Differential oil OPEL FRONTERA 1998 Owner's Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 479 of 6000

4A2A–12

DIFFERENTIAL (REAR 220mm)

11. Remove the drive pinion assembly using a soft metal

rod and a hammer.

425RW056

12. Remove collapsible spacer.

13. Remove the inner bearing using a separator

5–8840–2197–0 and a press.

415RW039

14. Remove adjust shim.

15. Remove inner bearing outer race.

16. Remove oil seal.

17. Remove outer bearing.18. Remove the inner bearing outer race (1) and the outer

bearing outer race (2) by using a brass bar and a

hammer.

425RS014

425RS015

Page 480 of 6000

DIFFERENTIAL (REAR 220mm)

4A2A–13

Reassembly

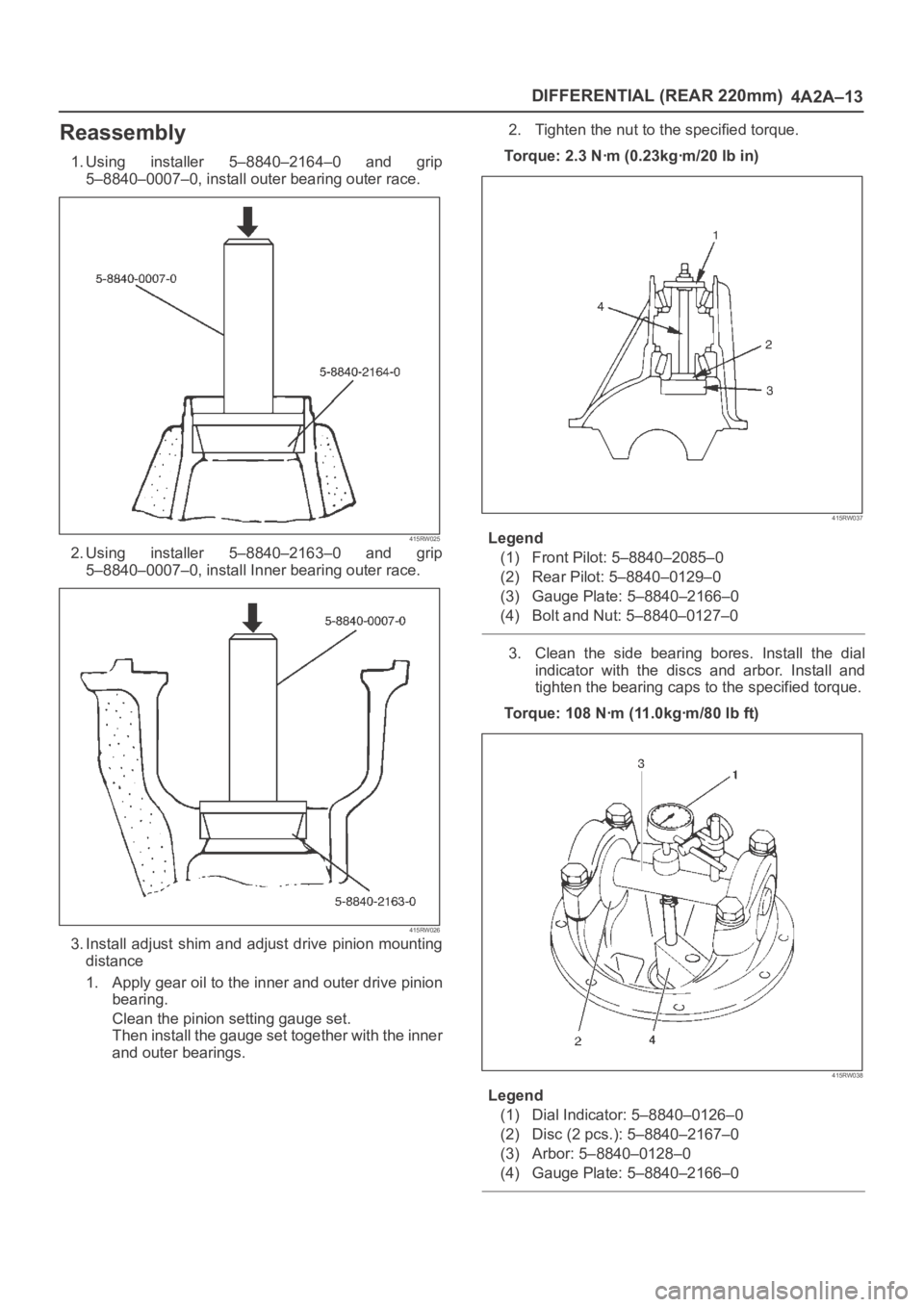

1. Using installer 5–8840–2164–0 and grip

5–8840–0007–0, install outer bearing outer race.

