ground clearance OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 959 of 6000

6A–3

ENGINE MECHANICAL

General Description

Engine Cleanliness And Care

An automobile engine is a combination of many

machined, honed, polished and lapped surfaces with

tolerances that are measured in the thousandths of a

millimeter (ten thousandths of an inch). Accordingly,

when any internal engine parts are serviced, care and

cleanliness are important. Throughout this section, it

should be understood that proper cleaning and protection

of machined surfaces and friction areas is part of the

repair procedure. This is considered standard shop

practice even if not specifically stated.

A liberal coating of engine oil should be applied to all

friction areas during assembly to protect and lubricate

the surfaces on initial operation.

Whenever valve train components, pistons, piston

rings, connecting rods, rod bearings, and crankshaft

journal bearings are removed for service, they should

be retained in order.

At the time of installation, they should be installed in

the same locations and with the same mating

surfaces as when removed.

Battery cables should be disconnected before any

major work is performed on the engine. Failure to

disconnect cables may result in damage to wire

harness or other electrical parts.

The six cylinders of this engine are identified by

numbers; Right side cylinders 1, 3 and 5, Left side

cylinders 2, 4 and 6, as counted from crankshaft

pulley side to flywheel side.

General Information on Engine Service

The following information on engine service should be

noted carefully, as it is important in preventing damage

and contributing to reliable engine performance:

When raising or supporting the engine for any reason,

do not use a jack under the oil pan. Due to the small

clearance between the oil pan and the oil pump

strainer, jacking against the oil pan may cause

damage to the oil pick–up unit.

The 12–volt electrical system is capable of damaging

circuits. When performing any work where electrical

terminals could possibly be grounded, the ground

cable of the battery should be disconnected at the

battery.

Any time the intake air duct or air cleaner is removed,

the intake opening should be covered. This will

protect against accidental entrance of foreign

material into the cylinder which could cause extensive

damage when the engine is started.

Cylinder Block

The cylinder block is made of aluminum die–cast casting

for 75

V–type six cylinders. It has a rear plate integrated

structure and employs a deep skint. The cylinder liner is

cast and the liner inner diameter and crankshaft journal

diameter are classified into grades. The crankshaft is

supported by four bearings of which width of No.3 bearing

on the body side is different in order to support the thrust

bearing. The bearing cap is made of nodular cast iron and

each bearing cap uses four bolts and two side bolts.

Cylinder Head

The cylinder head, made of aluminum alloy casting

employs a pent–roof type combustion chamber with a

spark plug in the center. The intake and exhaust valves

are placed in V–type design. The ports are cross–flow

type.

Va l v e Tr a i n

Intake and exhaust camshaft on the both side of banks

are driven through an camshaft drive gear by timing belt.

The valves are operated by the camshaft and the valve

clearance is adjusted to select suitable thickness shim.

Intake Manifold

The intake manifold system is composed of the aluminum

cast common chamber and intake manifold attached with

six fuel injectors.

Exhaust Manifold

The exhaust manifold is made of nodular cast iron.

Pistons and Connecting Rods

Aluminum pistons are used after selecting the grade that

meets the cylinder bore diameter. Each piston has two

compression rings and one oil ring. The piston pin is made

of chromium steel is offset 1mm toward the thrust side,

and the thrust pressure of piston to the cylinder wall varies

gradually as the piston travels. The connecting rods are

made of forged steel. The connecting rod bearings are

graded for correct seze selection.

Crankshaft and Bearings

The crankshaft is made of Ductile cast–iron. Pins and

journals are graded for correct size selection for their

bearing.

Engine Lubrication

The oil discharged by a trochoid–type oil pump driven by

the crankshaft is fed through full–flow oil filter and to the oil

gallery provided under the crankshaft bearing cap. The oil

is then led to the crankshaft journals and cylinder head.

The crank pins are lubricated with oil from crankshaft

journals through oil holes. Also, an oil jet is fed to each

cylinder from crankshaft juornals on the connecting rod

for piston cleaning. The oil pan flange is dealed with liquid

packing only; do not deform or damage the flange surface

during removal or installation.

Page 1464 of 6000

6E–347 ENGINE DRIVEABILITY AND EMISSIONS

the secondary ignition circuit to flow through the spark

plug to the ground.

TS24047

Ignition Control PCM Output

The PCM provides a zero volt (actually about 100 mV to

200 mV) or a 5-volt output signal to the ignition control (IC)

module. Each spark plug has its own primary and

secondary coil module (”coil-at-plug”) located at the spark

plug itself. When the ignition coil receives the 5-volt signal

from the PCM, it provides a ground path for the B+ supply

to the primary side of the coil-at -plug module. This

energizes the primary coil and creates a magnetic field in

the coil-at-plug module. When the PCM shuts off the

5-volt signal to the ignition control module, the ground

path for the primary coil is broken. The magnetic field

collapses and induces a high voltage secondary impulse

which fires the spark plug and ignites the air/fuel mixture.

