check oil OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 4737 of 6000

6E–80

ENGINE DRIVEABILITY AND EMISSIONS

Circuit Description

The electronic Ignition system uses a coil-at-plug method

of spark distribution. In this type of ignition system, the

powertrain control module (PCM) triggers the correct

driver inside the ignition coil, which then triggers the

correct ignition coil based on the 58X signal received from

the crankshaft position sensor (CKP). The spark plug

connected to the coil fires when the ICM opens the ground

circuit for the coil’s primary circuit.

During crank, the PCM monitors the CKP 58X signal. The

CKP signal is used to determine which cylinder will fire

first. After the CKP 58X signal has been processed by the

PCM, it will command all six injectors to allow a priming

shot of fuel for all the cylinders. After the priming, the

injectors are left “OFF” during the next six 58X reference

pulses from the CKP. This allows each cylinder a chance

to use the fuel from the priming shot. During this waiting

period, a camshaft position (CMP) signal pulse will have

been received by the PCM. The CMP signal allows the

PCM to operate the injectors sequentially based on

camshaft position. If the camshaft position signal is not

present at start-up, the PCM will begin sequential fuel

delivery with a 1-in-6 chance that fuel delivery is correct.

The engine will run without a CMP signal, but will set a

DTC code.

Diagnostic Aids

An intermittent problem may be caused by a poor

connection, rubbed-through wire insulation or a wire

broken inside the insulation. Check for the following

items:

Poor connection or damaged harness – Inspect the

PCM harness and connectors for improper mating,

broken locks, improperly formed or damaged

terminals, poor terminal-to-wire connection, and

damaged harness.

Faulty engine coolant temperature sensor – Using

Tech 2, compare engine coolant temperature with

intake air temperature on a completely cool engine.

Engine coolant temperature should be within 10

C of

intake air temperature. If not, replace the ECT sensor.

Test Description

Number(s) below refer to the step number(s) on the

Diagnostic Chart.

5. An obvious cause of low fuel pressure would be an

empty fuel tank.

6. The engine will easily start and run if a few injectors

are disabled. It is not necessary to test all injectors

at this time since this step is only a test to verify that

all of the injectors have not been disabled by fuel

contamination.

7. A blinking test light verifies that the PCM is

monitoring the 58X crankshaft reference signal and

is capable of activating the injectors. If there is an

open or shorted driver circuit, DTCs 201-206 should

be set.

19.By using a spark tester, each ignition coil’s ability to

produce 25,000 volts is verified.

25.If there is an open or shorted driver circuit, DTCs

201-206 should be set. All six injector driver circuits

can be checked at one time without removing the

intake manifold if a 5-8840-2636-0 test light is

available. This is the alternative procedure:

With the ignition “OFF,” disconnect the gray

connector located at the rear of the air filter, attached

to a bracket on the purge canister.

Connect test light 5-8840-2636-0 to the connector.

Do any of the light constantly illuminate or fail to blink

when the engine is cranked? If so, repair the short or

open circuit, or replace the PCM if indicated.

This procedure only tests the driver circuit as far as the

test connection, so step 31 is added to test the circuit all

the way to the injector.

Page 4738 of 6000

6E–81 ENGINE DRIVEABILITY AND EMISSIONS

Engine Cranks But Will Not Run

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

2Check the 15 A ignition coil fuse, the 15 A engine fuse,

and the 30 A PCM fuse.

Was a fuse blown?

—Go to Step 3Go to Step 4

3Check for a short to ground and replace the fuse.

Is the action complete?

—Verify repair—

41. Ignition “OFF,” install a fuel pressure gauge at the

test fitting on the fuel supply line in the engine

compartment. (Use a shop cloth to absorb any fuel

leakage while making the connection.)

2. Ignition “ON,” observe the fuel pressure.

Is the fuel pressure within the specified values, and

does it hold steady?

285-376 kPa

(43-55 psi)

Go to Step 6Go to Step 5

5Is any fuel pressure indicated?

—

Go to Fuel

System

Electrical TestGo to Fuel

System

Diagnosis

6Install an injector switch box to the injector test

connector, and attempt to operate the injector.

