Electrical OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 3463 of 6000

SUPPLEMENTAL RESTRAINT SYSTEM 9J–26

Special Tools

WARNING: TO AVOID DEPLOYMENT WHEN

TROUBLESHOOTING THE SRS, DO NOT USE

ELECTRICAL TEST EQUIPMENT SUCH AS A

BATTERY–POWERED OR AC–POWERED

VOLTMETER, OHMMETER, ETC., OR ANY TYPE OF

ELECTRICAL EQUIPMENT OTHER THAN THAT

SPECIFIED IN THIS MANUAL. DO NOT USE A

NONPOWERED PROBE–TYPE TESTER.

INSTRUCTIONS IN THIS MANUAL MUST BE

FOLLOWED CAREFULLY, OTHERWISE PERSONAL

INJURY MAY RESULT.

5–8840–2421–0 SRS Driver/Passenger

Load Tool

901RS146The SRS Driver/Passenger Load Tool 5–8840–2421–0 is

used only when called for in this section. It is used as a

diagnostic aid and safety device to prevent inadvertent air

bag assembly deployment.

The load tool has three yellow connectors attached to its

case.

The three small connectors are electrically functional and

serve as resistive load substitutions.

No more than two connectors are used at any time. One

of the small connectors is used to substitute for the load of

the driver air bag assembly when it is connected at the top

of the column to the SRS coil assembly. Another small

connector is used to substitute for the load of the driver air

bag assembly and the SRS coil assembly when it is

connected at the base of the column to the SRS wiring

harness. The third small connector is used to substitute

for the load of the passenger air bag assembly and

pretensioner seat belt assembly when connected to the

passenger air bag assembly and pretensioner seat belt

assembly harness connector.

By substituting the resistance of the load tool when called

for, a determination can be made as to whether an inflator

circuit component is causing system malfunction and

which component is causing the malfunction. The loadtool should be used only when specifically called for in the

diagnostic procedures.

NOTE: If comand to use 5–8840–2421–0 load tool when

repair the pretensioner seat belt, connect load tool

connector to use for driver air bag and/or passenger air

bag connector.

5–8840–0285–0 DVM

901RS153The 5–8840–0285–0 DVM is the preferred DVM for use in

SRS diagnosis and repair. However, 5–8840–0366–0

may be used if 5–8840–0285–0 is not available. No other

DVMs are approved for SRS diagnosis and repair.

Scan Tool

901RW176The Tech 2 is used to read and clear SRS Diagnostic

Trouble Codes (DTCs). Refer to the Tech 2 Operators,

Manual for specific information on how to use the Tech 2.

