oil OPEL FRONTERA 1998 Owner's Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 443 of 6000

DIFFERENTIAL (FRONT) 4A1–6

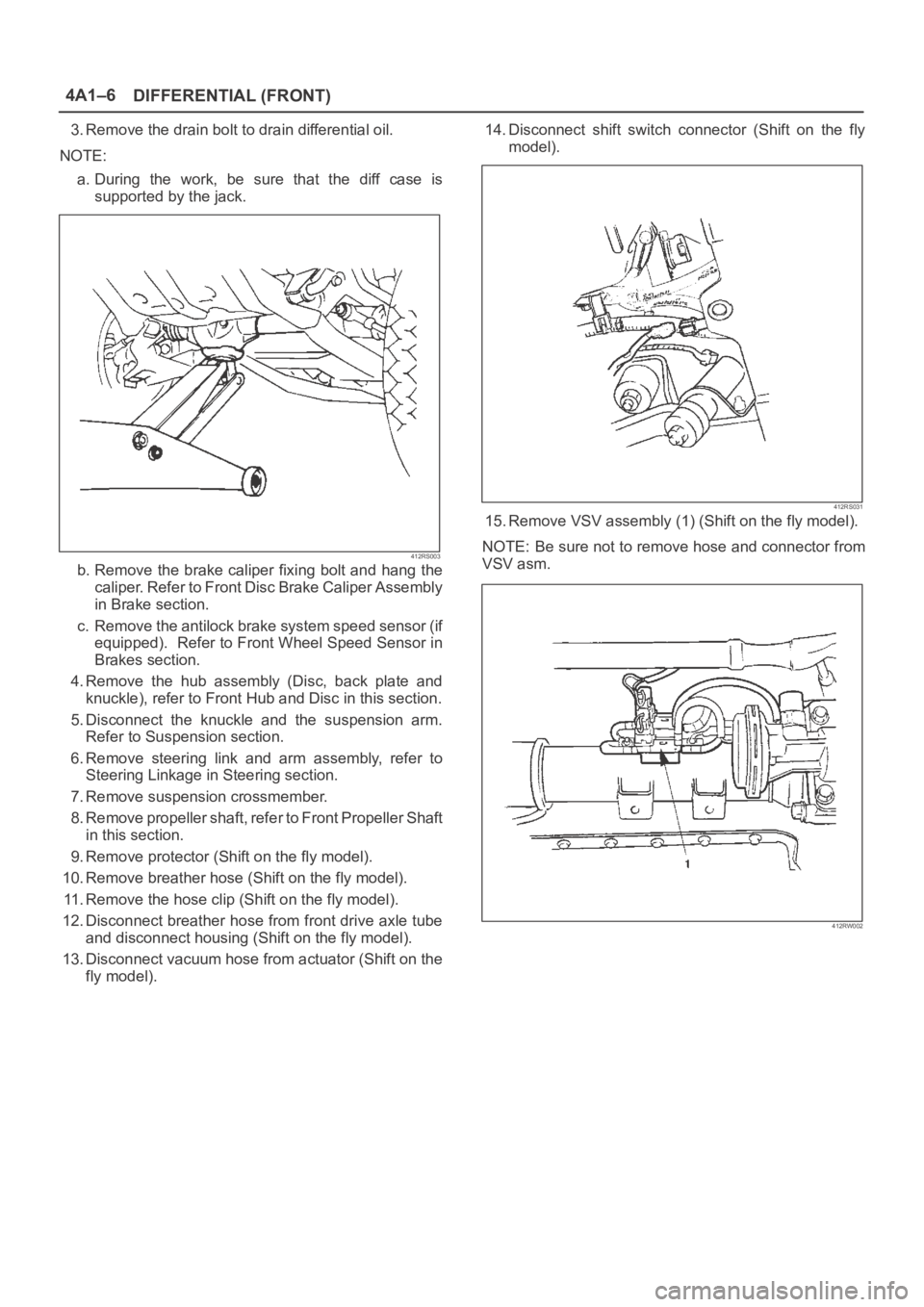

3. Remove the drain bolt to drain differential oil.

NOTE:

a. During the work, be sure that the diff case is

supported by the jack.

412RS003

b. Remove the brake caliper fixing bolt and hang the

caliper. Refer to Front Disc Brake Caliper Assembly

in Brake section.

c. Remove the antilock brake system speed sensor (if

equipped). Refer to Front Wheel Speed Sensor in

Brakes section.

4. Remove the hub assembly (Disc, back plate and

knuckle), refer to Front Hub and Disc in this section.

5. Disconnect the knuckle and the suspension arm.

Refer to Suspension section.