Did the fuel pressure drop when the injector is

operated?

—Go to Step 7Go to Step 12

7Install an injector test light at the #2 cylinder injector

harness connector.

Does the light blink when the engine is cranked?

—Go to Step 8Go to Step 18

81. Ignition “ON.”

2. While the coil connectors are disconnected, touch

each coil connector’s ignition feed terminal with a

grounded test light (the ignition feed wire is black

with orange tracer).

Did the test light illuminate?

—Go to Step 10Go to Step 9

9Repair the open ignition feed circuit.

Is the action complete?

—Verify repair—

10While the coil connectors are disconnected, touch

each connector’s secondary ground terminal with a

test light to B+. (The ground wires are black.)

Did the test light illuminate at each coil connector?

—Go to Step 12Go to Step 11

11Repair the open secondary ground circuit.

Is the action complete?

—Verify repair—

121. Test the fuel for contamination.

2. If a problem is found, clean the fuel system and

correct the contaminated fuel condition as

necessary. Replace the fuel filter and replace any

injectors that are not delivering fuel (see Injector

Balance Test).

Was a problem found?

—Verify repairGo to Step 13

Page 4743 of 6000

6E–86

ENGINE DRIVEABILITY AND EMISSIONS

CAUTION: To reduce the risk of fire and personal

injury:

It is necessary to relieve fuel system pressure

before connecting a fuel pressure gauge. Refer to

Fuel Pressure Relief Procedure, below.

A small amount of fuel may be released when

disconnecting the fuel lines. Cover fuel line

fittings with a shop towel before disconnecting, to

catch any fuel that may leak out. Place the towel in

an approved container when the disconnect is

completed.

Fuel Pressure Relief Procedure

1. Remove the fuel cap.

2. Remove the fuel pump relay from the underhood

relay center.

3. Start the engine and allow it to stall.

4. Crank the engine for an additional 3 seconds.

Fuel Gauge Installation

1. Remove the shoulder fitting cap.

2. Install fuel gauge 5-8840-0378-0 to the fuel feed line

located in front of and above the right side valve train

cover .

3. Reinstall the fuel pump relay.

Fuel System Electrical Test

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

21. Read the “Caution” above.

2. Relieve the fuel system pressure and install the fuel

pump pressure gauge to the test fitting.

3. Use Tech 2 to command the fuel pump “ON.”

Is there an immediate pressure build-up which

indicates the pump is running?

—Go to Step 3Go to Step 4

31. Verify that the pump is not running by removing the

fuel filler cap and listening.

2. Command the pump “ON” with Tech 2.

Did the pump turn “OFF” after 2 seconds?

—

Te s t

completed

Go to Step 12

41. Ignition “OFF.”

2. Remove the fuel pump relay.

3. Using a test light connected to ground, probe the

battery feed to the relay.

Did the light illuminate?

—Go to Step 6Go to Step 5

5Repair short or open battery feed to fuel pump relay.

Is the action complete?

—Verify repair—

61. Connect a test light between the two wires that

connect to the fuel pump relay pull-in coil.

2. Ignition “ON.”

Did the test light illuminate for 2 seconds and then turn

off?

—Go to Step 12Go to Step 7

71. With a test light connected to battery (–), probe the

fuel pump relay connector at the wire which runs

from the relay pull-in coil to the PCM.

2. Ignition “ON.”

Did the test light illuminate for 2 seconds and then turn

off?

—Go to Step 8Go to Step 9

8Locate and repair open in the fuel pump relay ground

circuit.

Is the action complete?

