OPEL FRONTERA 1998 Workshop Manual

Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 261 of 6000

871RX013

Page 262 of 6000

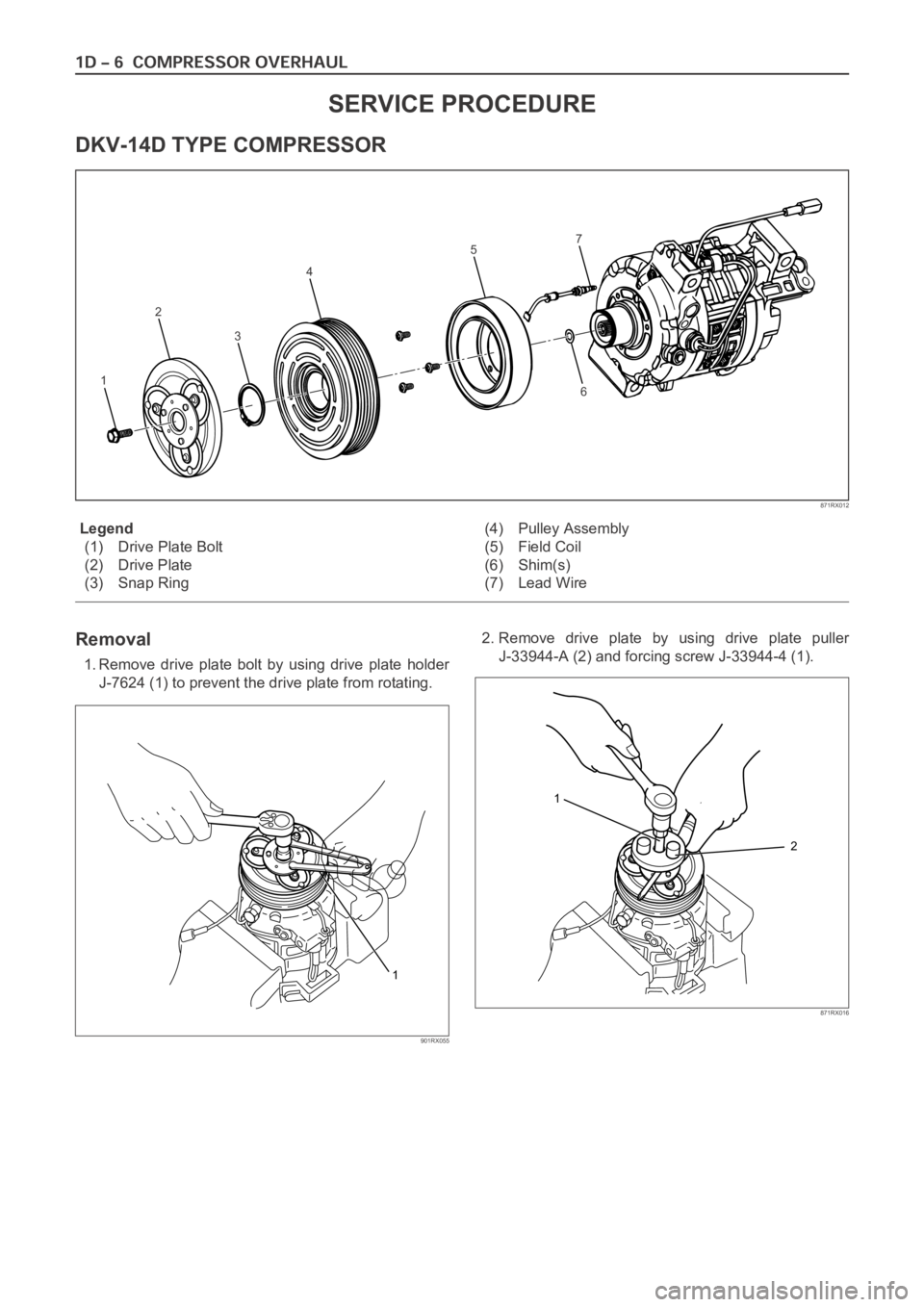

Legend

(1) Drive Plate Bolt

(2) Drive Plate

(3) Snap Ring(4) Pulley Assembly

(5) Field Coil

(6) Shim(s)