6. Remove steering link and arm assembly, refer to

Steering Linkage in Steering section.

7. Remove suspension crossmember.

8. Remove propeller shaft, refer to Front Propeller Shaft

in this section.

9. Remove protector (Shift on the fly model).

10. Remove breather hose (Shift on the fly model).

11. Remove the hose clip (Shift on the fly model).

12. Disconnect breather hose from front drive axle tube

and disconnect housing (Shift on the fly model).

13. Disconnect vacuum hose from actuator (Shift on the

fly model).14. Disconnect shift switch connector (Shift on the fly

model).

412RS031

15. Remove VSV assembly (1) (Shift on the fly model).

NOTE: Be sure not to remove hose and connector from

VSV asm.

412RW002

Page 446 of 6000

4A1–9 DIFFERENTIAL (FRONT)

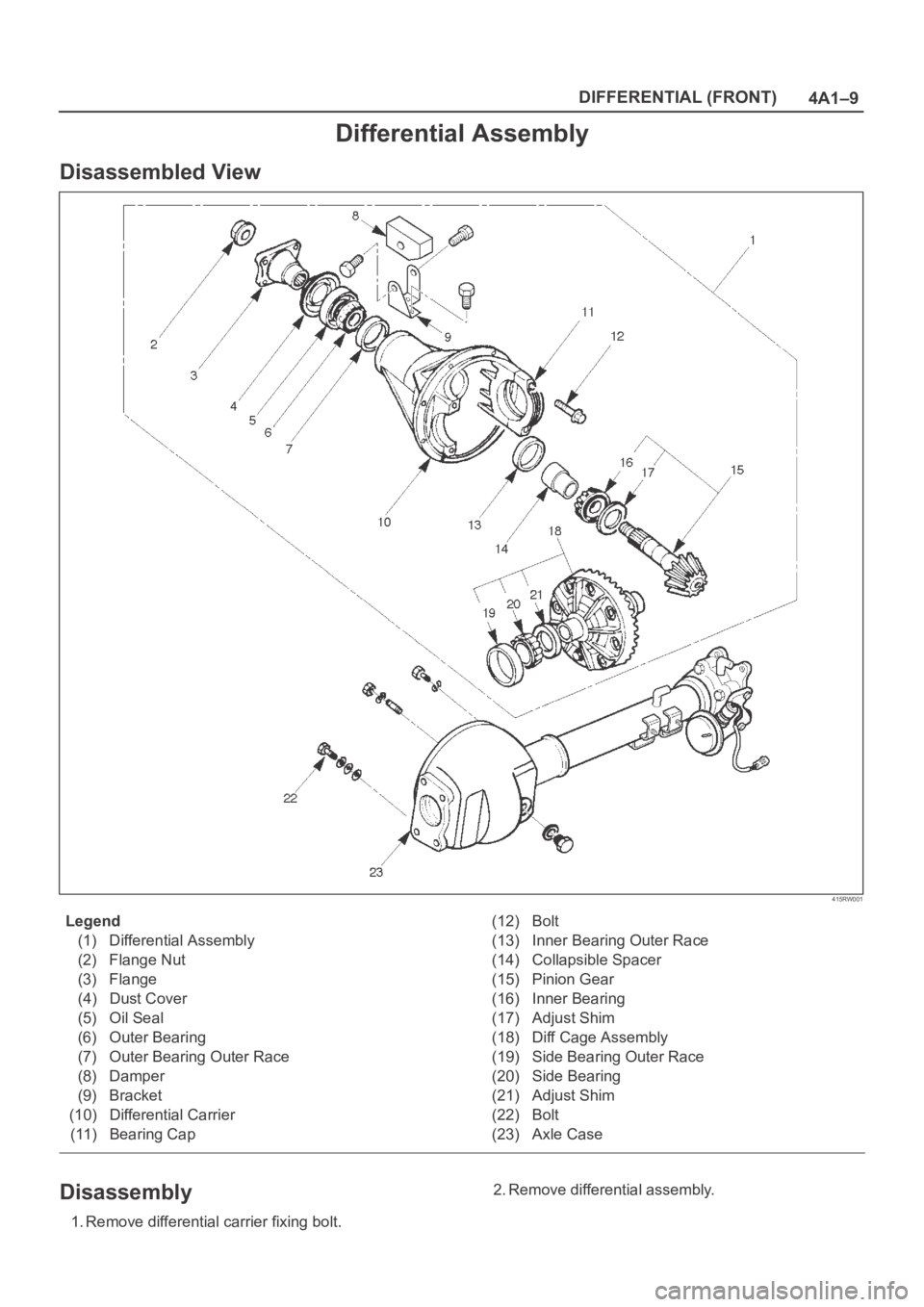

Differential Assembly

Disassembled View

415RW001

Legend

(1) Differential Assembly

(2) Flange Nut

(3) Flange

(4) Dust Cover

(5) Oil Seal

(6) Outer Bearing

(7) Outer Bearing Outer Race

(8) Damper

(9) Bracket

(10) Differential Carrier

(11) Bearing Cap(12) Bolt

(13) Inner Bearing Outer Race

(14) Collapsible Spacer

(15) Pinion Gear

(16) Inner Bearing

(17) Adjust Shim

(18) Diff Cage Assembly

(19) Side Bearing Outer Race

(20) Side Bearing

(21) Adjust Shim

(22) Bolt

(23) Axle Case

Disassembly

1. Remove differential carrier fixing bolt.2. Remove differential assembly.

Page 448 of 6000

4A1–11 DIFFERENTIAL (FRONT)

13. Remove the drive pinion assembly using a soft metal

rod and a hammer.

425RW041

14. Remove collapsible spacer.

15. Remove the inner bearing using a separator

5–8840–0015–0 and a press.

415RW033

16. Remove adjust shim.

17. Remove inner bearing outer race.

18. Remove oil seal.

19. Remove outer bearing.20. Remove the inner bearing outer race (1) and the outer

bearing outer race (2) by using a brass bar and a

hammer.