415RW025

2. Using installer 5–8840–2163–0 and grip

5–8840–0007–0, install Inner bearing outer race.

415RW026

3. Install adjust shim and adjust drive pinion mounting

distance

1. Apply gear oil to the inner and outer drive pinion

bearing.

Clean the pinion setting gauge set.

Then install the gauge set together with the inner

and outer bearings.2. Tighten the nut to the specified torque.

Torque: 2.3 Nꞏm (0.23kgꞏm/20 lb in)

415RW037

Legend

(1) Front Pilot: 5–8840–2085–0

(2) Rear Pilot: 5–8840–0129–0

(3) Gauge Plate: 5–8840–2166–0

(4) Bolt and Nut: 5–8840–0127–0

3. Clean the side bearing bores. Install the dial

indicator with the discs and arbor. Install and

tighten the bearing caps to the specified torque.

Torque: 108 Nꞏm (11.0kgꞏm/80 lb ft)

415RW038

Legend

(1) Dial Indicator: 5–8840–0126–0

(2) Disc (2 pcs.): 5–8840–2167–0

(3) Arbor: 5–8840–0128–0

(4) Gauge Plate: 5–8840–2166–0

Page 483 of 6000

4A2A–16

DIFFERENTIAL (REAR 220mm)

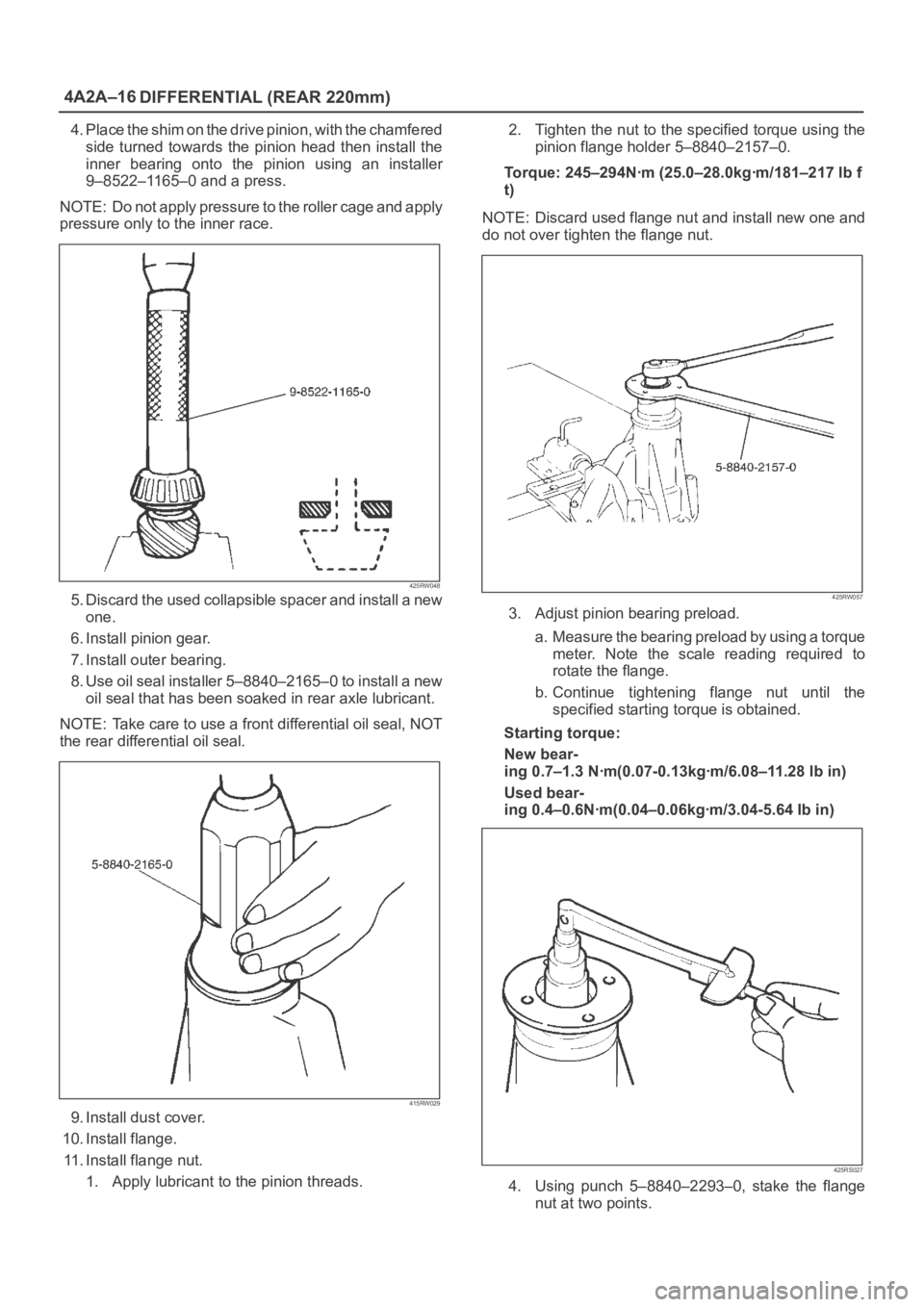

4. Place the shim on the drive pinion, with the chamfered

side turned towards the pinion head then install the

inner bearing onto the pinion using an installer

9–8522–1165–0 and a press.

NOTE: Do not apply pressure to the roller cage and apply

pressure only to the inner race.

425RW048

5. Discard the used collapsible spacer and install a new

one.

6. Install pinion gear.

7. Install outer bearing.

8. Use oil seal installer 5–8840–2165–0 to install a new

oil seal that has been soaked in rear axle lubricant.

NOTE: Take care to use a front differential oil seal, NOT

the rear differential oil seal.

415RW029

9. Install dust cover.

10. Install flange.

11. Install flange nut.