The circuit between the PCM and the ignition coil is

monitored for open circuits, shorts to voltage, and shorts

to ground. If the PCM detects one of these events, it will

set one of the following DTCs:

P0351: Ignition coil Fault on Cylinder #1

P0352: Ignition coil Fault on Cylinder #2

P0353: Ignition coil Fault on Cylinder #3

P0354: Ignition coil Fault on Cylinder #4

P0355: Ignition coil Fault on Cylinder #5

P0356: Ignition coil Fault on Cylinder #6

Knock Sensor (KS) PCM Input

The knock sensor (KS) system is comprised of a knock

sensor and the PCM. The PCM monitors the KS signals

to determine when engine detonation occurs. When a

knock sensor detects detonation, the PCM retards the

spark timing to reduce detonation. Timing may also be

retarded because of excessive mechanical engine or

transmission noise.

Powertrain Control Module (PCM)

The PCM is responsible for maintaining proper spark and

fuel injection timing for all driving conditions. To provideoptimum driveability and emissions, the PCM monitors

the input signals from the following components in order

to calculate spark timing:

Engine coolant temperature (ECT) sensor.

Intake air temperature (IAT) sensor.

Mass air flow (MAF) sensor.

PRNDL input from transmission range switch.

Throttle position (TP) sensor.

Vehicle speed sensor (VSS) .

Crankshaft position (CKP) sensor.

Spark Plug

Although worn or dirty spark plugs may give satisfactory

operation at idling speed, they frequency fail at higher

engine speeds. Faulty spark plugs may cause poor fuel

economy, power loss, loss of speed, hard starting and

generally poor engine performance. Follow the

scheduled maintenance service recommendations to

ensure satisfactory spark plug performance. Refer to

Maintenance and Lubrication.

Normal spark plug operation will result in brown to

grayish-tan deposits appearing on the insulator portion of

the spark plug. A small amount of red-brown, yellow, and

white powdery material may also be present on the

insulator tip around the center electrode. These deposits

are normal combustion by-products of fuels and

lubricating oils with additives. Some electrode wear will

also occur. Engines which are not running properly are

often referred to as “misfiring.” This means the ignition

spark is not igniting the air/fuel mixture at the proper time.

While other ignition and fuel system causes must also be

considered, possible causes include ignition system

conditions which allow the spark voltage to reach ground

in some other manner than by jumping across the air gap

at the tip of the spark plug, leaving the air/fuel mixture

unburned. Misfiring may also occur when the tip of the

spark plug becomes overheated and ignites the mixture

before the spark jumps. This is referred to as

“pre-ignition.”

Spark plugs may also misfire due to fouling, excessive

gap, or a cracked or broken insulator. If misfiring occurs

before the recommended replacement interval, locate

and correct the cause.

Carbon fouling of the spark plug is indicated by dry, black

carbon (soot) deposits on the portion of the spark plug in

the cylinder. Excessive idling and slow speeds under

light engine loads can keep the spark plug temperatures

so low that these deposits are not burned off. Very rich

fuel mixtures or poor ignition system output may also be

the cause. Refer to DTC P0172.

Oil fouling of the spark plug is indicated by wet oily

deposits on the portion of the spark plug in the cylinder,

usually with little electrode wear. This may be caused by

oil during break-in of new or newly overhauled engines.

Deposit fouling of the spark plug occurs when the normal

red-brown, yellow or white deposits of combustion by

products become sufficient to cause misfiring. In some

c a s e s , t h e s e d e p o s i t s m a y m e l t a n d f o r m a s h i n y g l a z e o n