425RS014

425RS015

Page 449 of 6000

DIFFERENTIAL (FRONT) 4A1–12

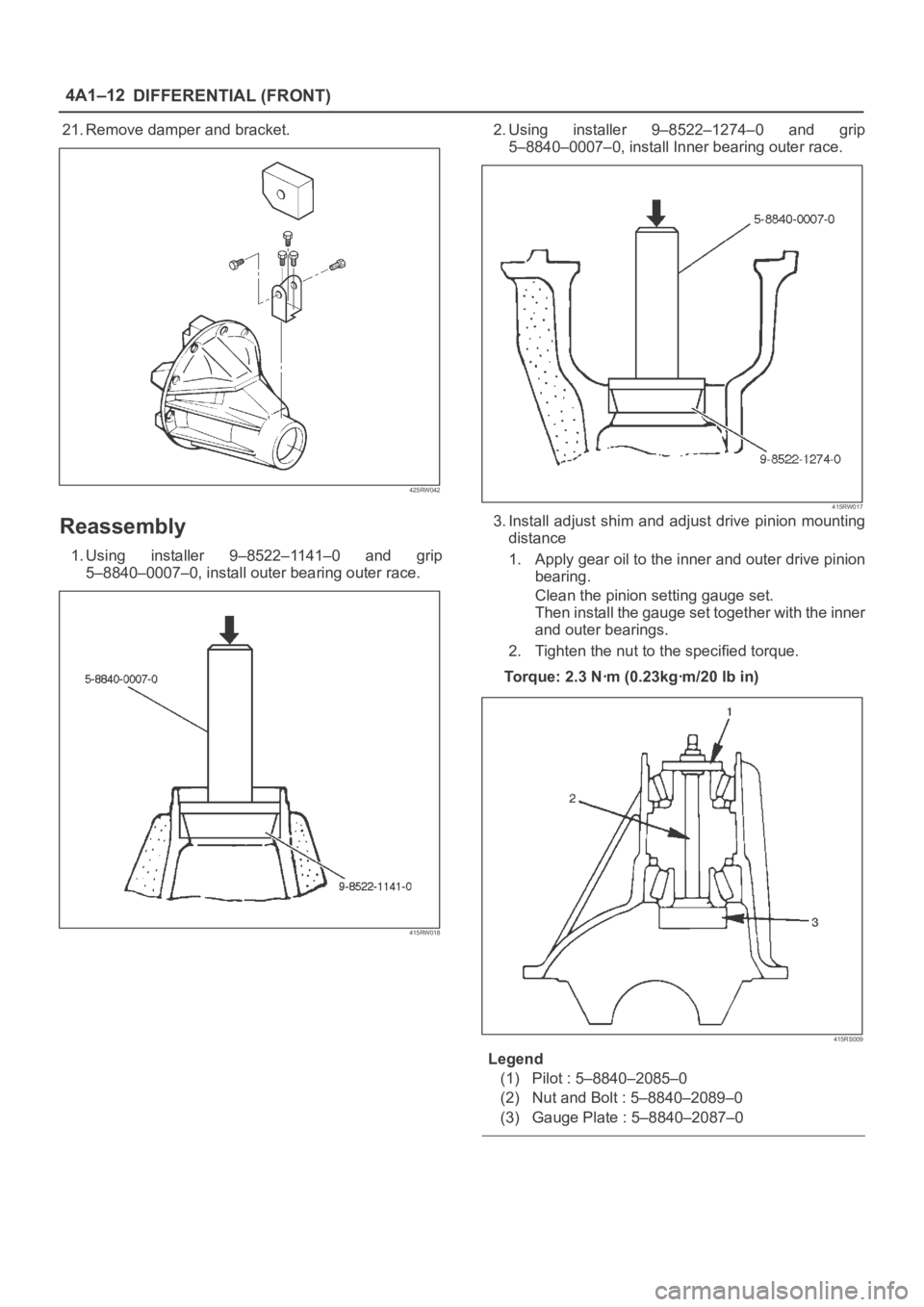

21. Remove damper and bracket.

425RW042

Reassembly

1. Using installer 9–8522–1141–0 and grip

5–8840–0007–0, install outer bearing outer race.

415RW018

2. Using installer 9–8522–1274–0 and grip

5–8840–0007–0, install Inner bearing outer race.

415RW017

3. Install adjust shim and adjust drive pinion mounting

distance

1. Apply gear oil to the inner and outer drive pinion

bearing.

Clean the pinion setting gauge set.

Then install the gauge set together with the inner

and outer bearings.

2. Tighten the nut to the specified torque.

Torque: 2.3 Nꞏm (0.23kgꞏm/20 lb in)