Page 3489 of 6000

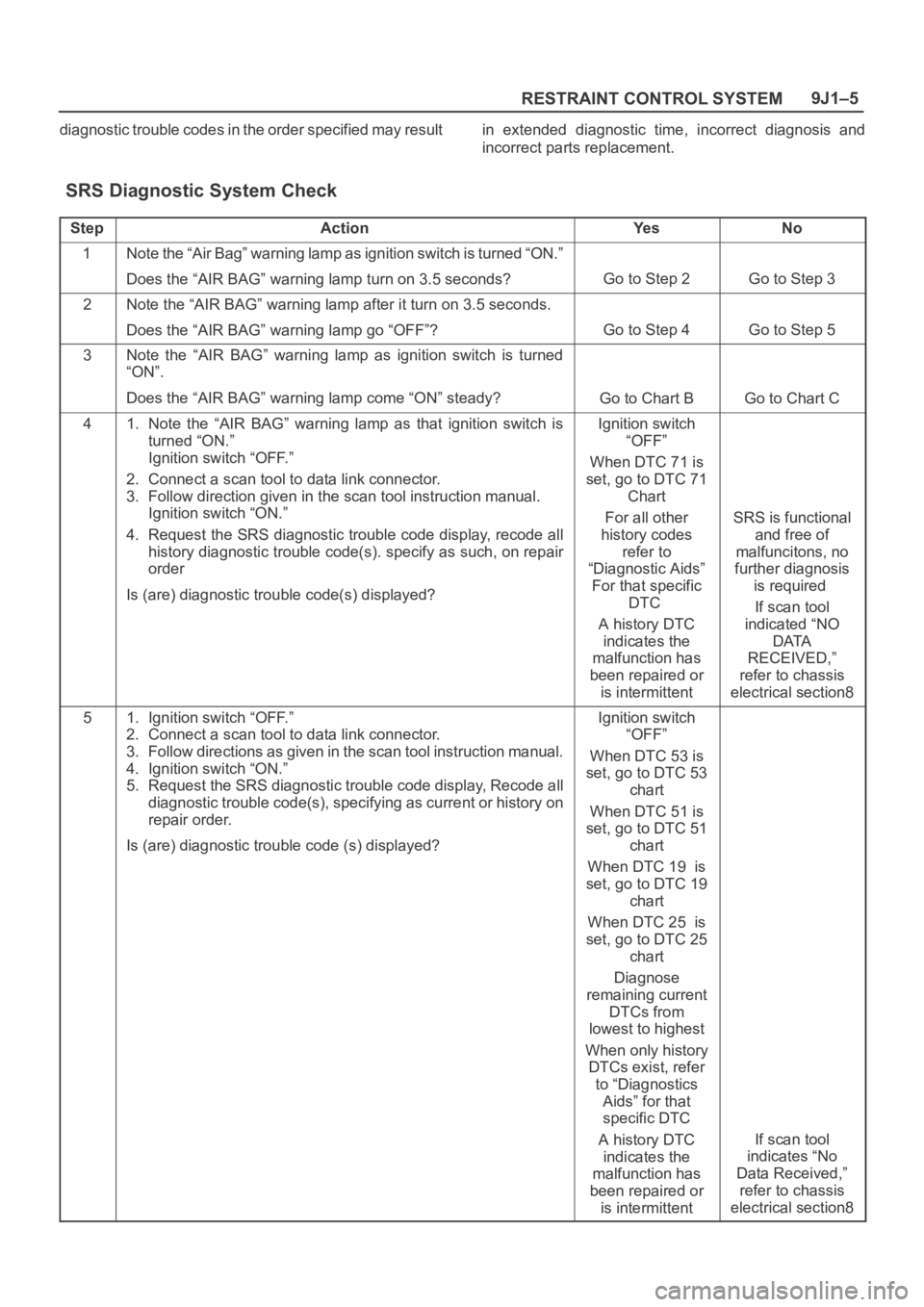

RESTRAINT CONTROL SYSTEM 9J1–2

Diagnostic Information

CAUTION: When fasteners are removed, always

reinstall them at the same location from which they

were removed. if a fastener needs to be replaced, use

the correct part number fastener for that application.

if the correct part number fastener is not available, a

fastener of equal size and strength (or stronger) may

be used. fasteners that are not reused, and those

requiring thread locking compound will be called

out. the correct torque value must be used when

installing fasteners that require it. if the above

conditions are not followed, parts or system damage

could result.

Diagnostic Procedures

WARNING: TO AVOID DEPLOYMENT WHEN

TROUBLESHOOTING THE SRS, DO NOT USE

ELECTRICAL TEST EQUIPMENT SUCH AS A

BATTERY–POWERED OR AC–POWERED

VOLTMETER, OHMMETER, ETC., OR ANY TYPE OF

ELECTRICAL EQUIPMENT OTHER THAN THAT

SPECIFIED IN THIS MANUAL. DO NOT USE A NON

POWERED, PROBE–TYPE TESTER.

INSTRUCTIONS IN THIS MANUAL MUST BE

FOLLOWED CAREFULLY, OTHERWISE PERSONAL

INJURY MAY RESULT.

The diagnostic procedures used in this section are

designed to aid in finding and repairing SRS problems.

Outlined below are the steps to find and repair SRS

problems quickly and effectively. Failure to carefully

follow these procedures may result in extended

diagnostic time, incorrect diagnosis and incorrect parts

replacement.

1.Perform The “SRS Diagnostic System Check”.

The “SRS Diagnostic System Check” should always

be the starting point of any SRS diagnostics. The

“SRS Diagnostic System Check” checks for proper

“AIR BAG” warning lamp operation and checks for

SRS trouble codes using both “Flash Code” and

“Scan Tool” Methods.

2.Refer To The Proper Diagnostic Chart As Directed

By The “SRS Diagnostic System Check”.

The “SRS Diagnostic System Check” will lead you to

the correct chart to diagnose any SRS problems.

Bypassing these procedures may result in extended

diagnostic time, incorrect diagnosis and incorrect

parts replacement.

3.Repeat The “SRS Diagnostic System Check”

After Any Repair Or Diagnostic Procedures Have

Been Performed.

Preforming the “SRS Diagnostic System Check” after

all repair or diagnostic procedures will assure that the

repair has been made correctly and that no other

conditions exist.