the insulator around the center electrode. If the fouling is

found in only one or two cylinders, valve stem clearances

or intake valve seals may be allowing excess lubricating

Page 1736 of 6000

ENGINE MECHANICAL 6A – 3

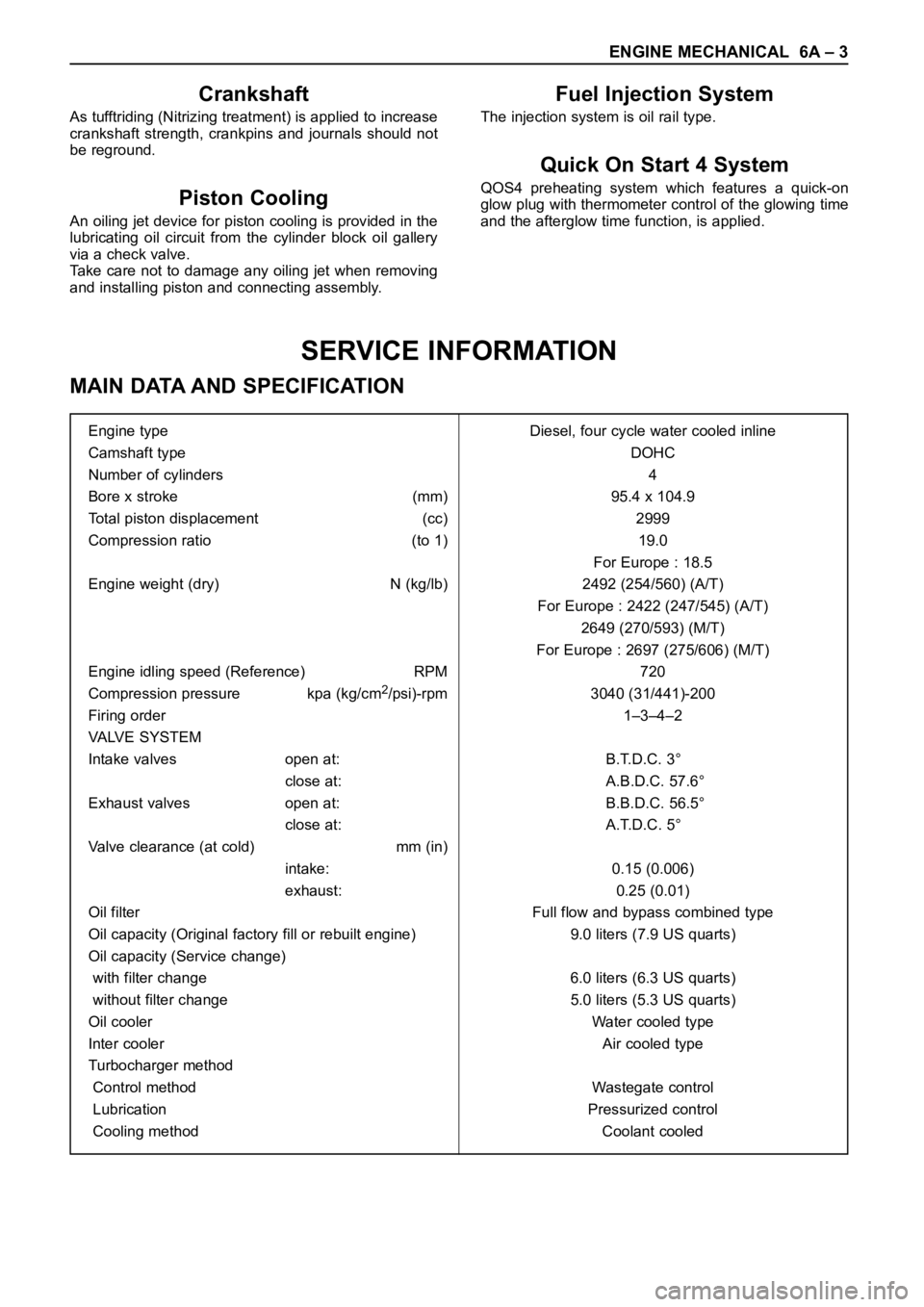

SERVICE INFORMATION

MAIN DATA AND SPECIFICATION

Engine type Diesel, four cycle water cooled inline

Camshaft type DOHC

Number of cylinders 4

Bore x stroke (mm) 95.4 x 104.9

Total piston displacement (cc) 2999

Compression ratio (to 1) 19.0

For Europe : 18.5

Engine weight (dry) N (kg/lb) 2492 (254/560) (A/T)

For Europe : 2422 (247/545) (A/T)

2649 (270/593) (M/T)

For Europe : 2697 (275/606) (M/T)

Engine idling speed (Reference) RPM 720

Compression pressure kpa (kg/cm

2/psi)-rpm 3040 (31/441)-200

Firing order 1–3–4–2

VALVE SYSTEM

Intake valves open at: B.T.D.C. 3°

close at: A.B.D.C. 57.6°

Exhaust valves open at: B.B.D.C. 56.5°

close at: A.T.D.C. 5°

Valve clearance (at cold) mm (in)

intake: 0.15 (0.006)

exhaust: 0.25 (0.01)

Oil filter Full flow and bypass combined type

Oil capacity (Original factory fill or rebuilt engine) 9.0 liters (7.9 US quarts)

Oil capacity (Service change)

with filter change 6.0 liters (6.3 US quarts)

without filter change 5.0 liters (5.3 US quarts)

Oil cooler Water cooled type

Inter cooler Air cooled type

Turbocharger method

Control method Wastegate control

Lubrication Pressurized control

Cooling method Coolant cooled

Crankshaft

As tufftriding (Nitrizing treatment) is applied to increase

crankshaft strength, crankpins and journals should not

be reground.

Piston Cooling

An oiling jet device for piston cooling is provided in the

lubricating oil circuit from the cylinder block oil gallery

via a check valve.

Take care not to damage any oiling jet when removing

and installing piston and connecting assembly.

