OPEL FRONTERA 1998 Workshop Manual

Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 271 of 6000

8. Install front valve plate.

Apply a coat of new compressor oil to the new

valve plate.

Install the valve plate to the suction valve by

aligning it with the spring pin.

NOTE

Do not mix up the front and rear valve plates.

9. Install gasket

Apply new compressor oil to the new gasket.

Install the gasket to the valve plate by a aligning it

with the spring pin.

10. Install o-ring.

11. Install front cylinder head.

Apply a coat of new compressor oil to the new O-

ring.

Install the O-ring to the front cylinder head.

Install the front cylinder head.

Tap the front cylinder head into place with a

plastic hammer.

NOTE

When installing the cylinder head, be careful

that the end of the drive shaft does not

damage the shaft seal assembly surface in the

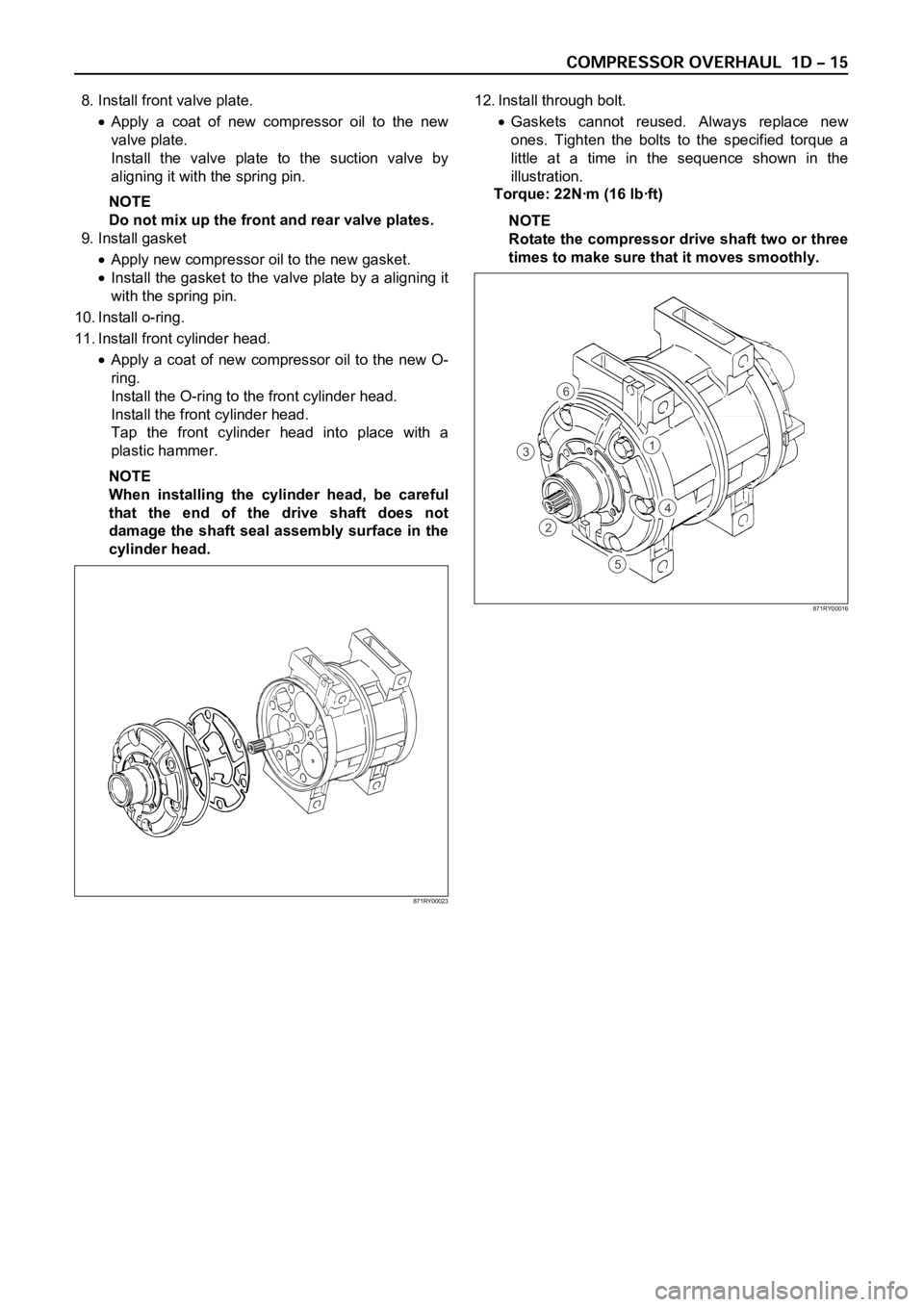

cylinder head.12. Install through bolt.

Gaskets cannot reused. Always replace new

ones. Tighten the bolts to the specified torque a

little at a time in the sequence shown in the

illustration.

Torque: 22Nꞏm (16 lbꞏft)

NOTE

Rotate the compressor drive shaft two or three

times to make sure that it moves smoothly.