1. Apply lubricant to the pinion threads.2. Tighten the nut to the specified torque using the

pinion flange holder 5–8840–2157–0.

Torque: 245–294Nꞏm (25.0–28.0kgꞏm/181–217 lb f

t)

NOTE: Discard used flange nut and install new one and

do not over tighten the flange nut.

425RW057

3. Adjust pinion bearing preload.

a. Measure the bearing preload by using a torque

meter. Note the scale reading required to

rotate the flange.

b. Continue tightening flange nut until the

specified starting torque is obtained.

Starting torque:

New bear-

ing 0.7–1.3 Nꞏm(0.07-0.13kgꞏm/6.08–11.28 lb in)

Used bear-

ing 0.4–0.6Nꞏm(0.04–0.06kgꞏm/3.04-5.64 Ib in)

425RS027

4. Using punch 5–8840–2293–0, stake the flange

nut at two points.

Page 489 of 6000

4A2A–22

DIFFERENTIAL (REAR 220mm)

4. Remove the cross pin, using a soft metal rod and a

hammer.

425RS043

5. Remove pinion gear.

6. Remove side gear.

7. Remove thrust washer.

Inspection and Repair

Make necessary correction or parts replacement if wear,

damage, corrosion or any other abnormal conditions are

found through inspection.

Check the following parts:

1. Ring gear, pinion gear

2. Bearing

3. Side gear, pinion gear, cross pin

4. Differential cage, carrier

5. Thrust washer

6. Oil seal

Ring gear replacement:

1. The ring gear should always be replaced with the

drive pinion as a set.

2. Clean the ring gear threaded holes to remove the

locking agent.

3. When installing the ring gear, apply LOCTITE 271 or

equivalent to all the threaded area and half of the

unthreaded area of the bolt.

4. Discard used bolts and install new ones.

Torque: 108 Nꞏm (11.0kgꞏm/80 lb ft)5. Tighten the fixing bolts in a diagonal sequence as

illustrated.

