Differential oil OPEL FRONTERA 1998 Service Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 524 of 6000

DIFFERENTIAL (REAR 244mm)

4A2B–21

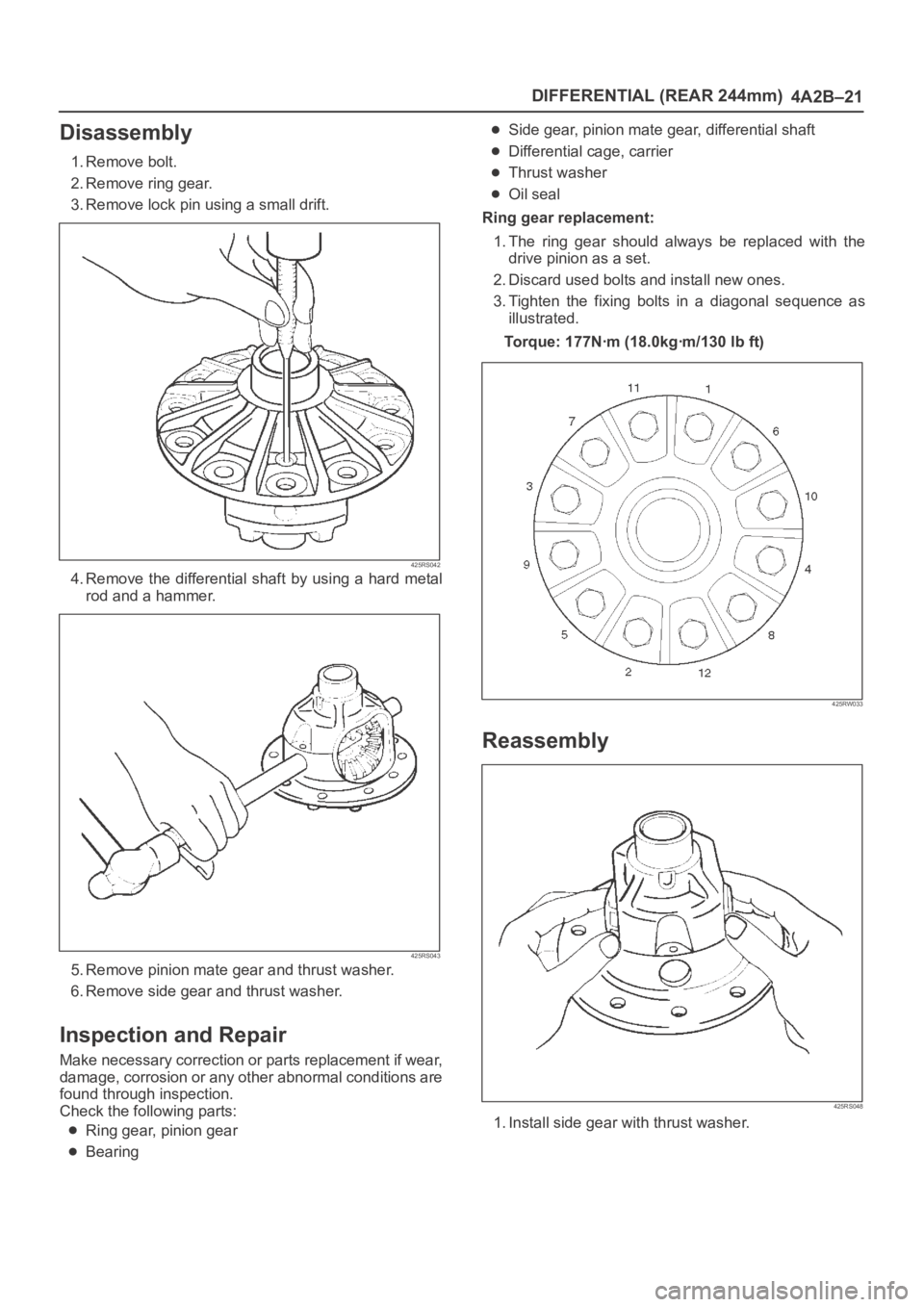

Disassembly

1. Remove bolt.

2. Remove ring gear.

3. Remove lock pin using a small drift.

425RS042

4. Remove the differential shaft by using a hard metal

rod and a hammer.