(7) Lead Wire

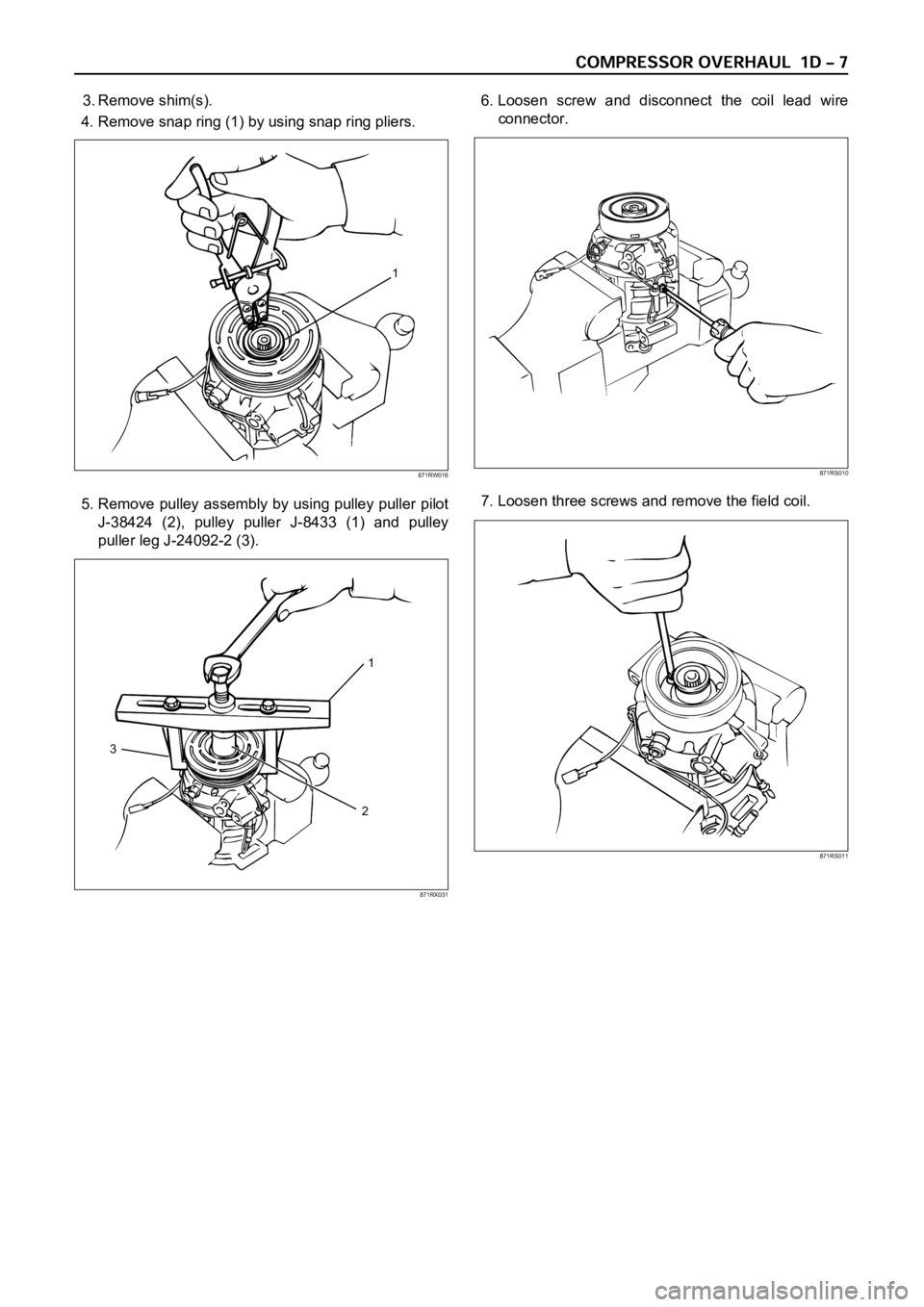

Removal

1. Remove drive plate bolt by using drive plate holder

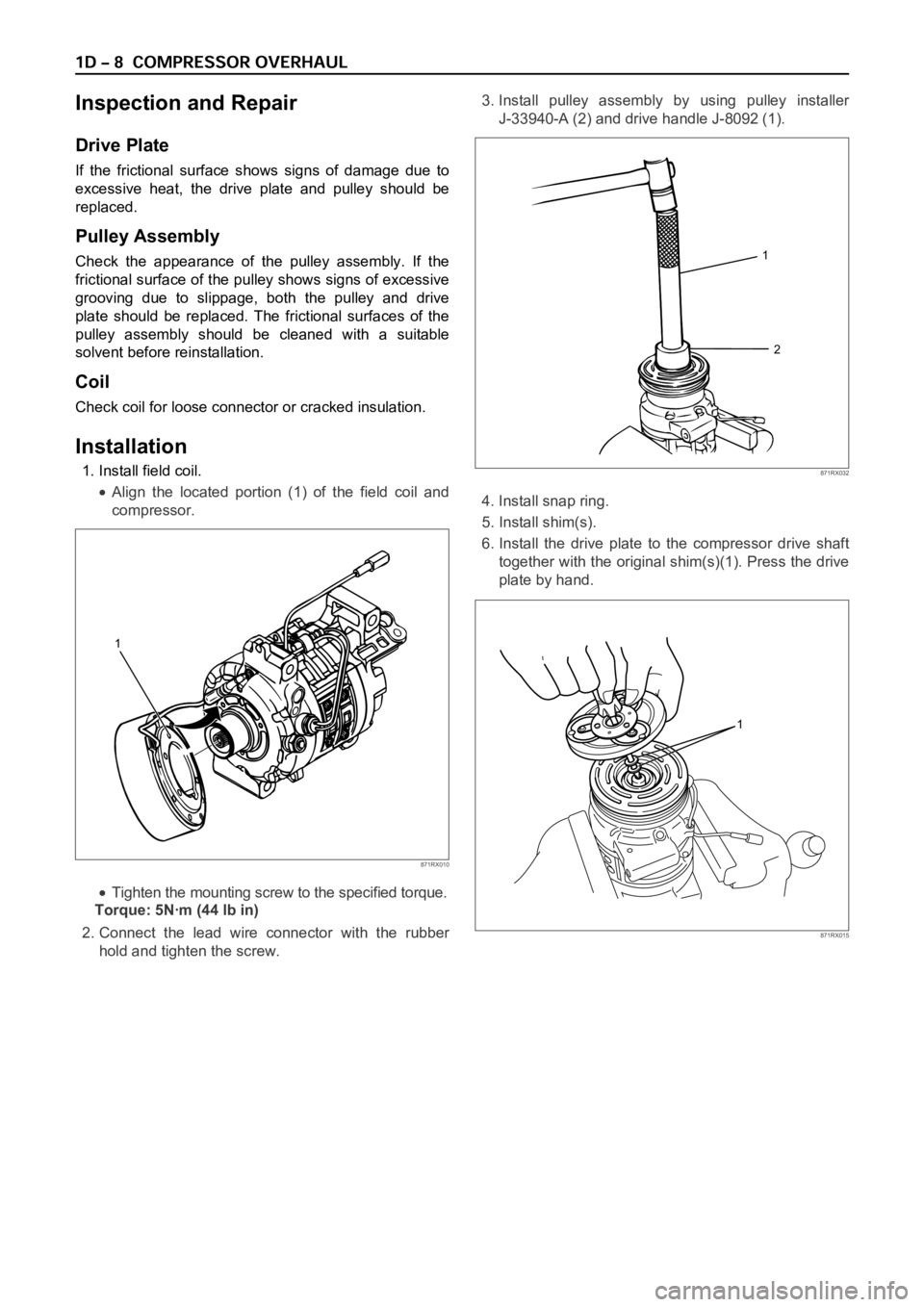

J-7624 (1) to prevent the drive plate from rotating.2. Remove drive plate by using drive plate puller

J-33944-A (2) and forcing screw J-33944-4 (1).

