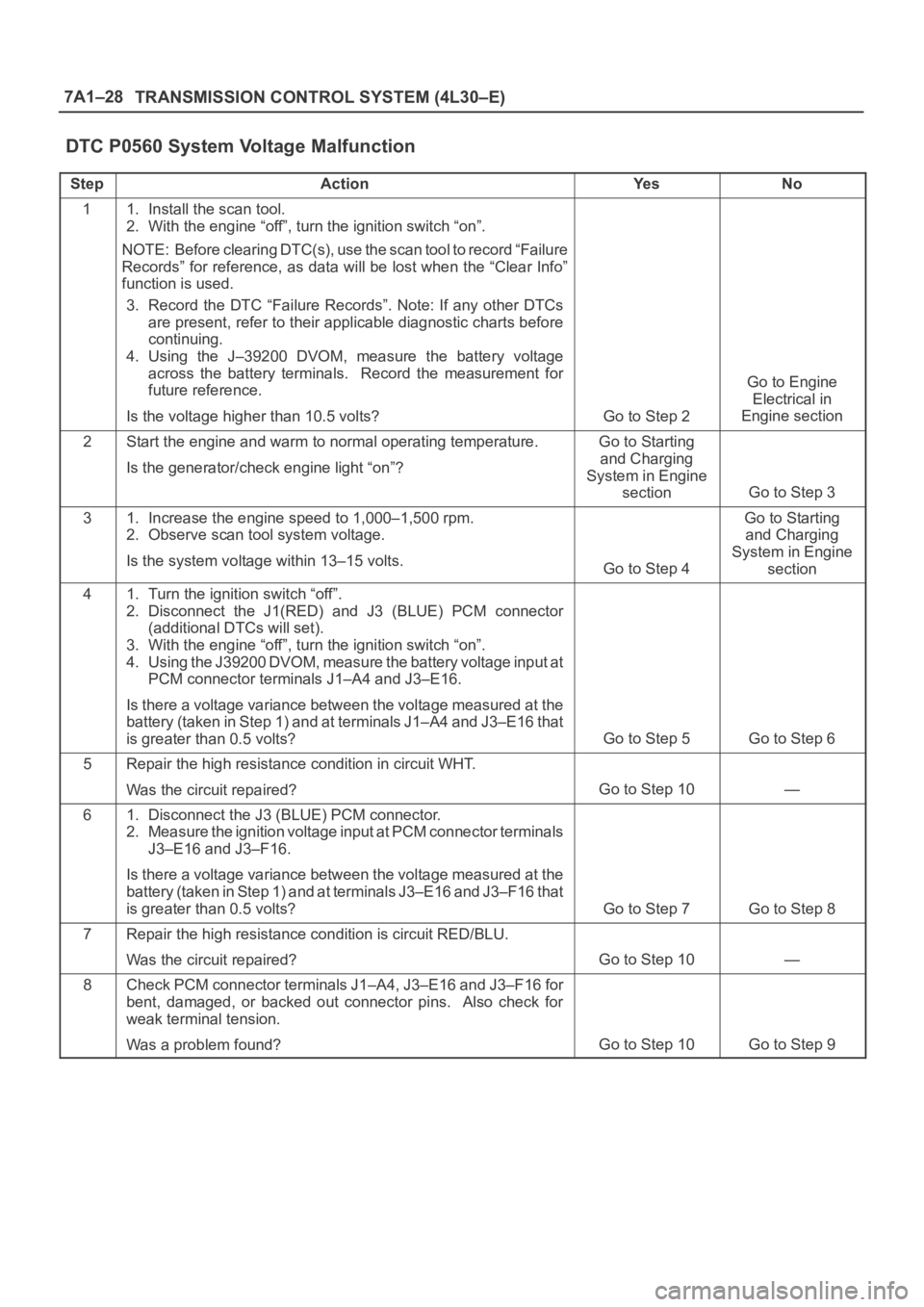

DTC P0560 System Voltage Malfunction

StepActionYe sNo

11. Install the scan tool.

2. With the engine “off”, turn the ignition switch “on”.

NOTE: Before clearing DTC(s), use the scan tool to record “Failure

Records” for reference, as data will be lost when the “Clear Info”

function is used.