Diagnostic Codes

The Sensing and Diagnostic Module (SDM) maintains a

history record of all diagnostic codes that have beendetected since the SRS codes were last cleared during

service.

1. Active Codes — Faults that are presently detected

this ignition cycle. Active codes are stored in RAM

(Random Access Memory).

2. History Codes — All faults detected since the last

time the history fault memory was cleared. History

codes are stored in EEPROM. (Electronically

Erasable Programmable Read only Memory)

How To Read Trouble Codes

All codes (Active and history) can be read (or cleared) by

using a scan tool or equivalent.

If a PDT is not available, have the vehicle serviced by

ISUZU dealer.

How To Clear Trouble Codes

Trouble codes can only be cleared by using a Scan Tool.

If a “scan tool” is not available then inform the owner of the

stored codes and suggest that the codes are cleared

upon the next visit to an Isuzu dealership.

Scan Tool Diagnostics

A scan tool can be used to read current and history codes

and to clear all history codes after a repair is complete.

The scan tool must be updated to communicate with the

SRS through a memory card or a manufacturer’s update

before it can be used for SRS diagnostics. To use the

scan tool, connect it to the DLC connector and turn the

ignition switch “ON”. Then follow the manufacturer’s

directions for communication with the SRS. The scan tool

reads serial data from the SDM “Serial Data” output

(terminal 24) to the DLC connector (terminal 9).

Basic Knowledge Required

Before using this section of the Service Manual, there is

some basic knowledge which will be required. Without

this knowledge, you will have trouble using the diagnostic

procedures in this section. Use care to prevent harm or

unwanted deployment. Read all cautions in the service

manual and on warning labels attached to SRS

components.

Basic Electrical Circuits

You should understand the basic theory of electricity

including series and parallel circuits, and understand the

voltage drops across series resistors. You should know

the meaning of voltage (volts), current (amps), and

resistance (ohms). You should understand what happens

in a circuit with an open or a shorted wire. You should be

able to read and understand a wiring diagram.

“Flash Code” Diagnostics

Flash code diagnostics can be used to read active codes

and to determine if history codes are present but cannot

be used to clear codes or read history codes. Flash code

diagnostics is enabled by grounding by terminal 4

shorting to terminal 13 of the DLC connector with the

ignition switch “ON”. Grounding terminal 4 of the DLC

connector pulls the “Diagnostics Request” input (Terminal

1) of the SDM low and signals the SDM to enter the flash

code diagnostic display mode.

Page 3492 of 6000

9J1–5

RESTRAINT CONTROL SYSTEM

diagnostic trouble codes in the order specified may result in extended diagnostic time, incorrect diagnosis and

incorrect parts replacement.