Fuel Injection System

The injection system is oil rail type.

Quick On Start 4 System

QOS4 preheating system which features a quick-on

glow plug with thermometer control of the glowing time

and the afterglow time function, is applied.

Page 1739 of 6000

6A – 6 ENGINE MECHANICAL

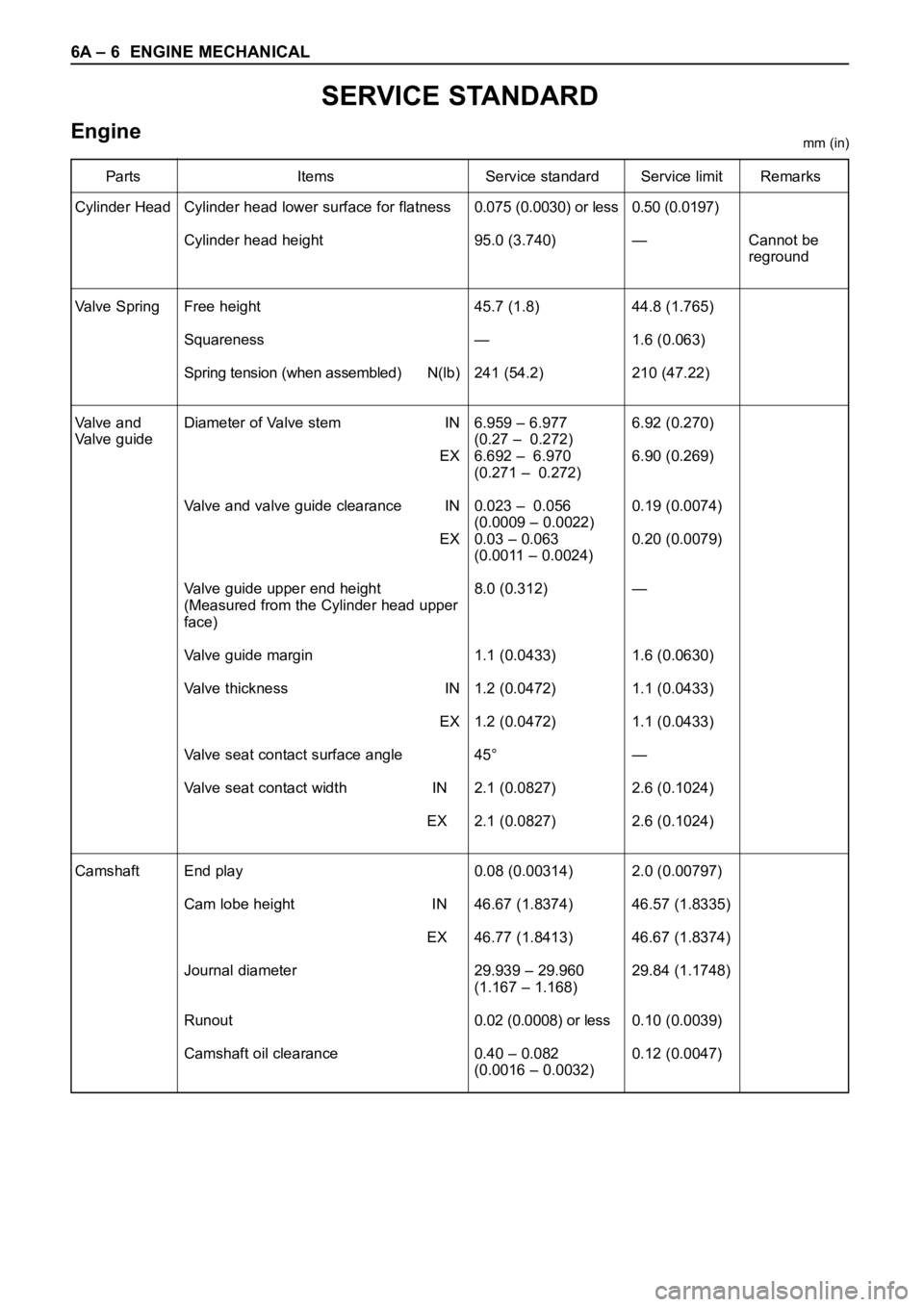

SERVICE STANDARD

Enginemm (in)

Parts Items Service standard Service limit Remarks

Cylinder Head

Va l v e S p r i n g

Va l v e a n d

Valve guide

Camshaft0.075 (0.0030) or less

95.0 (3.740)

45.7 (1.8)

—

241 (54.2)

6.959 – 6.977

(0.27 – 0.272)

6.692 – 6.970

(0.271 – 0.272)

0.023 – 0.056

(0.0009 – 0.0022)

0.03 – 0.063

(0.0011 – 0.0024)

8.0 (0.312)

1.1 (0.0433)

1.2 (0.0472)

1.2 (0.0472)