1

4

5

2

3

6

871RY00016

871RY00023

Page 272 of 6000

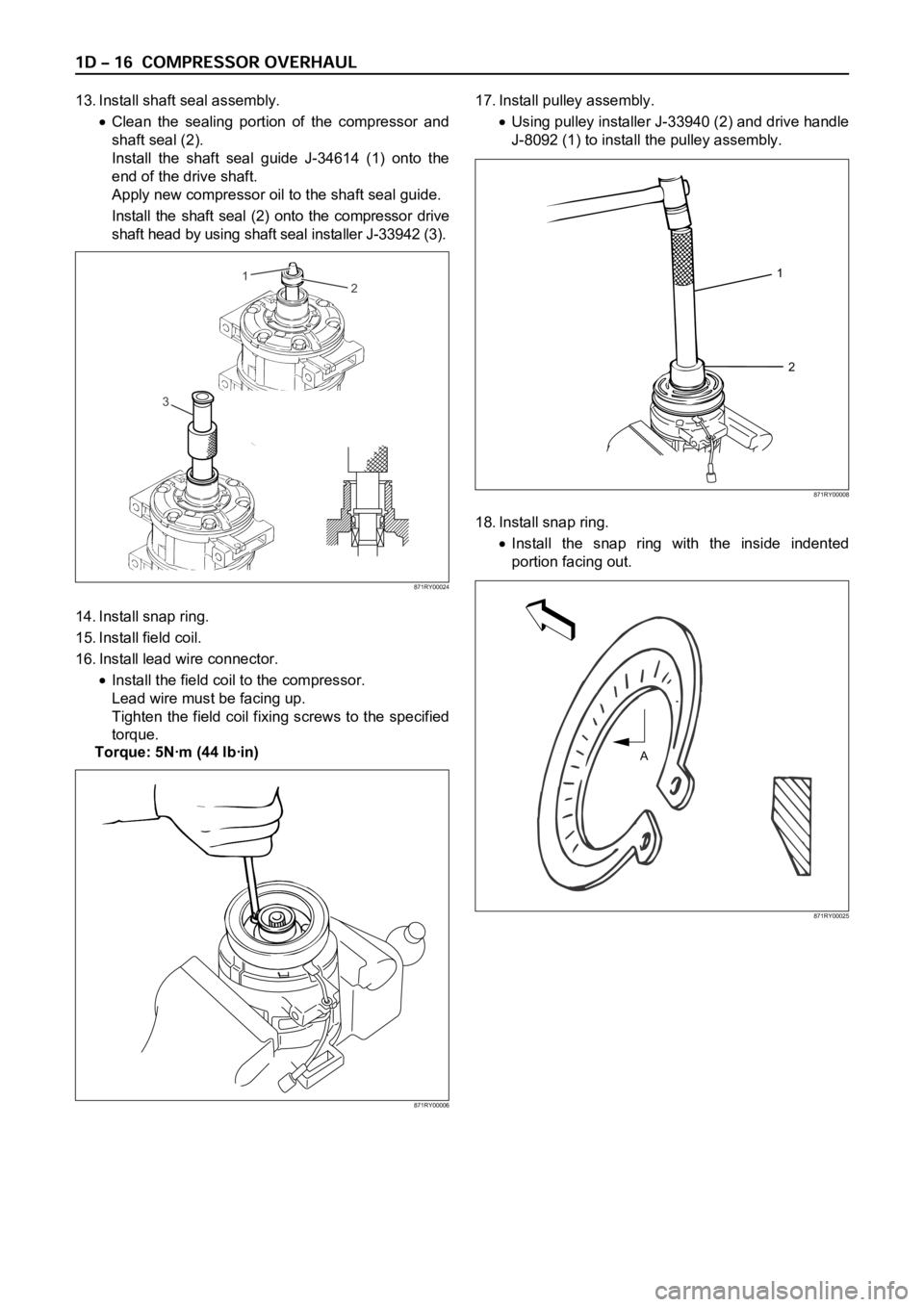

13. Install shaft seal assembly.

Clean the sealing portion of the compressor and

shaft seal (2).

Install the shaft seal guide J-34614 (1) onto the

end of the drive shaft.

Apply new compressor oil to the shaft seal guide.

Install the shaft seal (2) onto the compressor drive

shaft head by using shaft seal installer J-33942 (3).

14. Install snap ring.

15. Install field coil.

16. Install lead wire connector.

Install the field coil to the compressor.

Lead wire must be facing up.

Tighten the field coil fixing screws to the specified

torque.

Torque: 5Nꞏm (44 lbꞏin)17. Install pulley assembly.

Using pulley installer J-33940 (2) and drive handle

J-8092 (1) to install the pulley assembly.

18. Install snap ring.

Install the snap ring with the inside indented

portion facing out.

