service OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 5629 of 6000

6E–200

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

SymptomsInitial DiagnosisDefault Section(s)

Hesitation, Sag, Stumble1. OBD system check.

2. AP.

3. MAP output check.

4. Fuel system diagnosis.

5. Injector system.Generator Output Voltage (refer

to

Chassis Electrical),

Calibration ID/Service Bulletins,

Ignition System Check

Rough, Unstable, or Incorrect Idle,

Stalling1. OBD system check.

2. Fuel injector test.MAP Output Check, Throttle

Linkage, A/C Clutch Control

Circuit Diagnosis, Calibration

ID/Service Bulletins, Generator

Output Voltage (refer to

Chassis

Electrical

), Exhaust Diagnosis

Poor Fuel Economy1. OBD system check.

2. Careful visual/physical inspection.

3. Injector system.

4. Cooling system.TCC Operation, Exhaust

System (refer to

Engine

Exhaust

)

Engine Cranks But Will Not Run1. OBD system check.Fuel System Electrical

Diagnosis, Fuel System

Diagnosis, Fuel Injector Test.

Excessive Exhaust Emissions or

Odors1. OBD system check.

2. Emission test.

3. Cooling system.

4. Fuel system diagnosis.

5. Fuel injector test.

6. Injector system.

7. MAP output check.Exhaust Diagnosis, Calibration

ID/Service Bulletins

Dieseling, Run-On1. OBD system check.

2. Careful visual/physical inspection.

3. Fuel system diagnosis.—

Page 5630 of 6000

6E–201 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

On–Vehicle Service

Camshaft Position (CMP)

Sensor

Removal Procedure

1. Disconnect the negative battery cable.

2. Disconnect the electrical connector to the CMP

sensor.

035RW071

3. Remove the CMP sensor retaining bolt from the

cylinder head cover.

035RW075

Inspection Procedure

1. Inspect the sensor O-ring for cracks or leaks.

2. Replace the O-ring if it is worn or damaged.

3. Lubricate the new O-ring with engine oil.

4. Install the lubricated O-ring.

Installation Procedure

1. Install the CMP sensor in the cylinder head cover.

2. Install the CMP sensor retaining bolt.

Tighten

Tighten the retaining bolt to 9 Nꞏm (78 lb in.).

035RW075

3. Connect the electrical connector to the CMP sensor.

035RW071

4. Connect the negative battery cable.

Page 5635 of 6000

6E–206

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

3. Disconnect the electrical connector from the OT

sensor.

4. Remove the OT sensor.

035RW061

Installation Procedure

1. Install the OT sensor.

035RW061

2. Connect the OT sensor electrical connector.

3. Install the battery.

035RW095

4. Connect the negative battery cable.

Malfunction Indicator Lamp

(MIL)

Removal and Installation Procedure

Refer to Meter in Electrical section.

Engine Control Module (ECM)

Service Precaution

NOTE: To prevent possible electrostatic discharge

damage to the ECM, do not touch the connector pins or

soldered components on the circuit board.

When replacing the ECM to prevent possible electro

damage, follow these guidelines:

Before removing the ECM, disconnect the negative

battery cable.

Before install the ECM, install the negative battery cable.

Electrostatic Discharge (ESD)

Damage

Electronic components used in the control systems are

often designed to carry very low voltage. Electronic

components are susceptible to damage caused by

electrostatic discharge. Less than 100 volts of static

electricity can cause damage to some electronic

components. By comparison, it takes as much as 4,000

volts for a person to even feel the zap of a static

discharge.

There are several ways for a person to become statically

charged. The most common methods of charging are by

friction and by induction. An example of charging by

friction is a person sliding across a car seat.

Charging by induction occurs when a person with well

insulated shoes stands near a highly charged object and

momentarily touches ground. Charges of the same

polarity are drained off leaving the person highly charged

with the opposite polarity. Static charges can cause

Page 5636 of 6000

6E–207 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

damage, therefore, it is important to use care when

handling and testing electronic components.

NOTE: To prevent possible Electrostatic Discharge

damage, follow these guidelines:

Do not touch the control module connector pins or

soldered components on the control module circuit

board.

Do not open the replacement part package until the

part is ready to be installed.

Before removing the part from the package, ground

the package to a known good ground on the vehicle.

If the part has been handled while sliding across the

seat, or while sitting down from a standing position, or

while walking a distance, touch a known good ground

before installing the part.