415RS009

Legend

(1) Pilot : 5–8840–2085–0

(2) Nut and Bolt : 5–8840–2089–0

(3) Gauge Plate : 5–8840–2087–0

Page 453 of 6000

DIFFERENTIAL (FRONT) 4A1–16

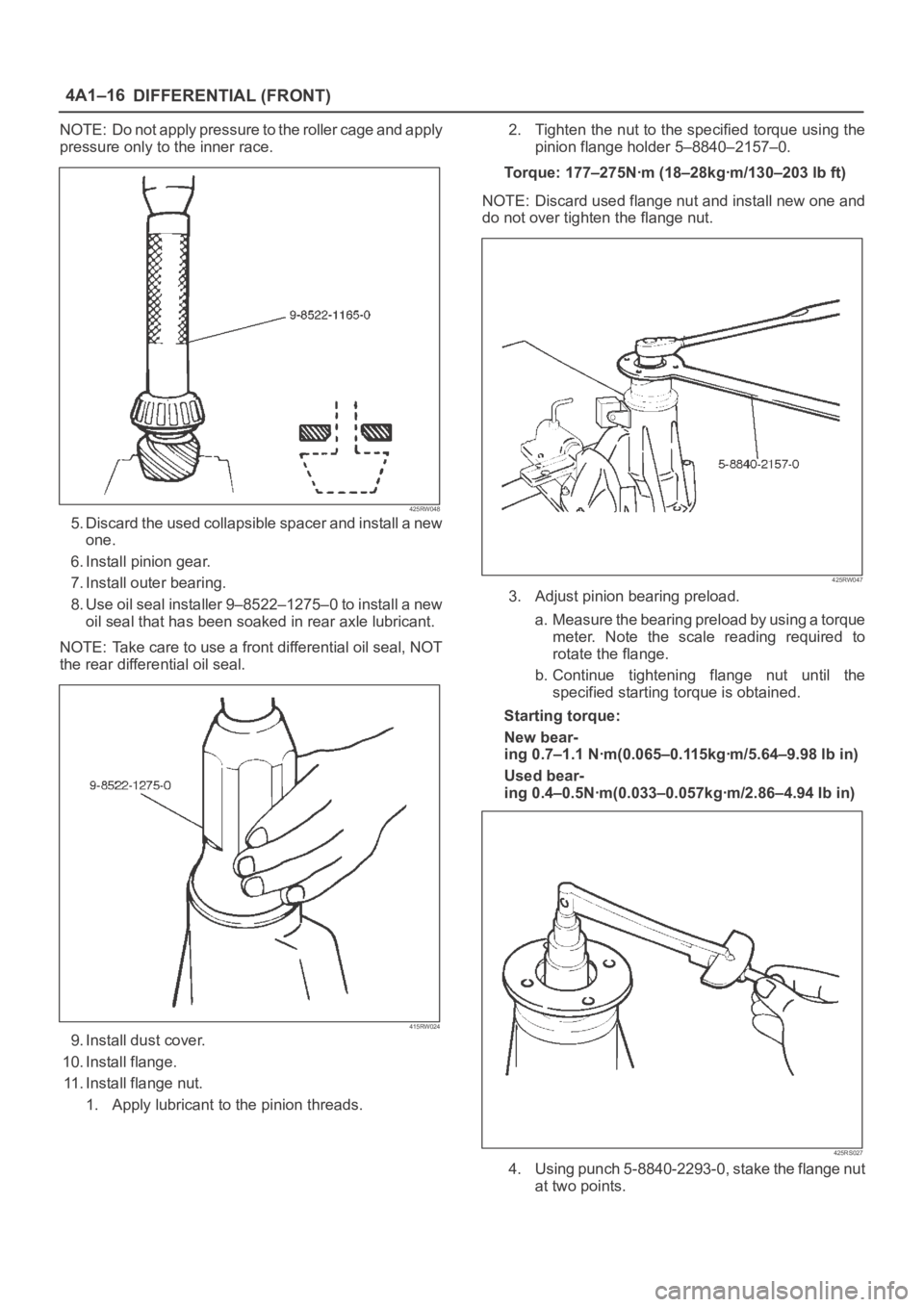

NOTE: Do not apply pressure to the roller cage and apply

pressure only to the inner race.

425RW048

5. Discard the used collapsible spacer and install a new

one.

6. Install pinion gear.

7. Install outer bearing.

8. Use oil seal installer 9–8522–1275–0 to install a new

oil seal that has been soaked in rear axle lubricant.

NOTE: Take care to use a front differential oil seal, NOT

the rear differential oil seal.

415RW024

9. Install dust cover.

10. Install flange.

11. Install flange nut.

1. Apply lubricant to the pinion threads.2. Tighten the nut to the specified torque using the

pinion flange holder 5–8840–2157–0.

Torque: 177–275Nꞏm (18–28kgꞏm/130–203 lb ft)

NOTE: Discard used flange nut and install new one and

do not over tighten the flange nut.

425RW047

3. Adjust pinion bearing preload.

a. Measure the bearing preload by using a torque

meter. Note the scale reading required to

rotate the flange.

b. Continue tightening flange nut until the

specified starting torque is obtained.

Starting torque:

New bear-

ing 0.7–1.1 Nꞏm(0.065–0.115kgꞏm/5.64–9.98 lb in)

Used bear-

ing 0.4–0.5Nꞏm(0.033–0.057kgꞏm/2.86–4.94 Ib in)

425RS027

4. Using punch 5-8840-2293-0, stake the flange nut

at two points.