3. Record the DTC “Failure Records”. Note: If any other DTCs

are present, refer to their applicable diagnostic charts before

continuing.

4. Using the J–39200 DVOM, measure the battery voltage

across the battery terminals. Record the measurement for

future reference.

Is the voltage higher than 10.5 volts?

Go to Step 2

Go to Engine

Electrical in

Engine section

2Start the engine and warm to normal operating temperature.

Is the generator/check engine light “on”?Go to Starting

and Charging

System in Engine

section

Go to Step 3

31. Increase the engine speed to 1,000–1,500 rpm.

2. Observe scan tool system voltage.

Is the system voltage within 13–15 volts.

Go to Step 4

Go to Starting

and Charging

System in Engine

section

41. Turn the ignition switch “off”.

2. Disconnect the J1(RED) and J3 (BLUE) PCM connector

(additional DTCs will set).

3. With the engine “off”, turn the ignition switch “on”.

4. Using the J39200 DVOM, measure the battery voltage input at

PCM connector terminals J1–A4 and J3–E16.

Is there a voltage variance between the voltage measured at the

battery (taken in Step 1) and at terminals J1–A4 and J3–E16 that

is greater than 0.5 volts?

Go to Step 5Go to Step 6

5Repair the high resistance condition in circuit WHT.

Was the circuit repaired?

Go to Step 10—

61. Disconnect the J3 (BLUE) PCM connector.

2. Measure the ignition voltage input at PCM connector terminals

J3–E16 and J3–F16.

Is there a voltage variance between the voltage measured at the

battery (taken in Step 1) and at terminals J3–E16 and J3–F16 that

is greater than 0.5 volts?

Go to Step 7Go to Step 8

7Repair the high resistance condition is circuit RED/BLU.

Was the circuit repaired?

Go to Step 10—

8Check PCM connector terminals J1–A4, J3–E16 and J3–F16 for

bent, damaged, or backed out connector pins. Also check for

weak terminal tension.

Was a problem found?

Go to Step 10Go to Step 9

Page 2275 of 6000

7A1–30

TRANSMISSION CONTROL SYSTEM (4L30–E)

DTC P0705 Transmission Range Switch (Mode Switch) Illegal Position

D07RW031

Circuit Description

The range switch supplies the Powertrain Control

Module (PCM) with information regarding the selector

lever position: P, R, N, D 3, 2 or L. The selector lever

position is indicated by the state of four ON/OFF

contracts. The range switch is located on one side of

the transmission. It is on the transmission manual

shaft and is fixed to the main case.

The range switch is also used to provide the

information P or N to the engine crank wiring. The

engine can be cranked only if connector M–25

terminal 4(H) is connected to terminal 1(E) which is

connected to ground.

The range switch is also used to provide the backup

lamp power in reverse. This is why the range switch is

supplied through a 10A fuse (C–3). This fuse can

burn due to a short circuit in the backup lamp.

This DTC detects when a fuse is open or the range switch

circuit does not work. This is a type “D” DTC.

Conditions For Setting The DTC

Range switch illegal positions met for 5 seconds.

Action Taken When The DTC Sets

Default to D position.

Inhibit torque management.

Maximum line pressure.

The PCM will not illuminate the CHECK TRANS

Lamp.

Conditions For Clearing The DTC

The DTC can be cleared from the PCM history by

using a scan tool.

The DTC will be cleared from history when the vehicle

has achieved 40 warmup cycles without a failure

reported.

The PCM will cancel the DTC default actions when

the fault no longer exists and the ignition is cycled “off”

long enough to power down the PCM.

Diagnostic Aids

Refer to accompanying chart for the normal range

signals and the illegal combinations.

Inspect the wiring for poor electrical connections at

the PCM and at the transmission 8–way connector.

Look for possible bent, backed out, deformed or

damaged terminals. Check for weak terminal tension

as we ll. A lso ch eck fo r a ch af e d w ire th at cou l d s ho r t

to bare metal or other wiring. Inspect for a broken wire

inside the insulation.

When diagnosing for a possible intermittent short or

open condition, move the wiring harness while

observing test equipment for a change.