NOTE: To prevent internal ECM damage, the ignition

must be in the “OFF” position in order to disconnect or

reconnect power to the ECM (for example: battery cable,

ECM pigtail, ECM fuse, jumper cables, etc.).

IMPORTANT:When replacing the production ECM

with a service ECM, it is important to transfer the

broadcast code and production ECM number to the

service ECM label. This will allow positive identification of

ECM parts throughout the service life of the vehicle. Do

not record this information on the metal ECM cover.

IMPORTANT:The ignition should always be in the

“OFF” position in order to install or remove the ECM

connectors.

Service of the ECM should normally consist of either re-

placement of the ECM. If the diagnostic procedures call

for the ECM to be replaced, the ECM should be checked

first to ensure it is the correct part. If it is, remove the

faulty ECM and install the new service ECM.

DTC P0601 indicates the check sum error.

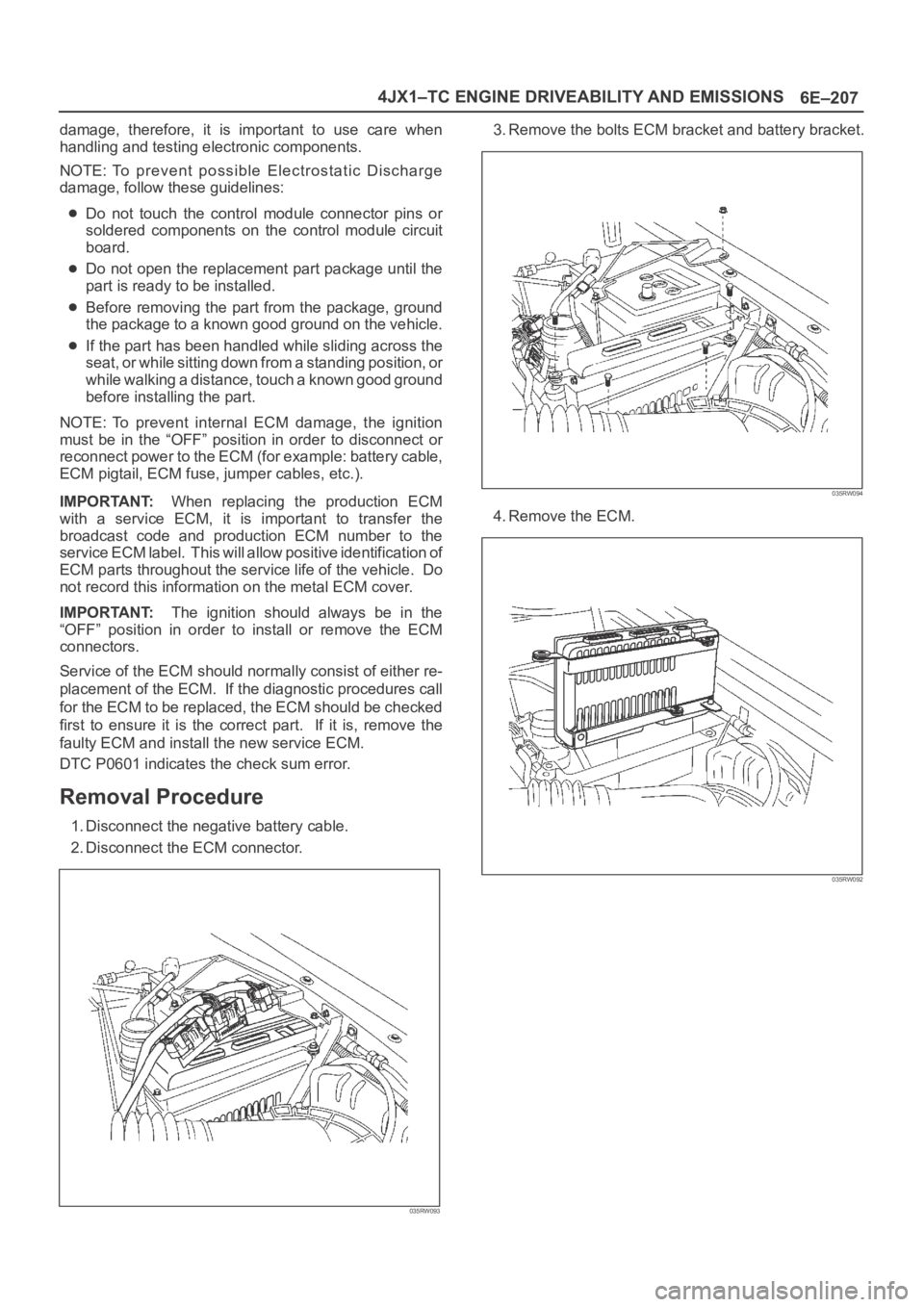

Removal Procedure

1. Disconnect the negative battery cable.

2. Disconnect the ECM connector.

035RW093

3. Remove the bolts ECM bracket and battery bracket.

035RW094

4. Remove the ECM.

035RW092

Page 5649 of 6000

6E–220

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Installation Procedure

1. Install the EVRV.

035RW064

2. Connect the EVRV hose and the EVRV connector.

035RW065

3. Connect the negative battery cable.

Wiring and Connectors

Wiring Harness Service

The ECM harness electrically connects the ECM to the

various solenoids, switches and sensors in the vehicle

engine compartment and passenger compartment.

Replace wire harnesses with the proper part number

replacement.

Because of the low amperage and voltage levels utilized

in powertrain control systems, it is essential that all wiring

in environmentally exposed areas be repaired with crimp

and seal splice sleeves.The following wire harness repair information is intended

as a general guideline only. Refer to

Chassis Electrical f o r

all wire harness repair procedures.

Connectors and Terminals

Use care when probing a connector and when replacing

terminals. It is possible to short between opposite

terminals. Damage to components could result. Always

use jumper wires between connectors for circuit

checking. NEVER probe through Weather-Pack seals.

Use an appropriate connector test adapter kit which

contains an assortment of flexible connectors used to

probe terminals during diagnosis. Use an appropriate

fuse remover and test tool for removing a fuse and to