871RY00006

32 1

871RY00024

A

871RY00025

1

2

871RY00008

Page 273 of 6000

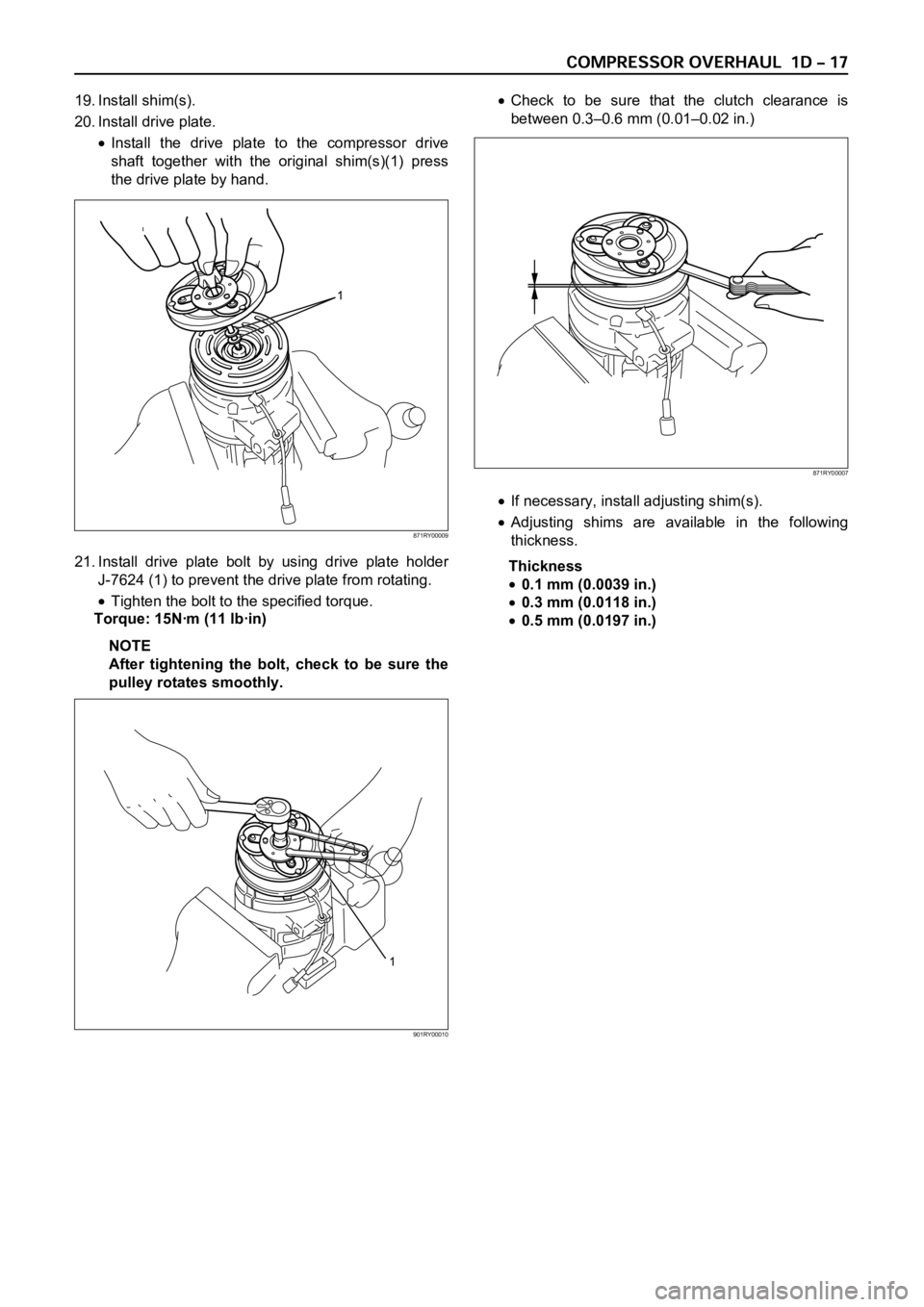

19. Install shim(s).

20. Install drive plate.

Install the drive plate to the compressor drive

shaft together with the original shim(s)(1) press

the drive plate by hand.

21. Install drive plate bolt by using drive plate holder

J-7624 (1) to prevent the drive plate from rotating.

Tighten the bolt to the specified torque.

Torque: 15Nꞏm (11 lbꞏin)

NOTE

After tightening the bolt, check to be sure the

pulley rotates smoothly.

Check to be sure that the clutch clearance is

between 0.3–0.6 mm (0.01–0.02 in.)

If necessary, install adjusting shim(s).

Adjusting shims are available in the following

thickness.

Thickness

0.1 mm (0.0039 in.)

0.3 mm (0.0118 in.)

0.5 mm (0.0197 in.)

1

871RY00009

871RY00007

1

901RY00010

Page 274 of 6000

HD6 TYPE COMPRESSOR

Metric Thread Size Information

Compressor to mounting bracket bolts (Front)

M10

1.5 – 6H

Compressor to mounting bracket bolts (Rear)

