oil reset OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 971 of 6000

6A–15

ENGINE MECHANICAL

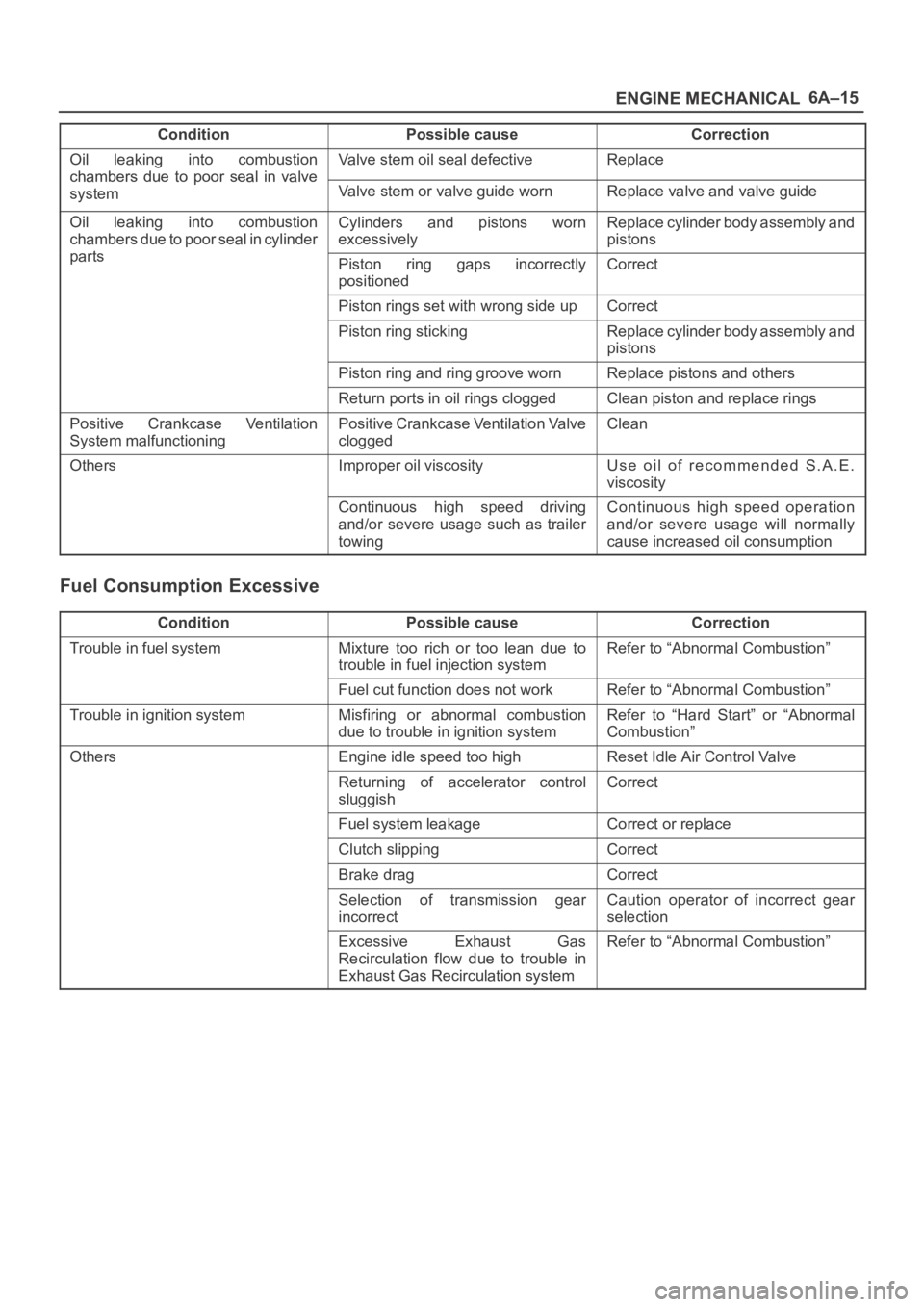

Condition CorrectionPossible cause

Oil leaking into combustion

chambers due topoor seal in valve

Valve stem oil seal defectiveReplace

chambers due to oor seal in valve

systemValve stem or valve guide wornReplace valve and valve guide

Oil leaking into combustion

chambers due to poor seal in cylinder

t

Cylinders and pistons worn

excessivelyReplace cylinder body assembly and

pistons

partsPiston ring gaps incorrectly

positionedCorrect

Piston rings set with wrong side upCorrect

Piston ring stickingReplace cylinder body assembly and

pistons

Piston ring and ring groove wornReplace pistons and others

Return ports in oil rings cloggedClean piston and replace rings

Positive Crankcase Ventilation

System malfunctioningPositive Crankcase Ventilation Valve

cloggedClean

OthersImproper oil viscosityUse oil of recommended S.A.E.

viscosity

Continuous high speed driving

and/or severe usage such as trailer

towingContinuous high speed operation

and/or severe usage will normally

cause increased oil consumption

Fuel Consumption Excessive

ConditionPossible causeCorrection

Trouble in fuel systemMixture too rich or too lean due to

trouble in fuel injection systemRefer to “Abnormal Combustion”

Fuel cut function does not workRefer to “Abnormal Combustion”

Trouble in ignition systemMisfiring or abnormal combustion

due to trouble in ignition systemRefer to “Hard Start” or “Abnormal

Combustion”

OthersEngine idle speed too highReset Idle Air Control Valve

Returning of accelerator control

sluggishCorrect

Fuel system leakageCorrect or replace

Clutch slippingCorrect

Brake dragCorrect

Selection of transmission gear

incorrectCaution operator of incorrect gear

selection

Excessive Exhaust Gas

Recirculation flow due to trouble in

Exhaust Gas Recirculation systemRefer to “Abnormal Combustion”

Page 1288 of 6000