425RS043

5. Remove pinion mate gear and thrust washer.

6. Remove side gear and thrust washer.

Inspection and Repair

Make necessary correction or parts replacement if wear,

damage, corrosion or any other abnormal conditions are

found through inspection.

Check the following parts:

Ring gear, pinion gear

Bearing

Side gear, pinion mate gear, differential shaft

Differential cage, carrier

Thrust washer

Oil seal

Ring gear replacement:

1. The ring gear should always be replaced with the

drive pinion as a set.

2. Discard used bolts and install new ones.

3. Tighten the fixing bolts in a diagonal sequence as

illustrated.

Torque: 177Nꞏm (18.0kgꞏm/130 lb ft)

425RW033

Reassembly

425RS048

1. Install side gear with thrust washer.

Page 532 of 6000

DIFFERENTIAL (REAR 244mm)

4A2B–29

Special Tools

ILLUSTRATIONTOOL NO.

TOOL NAME

5–8840–2294–0

(J–39210)

Installer; Axle shaft inner

seal

5–8840–0133–0

(J–8614–01)

Pinion flange holder

5–8840–2165–0

(J–37263)

Installer; Pinion oil seal

5–8840–2029–0

(J–42832)

Holding fixture

5–8840–0003–0

(J–3289–20)

Holding fixture base

5–8840–2587–0

(J–42379)

Remover; Bearing

ILLUSTRATIONTOOL NO.

TOOL NAME

5–8840–2576–0

(J–8107–3)

Adapter; Side bearing

plug

5–8840–0008–0

(J–8611–01)

Installer; Outer bearing

outer race

5–8840–0007–0

(J–8092)

Grip

5–8840–2571–0

(J–42831)

Installer; Inner bearing

outer race

5–8840–2575–0

(J–42824)

Pilot;Outer

5–8840–0127–0

(J–21777–43)