415RW036

Clearance between the differential pinion

and the cross pin measurement:

Standard: 0.06 – 0.12 mm (0.002–0.005 in)

Limit: 0.2 mm (0.008 in)

425RS045

Page 494 of 6000

DIFFERENTIAL (REAR 220mm)

4A2A–27

Pressure ring

425RS057

Legend

(3) Sliding surface with the friction disc. When

nicks or scratches are found, polish with an oil

stone and repair on a level block using a

compound.

(4) Sliding spherical surface with the pinion gear.

(5) Sliding surface with the side gear.

(6) V–shaped groove of the pressure ring and V

–shaped section of the pinion shaft.

(7) Fitting section with the case.

(8) Face contacting the inner surface of the

differential case. Repair burrs and nicks using

an oil stone.

Thrust washer

425RS058

Legend

(9) Sliding surface with the side gear or case.

(10) Peripheral groove of the side gear.

Repair light nicks and burrs using an oil stone.

Case

425RS059

Legend

(11) Contact surface with the spring disc.

(12) Inner groove of the differential cage B.

Repair light nicks and burrs using an oil stone.

425RS060

Page 495 of 6000

4A2A–28

DIFFERENTIAL (REAR 220mm)

Legend

(7) Fitting section with the case.

(8) Face contacting the inner surface of the

differential case.

Repair burrs and nicks using an oil stone.

(9) Sliding surface with the side gear or case.

(11) Contact surface with spring disc.

Measure the Deformation of the friction disc & plate.

Limit: 0.08 mm (0.003 in)

425RS061

Measure the wear of the friction plate & disc

Limit(A–B): 0.1 mm (0.004 in)

Remarks:

A=Inner or outer projections

B=Sliding surface subjected to abrasion

425RS062

Measure the wear of the thrust washer

Limit: 1.3 mm (0.05 in)

425RS063

Reassembly

Adjust the clearance between the friction disc and plate.

1. Measuring the depth of the differential cage.

Standard (A–B): 80.58 mm (3.17 in)

(C): 10.58 mm (0.41 in)

425RS064

2. Measuring the overall length of the pressurering,

friction disc and friction plate.

Mount the pinion shaft in the pressurering and then

install the friction disc & plate.

Page 497 of 6000

4A2A–30

DIFFERENTIAL (REAR 220mm)