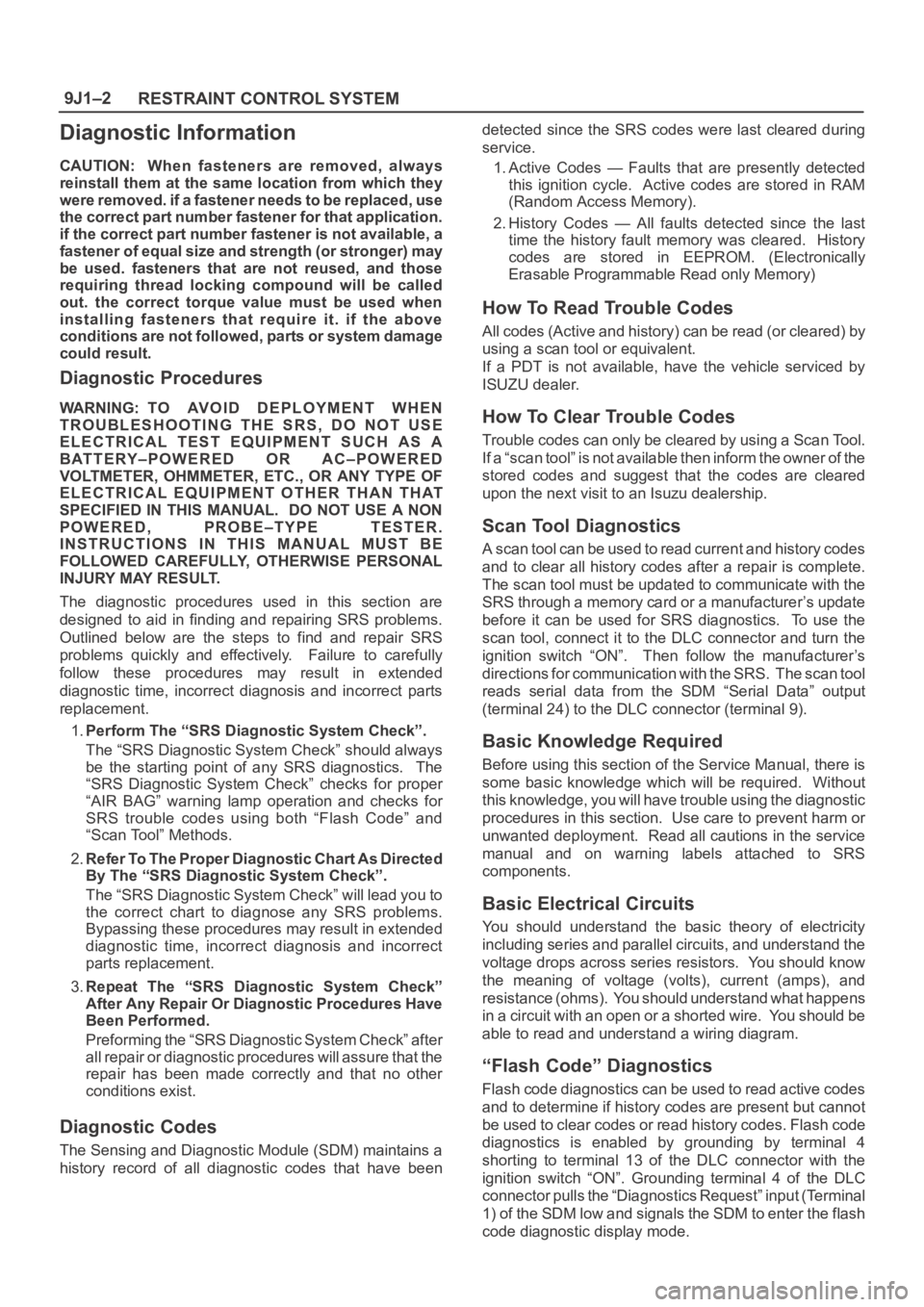

SRS Diagnostic System Check

StepActionYe sNo

1Note the “Air Bag” warning lamp as ignition switch is turned “ON.”

Does the “AIR BAG” warning lamp turn on 3.5 seconds?

Go to Step 2Go to Step 3

2Note the “AIR BAG” warning lamp after it turn on 3.5 seconds.

Does the “AIR BAG” warning lamp go “OFF”?

Go to Step 4Go to Step 5

3Note the “AIR BAG” warning lamp as ignition switch is turned

“ON”.

Does the “AIR BAG” warning lamp come “ON” steady?

Go to Chart BGo to Chart C

41. Note the “AIR BAG” warning lamp as that ignition switch is

turned “ON.”

Ignition switch “OFF.”

2. Connect a scan tool to data link connector.

3. Follow direction given in the scan tool instruction manual.

Ignition switch “ON.”

4. Request the SRS diagnostic trouble code display, recode all

history diagnostic trouble code(s). specify as such, on repair

order

Is (are) diagnostic trouble code(s) displayed?Ignition switch

“OFF”

When DTC 71 is

set, go to DTC 71

Chart

For all other

history codes

refer to

“Diagnostic Aids”

For that specific

DTC

A history DTC

indicates the

malfunction has

been repaired or

is intermittent

SRS is functional

and free of

malfuncitons, no

further diagnosis

is required

If scan tool

indicated “NO

DATA

RECEIVED,”

refer to chassis

electrical section8

51. Ignition switch “OFF.”

2. Connect a scan tool to data link connector.

3. Follow directions as given in the scan tool instruction manual.

4. Ignition switch “ON.”

5. Request the SRS diagnostic trouble code display, Recode all

diagnostic trouble code(s), specifying as current or history on

repair order.

Is (are) diagnostic trouble code (s) displayed?Ignition switch

“OFF”

When DTC 53 is

set, go to DTC 53

chart

When DTC 51 is

set, go to DTC 51

chart

When DTC 19 is

set, go to DTC 19

chart

When DTC 25 is

set, go to DTC 25

chart

Diagnose

remaining current

DTCs from

lowest to highest

When only history

DTCs exist, refer

to “Diagnostics

Aids” for that

specific DTC

A history DTC

indicates the

malfunction has

been repaired or

is intermittent

If scan tool

indicates “No

Data Received,”

refer to chassis

electrical section8

Page 3522 of 6000

9J1–35

RESTRAINT CONTROL SYSTEM

DTC 51 Air Bag Deployment Event Commanded

D09RW014

Circuit Description:

The SDM contains a sensing device which converts

vehicle velocity changes to an electrical signal. The

electrical signal generated is processed by the SDM and

then compared to a value stored in memory. When the

generated signal exceeds the stored value, the SDM will

cause current to flow through the air bag assembly

deploying the air bags and causing DTC 51 to set.