M8

1.25 – 6H

Suction-discharge port screw

M10

1.5 – 6HCompressor shaft

M9

1.25 – 6H

Internal hub-clutch drive assembly

M22

1.5 – 6H

COMPRESSOR CLUTCH PLATE AND HUB

ASSEMBLY

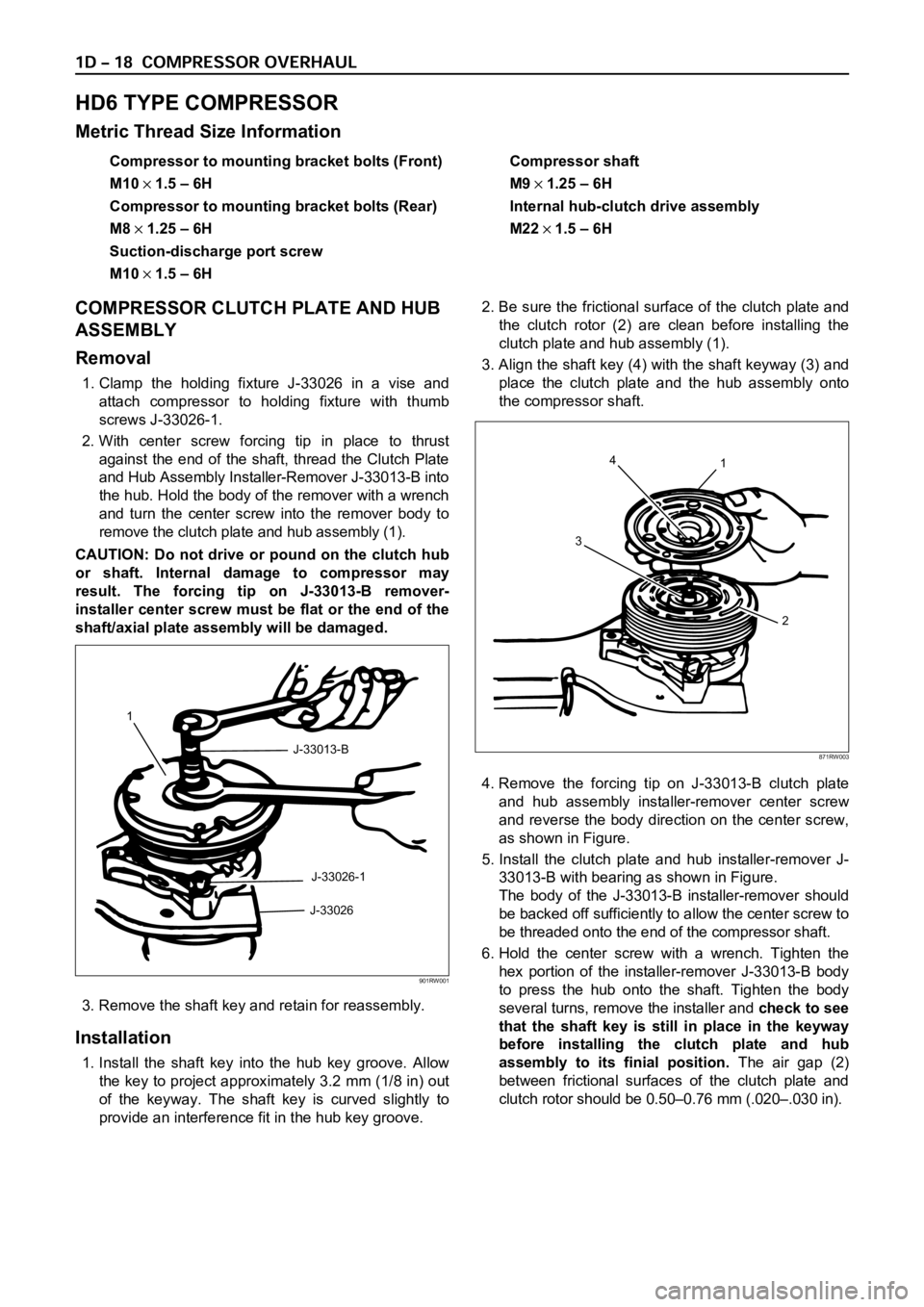

Removal

1. Clamp the holding fixture J-33026 in a vise and

attach compressor to holding fixture with thumb

screws J-33026-1.

2. With center screw forcing tip in place to thrust

against the end of the shaft, thread the Clutch Plate

and Hub Assembly Installer-Remover J-33013-B into

the hub. Hold the body of the remover with a wrench

and turn the center screw into the remover body to

remove the clutch plate and hub assembly (1).

CAUTION: Do not drive or pound on the clutch hub

or shaft. Internal damage to compressor may

result. The forcing tip on J-33013-B remover-

installer center screw must be flat or the end of the

shaft/axial plate assembly will be damaged.

3. Remove the shaft key and retain for reassembly.

Installation

1. Install the shaft key into the hub key groove. Allow

the key to project approximately 3.2 mm (1/8 in) out

of the keyway. The shaft key is curved slightly to

provide an interference fit in the hub key groove.2. Be sure the frictional surface of the clutch plate and

the clutch rotor (2) are clean before installing the

clutch plate and hub assembly (1).

3. Align the shaft key (4) with the shaft keyway (3) and

place the clutch plate and the hub assembly onto

the compressor shaft.

4. Remove the forcing tip on J-33013-B clutch plate

and hub assembly installer-remover center screw

and reverse the body direction on the center screw,

as shown in Figure.

5. Install the clutch plate and hub installer-remover J-

33013-B with bearing as shown in Figure.

The body of the J-33013-B installer-remover should

be backed off sufficiently to allow the center screw to

be threaded onto the end of the compressor shaft.