adapt the fuse holder to a meter for diagnosis.

Open circuits are often difficult to locate by sight because

oxidation or terminal misalignment are hidden by the

connectors. Merely wiggling a connector on a sensor, or

in the wiring harness, may temporarily correct the open

circuit. Intermittent problems may also be caused by

oxidized or loose connections.

Be certain of the type of connector/terminal before

making any connector or terminal repair. Weather-Pack

and Com-Pack III terminals look similar, but are serviced

differently.

Wire Harness Repair: Twisted

Shielded Cable

Removal Procedure

1. Remove the outer jacket.

2. Unwrap the aluminum/mylar tape. Do not remove the

mylar.

047

Page 5655 of 6000

6E–226

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

0018

Manifold Absolute Pressure (MAP) Sensor

The manifold absolute pressure (MAP) sensor responds

to changes in intake manifold pressure. The MAP sensor

signal voltage to the ECM varies from below 2 volts at idle

(high vacuum) to above 4 volts.

The MAP sensor is used to determine the following:

Boost pressure for injector control.

Barometric pressure (BARO).

If the ECM detects a voltage that is lower than the

possible range of the MAP sensor, DTC P0107 will be set.

A signal voltage higher than the possible range of the

sensor will set DTC P0108. An intermittent low or high

voltage will set DTC P1107 or DTC P1106, respectively.

The ECM can detect a shifted MAP sensor. The ECM

compares the MAP sensor signal to a calculated MAP

based on throttle position and various engine load factors.

If the ECM detects a MAP signal that varies excessively

above or below the calculated value, DTC P0106 will set.

Engine Control Module (ECM)

The engine control module (ECM) is located in the engine

room.

The ECM constantly observes the information from

various sensors. The ECM controls the systems that

affect vehicle performance. The ECM performs the

diagnostic function of the system. It can recognize

operational problems, alert the driver through the MIL

(Service Engine Soon lamp), and store diagnostic trouble

codes (DTCs). DTCs identify the problem areas to aid the

technician in making repairs.

ECM Function

The ECM supplies 5, 12 and 110 volts to power various

sensors or switches. The power is supplied through

resistances in the ECM which are so high in value that a

test light will not light when connected to the circuit. In

some cases, even an ordinary shop voltmeter will not give

an accurate reading because its resistance is too low.