Page 459 of 6000

DIFFERENTIAL (FRONT) 4A1–22

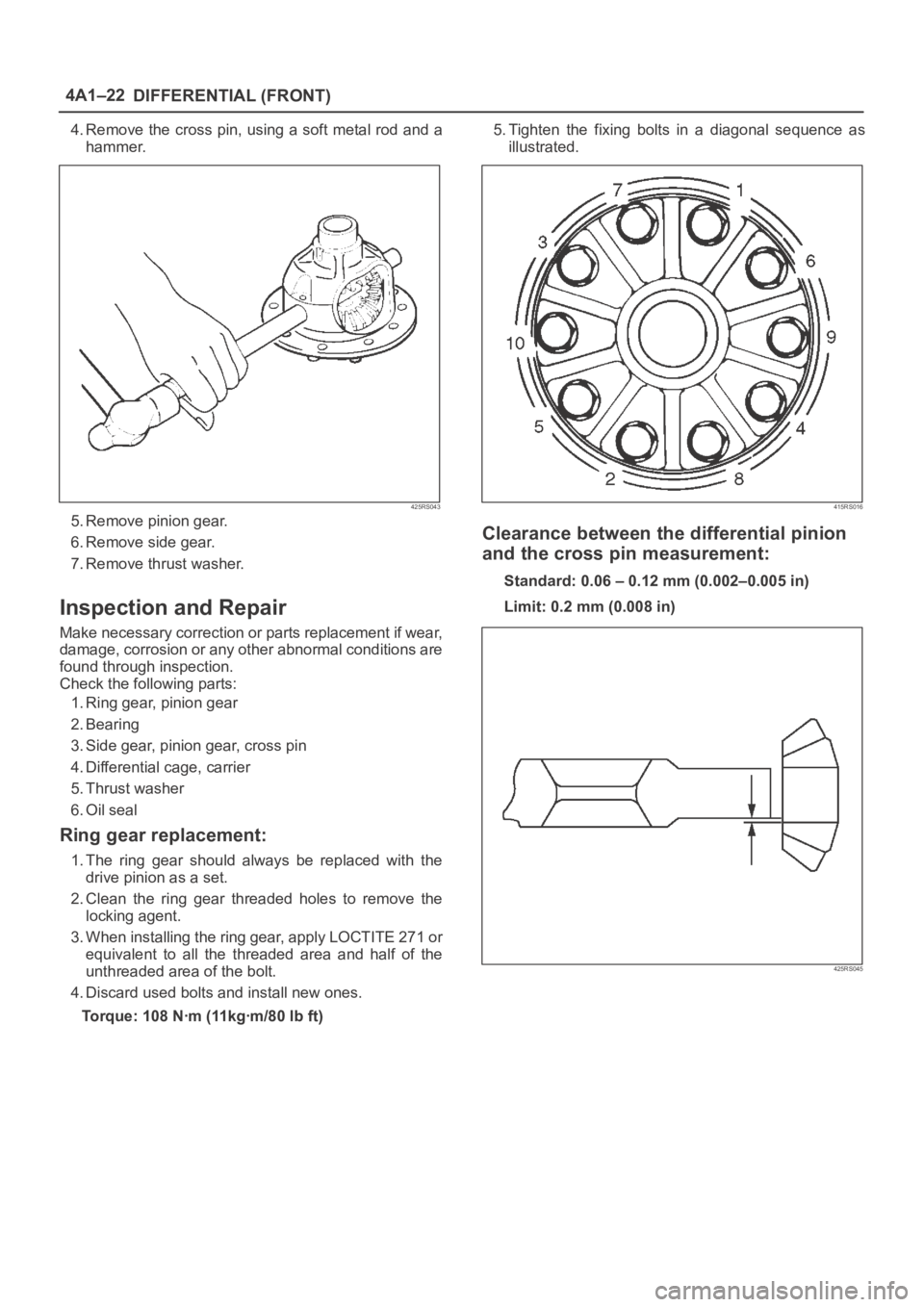

4. Remove the cross pin, using a soft metal rod and a

hammer.

425RS043

5. Remove pinion gear.

6. Remove side gear.

7. Remove thrust washer.

Inspection and Repair

Make necessary correction or parts replacement if wear,

damage, corrosion or any other abnormal conditions are

found through inspection.

Check the following parts:

1. Ring gear, pinion gear

2. Bearing

3. Side gear, pinion gear, cross pin

4. Differential cage, carrier

5. Thrust washer

6. Oil seal

Ring gear replacement:

1. The ring gear should always be replaced with the

drive pinion as a set.

2. Clean the ring gear threaded holes to remove the

locking agent.

3. When installing the ring gear, apply LOCTITE 271 or

equivalent to all the threaded area and half of the

unthreaded area of the bolt.