Nut & Stud

Page 659 of 6000

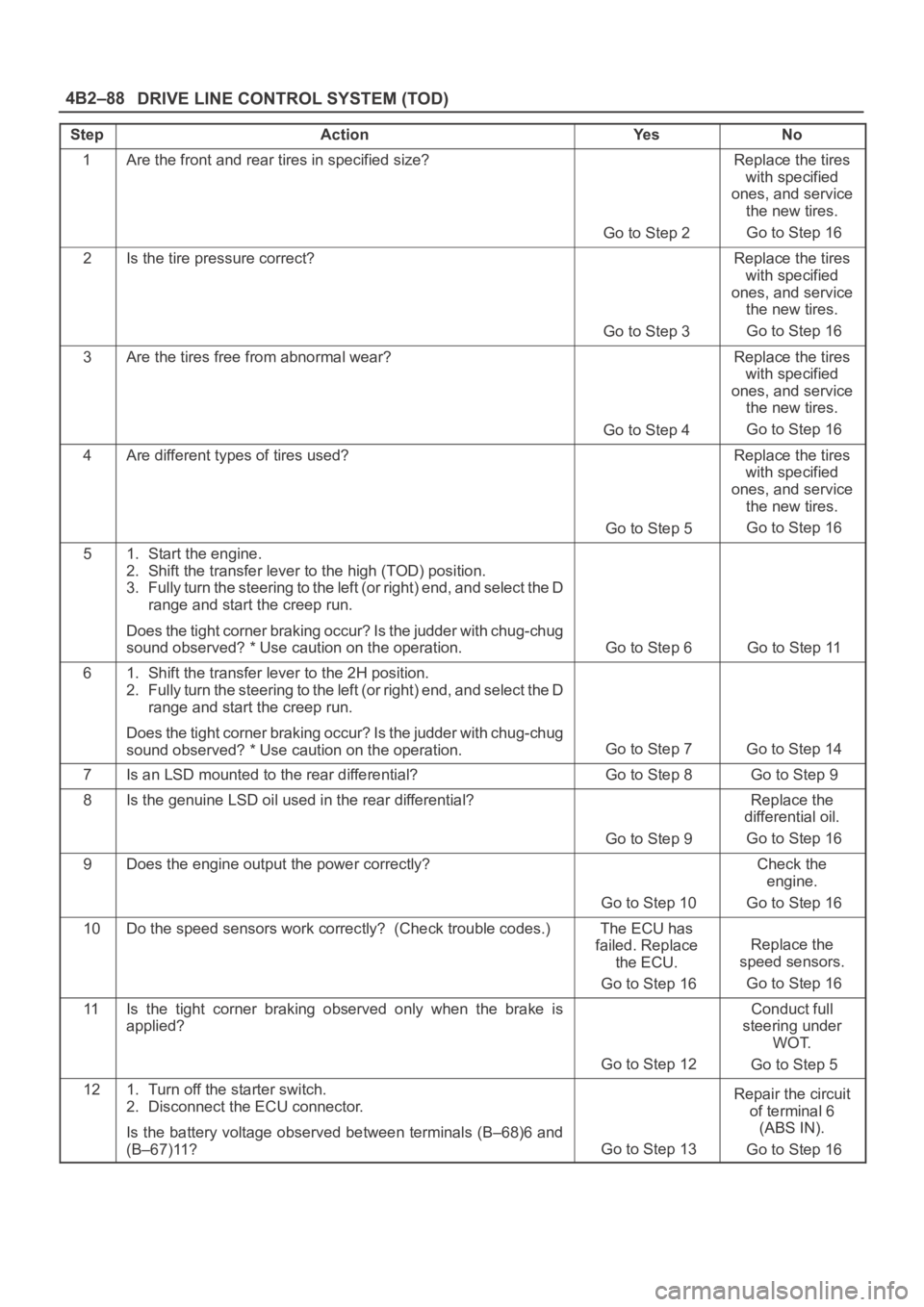

DRIVE LINE CONTROL SYSTEM (TOD) 4B2–88

StepActionYe sNo

1Are the front and rear tires in specified size?

Go to Step 2

Replace the tires

with specified

ones, and service

the new tires.

Go to Step 16

2Is the tire pressure correct?

Go to Step 3

Replace the tires

with specified

ones, and service

the new tires.

Go to Step 16

3Are the tires free from abnormal wear?

Go to Step 4

Replace the tires

with specified

ones, and service

the new tires.

Go to Step 16

4Are different types of tires used?

Go to Step 5

Replace the tires

with specified

ones, and service

the new tires.

Go to Step 16

51. Start the engine.

2. Shift the transfer lever to the high (TOD) position.

3. Fully turn the steering to the left (or right) end, and select the D

range and start the creep run.

Does the tight corner braking occur? Is the judder with chug-chug

sound observed? * Use caution on the operation.

Go to Step 6 Go to Step 11

61. Shift the transfer lever to the 2H position.

2. Fully turn the steering to the left (or right) end, and select the D

range and start the creep run.

Does the tight corner braking occur? Is the judder with chug-chug

sound observed? * Use caution on the operation.

Go to Step 7 Go to Step 14

7Is an LSD mounted to the rear differential? Go to Step 8 Go to Step 9

8Is the genuine LSD oil used in the rear differential?

Go to Step 9

Replace the

differential oil.

Go to Step 16

9Does the engine output the power correctly?

Go to Step 10

Check the

engine.

Go to Step 16

10Do the speed sensors work correctly? (Check trouble codes.)The ECU has

failed. Replace

the ECU.

Go to Step 16

Replace the

speed sensors.

Go to Step 16

11Is the tight corner braking observed only when the brake is

applied?

Go to Step 12

Conduct full

steering under

WOT.

Go to Step 5

121. Turn off the starter switch.

2. Disconnect the ECU connector.

Is the battery voltage observed between terminals (B–68)6 and

(B–67)11?

Go to Step 13

Repair the circuit

of terminal 6

(ABS IN).