6. Hold the center screw with a wrench. Tighten the

hex portion of the installer-remover J-33013-B body

to press the hub onto the shaft. Tighten the body

several turns, remove the installer and check to see

that the shaft key is still in place in the keyway

before installing the clutch plate and hub

assembly to its finial position.The air gap (2)

between frictional surfaces of the clutch plate and

clutch rotor should be 0.50–0.76 mm (.020–.030 in).

1

J-33013-B

J-33026-1

J-33026

901RW001

4

31

2

871RW003

Page 275 of 6000

CAUTION: If the center screw is threaded fully onto

the end of the compressor shaft. or if the body of

the installer is held and the center screw is rotated,

the key will wedge and will break the clutch hub.7. Remove installer J-33013-B, check for proper

positioning of the shaft key (even or slightly above

the clutch hub).

8. Spin the pulley rotor by hand to see that the rotor is

not rubbing the clutch drive plate.

COMPRESSOR CLUTCH ROTOR AND/OR

BEARING

Removal

1. Remove the clutch plate and hub assembly as

described previously.

2. Remove rotor (1) and bearing assembly retaining

ring (2), using snap ring pliers.

3. Install pulley rotor and bearing puller guide J-33023-A

to the front head and install J-41552 pulley rotor and

bearing puller down into the inner circle of slots (1) in

the rotor. Turn the J-41552 puller clockwise in the

slots in the rotor.4.Hold the J-41552 puller in place and tighten the

puller screw against the puller guide to remove the

pulley rotor and bearing assembly.

Installation

1. With the compressor mounted to the J-34992

holding fixture, position the rotor and bearing

assembly on the front head.

2. Position the J-33017 pulley, rotor and bearing

installer and J-33023-A puller pilot directly over the

inner race of the bearing.

1

2 J-33013-B

901RW002

1

2

901RW003

J-41552

1

871RW007

Page 276 of 6000

3. Position puller crossbar J-8433-1 on the puller pilot

J-33023-A and assemble the two J-33026 through

bolts and washers through the puller bar slots and

thread them into the J-33026 holding fixture. The

thread of the through bolts should engage the full

thickness of the holding fixture.

4. Tighten the center screw in the J-8433-1 puller

crossbar to force the pulley rotor (1) and bearing

assembly onto the compressor front head. Should

the J-33017 pulley rotor and bearing installer slip off

direct in-line contact with the inner race of the

bearing, loosen the J-8433-1 center forcing screw

and realign the installer and pilot so that the J-

33017 installer will properly clear the front head.5. Install rotor and bearing assembly retainer ring,

using snap ring pliers.

6. Reinstall clutch plate and hub assembly as

described previously.

COMPRESSOR CLUTCH COIL

Removal

1. Perform Steps 1 through 4 of "Clutch Rotor and/or

Bearings" removal procedure. Mark clutch coil

terminal location (1) on compressor front head.

2. Install J-33023-A puller pilot on front head of

compressor. Also install J-8433-1 puller crossbar

with J-33025 puller legs as shown in figure.

3. Tighten J-8433-3 forcing screw against the puller

pilot to remove the clutch coil (2).

J-8433-3

J-33023

J-33026 J-8433-1

J-33017

1

901RW005

J-33023-AJ-8433-3

J-8433-1

J-33025

1 2

901RW006

Page 277 of 6000

Installation

1. Place the clutch coil assembly (1) on the front head

with the terminals positioned at the "marked" location.

2. Place the J-33024 clutch coil installer over the

internal opening of the clutch coil housing and align

installer with the compressor front head.

3. Center the J-8433-1 puller crossbar in the counter-

sunk center hole of the J-33024 clutch coil installer.

Install the J-33026 through bolts and washers

through the crossbar slots and thread them into the

holding fixture J-33026 to full fixture thickness.

4. Turn the center forcing screw of J-8433-1 puller

crossbar to force the clutch coil onto the front head.

Be sure clutch coil and J-33024 installer stay "in-

line" during installation.

5. When coil is fully seated on the front head, use a

1/8 in diameter drift punch (2) and stake the front

head at three places 120 degrees apart, to ensure

clutch coil (3) remains in position.

Stake size should be only one-half the area of the

punch tip and be only approximately 0.28–0.35

mm (.010–.015 in) deep.

Legend

(1) Stake Front Head 0.28–0.35 mm Deep

(0.10–015 in)

(2) Clutch Coil Housing

(3) Front Head Surface

6. Install rotor and bearing assembly and the clutch

plate and hub assembly as described previously.

J-8433-3

J-8433-1

J-33024

1

901RW007

2

3

871RW004

1

23

871RW005

Page 278 of 6000

COMPRESSOR SHAFT SEAL

Service Precaution

When replacing the shaft seal assembly, pressure relief

valve or control switches, it will be necessary to recover

the refrigerant. Other than clutch repair procedures, the

same holds true for any disassembly of the compressor.

A clean workbench covered with a sheet of clean

paper, and a place (clean trays, etc) for all parts being

removed and replaced is important, as is the use of

proper clean service tools.

CAUTION: Any attempt to use makeshift or

inadequate service tools or equipment may result

in damage and/or improper compressor operation.