6E–171 ENGINE DRIVEABILITY AND EMISSIONS

If the test light blinks while cranking, the PCM and

the wiring to the injectors are OK. The Fuel Injector

Coil Test Procedure will check if the injectors are

faulty.

R321054

7. Because the test light was “ON” steady, voltage to

the injector is OK, but the driver circuit is grounded

at all times. This step determines if the circuit is

shorted to ground or the PCM is faulty.

9. The reading should be about 12-14

.

10.Locating the open in the harness or in the injector

will require removal of the manifold to provide

access.

DTC P0201 – Injector 1 Control Circuit

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

2Will the engine start?

—Go to Step 3

Go to Engine

Cranks But

Will Not Run

chart

31. Install the Tech 2. Clear the DTC.

2. Idle the engine for one minute.

Does DTC P0201 reset?

—Go to Step 5Go to Step 4

41. Review the Freeze Frame data with the ignition

“ON” and the engine “OFF” and note the

parameters.

2. Operate the vehicle within the Freeze Frame

conditions as noted.

Does P0201 reset?

—Go to Step 5

Go to

Diagnostic

Aids

51. Engine “OFF.”

2. Disconnect the injector connector.

3. Install an injector test light 5-8840-2636-0 on the

injector test connector.

4. Crank the engine and note the light.

Does the injector test light blink?

—

Go to Fuel

Injector Coil

Te s t

Procedure

Go to Step 6

6Note whether the injector test light for cylinder 1 was

“OFF” or “ON” steady in step 5.

Was the test light “ON” steady while cranking the

engine?

—Go to Step 7Go to Step 9

Page 1291 of 6000

6E–174

ENGINE DRIVEABILITY AND EMISSIONS

If the test light blinks while cranking, the PCM and

the wiring to the injectors are OK. The Fuel Injector

Coil Test Procedure will check if the injectors are

faulty.

R321055

7. Because the test light was “ON” steady, voltage to

the injector is OK, but the driver circuit is grounded

at all times. This step determines if the circuit is

shorted to ground or the PCM is faulty.