Go to Step 16

Page 669 of 6000

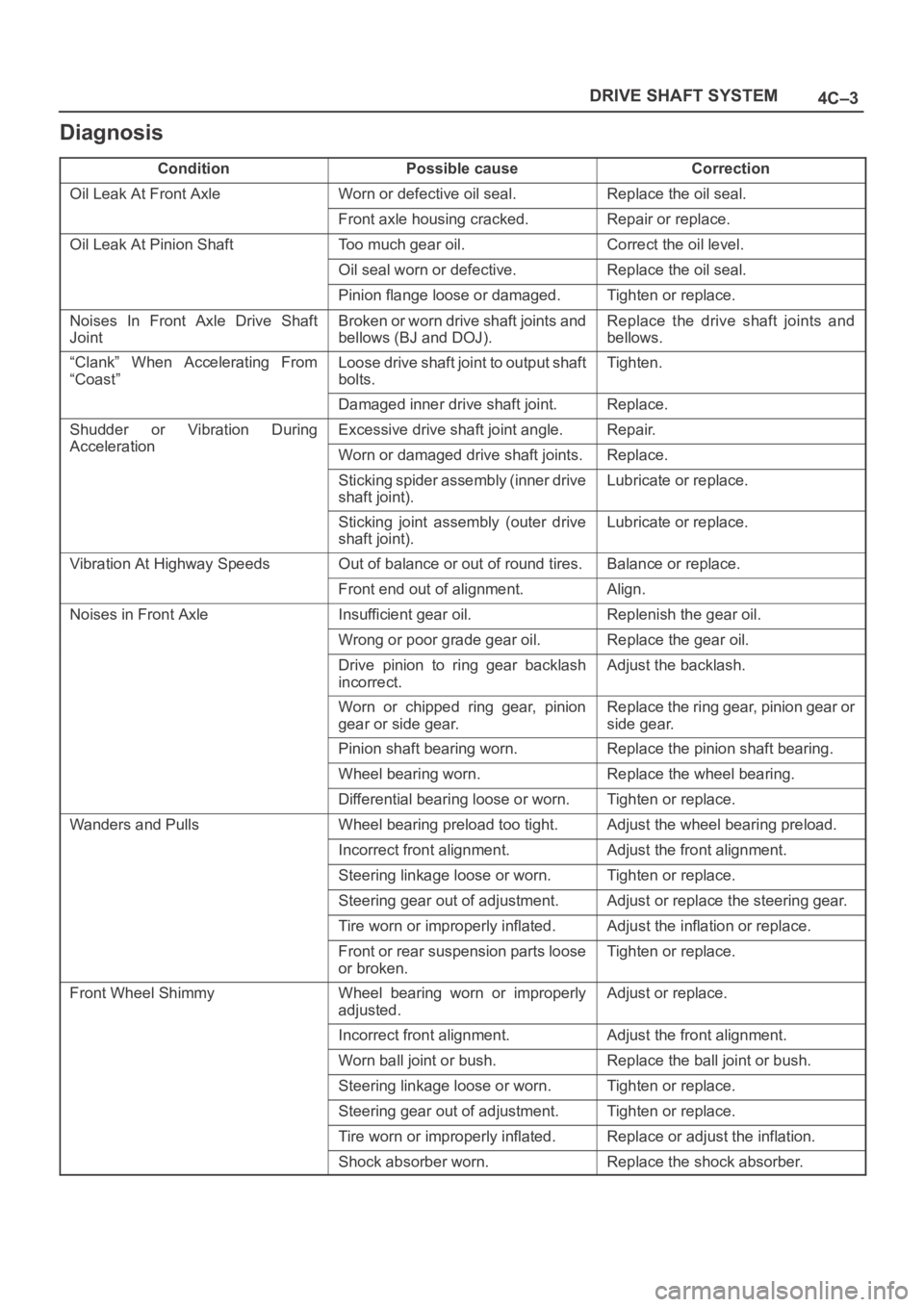

4C–3 DRIVE SHAFT SYSTEM

Diagnosis

ConditionPossible causeCorrection

Oil Leak At Front AxleWorn or defective oil seal.Replace the oil seal.

Front axle housing cracked.Repair or replace.

Oil Leak At Pinion ShaftToo much gear oil.Correct the oil level.

Oil seal worn or defective.Replace the oil seal.

Pinion flange loose or damaged.Tighten or replace.

Noises In Front Axle Drive Shaft

JointBroken or worn drive shaft joints and

bellows (BJ and DOJ).Replace the drive shaft joints and

bellows.

“Clank” When Accelerating From

“Coast”Loose drive shaft joint to output shaft

bolts.Tighten.

Damaged inner drive shaft joint.Replace.

Shudder or Vibration During

Acceleration

Excessive drive shaft joint angle.Repair.

AccelerationWorn or damaged drive shaft joints.Replace.

Sticking spider assembly (inner drive

shaft joint).Lubricate or replace.

Sticking joint assembly (outer drive

shaft joint).Lubricate or replace.

Vibration At Highway SpeedsOut of balance or out of round tires.Balance or replace.

Front end out of alignment.Align.

Noises in Front AxleInsufficient gear oil.Replenish the gear oil.