45°

2.1 (0.0827)

2.1 (0.0827)

0.08 (0.00314)

46.67 (1.8374)

46.77 (1.8413)

29.939 – 29.960

(1.167 – 1.168)

0.02 (0.0008) or less

0.40 – 0.082

(0.0016 – 0.0032)0.50 (0.0197)

—

44.8 (1.765)

1.6 (0.063)

210 (47.22)

6.92 (0.270)

6.90 (0.269)

0.19 (0.0074)

0.20 (0.0079)

—

1.6 (0.0630)

1.1 (0.0433)

1.1 (0.0433)

—

2.6 (0.1024)

2.6 (0.1024)

2.0 (0.00797)

46.57 (1.8335)

46.67 (1.8374)

29.84 (1.1748)

0.10 (0.0039)

0.12 (0.0047)Cannot be

reground Cylinder head lower surface for flatness

Cylinder head height

Free height

Squareness

Spring tension (when assembled) N(lb)

Diameter of Valve stem IN

EX

Valve and valve guide clearance IN

EX

Valve guide upper end height

(Measured from the Cylinder head upper

face)

Valve guide margin

Valve thickness IN

EX

Valve seat contact surface angle

Valve seat contact width IN

EX

End play

Cam lobe height IN

EX

Journal diameter

Runout

Camshaft oil clearance

Page 3263 of 6000

8F–68BODY STRUCTURE

Rear Door Moulding

Parts Location

645RS003

Legend

(1) Rear Door Side Moulding(2) Rear Door Corner Moulding

(3) Rear Door Upper Moulding

Removal

1. Disconnect the battery ground cable.

2. Remove rear door side moulding.

3. Remove rear door upper moulding.

4. Remove rear door corner moulding.

Avoiding the weatherstrip (3), pry the moulding (2)

out from the door frame (1).

645RS004

Installation

To install, follow the removal steps in the reverse order,

noting the following points.

1. Install each moulding with no clearance between

each piece of moulding.

2. Assemble the edge portion (A portion) of the

moulding so that the clearance between the rear side

moulding and the waist seal is 1 mm (0.04 in).

Page 3278 of 6000

8F–83 BODY STRUCTURE

Tailgate Frame Cover (LH)

Parts Location

684RW001

Legend

(1) High Mount Stop Light(2) Washer Tube

(3) Tailgate Frame Cover

Removal

1. Disconnect the battery ground cable.

2. Remove tailgate frame cover.

Pull the tailgate frame cover (2) out.

Disconnect the washer tube (1) at the nozzle and

pull the washer tube out from the frame cover (2).

Disconnect the rear defogger and pull the harness

from the cover.

684RW002

Installation

1. Install the tailgate frame cover (1).

Hit the lower A edge portion of the cover to the

tailgate flange.

Clearance between the frame cover and the tailgate

panel (B portion) is 1 mm (0.04 in).

684RS008

Page 3335 of 6000

SEATS8G–23

Reassembly (Bench Type)

To reassemble, follow the disassembly steps in the

reverse order, noting the following point.

1. Tighten the reclining device fixing bolts to the

specified torque.

Torque: 27 Nꞏm (2.8kgꞏm/20 lb ft)

2. Loosen the rubber stopper lock nut(1) and adjust the

stopper rubber(3) so there is no clearance between

the bottom of the stopper and the carpet(2), while

ensuring the rear seat is firmly locked.

Tighten the lock nut securely.

755RS005

Third Seat Assembly

Parts Location

755RW034

Legend

(1) Cover(2) Rear Side of LH

(3) Third Seat Assembly

Removal

1. Disconnect the battery ground cable.2. Remove the cover.

3. Remove the third seat assembly.

Page 3450 of 6000

SUPPLEMENTAL RESTRAINT SYSTEM9J–13

HARNESS TO ANY POWER SOURCE BEFORE

CONNECTING DEPLOYMENT HARNESS TO THE

DRIVER AIR BAG ASSEMBLY. DEPLOYMENT

HARNESS SHALL REMAIN SHORTED AND NOT BE

CONNECTED TO A POWER SOURCE UNTIL THE AIR

BAG IS TO BE DEPLOYED. THE AIR BAG

ASSEMBLY WILL IMMEDIATELY DEPLOY THE AIR

BAG WHEN A POWER SOURCE IS CONNECTED TO

IT. WEAR SAFETY GLASSES THROUGHOUT THIS

ENTIRE DEPLOYMENT AND DISPOSAL

PROCEDURE.

NOTE: This information applies only to driver air bag

assembly . Refer to “Deployment Outside Vehicle

(Passenger Air Bag assembly)” in this section for

information on passenger air bag assembly scrapping.

1. Turn ignition switch to “LOCK”, remove key.

2. Inspect 5–8840–2468–0 SRS Deployment Harness

and appropriate pigtail adapter for damage. If

harness or pigtail adapter is damaged, discard and

obtain a replacement.