9.The reading should be about 12-14

.

10.Locating the open in the harness or in the injector

will require removal of the manifold to provide

access.

DTC P0202 – Injector 2 Control Circuit

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

2Will the engine start?

—Go to Step 3

Go to Engine

Cranks But

Will Not Run

chart

31. Install the Tech 2. Clear the DTC.

2. Idle the engine for one minute.

Does DTC P0202 reset?

—Go to Step 5Go to Step 4

41. Review the Freeze Frame data with the ignition

“ON” and the engine “OFF” and note the

parameters.

2. Operate the vehicle within the Freeze Frame

conditions as noted.

Does P0202 reset?

—Go to Step 5

Go to

Diagnostic

Aids

51. Engine “OFF.”

2. Disconnect the injector test connector.

3. Install an injector test light 5-8840-2636-0 on

injector connector.

4. Crank the engine and note the light.

Does the cylinder 2 test light blink?

—

Go to Fuel

Injector Coil

Te s t

Procedure

Go to Step 6

6Note whether the injector test light for cylinder 2 was

“OFF” or “ON” steady in step 5.

Was the test light “ON” steady while cranking the

engine?

—Go to Step 7Go to Step 9

Page 1294 of 6000

6E–177 ENGINE DRIVEABILITY AND EMISSIONS

If the test light blinks while cranking, the PCM and

the wiring to the injectors are OK. The Fuel Injector

Coil Test Procedure will check if the injectors are

faulty.

R321056

7. Because the test light was “ON” steady, voltage to

the injector is OK, but the driver circuit is grounded

at all times. This step determines if the circuit is

shorted to ground or the PCM is faulty.

9. The reading should be about 12-14

.

10.Locating the open in the harness or in the injector

will require removal of the manifold to provide

access.

DTC P0203 – Injector 3 Control Circuit

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

2Will the engine start?

—Go to Step 3

Go to Engine

Cranks But

Will Not Run

chart

31. Install the Tech 2. Clear the DTC.

2. Idle the engine for one minute.

Does DTC P0203 reset?

—Go to Step 5Go to Step 4

41. Review the Freeze Frame data with the ignition

“ON” and the engine “OFF” and note the

parameters.

2. Operate the vehicle within the Freeze Frame

conditions as noted.

Does P0203 reset?

—Go to Step 5

Go to

Diagnostic

Aids

51. Engine “OFF.”

2. Disconnect the injector test connector .

3. Install an injector test light 5-8840-2636-0 on

injector connector.

4. Crank the engine and note the light.

Does the cylinder 3 test light blink?

—

Go to Fuel

Injector Coil

Te s t

Procedure

Go to Step 6

6Note whether the injector test light for cylinder 3 was

“OFF” or “ON” steady in step 5.

Was the test light “ON” steady while cranking the

engine?

—Go to Step 7Go to Step 9

Page 1297 of 6000

6E–180

ENGINE DRIVEABILITY AND EMISSIONS

If the test light blinks while cranking, the PCM and

the wiring to the injectors are OK. The Fuel Injector

Coil Test Procedure will check if the injectors are

faulty.

R321057

7. Because the test light was “ON” steady, voltage to

the injector is OK, but the driver circuit is grounded

at all times. This step determines if the circuit is

shorted to ground or the PCM is faulty.

9. The reading should be about 12-14

.

10.Locating the open in the harness or in the injector

will require removal of the manifold to provide

access.

DTC P0204 – Injector 4 Control Circuit

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

2Will the engine start?

—Go to Step 3

Go to Engine

Cranks But

Will Not Run

chart

31. Install the Tech 2. Clear the DTC.

2. Idle the engine for one minute.

Does DTC P0204 reset?

—Go to Step 5Go to Step 4

41. Review the Freeze Frame data with the ignition

“ON” and the engine “OFF” and note the

parameters.

2. Operate the vehicle within the Freeze Frame

conditions as noted.

Does P0204 reset?