Wrong or poor grade gear oil.Replace the gear oil.

Drive pinion to ring gear backlash

incorrect.Adjust the backlash.

Worn or chipped ring gear, pinion

gear or side gear.Replace the ring gear, pinion gear or

side gear.

Pinion shaft bearing worn.Replace the pinion shaft bearing.

Wheel bearing worn.Replace the wheel bearing.

Differential bearing loose or worn.Tighten or replace.

Wanders and PullsWheel bearing preload too tight.Adjust the wheel bearing preload.

Incorrect front alignment.Adjust the front alignment.

Steering linkage loose or worn.Tighten or replace.

Steering gear out of adjustment.Adjust or replace the steering gear.

Tire worn or improperly inflated.Adjust the inflation or replace.

Front or rear suspension parts loose

or broken.Tighten or replace.

Front Wheel ShimmyWheel bearing worn or improperly

adjusted.Adjust or replace.

Incorrect front alignment.Adjust the front alignment.

Worn ball joint or bush.Replace the ball joint or bush.

Steering linkage loose or worn.Tighten or replace.

Steering gear out of adjustment.Tighten or replace.

Tire worn or improperly inflated.Replace or adjust the inflation.

Shock absorber worn.Replace the shock absorber.

Page 689 of 6000

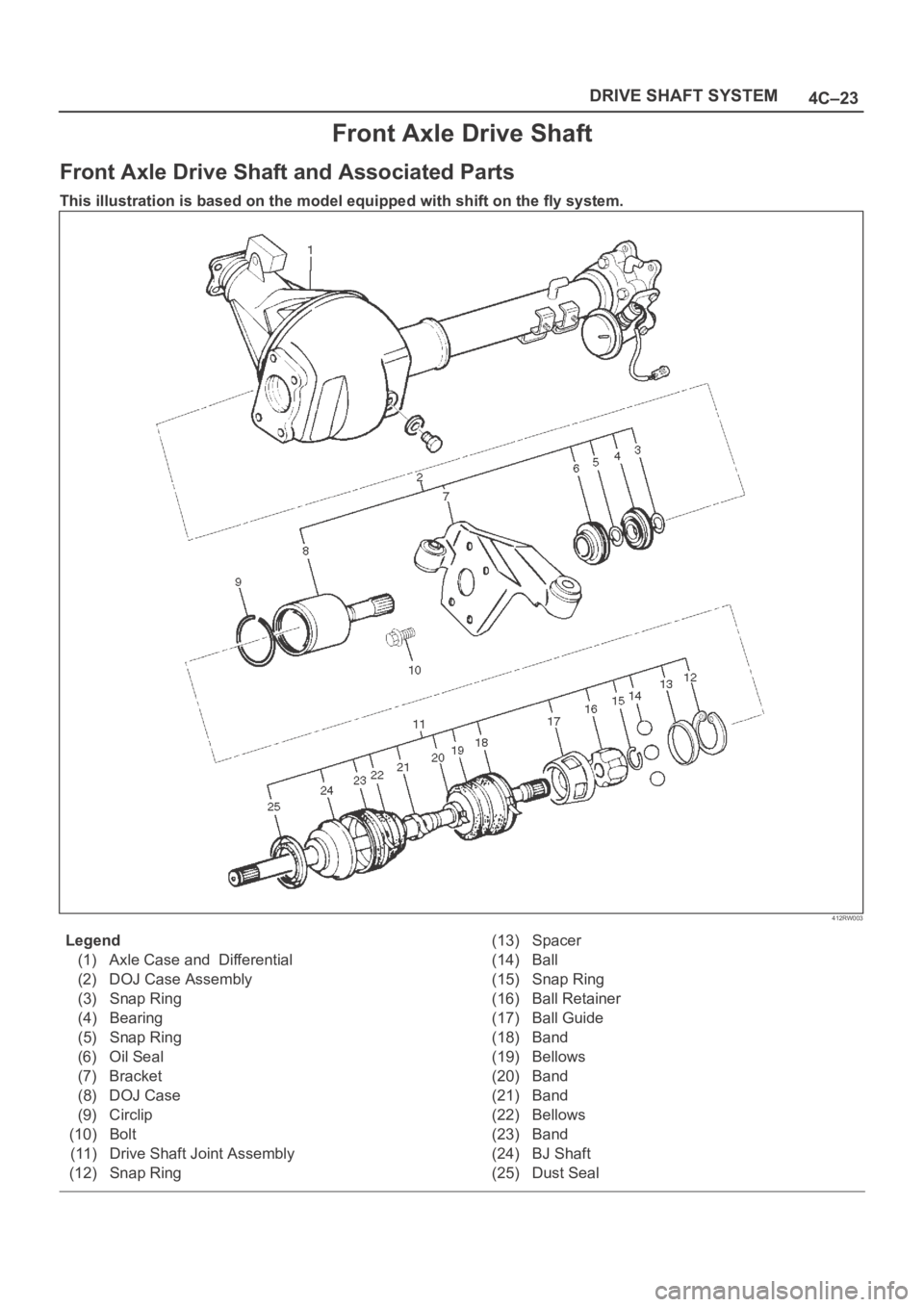

4C–23 DRIVE SHAFT SYSTEM

Front Axle Drive Shaft

Front Axle Drive Shaft and Associated Parts

This illustration is based on the model equipped with shift on the fly system.

412RW003

Legend

(1) Axle Case and Differential

(2) DOJ Case Assembly

(3) Snap Ring

(4) Bearing

(5) Snap Ring

(6) Oil Seal

(7) Bracket

(8) DOJ Case

(9) Circlip

(10) Bolt

(11) Drive Shaft Joint Assembly

(12) Snap Ring(13) Spacer

(14) Ball

(15) Snap Ring

(16) Ball Retainer

(17) Ball Guide

(18) Band

(19) Bellows

(20) Band

(21) Band

(22) Bellows

(23) Band

(24) BJ Shaft

(25) Dust Seal

Page 699 of 6000

4C–33 DRIVE SHAFT SYSTEM

412RS037

Reassembly

1. Install the new oil seal which has been immersed in