DTC Will Set When:

The SDM detects a frontal crash, up to 30 degrees off the

centerline of the vehicle, of sufficient force to warrant

deployment of the air bags.

Action Taken:

SDM turns “ON” the “AIR BAG” warning lamp records

“Crash Data”, and sets a diagnostic trouble code.

DTC Will Clear When:

The SDM is replaced.

DTC Chart Test Description:

Number(s) below refer to step number(s) on the

diagnostic chart:

2. If air bag assembly (s) has not deployed, DTC 51

may have falsely set.

3. If DTC 51 has set with no signs of frontal impact, the

diagnostic trouble code has falsely set.

Page 3524 of 6000

9J1–37

RESTRAINT CONTROL SYSTEM

DTC 53 Deployment Commanded With Deployment Loop Fault Or Energy

Reserves Out Of Range

D09RW014

Circuit Description:

The SDM contains a sensing drive which converts vehicle

velocity changes to an electrical signal. The electrical

signal generated is processed by the SDM and then

compared to a value stored in memory. When the

generated signal exceeds the stored value, the SDM will

cause current to flow through the air bag assembly

deploying the air bags. DTC 53 is set accompanying with

DTC 51 when a deployment occurs while an air bag

assembly circuit fault is present that could possible result

in a no deployment situation in one or both air bag

assemblies.

DTC Will Set When:

The SDM detects a frontal crash, up to 30 degrees off the

centerline of the vehicle, of sufficient force to warrant

deployment of the air bags and an inflator circuit fault is

present..

Action Taken:

SDM turns “ON” the “AIR BAG” warning lamp records

“Crash Data”, and sets a diagnostic trouble code.

DTC Will Clear When:

The SDM is replaced. If DTC 53 is set, one or more DTCs

will be set in addition to DTC 53. Malfunction(s) setting

DTC(s) (other than DTC 71) must be repaired so that

DTC(s) will not be set when a new SDM is installed.

DTC Chart Test Description:

Number(s) below refer to step number(s) on the

diagnostic chart:

2. If air bag assembly have not deployed, DTC 53 may

have falsely set.

3. If DTC 53 has set with no signs of frontal impact, the

diagnostic trouble code has falsely set.

Page 3550 of 6000

9J1–63

RESTRAINT CONTROL SYSTEM

DTC 52 Pretensioner Deployment Event Commanded

D09RW014

Circuit Description:

The SDM contains a sensing device which converts

vehicle velocity changes to an electrical signal. The

electrical signal generated is processed by the SDM and

then compared to a value stored in memory. When the

generated signal exceeds the stored value, the SDM will

cause current to flow through the pretensioner assembly

deploying the pretensioners and causing DTC 52 to set.

DTC Will Set When:

The SDM detects a frontal crash, up to 30 degrees off the

centerline of the vehicle, of sufficient force to warrant

deployment of the air bags and pretensioner seat belt.

Action Taken:

SDM turns “ON” the “AIR BAG” warning lamp records

“Crash Data”, and sets a diagnostic trouble code.

DTC Will Clear When:

The SDM is replaced.

DTC Chart Test Description:

Number(s) below refer to step number(s) on the

diagnostic chart:

2. If pretensioner assembly (s) has not deployed, DTC

52 may have falsely set.

3. If DTC 52 has set with no signs of frontal impact, the

diagnostic trouble code has falsely set.