Therefore, a digital voltmeter with at least 10 megohms

input impedance is required to ensure accurate voltage

readings. The ECM controls output circuits such as theinjectors, glow relays, etc., by controlling the ground or

the power feed circuit through transistors or through

either of the following two devices:

Output Driver Module (ODM)

Quad Driver Module (QDM)

ECM Components

The ECM is designed to maintain exhaust emission levels

to government mandated standards while providing

excellent driveability and fuel efficiency. The ECM

monitors numerous engine and vehicle functions via

electronic sensors such as the crankshaft position (CKP)

sensor, and vehicle speed sensor (VSS). The ECM also

controls certain engine operations through the following:

Fuel injector control

Rail pressure control

ECM Voltage Description

The ECM supplies a buffered voltage to various switches

and sensors. It can do this because resistance in the

ECM is so high in value that a test light may not illuminate

when connected to the circuit. An ordinary shop

voltmeter may not give an accurate reading because the

voltmeter input impedance is too low. Use a 10-megohm

input impedance digital voltmeter to assure accurate

voltage readings.

The input/output devices in the ECM include

analog-to-digital converters, signal buffers, counters,

and special drivers. The ECM controls most components

with electronic switches which complete a ground circuit

when turned “ON.” These switches are arranged in

groups of 4 and 7, called either a surface-mounted quad

driver module (QDM), which can independently control up

to 4 output terminals, or QDMs which can independently

control up to 7 outputs. Not all outputs are always used.

ECM Input/Outputs

Inputs – Operating Conditions Read

Air Conditioning “ON” or “OFF”

Engine Coolant Temperature

Crankshaft Position

Electronic Ignition

Manifold Absolute Pressure

Battery Voltage

Intake Throttle Position

Vehicle Speed

Fuel Temperature

Oil Temperature

Intake Air Temperature

EGR boost pressure

Oil rail pressure

Camshaft Position

Accelerator position

Outputs – Systems Controlled

Exhaust Gas Recirculation (EGR)

Injector Control

QWS

Page 5656 of 6000

6E–227 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

QOS

Diagnostics

– Malfunction Indicator Lamp (Service Engine

Soon lamp)

– Data Link Connector (DLC)

– Data Output

ECM Service Precautions

The ECM is designed to withstand normal current draws

associated with vehicle operation. Avoid overloading any

circuit. When testing for opens and shorts, do not ground

or apply voltage to any of the ECM’s circuits unless

instructed to do so. These circuits should only be tested

using digital voltmeter. The ECM should remain

connected to the ECM or to a recommended breakout

box.

Intake Throttle Position (ITP) Sensor

ITP sensor is a potentiometer type and installed to the

intake throttle valve body. A voltage of 5V is applied

constantly from ECM to ITP sensor thereby to determine

by change in voltage the opening of the intake throttle

valve during warming up.

Transmission Range Switch

IMPORTANT:The vehicle should not be driven with the

transmission range switch disconnected; idle quality will

be affected.

The four inputs from the transmission range switch

indicate to the ECM which position is selected by the

transmission selector lever.

For more information on the transmission on the

transmission range switch, refer to

Automatic

Tr a n s m i s s i o n

.

Accelerator Position Sensor (AP)

AP sensor is a potentiometer type and installed to

accelerator pedal bracket. A voltage of 5V constantly

applied from ECM to the sensor thereby to determine the

accelerator pedaling angle by change in voltage. Further,

this sensor is provided with an accelerator switch, which

is set off only when the accelerator pedal is stepped on.

Aftermarket Electrical and Vacuum

Equipment

Aftermarket (add-on) electrical and vacuum equipment is

defined as any equipment which connects to the vehicle’s

electrical or vacuum systems that is installed on a vehicle

after it leaves the factory. No allowances have been

made in the vehicle design for this type of equipment.

NOTE: No add-on vacuum equipment should be added

to this vehicle.

NOTE: Add-on electrical equipment must only be

connected to the vehicle’s electrical system at the battery

(power and ground).

Add-on electrical equipment, even when installed to

these guidelines, may still cause the powertrain system to

malfunction. This may also include equipment not

connected to the vehicle electrical system such asportable telephones and radios. Therefore, the first step

in diagnosing any powertrain problem is to eliminate all

aftermarket electrical equipment from the vehicle. After

this is done, if the problem still exists, it may be diagnosed

in the normal manner.

Electrostatic Discharge Damage

Electronic components used in the ECM are often

designed to carry very low voltage. Electronic

components are susceptible to damage caused by

electrostatic discharge. Less than 100 volts of static

electricity can cause damage to some electronic

components. By comparison, it takes as much as 4000

volts for a person to feel even the zap of a static

discharge.