differential gear oil, by using an oil seal installer

5–8840–2407–0 and grip 5–8840–0007–0.

412RS043

2. Force a new needle bearing into inner shaft by using a

installer 5–8840–2408–0 and grip 5–8840–0007–0.

412RS051

3. Place a new snap ring(internal) in inner shaft.

Force a new inner shaft bearing into the inner shaft by

using a installer 5–8840–2197–0 and press.

412RS044

4. Install snap ring(external).

NOTE: Be careful not to damage the inner shaft.

5. Clean the housing contact surface of the front axle

case and insert inner shaft assembly into the front

axle case.

Page 700 of 6000

4C–34

DRIVE SHAFT SYSTEM

NOTE: Be careful not to damage seal.

6. Install snap ring (internal) in the groove of front axle

case.

NOTE: Be sure to install the snap ring properly.

412RW017

7. Apply differential gear oil to clutch gear, then install

clutch gear.

8. Apply differential gear oil to sleeve, then install

sleeve.

9. Clean contact surface with the front axle and actuator

mounting surface. Apply liquid gasket to the contact

surface on the front axle case, then install in the

housing.

412RW023

10. Tighten bolts to specified torque.

Torque: 116Nꞏm (11.8 kgꞏm/85 lb ft)11. Clean the actuator contact surface with the housing

then Install and tighten shift position switch to

specified torque.

Torque: 39Nꞏm (4.0 kgꞏm/29 lb ft)

12. Apply liquid gasket to the contact surface on the

actuator side.

412RW012

13. Align shift arm with the groove of sleeve and install the

actuator.

14. Tighten bolts to specified torque.

Torque: 13Nꞏm (1.3 kgꞏm/113 lb in)

15. Install front axle drive shaft and mounting bracket.

Tighten fitting bolts to specified torque.

Torque: 116Nꞏm (11.8 kgꞏm/85 lb ft)

16. Pour specified amount of differential gear oil to filler

plug.

Front Differential

Oil Capacity: 1.4lit (1.23 Imp qt/1.48 US qt)

Actuator Housing

Oil Capacity: 0.12lit (0.10 Imp qt/0.13 US qt)

17. Install filler plug through gasket and tighten to

specified torque.