SERVICE PROCEDURE

DKV-14D TYPE COMPRESSOR

1

2

3

4

5

67

871RX012

1

901RX055

1

2

871RX016

Page 263 of 6000

3. Remove shim(s).

4. Remove snap ring (1) by using snap ring pliers.

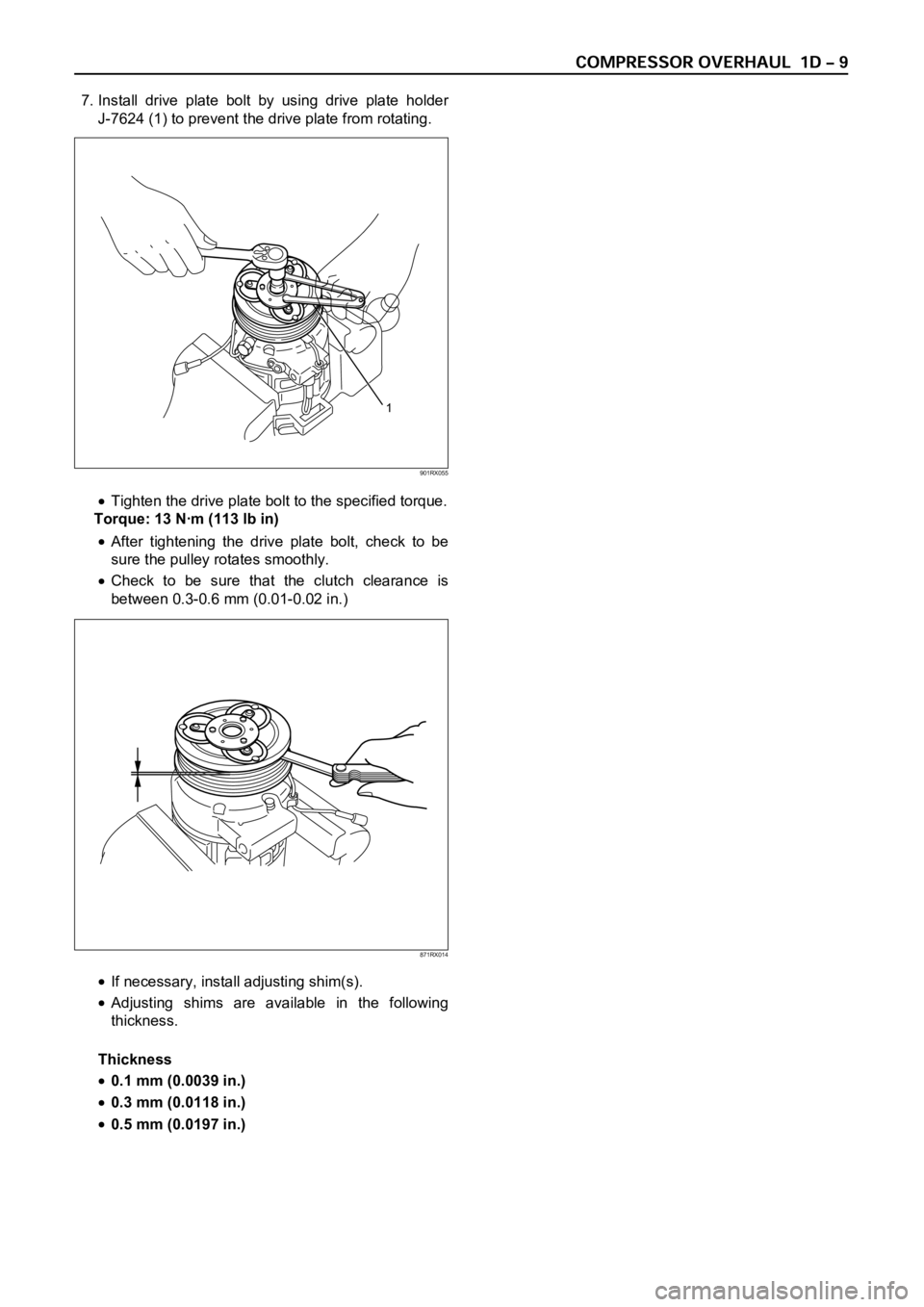

5. Remove pulley assembly by using pulley puller pilot

J-38424 (2), pulley puller J-8433 (1) and pulley

puller leg J-24092-2 (3).6. Loosen screw and disconnect the coil lead wire

connector.

7. Loosen three screws and remove the field coil.

1

871RW016871RS010

3

1

2

871RX031

871RS011

Page 264 of 6000

Inspection and Repair

Drive Plate

If the frictional surface shows signs of damage due to

excessive heat, the drive plate and pulley should be

replaced.

Pulley Assembly

Check the appearance of the pulley assembly. If the

frictional surface of the pulley shows signs of excessive

grooving due to slippage, both the pulley and drive

plate should be replaced. The frictional surfaces of the

pulley assembly should be cleaned with a suitable

solvent before reinstallation.

Coil

Check coil for loose connector or cracked insulation.

Installation

1. Install field coil.

Align the located portion (1) of the field coil and

compressor.

Tighten the mounting screw to the specified torque.

Torque: 5Nꞏm (44 lb in)

2. Connect the lead wire connector with the rubber

hold and tighten the screw.3. Install pulley assembly by using pulley installer

J-33940-A (2) and drive handle J-8092 (1).