TS23793

There are several ways for a person to become statically

charged. The most common methods of charging are by

friction and induction.

An example of charging by friction is a person sliding

across a vehicle seat.

Charge by induction occurs when a person with well

insulated shoes stands near a highly charged object

and momentary touches ground. Charges of the

same polarity are drained off leaving the person

highly charged with the opposite polarity. Static

charges can cause damage, therefore it is important

to use care when handling and testing electronic

components.

NOTE: To prevent possible electrostatic discharge

damage, follow these guidelines:

Do not touch the ECM connector pins or soldered

components on the ECM circuit board.

Do not open the replacement part package until the

part is ready to be installed.

Before removing the part from the package, ground

the package to a known good ground on the vehicle.

If the part has been handled while sliding across the

seat, while sitting down from a standing position, or

while walking a distance, touch a known good ground

before installing the part.

Page 5660 of 6000

ENGINE EXHAUST 6F – 1

ENGINE EXHAUST

CONTENTS

CAUTION: Exhaust system components must have

enough clearance from the underbody to prevent

overheating of the floor pan and possible damage to the passenger compartment, insulation and trim

materials.

General Description . . . . . . . . . . . . . . . . . . 6F–2

Hangers . . . . . . . . . . . . . . . . . . . . . . . . . 6F–2

Gasket . . . . . . . . . . . . . . . . . . . . . . . . . . 6F–2

On-Vehicle Service . . . . . . . . . . . . . . . . . . . 6F–3

Front Exhaust Pipe . . . . . . . . . . . . . . . . . 6F–3Center Exhaust Pipe . . . . . . . . . . . . . . . . 6F–5

Exhaust Silencer . . . . . . . . . . . . . . . . . . . 6F–6

Rear Exhaust Pipe . . . . . . . . . . . . . . . . . 6F–7

Page 5662 of 6000

ENGINE EXHAUST 6F – 3

ON-VEHICLE SERVICE

FRONT EXHAUST PIPE

Rattles and noise vibrations in the exhaust system are

usually caused by misalignment of parts. When aligning

the system, leave all bolts or nuts loose until all parts

are properly aligned; then tighten, working from front to

rear.

1. Check connections for looseness or damage,

especially for exhaust gas leakage.

2. Check clamps and rubbers for weakness, cracks or

damage.3. If any part of the converter heat shield is damaged

or dented to the extent that it contacts the catalyst,

repair or replace.

4. Check for dents or damage and for any holes or

cracks caused by corrosion.

3

2 1

Legend

(1) Front exhaust pipe

(2) Center exhaust pipe

(3) Mounting rubber

150RW071

Page 5682 of 6000

INDUCTION 6J – 5

INSPECTION AND REPAIR

Make the necessary adjustments, repairs and part

replacements if excessive wear or damage is

discovered during inspection.

Minor servicing operations are described in this section.

Contact the nearest IHI SERVICE FACILITY for major

repairs and maintenance.

Refer to IHI SERVICE NETWORK at the end of this

section for the location of your area’s IHI SERVICE

FACILITY.

Turbine shaft end play.

1) Set a dial indicator to the turbine shaft end.

2) Apply a force of 11.8 N (1.2 kg / 2.6 lb)

alternately to the compressor wheel and and the

turbine wheel end.

3) Read the dial indicator.

Turbine End Play

Standard: 0.03 – 0.06 mm (0.0012 – 0.0024 in)

Limit: 0.09 mm (0.0035 in)Turbine shaft and bearing clearance

1) Set a dial indicator to the turbine shaft center

through the center housing oil drain port.

2) Move the turbine shaft from side to side.

3 Read the dial indicator.

Turbine Shaft and Bearing Clearance

Standard: 0.056 - 0.127 mm (0.0022 - 0.0050 in)

Limit: 0.14 mm (0.0055 in)

Waste gate operation

1) Remove hose from waste gate actuator side and

install pressure gauge (1) to the waste gate

actuator.

2) Operate pump of pressure gauge while engine is

stopped.

3) Read pressure at the control rod (2) move 2mm.

Pressure: 106 – 115 kPa

(796 – 862 mmHg/ 15.4 – 16.7 PSi)

036RW008

036RW010

036RW009

036RW007