To r q u e : 7 8 N ꞏm ( 5 8 l b f t )

Page 701 of 6000

4C–35 DRIVE SHAFT SYSTEM

Main Data and Specifications

General Specifications

Front drive axle oil capacity1.4 liter (1.23 Imp qt/1.48 US qt)(Differential)

0.12 liter (0.10 Imp qt/0.13 US qt)(Actuator Housing:Shift on the fly)

Type of lubricantGL–5 (Multi grade type) Refer to chart in General Information

Axle shaft typeConstant velocity joint(Birfield joint type and double offset joint)

Torque Specifications

E04RW020

Page 1070 of 6000

6C–3

ENGINE FUEL

Adhere to all Notices and Cautions.

All gasoline engines are designed to use only unleaded

gasoline. Unleaded gasoline must be used for proper

emission control system operation.

Its use will also minimize spark plug fouling and extend

engine oil life. Using leaded gasoline can damage the

emission control system and could result in loss of

emission warranty coverage.

All cars are equipped with an Evaporative Emission

Control System. The purpose of the system is to minimize

the escape of fuel vapors to the atmosphere.

Fuel Metering

The Engine Control Module (ECM) is in complete control

of this fuel delivery system during normal driving

conditions.

The intake manifold function, like that of a diesel, is used

only to let air into the engine. The fuel is injected by

separate injectors that are mounted over the intake

manifold.

The Manifold Absolute Pressure (MAP) sensor measures

the changes in the intake manifold pressure which result

from engine load and speed changes, which the MAP

sensor converts to a voltage output.

This sensor generates the voltage to change

corresponding to the flow of the air drawn into the engine.

The changing voltage is transformed into an electric

signal and provided to the ECM.

With receipt of the signals sent from the MAP sensor,

Intake Air Temperature sensor and others, the ECM

determines an appropriate fuel injection pulse width

feeding such information to the fuel injector valves to

effect an appropriate air/fuel ratio.

The Multiport Fuel Injection system utilizes an injection

system where the injectors turn on at every crankshaft

re vol u tion . Th e EC M con tro ls t he in je cto r on tim e so t ha t

the correct amount of fuel is metered depending on

driving conditions.

Two interchangeable “O” rings are used on the injector

that must be replaced when the injectors are removed.

The fuel rail is attached to the top of the intake manifold

and supplies fuel to all the injectors.

Fuel is recirculated through the rail continually while the

engine is running. This removes air and vapors from the

fuel as well as keeping the fuel cool during hot weather

operation.

The fuel pressure control valve that is mounted on the fuel

rail maintains a pressure differential across the injectors

under all operating conditions. It is accomplished by

controlling the amount of fuel that is recirculated back to

the fuel tank based on engine demand.

See Section “Driveability and Emission” for more

information and diagnosis.