All parts required for servicing the internal compressor

are protected by a preservative process and packaged

in a manner which will eliminate the necessity of

cleaning, washing or flushing of the parts. The parts

can be used in the internal assembly just as they are

removed from the service package. Seals and

protective packaging should be left intact until just

prior to installation.

If the compressor rear head, front head or cylinder and

shaft assembly is to be serviced or replaced, the oil in

the compressor must be drained, measured, recorded

and replaced.

Legend

(1) Suction Port

(2) Discharge Port

(3) Mounting Boss

(4) Mounting Boss

(5) Pressure Relief Valve

(6) Mounting Boss

Seal Leak Detection

A shaft seal should not be changed because of small

amounts of oil found on an adjacent surface but only

after actual refrigerant leakage is found using an

approved leak detector.

CAUTION: Handling and care of seal protector is

important. If seal protector is nicked or the bottom

flared, the new seal may be damaged during

installation.

Removal

1. Recover the refrigerant using Refrigerant Recovery

System.

2. Loosen and reposition compressor in mounting

brackets, if necessary.

3. Remove clutch plate and hub assembly from

compressor as described previously.

4. Remove the shaft seal retainer ring, using snap ring

pliers.

5. Thoroughly clean inside of compressor neck area

surrounding the shaft, the exposed portion of the

seal, the retainer ring groove and the shaft itself.

Any dirt or foreign material getting into compressor

may cause damage.

6. Fully engage the knurled tangs of Seal Remover-

Installer J-23128-A into the recessed portion of the

Seal (1) by turning the handle clockwise. Remove

the Seal from the compressor with a rotary-pulling

motion.

Discard the seal. The handle must be hand-

tightened securely. Do not use a wrench or pliers.

1

2

3

456

871RW006

J-23128-A1

901RW008

Page 279 of 6000

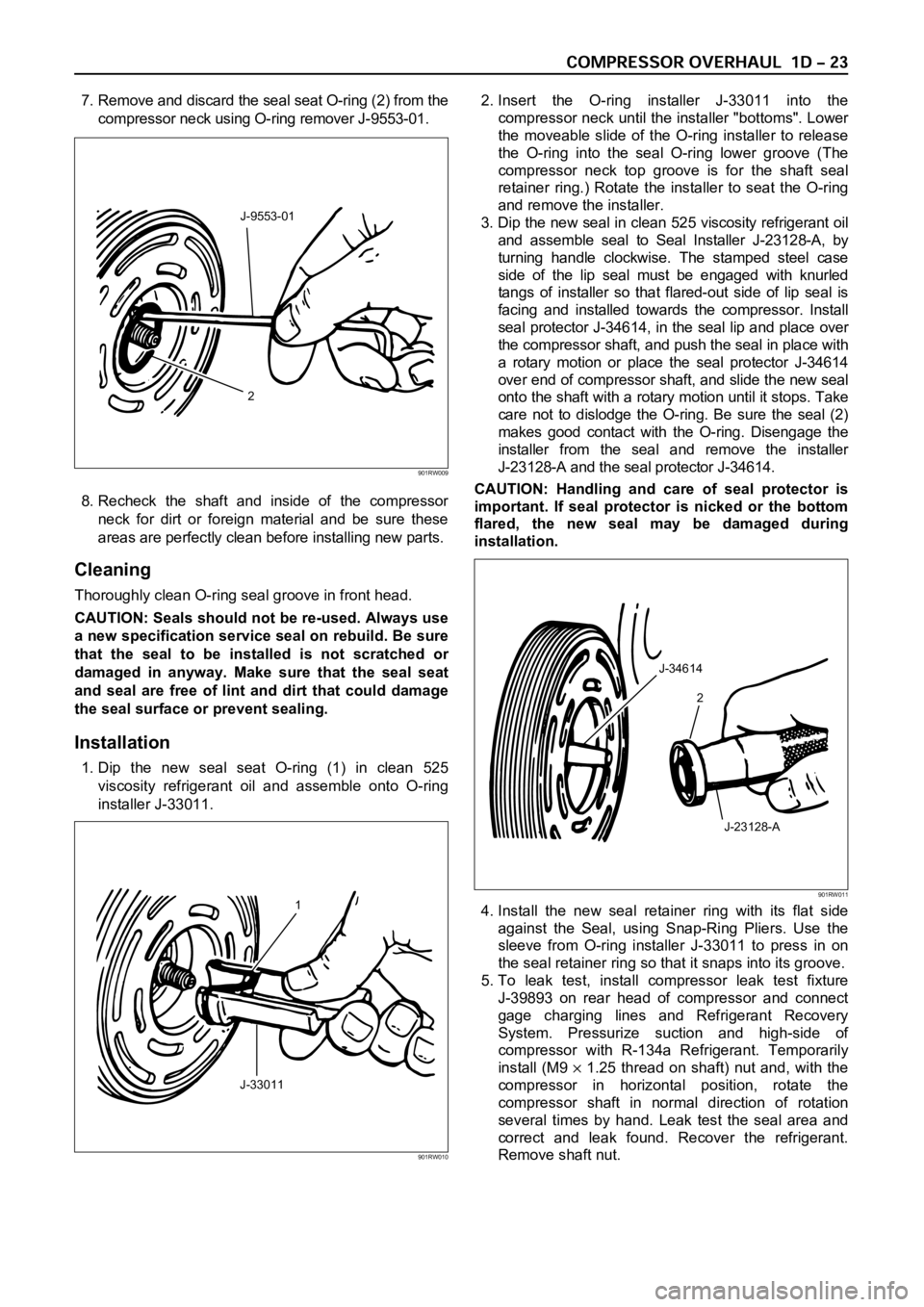

7. Remove and discard the seal seat O-ring (2) from the

compressor neck using O-ring remover J-9553-01.