3. Short the two SRS deployment harness leads

together by fully seating one banana plug into the

other. SRS deployment harness shall remain shorted

and not be connected to a power source until the air

bag is to be deployed.

827RS004

4. Connect the appropriate pigtail adapter to the SRS

deployment harness.

5. Remove the driver air bag assembly from vehicle.

Refer to “Inflator Module Removal” in this manual.

WARNING: WHEN STORING A LIVE AIR BAG

ASSEMBLY OR WHEN LEAVING A LIVE AIR BAG

ASSEMBLY UNATTENDED ON A BENCH OR OTHER

SURFACE, ALWAYS FACE THE AIR BAG AND TRIM

COVER UP AND AWAY FROM THE SURFACE. THIS

IS NECESSARY SO THAT A FREE SPACE IS

PROVIDED TO ALLOW THE AIR BAG TO EXPAND IN

THE UNLIKELY EVENT OF ACCIDENTAL

DEPLOYMENT. FAILURE TO FOLLOW

PROCEDURES MAY RESULT IN PERSONAL INJURY.6. Place the driver air bag assembly on a work bench or

other surface away from all loose or flammable

objects with its trim cover facing up, away from the

surface.

827RV003

7. Clear a space on the ground about 183 cm (six feet) in

clearance where the driver air bag assembly is to be

deployed. A paved, outdoor location where there is

no activity is preferred. If an outdoor location is not

available, a space on the shop floor where there is no

activity and sufficient ventilation is recommended.

Ensure no loose or flammable objects are within the

deployment area.

827RX032

8. Place the driver air bag assembly, with its trim cover

facing up, on the ground in the space just cleared.

9. Stretch the SRS deployment harness and pigtail

adapter from the driver air bag assembly to its full

length.

Page 3453 of 6000

SUPPLEMENTAL RESTRAINT SYSTEM 9J–16

5. Remove passenger air bag assembly from vehicle.

Refer to “Passenger Air Bag Assembly Removal ” in

this Section 9J–3.

6. Clear a space on the ground approximately 183 cm

(six feet) in clearance where the fixture with attached

air bag assembly is to be placed for deployment. A

paved outdoor location where there is no activity is

preferred. If an outdoor location is not available, a

space on the shop floor where is no activity and

sufficient ventilation is recommended. Ensure that no

loose or flammable objects are within the deployment

area.

7. Place the 5–8840–2420–0 on the bench vice. This is

necessary to provide sufficient stabilization of the

fixture during deployment.