Page 3566 of 6000

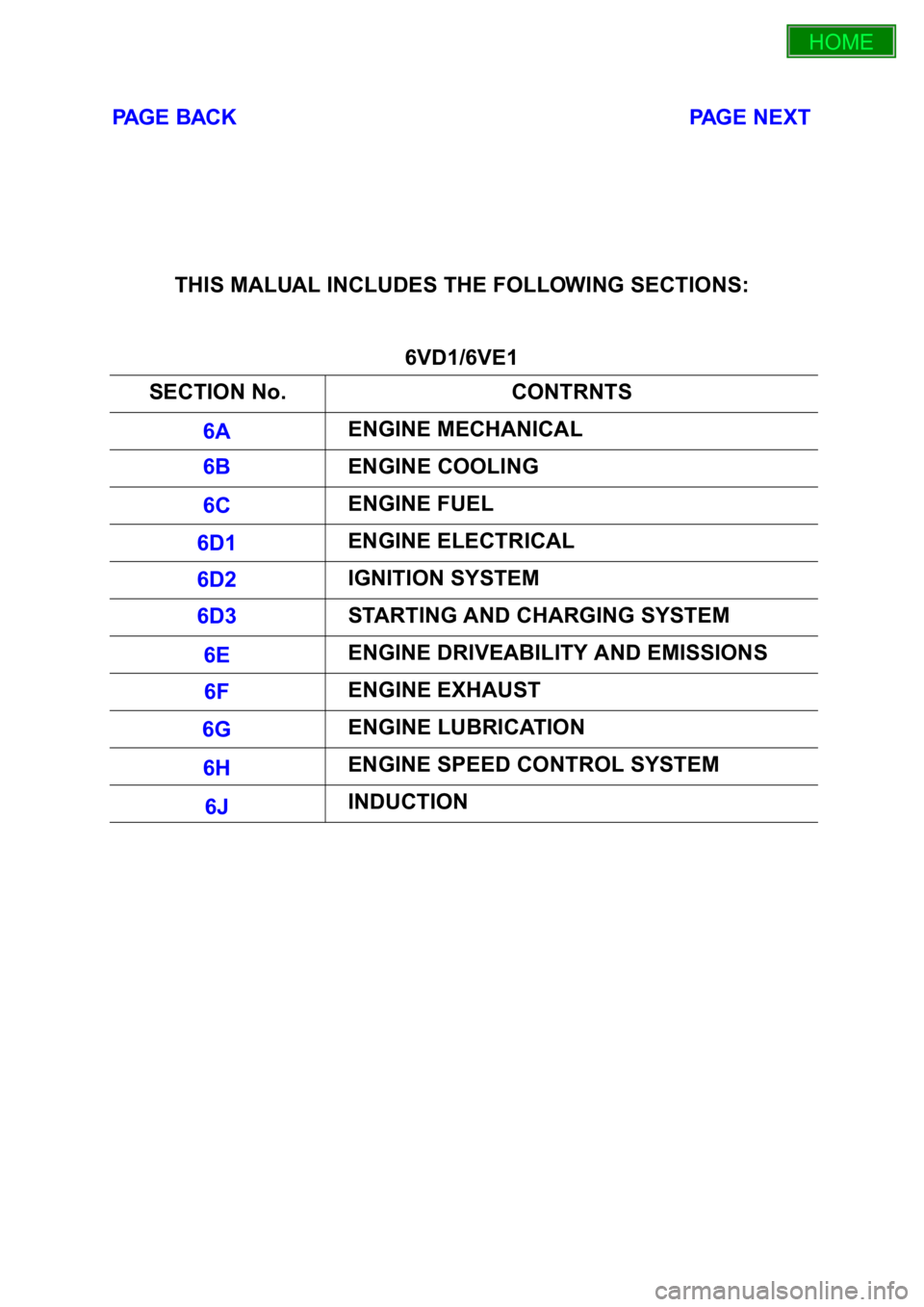

PAGE BACK PAGE NEXT

THIS MALUAL INCLUDES THE FOLLOWING SECTIONS:

6VD1/6VE1

SECTION No. CONTRNTS

6A ENGINE MECHANICAL

6B ENGINE COOLING

6C ENGINE FUEL

6D1 ENGINE ELECTRICAL

6D2 IGNITION SYSTEM

6D3 STARTING AND CHARGING SYSTEM

6E ENGINE DRIVEABILITY AND EMISSIONS

6F ENGINE EXHAUST

6G ENGINE LUBRICATION

6H ENGINE SPEED CONTROL SYSTEM

6J INDUCTION

HOME

6A

6B

6C

6D1

6D2

6D3

6E

6F

6G

6H

6J

Page 3567 of 6000

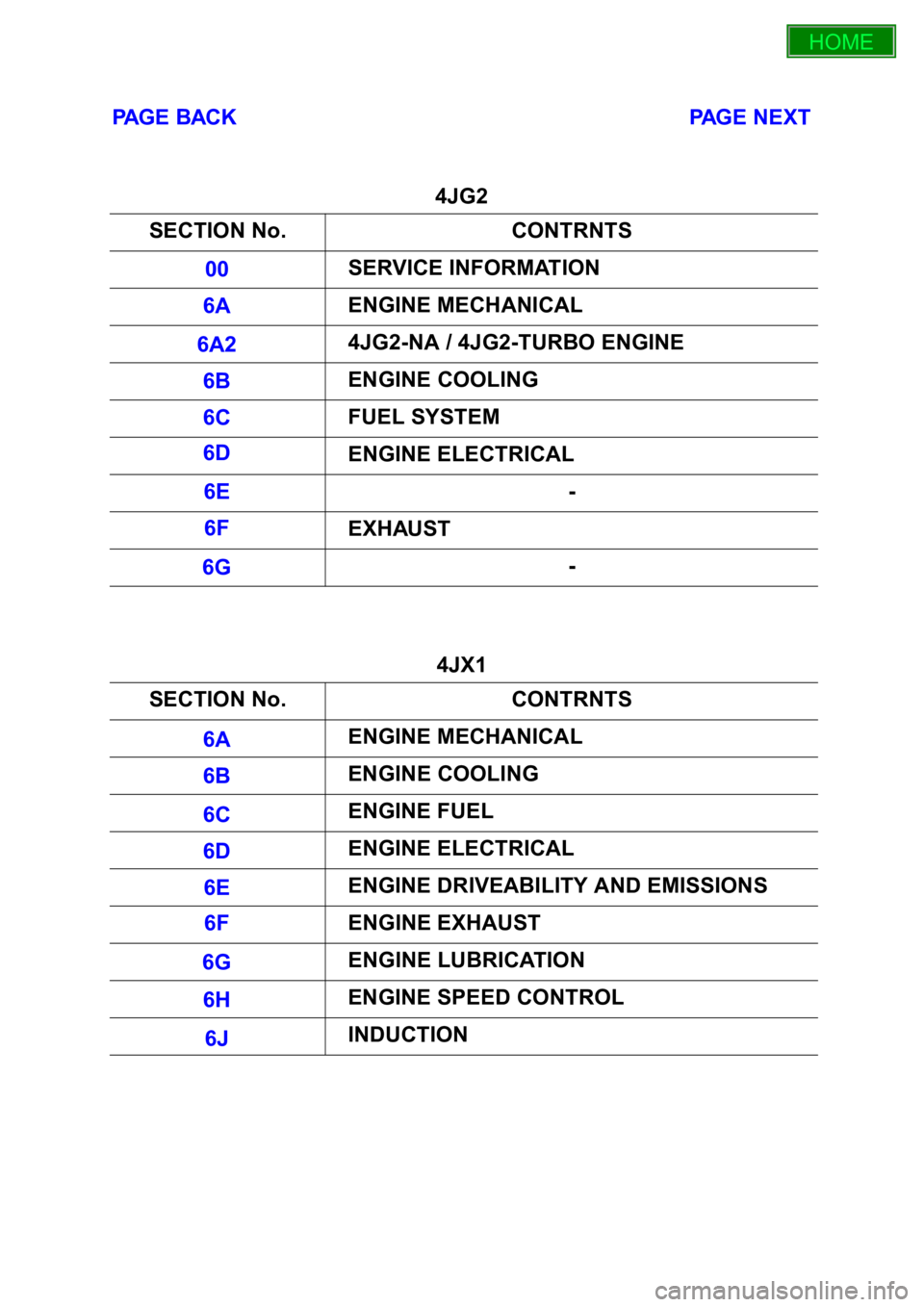

PAGE BACK PAGE NEXT

4JG2

4JX1 SECTION No. CONTRNTS

00 SERVICE INFORMATION

6A ENGINE MECHANICAL

6A2 4JG2-NA / 4JG2-TURBO ENGINE

6B ENGINE COOLING

6C FUEL SYSTEM

6D ENGINE ELECTRICAL

6E -

6F EXHAUST

6G -

SECTION No. CONTRNTS

6A ENGINE MECHANICAL

6B ENGINE COOLING

6C ENGINE FUEL

6D ENGINE ELECTRICAL

6E ENGINE DRIVEABILITY AND EMISSIONS

6F ENGINE EXHAUST

6G ENGINE LUBRICATION

6H ENGINE SPEED CONTROL

6J INDUCTION

HOME

00

6A

6A2

6B

6C

6D

6E

6F

6G

6A

6B

6C

6D

6E

6F

6G

6H

6J

Page 4052 of 6000

4B1–7 DRIVE LINE CONTROL SYSTEM (SHIFT ON THE FLY)

Shift on the Fly System (Push Button Type)

Outline of Shift on the Fly System (Push Button Type)

The shift on the fly system switches between 2 wheel

drive (2WD) and 4 wheel drive (4WD) electrically by

driver’s pressing the 4WD switch (push button type) on

instrument panel.