8. Recheck the shaft and inside of the compressor

neck for dirt or foreign material and be sure these

areas are perfectly clean before installing new parts.

Cleaning

Thoroughly clean O-ring seal groove in front head.

CAUTION: Seals should not be re-used. Always use

a new specification service seal on rebuild. Be sure

that the seal to be installed is not scratched or

damaged in anyway. Make sure that the seal seat

and seal are free of lint and dirt that could damage

the seal surface or prevent sealing.

Installation

1. Dip the new seal seat O-ring (1) in clean 525

viscosity refrigerant oil and assemble onto O-ring

installer J-33011.2. Insert the O-ring installer J-33011 into the

compressor neck until the installer "bottoms". Lower

the moveable slide of the O-ring installer to release

the O-ring into the seal O-ring lower groove (The

compressor neck top groove is for the shaft seal

retainer ring.) Rotate the installer to seat the O-ring

and remove the installer.

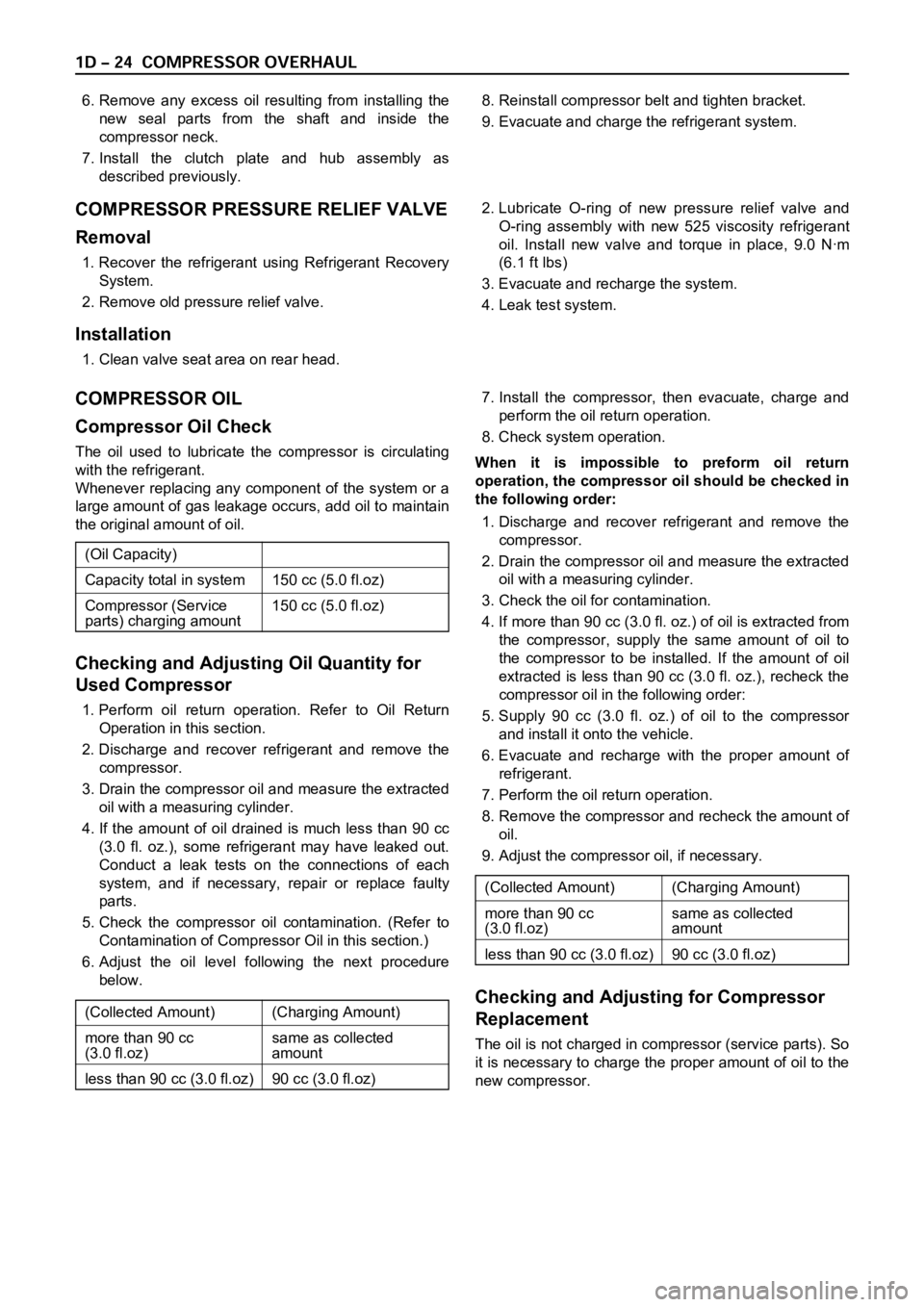

3. Dip the new seal in clean 525 viscosity refrigerant oil

and assemble seal to Seal Installer J-23128-A, by

turning handle clockwise. The stamped steel case

side of the lip seal must be engaged with knurled

tangs of installer so that flared-out side of lip seal is

facing and installed towards the compressor. Install

seal protector J-34614, in the seal lip and place over

the compressor shaft, and push the seal in place with

a rotary motion or place the seal protector J-34614

over end of compressor shaft, and slide the new seal

onto the shaft with a rotary motion until it stops. Take

care not to dislodge the O-ring. Be sure the seal (2)

makes good contact with the O-ring. Disengage the

installer from the seal and remove the installer

J-23128-A and the seal protector J-34614.

CAUTION: Handling and care of seal protector is

important. If seal protector is nicked or the bottom

flared, the new seal may be damaged during

installation.

4. Install the new seal retainer ring with its flat side

against the Seal, using Snap-Ring Pliers. Use the

sleeve from O-ring installer J-33011 to press in on

the seal retainer ring so that it snaps into its groove.

5. To leak test, install compressor leak test fixture

J-39893 on rear head of compressor and connect

gage charging lines and Refrigerant Recovery

System. Pressurize suction and high-side of

compressor with R-134a Refrigerant. Temporarily

install (M9

1.25 thread on shaft) nut and, with the

compressor in horizontal position, rotate the

compressor shaft in normal direction of rotation

several times by hand. Leak test the seal area and

correct and leak found. Recover the refrigerant.

Remove shaft nut.

2 J-9553-01

901RW009

1

J-33011

901RW010

J-34614

2

J-23128-A

901RW011

Page 280 of 6000

6. Remove any excess oil resulting from installing the

new seal parts from the shaft and inside the

compressor neck.

7. Install the clutch plate and hub assembly as