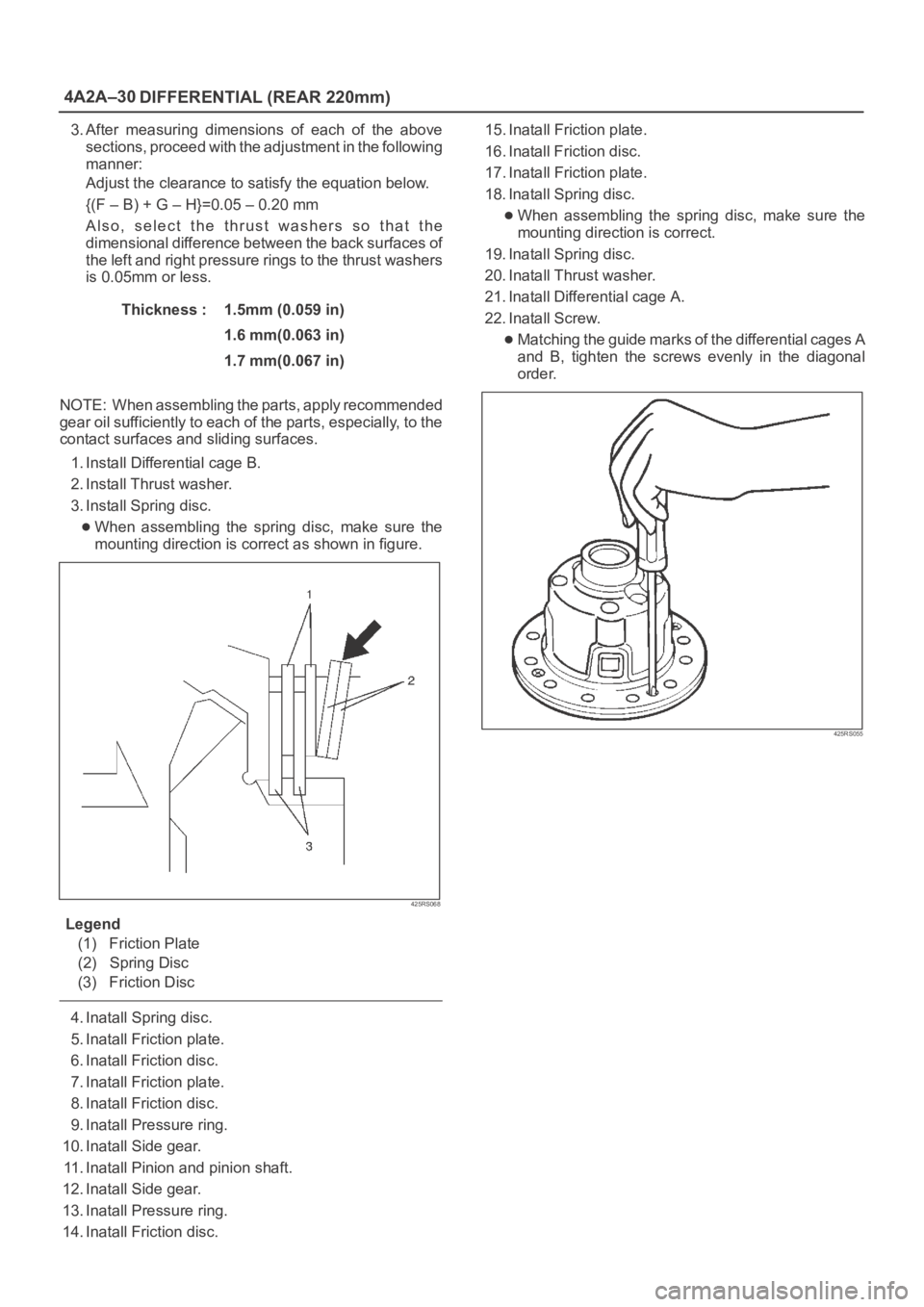

3. After measuring dimensions of each of the above

sections, proceed with the adjustment in the following

manner:

Adjust the clearance to satisfy the equation below.

{(F – B) + G – H}=0.05 – 0.20 mm

Also, select the thrust washers so that the

dimensional difference between the back surfaces of

the left and right pressure rings to the thrust washers

is 0.05mm or less.

Thickness : 1.5mm (0.059 in)

1.6 mm(0.063 in)

1.7 mm(0.067 in)

NOTE: When assembling the parts, apply recommended

gear oil sufficiently to each of the parts, especially, to the

contact surfaces and sliding surfaces.

1. Install Differential cage B.

2. Install Thrust washer.

3. Install Spring disc.

When assembling the spring disc, make sure the

mounting direction is correct as shown in figure.

425RS068

Legend

(1) Friction Plate

(2) Spring Disc

(3) Friction Disc

4. Inatall Spring disc.

5. Inatall Friction plate.

6. Inatall Friction disc.

7. Inatall Friction plate.

8. Inatall Friction disc.

9. Inatall Pressure ring.

10. Inatall Side gear.

11. Inatall Pinion and pinion shaft.

12. Inatall Side gear.

13. Inatall Pressure ring.

14. Inatall Friction disc.15. Inatall Friction plate.

16. Inatall Friction disc.

17. Inatall Friction plate.

18. Inatall Spring disc.

When assembling the spring disc, make sure the

mounting direction is correct.

19. Inatall Spring disc.

20. Inatall Thrust washer.

21. Inatall Differential cage A.

22. Inatall Screw.

Matching the guide marks of the differential cages A

and B, tighten the screws evenly in the diagonal

order.

425RS055

Page 501 of 6000

4A2A–34

DIFFERENTIAL (REAR 220mm)