4. Install snap ring.

5. Install shim(s).

6. Install the drive plate to the compressor drive shaft

together with the original shim(s)(1). Press the drive

plate by hand.

1

2

871RX032

1

871RX010

1

871RX015

Page 265 of 6000

7. Install drive plate bolt by using drive plate holder

J-7624 (1) to prevent the drive plate from rotating.

Tighten the drive plate bolt to the specified torque.

Torque: 13 Nꞏm (113 lb in)

After tightening the drive plate bolt, check to be

sure the pulley rotates smoothly.

Check to be sure that the clutch clearance is

between 0.3-0.6 mm (0.01-0.02 in.)

If necessary, install adjusting shim(s).

Adjusting shims are available in the following

thickness.

Thickness

0.1 mm (0.0039 in.)

0.3 mm (0.0118 in.)

0.5 mm (0.0197 in.)

1

901RX055

871RX014

Page 266 of 6000

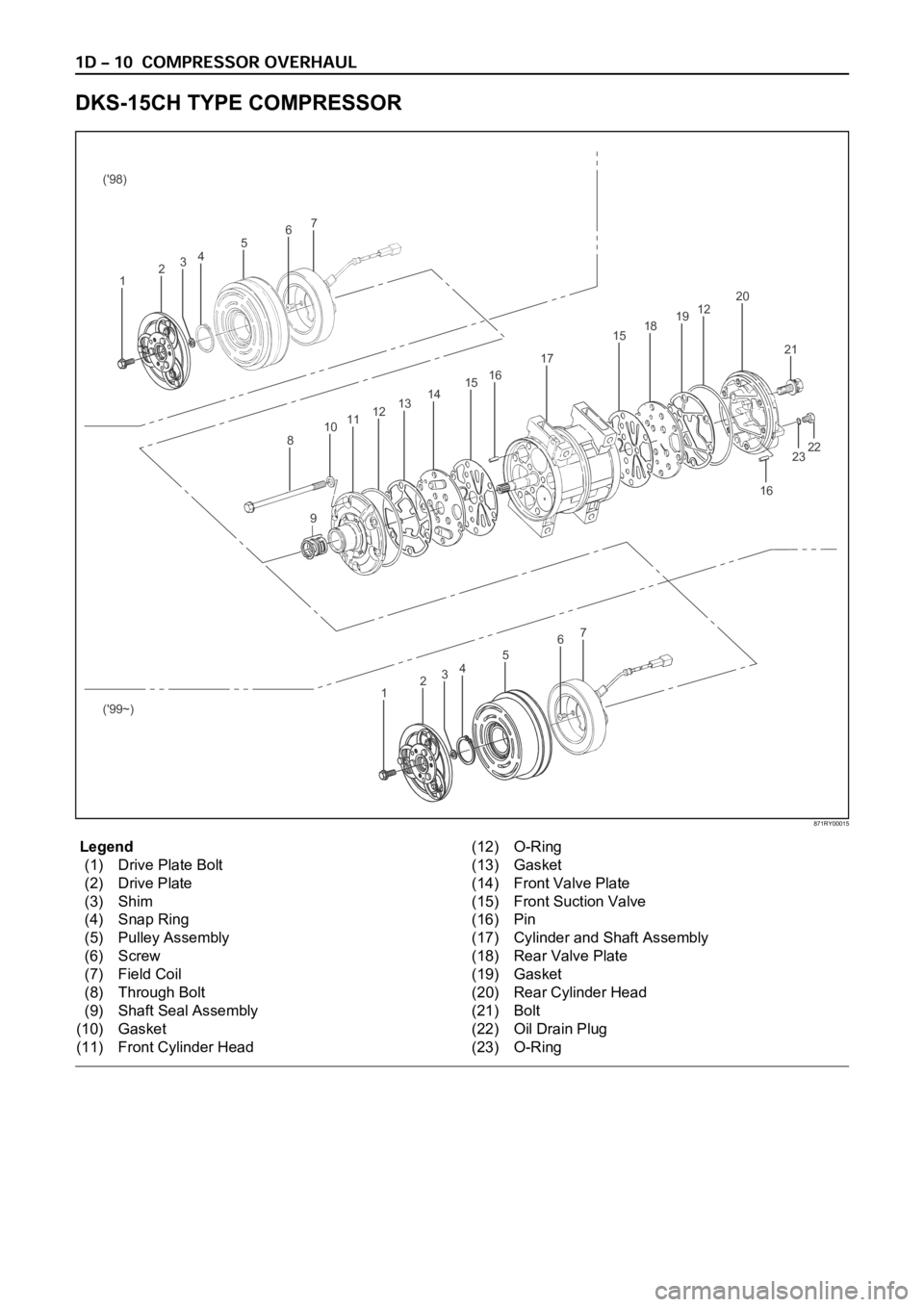

Legend

(1) Drive Plate Bolt

(2) Drive Plate

(3) Shim

(4) Snap Ring

(5) Pulley Assembly

(6) Screw

(7) Field Coil

(8) Through Bolt

(9) Shaft Seal Assembly

(10) Gasket

(11) Front Cylinder Head(12) O-Ring

(13) Gasket

(14) Front Valve Plate

(15) Front Suction Valve

(16) Pin

(17) Cylinder and Shaft Assembly

(18) Rear Valve Plate

(19) Gasket

(20) Rear Cylinder Head

(21) Bolt

(22) Oil Drain Plug

(23) O-Ring

DKS-15CH TYPE COMPRESSOR

16

23 2122 6

7

45

321 ('98)

('99~)

67

45

321

8

910111213141516

17

1518191220

871RY00015

Page 267 of 6000

Removal

1. Remove drive plate bolt by using drive plate holder

J-7624 (1) to prevent the drive plate from rotating.

2. Remove drive plate by using drive plate puller

J-33944-A (2) and forcing screw J-33944-4 (1).3. Remove shim(s).

4. Remove snap ring (1) by using snap ring pliers.

5. Remove pulley assembly by using pulley puller pilot

J-38424 (2), pulley puller J-8433 (1) and pulley

puller leg J-24092-2 (3).