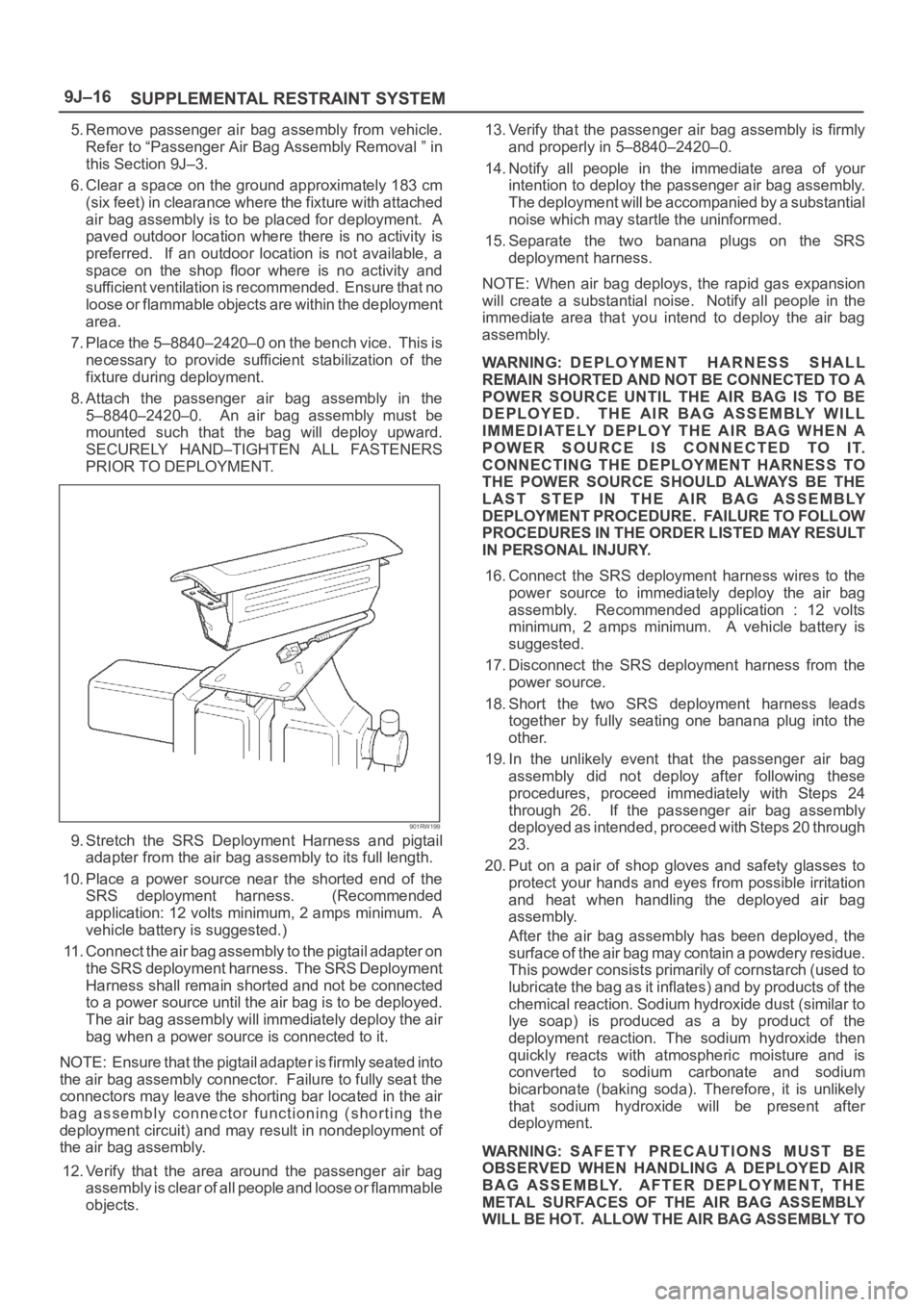

8. Attach the passenger air bag assembly in the

5–8840–2420–0. An air bag assembly must be

mounted such that the bag will deploy upward.

SECURELY HAND–TIGHTEN ALL FASTENERS

PRIOR TO DEPLOYMENT.

901RW199

9. Stretch the SRS Deployment Harness and pigtail

adapter from the air bag assembly to its full length.

10. Place a power source near the shorted end of the

SRS deployment harness. (Recommended

application: 12 volts minimum, 2 amps minimum. A

vehicle battery is suggested.)

11. Connect the air bag assembly to the pigtail adapter on

the SRS deployment harness. The SRS Deployment

Harness shall remain shorted and not be connected

to a power source until the air bag is to be deployed.

The air bag assembly will immediately deploy the air

bag when a power source is connected to it.

NOTE: Ensure that the pigtail adapter is firmly seated into

the air bag assembly connector. Failure to fully seat the

connectors may leave the shorting bar located in the air

bag assembly connector functioning (shorting the

deployment circuit) and may result in nondeployment of

the air bag assembly.

12. Verify that the area around the passenger air bag

assembly is clear of all people and loose or flammable

objects.13. Verify that the passenger air bag assembly is firmly

and properly in 5–8840–2420–0.

14. Notify all people in the immediate area of your

intention to deploy the passenger air bag assembly.

The deployment will be accompanied by a substantial

noise which may startle the uninformed.

15. Separate the two banana plugs on the SRS

deployment harness.

NOTE: When air bag deploys, the rapid gas expansion

will create a substantial noise. Notify all people in the

immediate area that you intend to deploy the air bag

assembly.

WARNING: DEPLOYMENT HARNESS SHALL

REMAIN SHORTED AND NOT BE CONNECTED TO A

POWER SOURCE UNTIL THE AIR BAG IS TO BE

DEPLOYED. THE AIR BAG ASSEMBLY WILL

IMMEDIATELY DEPLOY THE AIR BAG WHEN A

POWER SOURCE IS CONNECTED TO IT.

CONNECTING THE DEPLOYMENT HARNESS TO

THE POWER SOURCE SHOULD ALWAYS BE THE

LAST STEP IN THE AIR BAG ASSEMBLY

DEPLOYMENT PROCEDURE. FAILURE TO FOLLOW

PROCEDURES IN THE ORDER LISTED MAY RESULT

IN PERSONAL INJURY.

16. Connect the SRS deployment harness wires to the

power source to immediately deploy the air bag

assembly. Recommended application : 12 volts

minimum, 2 amps minimum. A vehicle battery is

suggested.

17. Disconnect the SRS deployment harness from the

power source.

18. Short the two SRS deployment harness leads

together by fully seating one banana plug into the

other.

19. In the unlikely event that the passenger air bag

assembly did not deploy after following these

procedures, proceed immediately with Steps 24

through 26. If the passenger air bag assembly

deployed as intended, proceed with Steps 20 through

23.

20. Put on a pair of shop gloves and safety glasses to

protect your hands and eyes from possible irritation

and heat when handling the deployed air bag

assembly.

After the air bag assembly has been deployed, the

surface of the air bag may contain a powdery residue.