4. Discard used bolts and install new ones.

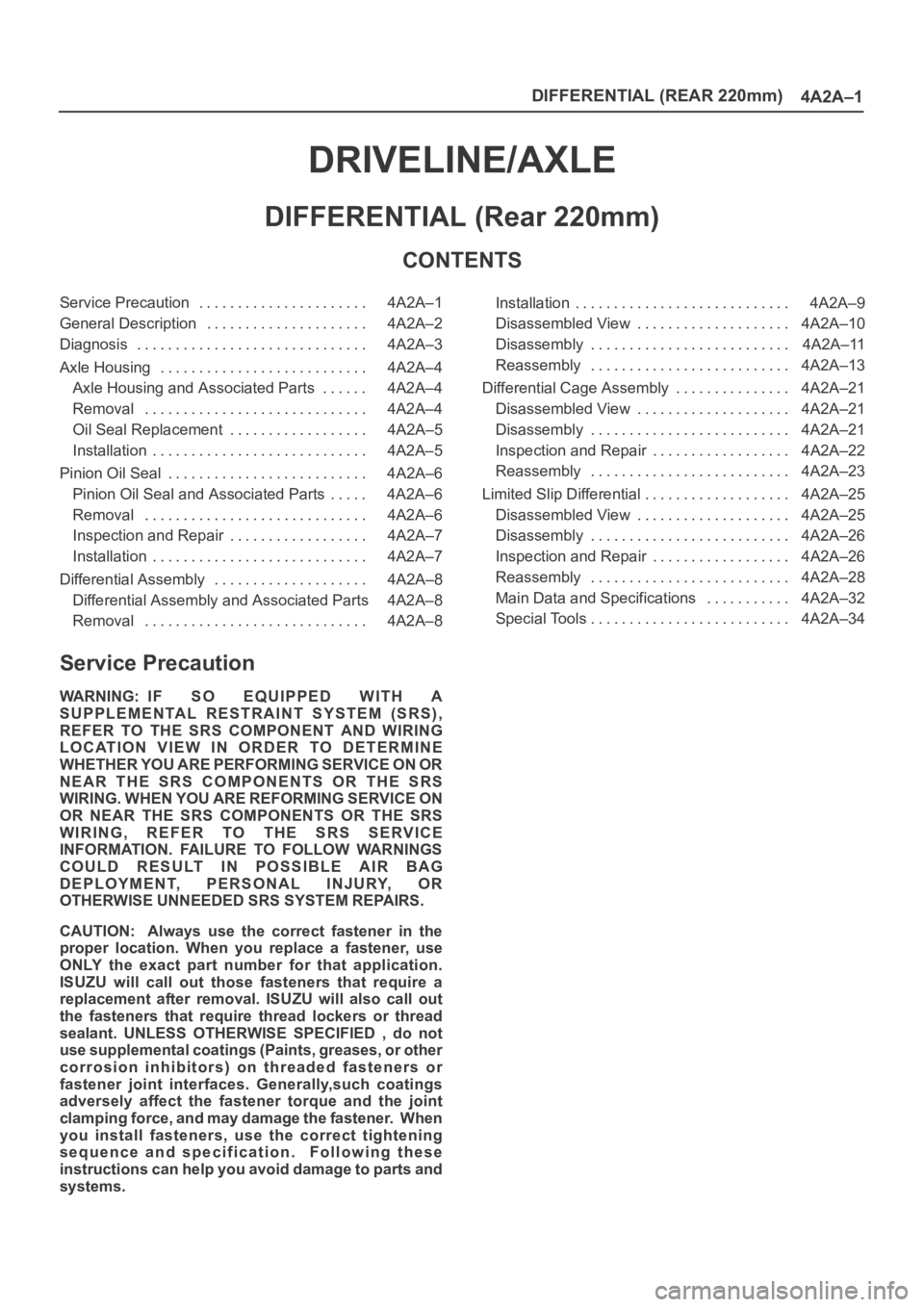

Torque: 108 Nꞏm (11kgꞏm/80 lb ft)5. Tighten the fixing bolts in a diagonal sequence as

illustrated.

415RS016

Clearance between the differential pinion

and the cross pin measurement:

Standard: 0.06 – 0.12 mm (0.002–0.005 in)

Limit: 0.2 mm (0.008 in)

425RS045

Page 462 of 6000

4A1–25 DIFFERENTIAL (FRONT)

Main Data and Specifications

General Specifications

Axle tube TypeIt consists of the duct, a cast iron housing and the axle

tube.

Gear typeHypoid

Gear ratio(to 1)4.100(6VE1)

4.300(4JX1, 6VE1)

4.555(4JG2–TC, 6VD1)

4.777(4JG2)

Differential typeTwo pinion

Oil capacityliter

(Imp qt/US qt)1.4 (1.2/1.5) (Differential)

0.12 (0.11/0.13) (Actuator Housing: Shift on the fly)

Type of lubricant75W–90 GL–5 (Multi grade type)

Refer to General Information

Axle shaft typeConstant velocity joint

(Birfield joint type and double offset joint)