1

901RX056

1

2

871RY00003

1

871RY00004

1

2 3

871RY00005

Page 268 of 6000

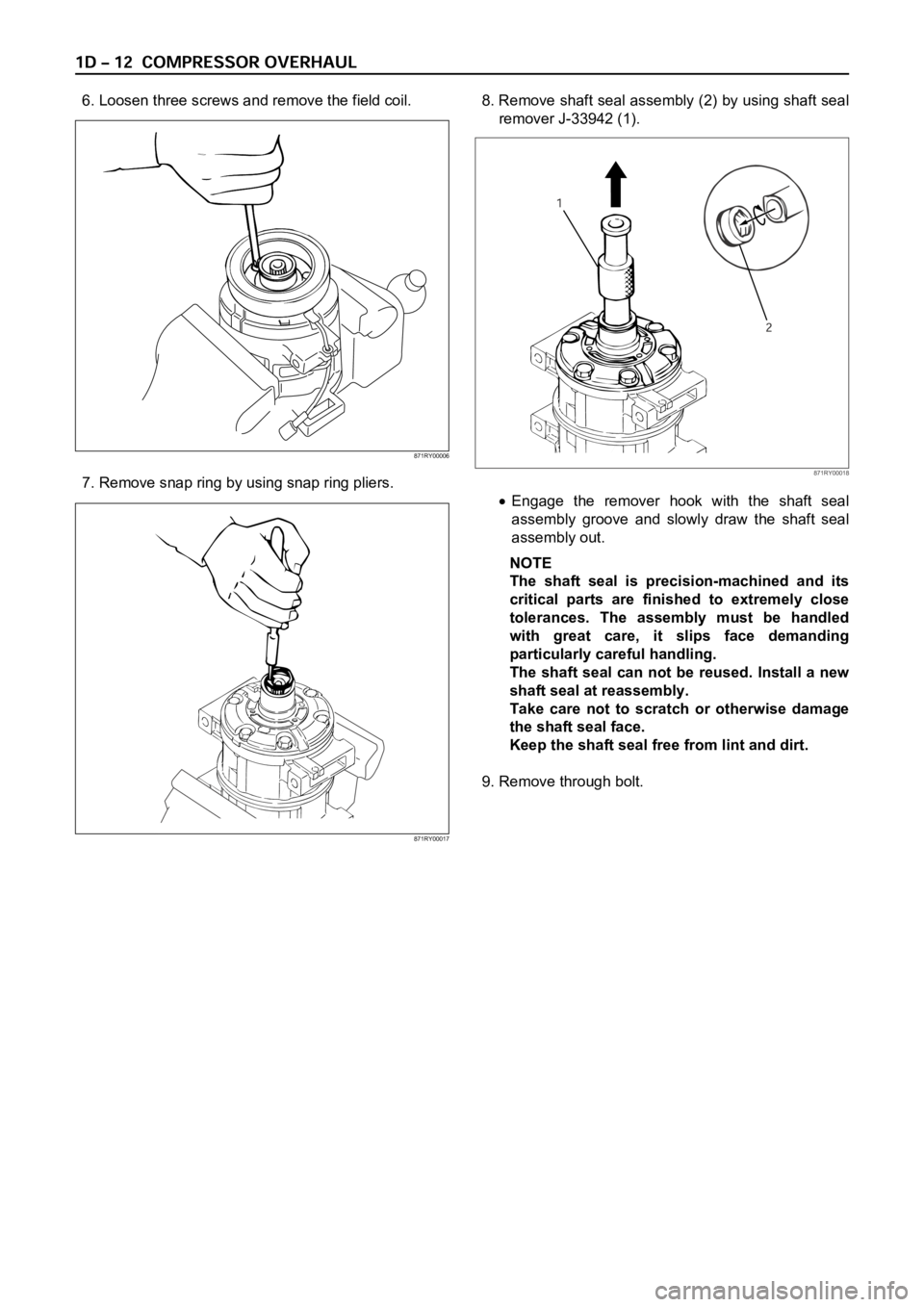

6. Loosen three screws and remove the field coil.

7. Remove snap ring by using snap ring pliers.8. Remove shaft seal assembly (2) by using shaft seal

remover J-33942 (1).

Engage the remover hook with the shaft seal

assembly groove and slowly draw the shaft seal

assembly out.

NOTE

The shaft seal is precision-machined and its

critical parts are finished to extremely close

tolerances. The assembly must be handled

with great care, it slips face demanding

particularly careful handling.

The shaft seal can not be reused. Install a new

shaft seal at reassembly.

Take care not to scratch or otherwise damage

the shaft seal face.

Keep the shaft seal free from lint and dirt.

9. Remove through bolt.

871RY00006

871RY00017

871RY00018

Page 269 of 6000

10. Remove front cylinder head.

11. Remove o-ring.

Alternately tap the projections on the

circumference of th front cylinder head with a

screwdriver and a plastic hammer to remove the

front cylinder head.

12. Remove gasket.

13. Remove front valve plate.

14. Remove front suction valve.

NOTE

Check the front valve plate for scratching and

bending.

Check the front valve plate and the front

cylinder head for nicks and burrs on the

sealing surface.

Buff or replace the valve plate and cylinder

head if nicks and burrs are present.

Check that the front valve plate passage is free

from obstructions.

Check the front valve plate and the cylinder

head for cracks.

Replace the valve plate and cylinder head if

cracks are present.15. Remove rear cylinder head.

16. Remove o-ring.Alternately tap the projections on the

circumference of the rear cylinder head with a

screwdriver and a plastic hammer to remove the

rear cylinder head.

17. Remove gasket.

18. Remove rear valve plate.

19. Remove rear suction valve.

20. Remove cylinder and shaft assembly.

NOTE

Check the rear valve plate for scratching and

bending.

Check the rear valve plate and the rear

cylinder head for nicks and burrs on the

sealing surface.

Buff or replace the valve plate and cylinder

head if nicks and burrs are present.

Check that the rear valve plate passage is free

from obstructions.

Check the rear valve plate and the cylinder

head for cracks.

Replace the valve plate and cylinder head if

cracks are present.