This system controls below operations. (Shifting between

“4H” and “4L” must be performed by transfer control lever

on the floor.)

1. Shifting the transfer front output gear (Connecting to,

and disconnecting from, front propeller shaft by motor

actuator).2. Retrial of shifting the transfer front output gear.

3. Connecting front wheels to, and disconnecting them

from, the front axles by vacuum actuator.

4. Indicator on instrument panel.

5. 4WD out signal to other Electronic Hydraulic Control

Unit (If anti–lock brake system is equipped).

System Diagrams

412RW050

Page 4355 of 6000

5A–5 BRAKE CONTROL SYSTEM

FR

Front Right

GEN

Generator

MV

Millivolts

RL

Rear Left

RR

Rear RightRPS

Revolution per Second

VDC

Vo l t s D C

VA C

Vo l t s A C

W/L

Warning Light

WSS

Wheel Speed Sensor

General Diagnosis

General Information

ABS malfunction can be classified into two types, those

which can be detected by the ABS warning light and those

which can be detected as a vehicle abnormality by the

driver.

In either case, locate the fault in accordance with the

“BASIC DIAGNOSTIC FLOWCHART” and repair.

Please refer to Section 5C for the diagnosis of

mechanical troubles such as brake noise, brake judder

(brake pedal or vehicle vibration felt when braking),

uneven braking, and parking brake trouble.

ABS Service Precautions

Required Tools and Items:

Box Wrench

Brake Fluid

Special Tool

Some diagnosis procedures in this section require the

installation of a special tool.

J-39200 High Impedance Multimeter

When circuit measurements are requested, use a circuit

tester with high impedance.

Computer System Service Precautions

The Anti-lock Brake System interfaces directly with the

Electronic Hydraulic Control Unit (EHCU) which is a

control computer that is similar in some regards to the

Powertrain Control Module. These modules are designed

to withstand normal current draws associated with

vehicle operation. However, care must be taken to avoid

overloading any of the EHCU circuits. In testing for opens

or shorts, do not ground or apply voltage to any of the

circuits unless instructed to do so by the appropriate

diagnostic procedure. These circuits should only be

tested with a high impedance multimeter (J-39200) or

special tools as described in this section. Power should

never be removed or applied to any control module with

the ignition in the “ON” position.

Before removing or connecting battery cables, fuses or

connectors, always turn the ignition switch to the “OFF”

position.

General Service Precautions

The following are general precautions which should be

observed when servicing and diagnosing the Anti-lock

Brake System and/or other vehicle systems. Failure toobserve these precautions may result in Anti-lock Brake

System damage.

If welding work is to be performed on the vehicle using

an electric arc welder, the EHCU and valve block

connectors should be disconnected before the

welding operation begins.

The EHCU and valve block connectors should never

be connected or disconnected with the ignition “ON” .

EHCU of the Anti-lock Brake System are not

separately serviceable and must be replaced as

assemblies. Do not disassemble any component

which is designated as non-serviceable in this

Section.

If only rear wheels are rotated using jacks or drum

tester, the system will diagnose a speed sensor

malfunction and the “ABS” warning light will

illuminate. But actually no trouble exists. After

inspection stop the engine once and re-start it, then

make sure that the “ABS” warning light does not

illuminate.

If the battery has been discharged

The engine may stall if the battery has been completely

discharged and the engine is started via jumper cables.

This is because the Anti-lock Brake System (ABS)

requires a large quantity of electricity. In this case, wait

until the battery is recharged, or set the ABS to a

non-operative state by removing the fuse for the ABS

(40A). After the battery has been recharged, stop the

engine and install the ABS fuse. Start the engine again,

and confirm that the ABS warning light does not light.

Note on Intermittents

As with virtually any electronic system, it is difficult to

identify an intermittent failure. In such a case duplicating

the system malfunction during a test drive or a good

description of vehicle behavior from the customer may be

helpful in locating a “most likely” failed component or

circuit. The symptom diagnosis chart may also be useful

in isolating the failure. Most intermittent problems are

caused by faulty electrical connections or wiring. When

an intermittent failure is encountered, check suspect

circuits for:

Suspected harness damage.

Poor mating of connector halves or terminals not fully

seated in the connector body (backed out).

Improperly formed or damaged terminals.