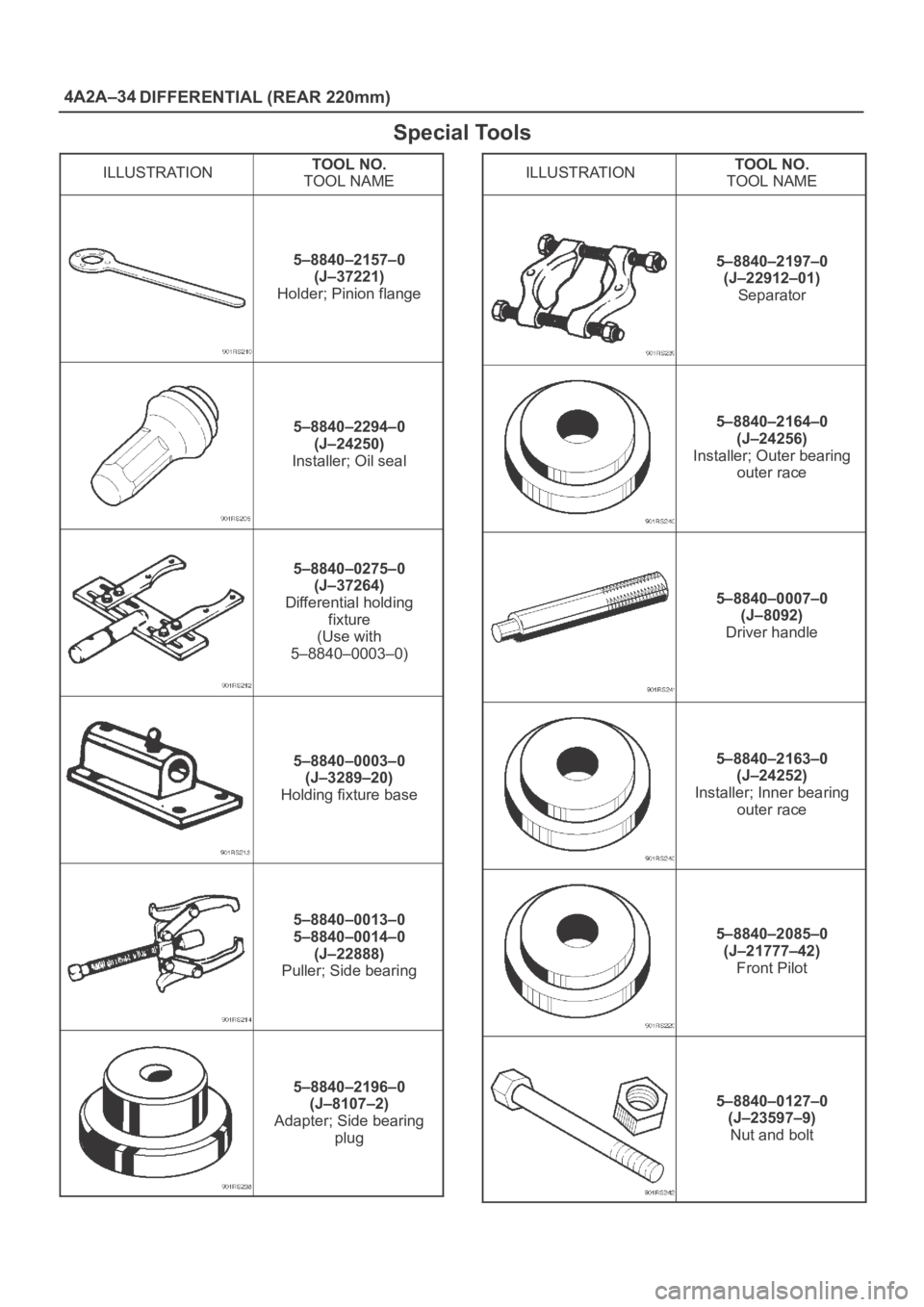

Special Tools

ILLUSTRATIONTOOL NO.

TOOL NAME

5–8840–2157–0

(J–37221)

Holder; Pinion flange

5–8840–2294–0

(J–24250)

Installer; Oil seal

5–8840–0275–0

(J–37264)

Differential holding

fixture

(Use with

5–8840–0003–0)

5–8840–0003–0

(J–3289–20)

Holding fixture base

5–8840–0013–0

5–8840–0014–0

(J–22888)

Puller; Side bearing

5–8840–2196–0

(J–8107–2)

Adapter; Side bearing

plug

ILLUSTRATIONTOOL NO.