Page 465 of 6000

DIFFERENTIAL (FRONT) 4A1–28

Special Tools

ILLUSTRATIONTOOL NO.

TOOL NAME

5–8840–2157–0

(J–37221)

Holder; Pinion flange

9–8522–1275–0

(J–24250)

Installer; Oil seal

5–8840–0275–0

(J–37264)

Differential holding

fixture

(Use with

5–8840–0003–0 base)

5–8840–0003–0

(J–3289–20)

Holding fixture base

5–8840–0013–0

5–8840–0014–0

(J–22888)

Puller; Side bearing

9–8521–1743–0

(J–8107–2)

Adapter; Side bearing

plug

ILLUSTRATIONTOOL NO.

TOOL NAME

5–8840–0015–0

(J–22912–01)

Separator

9–8522–1141–0

(J–24256)

Installer; Outer bearing

outer race

5–8840–0007–0

(J–8092)

Driver handle

9–8522–1274–0

(J–24252)

Installer; Inner bearing

outer race

5–8840–2085–0

(J–21777–42)

Pilot

5–8840–2089–0

(J–23597–9)

Nut and bolt

Page 468 of 6000

DIFFERENTIAL (REAR 220mm)

4A2A–1

DRIVELINE/AXLE

DIFFERENTIAL (Rear 220mm)

CONTENTS

Service Precaution 4A2A–1. . . . . . . . . . . . . . . . . . . . . .