Page 3505 of 6000

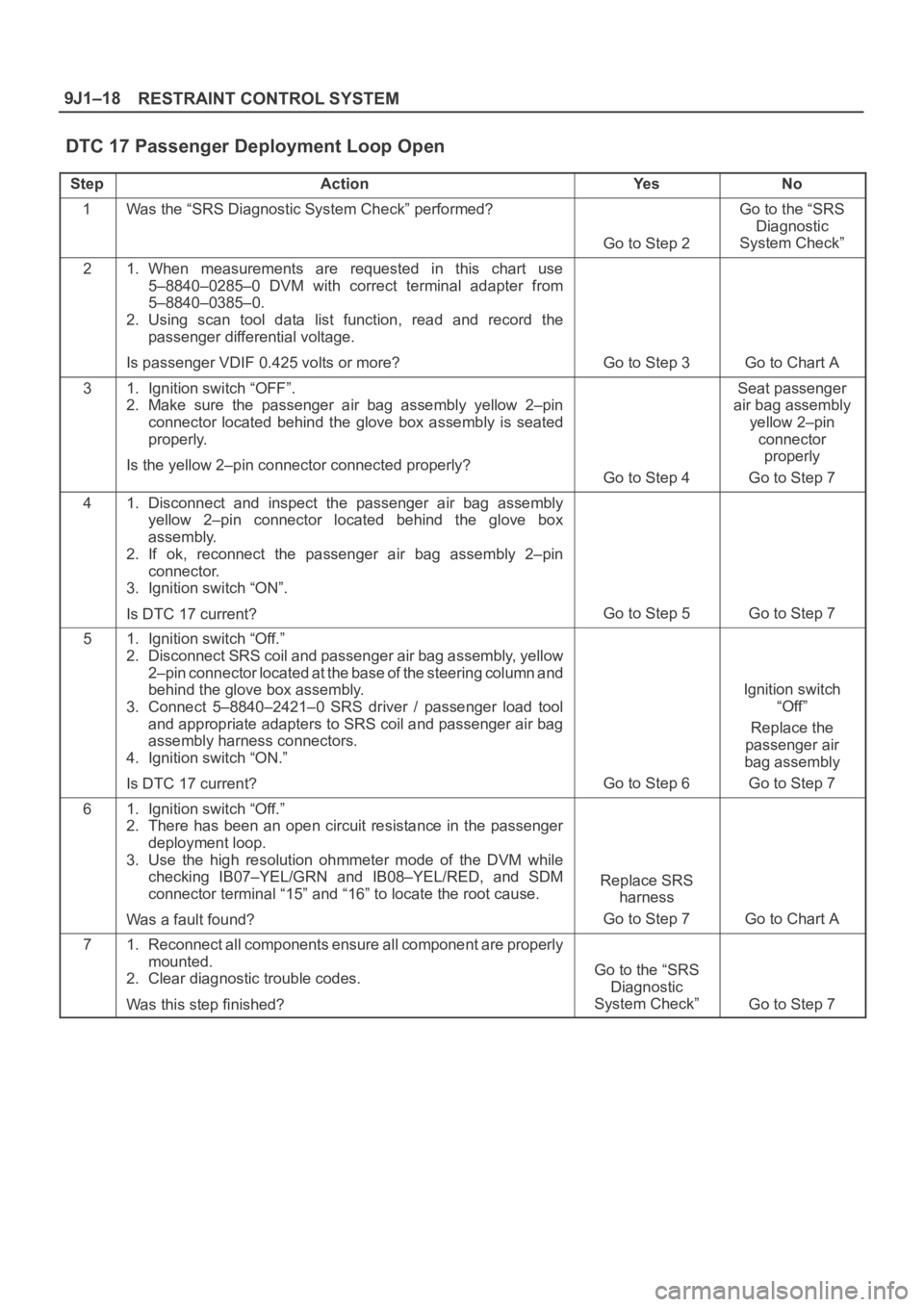

RESTRAINT CONTROL SYSTEM 9J1–18

DTC 17 Passenger Deployment Loop Open

StepActionYe sNo

1Was the “SRS Diagnostic System Check” performed?

Go to Step 2

Go to the “SRS

Diagnostic

System Check”

21. When measurements are requested in this chart use

5–8840–0285–0 DVM with correct terminal adapter from

5–8840–0385–0.

2. Using scan tool data list function, read and record the

passenger differential voltage.

Is passenger VDIF 0.425 volts or more?

Go to Step 3Go to Chart A

31. Ignition switch “OFF”.

2. Make sure the passenger air bag assembly yellow 2–pin

connector located behind the glove box assembly is seated

properly.

Is the yellow 2–pin connector connected properly?

Go to Step 4

Seat passenger

air bag assembly

yellow 2–pin

connector

properly

Go to Step 7

41. Disconnect and inspect the passenger air bag assembly

yellow 2–pin connector located behind the glove box

assembly.

2. If ok, reconnect the passenger air bag assembly 2–pin

connector.

3. Ignition switch “ON”.

Is DTC 17 current?

Go to Step 5Go to Step 7

51. Ignition switch “Off.”

2. Disconnect SRS coil and passenger air bag assembly, yellow

2–pin connector located at the base of the steering column and

behind the glove box assembly.

3. Connect 5–8840–2421–0 SRS driver / passenger load tool

and appropriate adapters to SRS coil and passenger air bag

assembly harness connectors.

4. Ignition switch “ON.”

Is DTC 17 current?

Go to Step 6

Ignition switch

“Off”

Replace the

passenger air

bag assembly

Go to Step 7

61. Ignition switch “Off.”

2. There has been an open circuit resistance in the passenger

deployment loop.

3. Use the high resolution ohmmeter mode of the DVM while

checking IB07–YEL/GRN and IB08–YEL/RED, and SDM

connector terminal “15” and “16” to locate the root cause.

Was a fault found?

Replace SRS

harness

Go to Step 7

Go to Chart A

71. Reconnect all components ensure all component are properly

mounted.

2. Clear diagnostic trouble codes.

Was this step finished?

Go to the “SRS

Diagnostic

System Check”

Go to Step 7