TOOL NAME

5–8840–2197–0

(J–22912–01)

Separator

5–8840–2164–0

(J–24256)

Installer; Outer bearing

outer race

5–8840–0007–0

(J–8092)

Driver handle

5–8840–2163–0

(J–24252)

Installer; Inner bearing

outer race

5–8840–2085–0

(J–21777–42)

Front Pilot

5–8840–0127–0

(J–23597–9)

Nut and bolt

Page 502 of 6000

DIFFERENTIAL (REAR 220mm)

4A2A–35

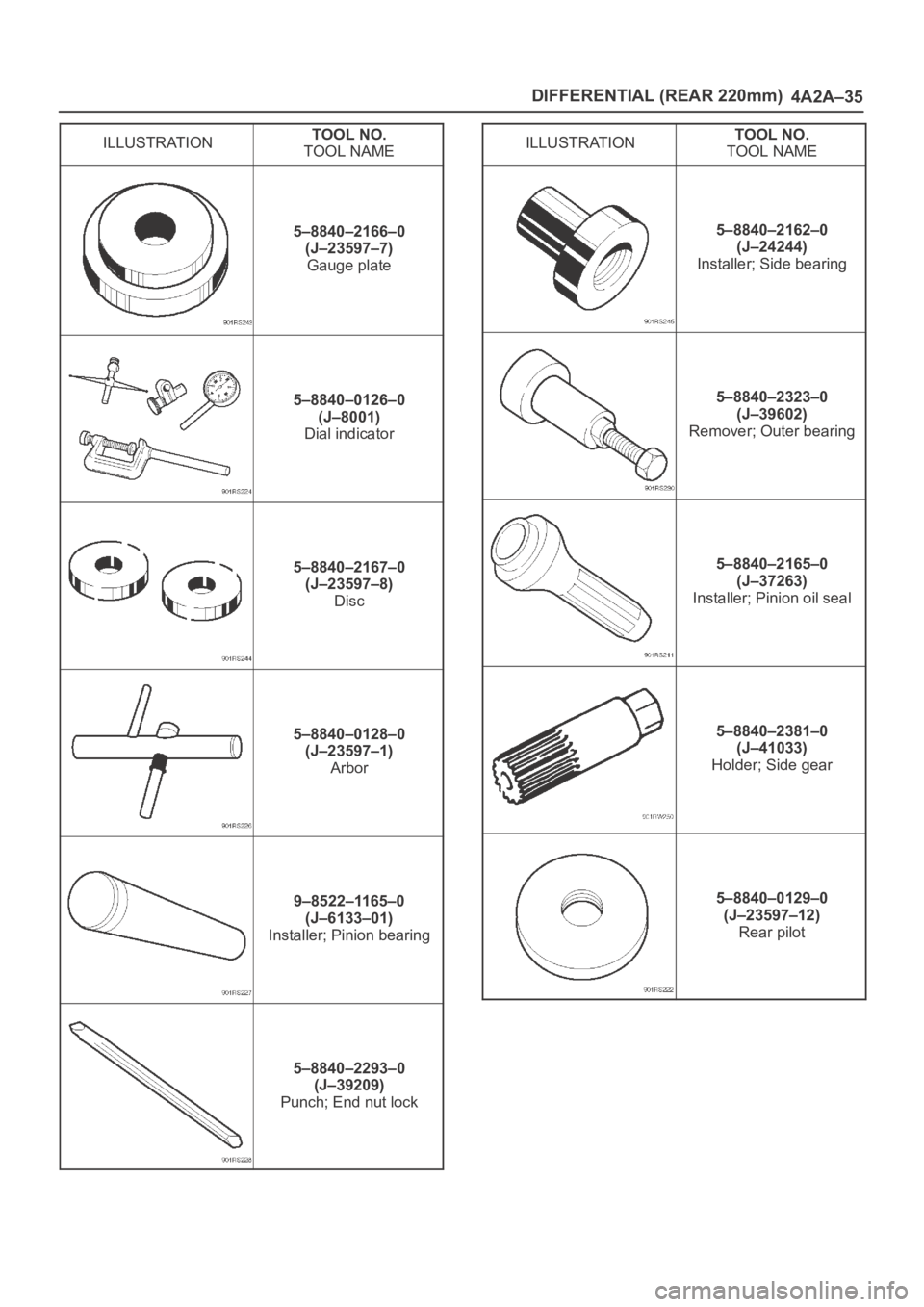

ILLUSTRATIONTOOL NO.