Th is p ow de r con sis ts prim a r ily of c or n sta r ch ( u sed to

lubricate the bag as it inflates) and by products of the

chemical reaction. Sodium hydroxide dust (similar to

lye soap) is produced as a by product of the

deployment reaction. The sodium hydroxide then

quickly reacts with atmospheric moisture and is

converted to sodium carbonate and sodium

bicarbonate (baking soda). Therefore, it is unlikely

that sodium hydroxide will be present after

deployment.

WARNING: SAFETY PRECAUTIONS MUST BE

OBSERVED WHEN HANDLING A DEPLOYED AIR

BAG ASSEMBLY. AFTER DEPLOYMENT, THE

METAL SURFACES OF THE AIR BAG ASSEMBLY

WILL BE HOT. ALLOW THE AIR BAG ASSEMBLY TO

Page 4499 of 6000

6A–3

ENGINE MECHANICAL

General Description

Engine Cleanliness And Care

An automobile engine is a combination of many

machined, honed, polished and lapped surfaces with

tolerances that are measured in the thousandths of a

millimeter (ten thousandths of an inch). Accordingly,

when any internal engine parts are serviced, care and

cleanliness are important. Throughout this section, it

should be understood that proper cleaning and protection

of machined surfaces and friction areas is part of the

repair procedure. This is considered standard shop

practice even if not specifically stated.

A liberal coating of engine oil should be applied to all

friction areas during assembly to protect and lubricate

the surfaces on initial operation.

Whenever valve train components, pistons, piston

rings, connecting rods, rod bearings, and crankshaft

journal bearings are removed for service, they should

be retained in order.

At the time of installation, they should be installed in

the same locations and with the same mating

surfaces as when removed.

Battery cables should be disconnected before any

major work is performed on the engine. Failure to

disconnect cables may result in damage to wire

harness or other electrical parts.

The six cylinders of this engine are identified by

numbers; Right side cylinders 1, 3 and 5, Left side

cylinders 2, 4 and 6, as counted from crankshaft

pulley side to flywheel side.

General Information on Engine Service

The following information on engine service should be

noted carefully, as it is important in preventing damage

and contributing to reliable engine performance:

When raising or supporting the engine for any reason,

do not use a jack under the oil pan. Due to the small

clearance between the oil pan and the oil pump

strainer, jacking against the oil pan may cause

damage to the oil pick–up unit.

The 12–volt electrical system is capable of damaging

circuits. When performing any work where electrical

terminals could possibly be grounded, the ground

cable of the battery should be disconnected at the

battery.

Any time the intake air duct or air cleaner is removed,

the intake opening should be covered. This will

protect against accidental entrance of foreign

material into the cylinder which could cause extensive

damage when the engine is started.

Cylinder Block

The cylinder block is made of aluminum die–cast casting

for 75

V–type six cylinders. It has a rear plate integrated

structure and employs a deep skint. The cylinder liner is

cast and the liner inner diameter and crankshaft journal

diameter are classified into grades. The crankshaft is

supported by four bearings of which width of No.3 bearing

on the body side is different in order to support the thrust

bearing. The bearing cap is made of nodular cast iron and

each bearing cap uses four bolts and two side bolts.

Cylinder Head

The cylinder head, made of aluminum alloy casting

employs a pent–roof type combustion chamber with a

spark plug in the center. The intake and exhaust valves

are placed in V–type design. The ports are cross–flow

type.

Va l v e Tr a i n

Intake and exhaust camshaft on the both side of banks

are driven through an camshaft drive gear by timing belt.

The valves are operated by the camshaft and the valve

clearance is adjusted to select suitable thickness shim.

Intake Manifold

The intake manifold system is composed of the aluminum

cast common chamber and intake manifold attached with

six fuel injectors.

Exhaust Manifold

The exhaust manifold is made of nodular cast iron.

Pistons and Connecting Rods

Aluminum pistons are used after selecting the grade that

meets the cylinder bore diameter. Each piston has two

compression rings and one oil ring. The piston pin is made

of chromium steel is offset 1mm toward the thrust side,

and the thrust pressure of piston to the cylinder wall varies

gradually as the piston travels. The connecting rods are

made of forged steel. The connecting rod bearings are

graded for correct seze selection.

Crankshaft and Bearings

The crankshaft is made of Ductile cast–iron. Pins and

journals are graded for correct size selection for their

bearing.

Engine Lubrication

The oil discharged by a trochoid–type oil pump driven by

the crankshaft is fed through full–flow oil filter and to the oil

gallery provided under the crankshaft bearing cap. The oil

is then led to the crankshaft journals and cylinder head.

The crank pins are lubricated with oil from crankshaft

journals through oil holes. Also, an oil jet is fed to each

cylinder from crankshaft juornals on the connecting rod

for piston cleaning. The oil pan flange is dealed with liquid

packing only; do not deform or damage the flange surface

during removal or installation.