—Go to Step 5

Go to

Diagnostic

Aids

51. Engine “OFF.”

2. Disconnect the injector test connector.

3. Install an injector test light 5-8840-2636-0 on

injector connector.

4. Crank the engine and note the light.

Does the cylinder 4 test light blink?

—

Go to Fuel

Injector Coil

Te s t

Procedure

Go to Step 6

6Note whether the injector test light for cylinder 4 was

“OFF” or “ON” steady in step 5.

Was the test light “ON” steady while cranking the

engine?

—Go to Step 7Go to Step 9

Page 1300 of 6000

6E–183 ENGINE DRIVEABILITY AND EMISSIONS

If the test light blinks while cranking, the PCM and

the wiring to the injectors are OK. The Fuel Injector

Coil Test Procedure will check if the injectors are

faulty.

R321058

7. Because the test light was “ON” steady, voltage to

the injector is OK, but the driver circuit is grounded

at all times. This step determines if the circuit is

shorted to ground or the PCM is faulty.

9. The reading should be about 12-14

.

10.Locating the open in the harness or in the injector

will require removal of the manifold to provide

access.

DTC P0205 – Injector 5 Control Circuit

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

2Will the engine start?

—Go to Step 3

Go to Engine

Cranks But

Will Not Run

chart

31. Install the Tech 2. Clear the DTC.

2. Idle the engine for one minute.

Does DTC P0205 reset?

—Go to Step 5Go to Step 4

41. Review the Freeze Frame data with the ignition

“ON” and the engine “OFF” and note the

parameters.

2. Operate the vehicle within the Freeze Frame

conditions as noted.

Does P0205 reset?

—Go to Step 5

Go to

Diagnostic

Aids

51. Engine “OFF.”

2. Disconnect the injector test connector.

3. Install an injector test light 5-8840-2636-0 on

injector connector.

4. Crank the engine and note the light.

Does the cylinder 5 test light blink?

—

Go to Fuel

Injector Coil

Te s t

Procedure

Go to Step 6

6 Note whether the injector test light for cylinder 5 was

“OFF” or “ON” steady in step 5.

Was the test light “ON” steady while cranking the

engine?

—Go to Step 7Go to Step 9

Page 1303 of 6000

6E–186

ENGINE DRIVEABILITY AND EMISSIONS

If the test light blinks while cranking, the PCM and

the wiring to the injectors are OK. The Fuel Injector

Coil Test Procedure will check if the injectors are

faulty.

R321059

7. Because the test light was “ON” steady, voltage to

the injector is OK, but the driver circuit is grounded

at all times. This step determines if the circuit is

shorted to ground or the PCM is faulty.

9. The reading should be about 12-14

.

10.Locating the open in the harness or in the injector

will require removal of the manifold to provide

access.

DTC P0206 – Injector 6 Control Circuit

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

2Will the engine start?

—Go to Step 3

Go to Engine

Cranks But

Will Not Run

chart

31. Install the Tech 2. Clear the DTC.

2. Idle the engine for one minute.

Does DTC P0206 reset?

—Go to Step 5Go to Step 4

41. Review the Freeze Frame data with the ignition

“ON” and the engine “OFF” and note the

parameters.

2. Operate the vehicle within the Freeze Frame

conditions as noted.

Does P0206 reset?

—Go to Step 5

Go to

Diagnostic

Aids

51. Engine “OFF.”

2. Disconnect the injector test connector.

3. Install an injector test light 5-8840-2636-0 on

injector connector.

4. Crank the engine and note the light.

Does the cylinder 6 test light blink?

—

Go to Fuel

Injector Coil

Te s t

Procedure

Go to Step 6

6Note whether the injector test light for cylinder 6 was

“OFF” or “ON” steady in step 5.

Was the test light “ON” steady while cranking the

engine?