871RY00019871RY00020

Page 270 of 6000

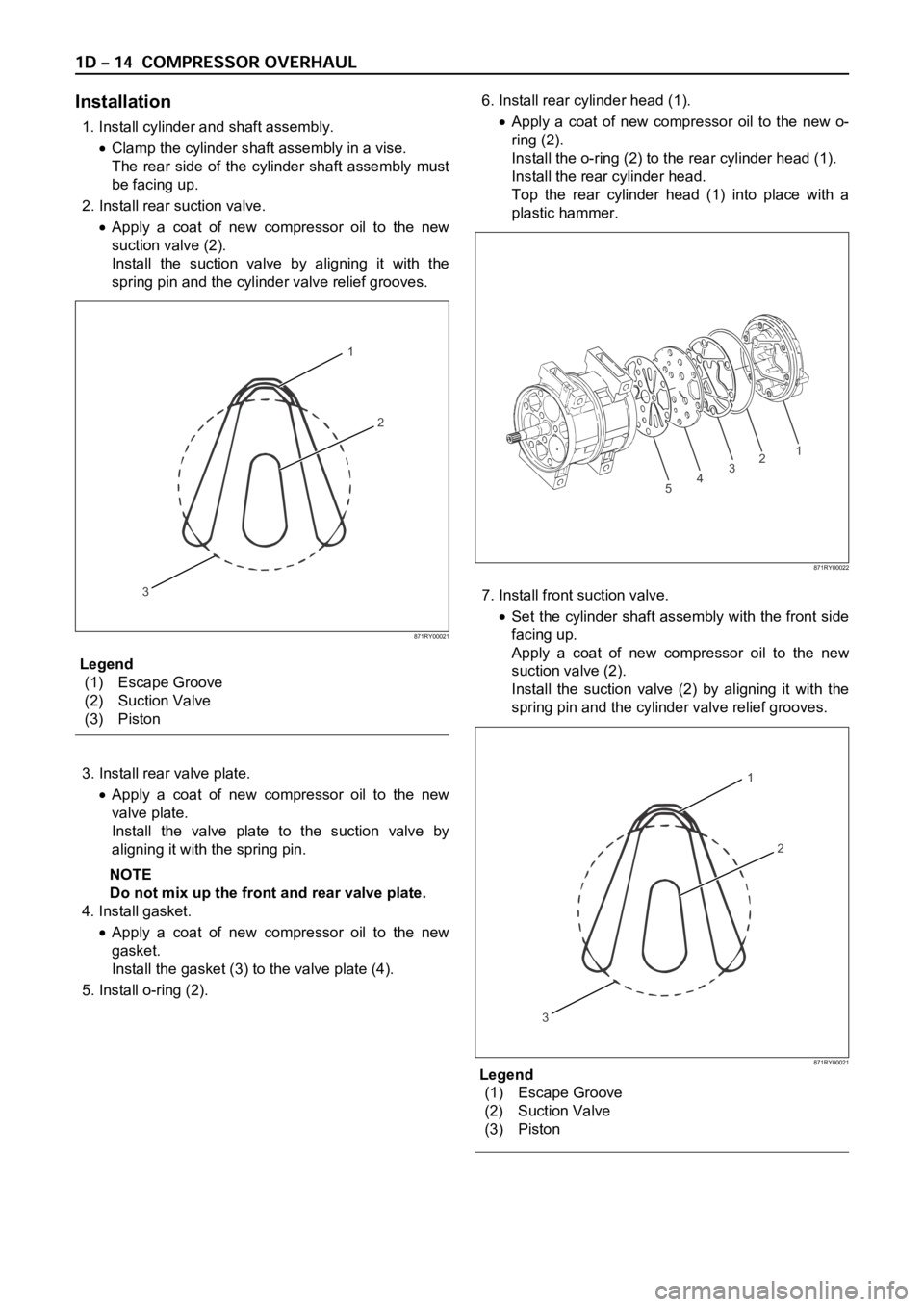

Installation

1. Install cylinder and shaft assembly.

Clamp the cylinder shaft assembly in a vise.

The rear side of the cylinder shaft assembly must

be facing up.

2. Install rear suction valve.

Apply a coat of new compressor oil to the new

suction valve (2).

Install the suction valve by aligning it with the

spring pin and the cylinder valve relief grooves.

Legend

(1) Escape Groove

(2) Suction Valve

(3) Piston

3. Install rear valve plate.

Apply a coat of new compressor oil to the new

valve plate.

Install the valve plate to the suction valve by

aligning it with the spring pin.

NOTE

Do not mix up the front and rear valve plate.

4. Install gasket.

Apply a coat of new compressor oil to the new

gasket.

Install the gasket (3) to the valve plate (4).

5. Install o-ring (2).6. Install rear cylinder head (1).

Apply a coat of new compressor oil to the new o-

ring (2).

Install the o-ring (2) to the rear cylinder head (1).

Install the rear cylinder head.

Top the rear cylinder head (1) into place with a

plastic hammer.

7. Install front suction valve.

Set the cylinder shaft assembly with the front side

facing up.

Apply a coat of new compressor oil to the new

suction valve (2).

Install the suction valve (2) by aligning it with the

spring pin and the cylinder valve relief grooves.

Legend

(1) Escape Groove

(2) Suction Valve

(3) Piston

1

2

3

871RY00021

54321

871RY00022

1

2

3

871RY00021