TOOL NAME

5–8840–2166–0

(J–23597–7)

Gauge plate

5–8840–0126–0

(J–8001)

Dial indicator

5–8840–2167–0

(J–23597–8)

Disc

5–8840–0128–0

(J–23597–1)

Arbor

9–8522–1165–0

(J–6133–01)

Installer; Pinion bearing

5–8840–2293–0

(J–39209)

Punch; End nut lock

ILLUSTRATIONTOOL NO.

TOOL NAME

5–8840–2162–0

(J–24244)

Installer; Side bearing

5–8840–2323–0

(J–39602)

Remover; Outer bearing

5–8840–2165–0

(J–37263)

Installer; Pinion oil seal

5–8840–2381–0

(J–41033)

Holder; Side gear

5–8840–0129–0

(J–23597–12)

Rear pilot

Page 504 of 6000

DIFFERENTIAL (REAR 244mm)

4A2B–1

DRIVELINE/AXLE

DIFFERENTIAL (REAR 244mm)

CONTENTS

Service Precaution 4A2B–1. . . . . . . . . . . . . . . . . . . . . .

General Description 4A2B–2. . . . . . . . . . . . . . . . . . . . .

Diagnosis 4A2B–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Axle Housing 4A2B–4. . . . . . . . . . . . . . . . . . . . . . . . . . .

Axle Housing and Associated Parts 4A2B–4. . . . . .

Removal 4A2B–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Oil Seal Replacement 4A2B–5. . . . . . . . . . . . . . . . . .

Installation 4A2B–5. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pinion Oil Seal 4A2B–6. . . . . . . . . . . . . . . . . . . . . . . . . .

Pinion Oil Seal and Associated Parts 4A2B–6. . . . .

Removal 4A2B–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 4A2B–7. . . . . . . . . . . . . . . . . .

Installation 4A2B–7. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Differential Assembly 4A2B–8. . . . . . . . . . . . . . . . . . . .

Differential Assembly and Associated Parts 4A2B–8

Removal 4A2B–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . Installation 4A2B–9. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disassembled View 4A2B–10. . . . . . . . . . . . . . . . . . . .

Disassembly 4A2B–11. . . . . . . . . . . . . . . . . . . . . . . . . .

Reassembly 4A2B–13. . . . . . . . . . . . . . . . . . . . . . . . . .

Differential Cage Assembly 4A2B–20. . . . . . . . . . . . . . .

Disassembled View 4A2B–20. . . . . . . . . . . . . . . . . . . .

Disassembly 4A2B–21. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 4A2B–21. . . . . . . . . . . . . . . . . .

Reassembly 4A2B–21. . . . . . . . . . . . . . . . . . . . . . . . . .

Locking Differential Assembly 4A2B–23. . . . . . . . . . . . .

Disassembled View 4A2B–23. . . . . . . . . . . . . . . . . . . .

Disassembly 4A2B–23. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 4A2B–25. . . . . . . . . . . . . . . . . .

Reassembly 4A2B–25. . . . . . . . . . . . . . . . . . . . . . . . . .

Main Data and Specifications 4A2B–27. . . . . . . . . . . . .

Special Tools 4A2B–29. . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Precaution

WARNING: IF SO EQUIPPED WITH A

SUPPLEMENTAL RESTRAINT SYSTEM (SRS),

REFER TO THE SRS COMPONENT AND WIRING

LOCATION VIEW IN ORDER TO DETERMINE

WHETHER YOU ARE PERFORMING SERVICE ON OR

NEAR THE SRS COMPONENTS OR THE SRS

WIRING. WHEN YOU ARE REFORMING SERVICE ON

OR NEAR THE SRS COMPONENTS OR THE SRS

WIRING, REFER TO THE SRS SERVICE

INFORMATION. FAILURE TO FOLLOW WARNINGS

COULD RESULT IN POSSIBLE AIR BAG

DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU will call out those fasteners that require a

replacement after removal. ISUZU will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED , do not

use supplemental coatings (Paints, greases, or other

corrosion inhibitors) on threaded fasteners or

fastener joint interfaces. Generally,such coatings

adversely affect the fastener torque and the joint

c l a m p i n g f o r c e , a n d m a y d a m a g e t h e f a s t e n e r. W h e n

you install fasteners, use the correct tightening

sequence and specification. Following these

instructions can help you avoid damage to parts and

systems.