described previously.8. Reinstall compressor belt and tighten bracket.

9. Evacuate and charge the refrigerant system.

COMPRESSOR PRESSURE RELIEF VALVE

Removal

1. Recover the refrigerant using Refrigerant Recovery

System.

2. Remove old pressure relief valve.

Installation

1. Clean valve seat area on rear head.2. Lubricate O-ring of new pressure relief valve and

O-ring assembly with new 525 viscosity refrigerant

oil. Install new valve and torque in place, 9.0 Nꞏm

(6.1 ft lbs)

3. Evacuate and recharge the system.

4. Leak test system.

COMPRESSOR OIL

Compressor Oil Check

The oil used to lubricate the compressor is circulating

with the refrigerant.

Whenever replacing any component of the system or a

large amount of gas leakage occurs, add oil to maintain

the original amount of oil.

Checking and Adjusting Oil Quantity for

Used Compressor

1. Perform oil return operation. Refer to Oil Return

Operation in this section.

2. Discharge and recover refrigerant and remove the

compressor.

3. Drain the compressor oil and measure the extracted

oil with a measuring cylinder.

4. If the amount of oil drained is much less than 90 cc

(3.0 fl. oz.), some refrigerant may have leaked out.

Conduct a leak tests on the connections of each

system, and if necessary, repair or replace faulty

parts.

5. Check the compressor oil contamination. (Refer to

Contamination of Compressor Oil in this section.)

6. Adjust the oil level following the next procedure

below.7. Install the compressor, then evacuate, charge and

perform the oil return operation.

8. Check system operation.

When it is impossible to preform oil return

operation, the compressor oil should be checked in

the following order:

1. Discharge and recover refrigerant and remove the

compressor.

2. Drain the compressor oil and measure the extracted

oil with a measuring cylinder.

3. Check the oil for contamination.

4. If more than 90 cc (3.0 fl. oz.) of oil is extracted from

the compressor, supply the same amount of oil to

the compressor to be installed. If the amount of oil

extracted is less than 90 cc (3.0 fl. oz.), recheck the

compressor oil in the following order:

5. Supply 90 cc (3.0 fl. oz.) of oil to the compressor

and install it onto the vehicle.

6. Evacuate and recharge with the proper amount of

refrigerant.

7. Perform the oil return operation.

8. Remove the compressor and recheck the amount of

oil.

9. Adjust the compressor oil, if necessary.

Checking and Adjusting for Compressor

Replacement

The oil is not charged in compressor (service parts). So

it is necessary to charge the proper amount of oil to the

new compressor. (Oil Capacity)

Capacity total in system 150 cc (5.0 fl.oz)

Compressor (Service 150 cc (5.0 fl.oz)

parts) charging amount

(Collected Amount) (Charging Amount)

more than 90 cc same as collected

(3.0 fl.oz) amount

less than 90 cc (3.0 fl.oz) 90 cc (3.0 fl.oz)

(Collected Amount) (Charging Amount)

more than 90 cc same as collected

(3.0 fl.oz) amount

less than 90 cc (3.0 fl.oz) 90 cc (3.0 fl.oz)