—Go to Step 7Go to Step 9

Page 3004 of 6000

D08RW722

3C-3910

H-42

0.5

B/R0.5

B/R 0.5

B/R

B

D

C

A

FENDER-RH

H-104

M-10

2

A

I 0.5

L/Y0.5

L/Y0.5

L/Y

1M-109

H-103

H-9

0.5

LG/W0.5

LG/W

0.5

LG/W0.5

LG/W 0.5

LG/W0.5

R/W

SPEEDO-

METER

RESET

SWTACHOMETERENGINE

COOLANT

TEMPERATURE

GAUGEFUEL

GAUGEOIL

PRESSURE

GAUGE FUSE C-15

3M-10125

H-9

11

H-10

VEHICLE

SPEED SENSOR

I-10

0.5

Y/B0.5

Y/B0.5

Y/B

1

E-191 4

H-24

11

H-6

I-10

2H-8

PCM

(D7)CRUISE CONTROL

UNIT(9)0.5

B/R

15H-9

PCM

(C10)9

I-9

0.5

Y/R

14

H-2520

I-10

ENGINE

COOLANT

TEMPERATURE

UNIT

0.5

Y/G0.5

Y/V0.5

Y/B

1

E-217 19

H-9

10

H-6

I-10

OIL

PRESSURE

UNIT

8I-10METER

ODO/TRIP

METER

Page 3016 of 6000

D08RW738

6C-3910

H-41

0.5

B/R0.5

B 0.5

B/R

FENDER-RH

H-514

E-20

2

0.5

Y 0.5

L/Y0.5

L/Y

1E-2016

H-5

H-93

0.5

LG/W0.5

LG/W

0.3

LG/W0.3

LG/W 0.5

LG/W0.5

R/W

SPEEDO-

METER

RESET

SWTACHOMETERENGINE

COOLANT

TEMPERATURE

GAUGEFUEL

GAUGEOIL

PRESSURE

GAUGE FUSE C-15

3E-20125

H-9

15

H-5

VEHICLE

SPEED SENSOR

I-10

0.5

Y/B0.5

Y/B0.5

Y/B

1

E-191 4

H-24

4

H-5

I-10

QOS-III

CONTROL

UNIT

(9)QOS/EGR

CONTROL

UNIT

(16)0.5

BR

0.5

BR

0.5

BR

0.5

BP15

H-9

6

H-49

I-9

1

E-36

0.5

Y/R

14

H-2520

I-10

ENGINE

COOLANT

TEMPERATURE

UNIT TACHO

SENSOR

0.5

Y/V0.5

LB 0.5

Y/V0.5

Y/B

1

E-217 19

H-9

2

H-5

2E-23

H-5

0.5

BP 0.5

BP6C-39

FENDER-RH4

H-42

I-10

OIL

PRESSURE

UNIT

8I-10METER

ODO/TRIP

METER

E-36

2

10

H-4

Page 3024 of 6000

D08RW924

8C-3910

H-42

0.5

B/R0.5

B/R 0.5

B/R

B

D

C

A

FENDER-RH

H-104

M-10

2

A

I 0.5

L/Y0.5

L/Y0.5

L/Y

1M-109

H-105

H-24

0.5

LG/W0.5

LG/W

0.5

LG/W0.5

LG/W 0.5

LG/W0.5

R/W

SPEEDO-

METER

RESET

SWTACHOMETERENGINE

COOLANT

TEMPERATURE

GAUGEFUEL

GAUGEOIL

PRESSURE

GAUGE FUSE C-15

3M-10145

H-9

11

H-10

VEHICLE

SPEED SENSOR

I-10

0.5

Y/B0.5

Y/B0.5

Y/B

1

E-191 4

H-9

11

H-6

I-10

8H-8

PCM

(D7)CRUISE CONTROL

UNIT(9)0.5

B/R

18H-9

PCM

(C10)9

I-9

0.5

Y/R

13

H-2620

I-10

ENGINE

COOLANT

TEMPERATURE

UNIT

0.5

Y/G0.5

Y/B0.5

Y/B

1

E-212 19

H-9

10

H-6

I-10

OIL

PRESSURE

UNIT

8I-10METER

ODO/TRIP

METER