General Description 4A2A–2. . . . . . . . . . . . . . . . . . . . .

Diagnosis 4A2A–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Axle Housing 4A2A–4. . . . . . . . . . . . . . . . . . . . . . . . . . .

Axle Housing and Associated Parts 4A2A–4. . . . . .

Removal 4A2A–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Oil Seal Replacement 4A2A–5. . . . . . . . . . . . . . . . . .

Installation 4A2A–5. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pinion Oil Seal 4A2A–6. . . . . . . . . . . . . . . . . . . . . . . . . .

Pinion Oil Seal and Associated Parts 4A2A–6. . . . .

Removal 4A2A–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 4A2A–7. . . . . . . . . . . . . . . . . .

Installation 4A2A–7. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Differential Assembly 4A2A–8. . . . . . . . . . . . . . . . . . . .

Differential Assembly and Associated Parts 4A2A–8

Removal 4A2A–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . Installation 4A2A–9. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disassembled View 4A2A–10. . . . . . . . . . . . . . . . . . . .

Disassembly 4A2A–11. . . . . . . . . . . . . . . . . . . . . . . . . .

Reassembly 4A2A–13. . . . . . . . . . . . . . . . . . . . . . . . . .

Differential Cage Assembly 4A2A–21. . . . . . . . . . . . . . .

Disassembled View 4A2A–21. . . . . . . . . . . . . . . . . . . .

Disassembly 4A2A–21. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 4A2A–22. . . . . . . . . . . . . . . . . .

Reassembly 4A2A–23. . . . . . . . . . . . . . . . . . . . . . . . . .

Limited Slip Differential 4A2A–25. . . . . . . . . . . . . . . . . . .

Disassembled View 4A2A–25. . . . . . . . . . . . . . . . . . . .

Disassembly 4A2A–26. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 4A2A–26. . . . . . . . . . . . . . . . . .

Reassembly 4A2A–28. . . . . . . . . . . . . . . . . . . . . . . . . .

Main Data and Specifications 4A2A–32. . . . . . . . . . .

Special Tools 4A2A–34. . . . . . . . . . . . . . . . . . . . . . . . . .

Service Precaution

WARNING: IF SO EQUIPPED WITH A

SUPPLEMENTAL RESTRAINT SYSTEM (SRS),

REFER TO THE SRS COMPONENT AND WIRING

LOCATION VIEW IN ORDER TO DETERMINE

WHETHER YOU ARE PERFORMING SERVICE ON OR

NEAR THE SRS COMPONENTS OR THE SRS

WIRING. WHEN YOU ARE REFORMING SERVICE ON

OR NEAR THE SRS COMPONENTS OR THE SRS

WIRING, REFER TO THE SRS SERVICE

INFORMATION. FAILURE TO FOLLOW WARNINGS

COULD RESULT IN POSSIBLE AIR BAG

DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU will call out those fasteners that require a

replacement after removal. ISUZU will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED , do not

use supplemental coatings (Paints, greases, or other

corrosion inhibitors) on threaded fasteners or

fastener joint interfaces. Generally,such coatings

adversely affect the fastener torque and the joint

c l a m p i n g f o r c e , a n d m a y d a m a g e t h e f a s t e n e r. W h e n

you install fasteners, use the correct tightening

sequence and specification. Following these

instructions can help you avoid damage to parts and

systems.

Page 471 of 6000

4A2A–4

DIFFERENTIAL (REAR 220mm)

Axle Housing

Axle Housing and Associated Parts

420RW022

Legend

(1) Coil Spring and Insulator

(2) Axle Housing Assembly

(3) ABS Speed Sensor and Harness(if equipped)

(4) Nut

(5) Parking Brake Cable

(6) Bolt and Nut

(7) Antilock Brake System (ABS) Connector and

Bracket (if equipped)

(8) Bolt and Nut(9) Nut

(10) Differential Assembly

(11) Axle Shaft Assembly

(12) Brake Disc

(13) Brake Pipe

(14) Brake Caliper

(15) Nut

(16) Breather Hose

(17) Flare Nut

Removal

1. Raise the vehicle and support it with suitable safety

stands.

The hoist must remain under the rear axle housing.

2. Drain brake fluid. Refer to Hydraulic Brakes in Brake

section.

3. Remove rear wheels and tires. Refer to Wheel in

Suspension section.4. Remove propeller shaft. Refer to Rear Propeller

Shaft in this section.

5. Drain the rear axle oil into a proper container.

6. Remove parking brake cable, release the connection

between the cable fixing clip equalizer. Refer to

Parking Brakes in Brake section.

7. Move the clip aside and pull out the breather hose.