—Verify repair—

Page 4762 of 6000

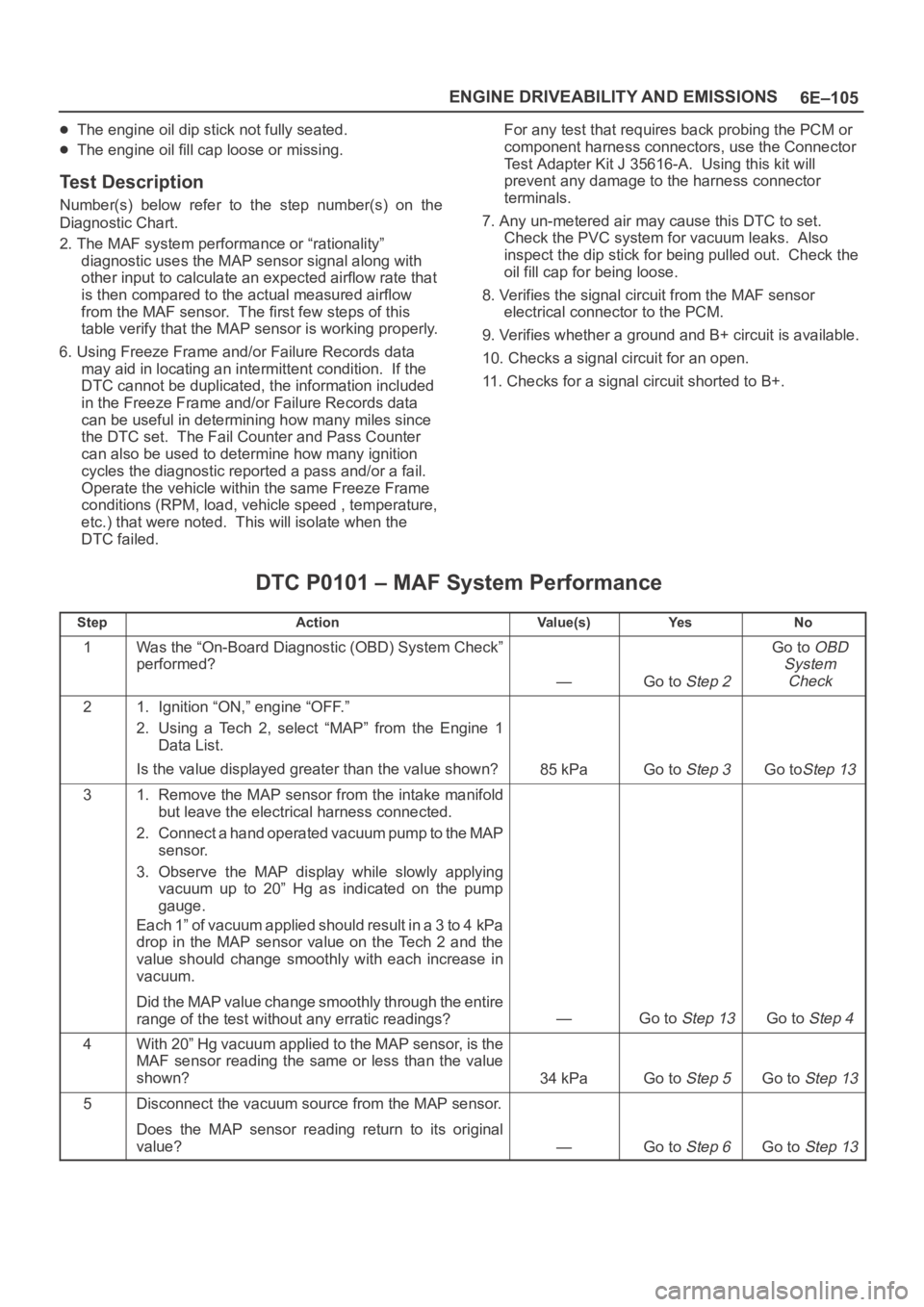

6E–105 ENGINE DRIVEABILITY AND EMISSIONS

The engine oil dip stick not fully seated.

The engine oil fill cap loose or missing.

Test Description

Number(s) below refer to the step number(s) on the

Diagnostic Chart.

2. The MAF system performance or “rationality”

diagnostic uses the MAP sensor signal along with

other input to calculate an expected airflow rate that

is then compared to the actual measured airflow

from the MAF sensor. The first few steps of this

table verify that the MAP sensor is working properly.

6. Using Freeze Frame and/or Failure Records data

may aid in locating an intermittent condition. If the

DTC cannot be duplicated, the information included

in the Freeze Frame and/or Failure Records data

can be useful in determining how many miles since

the DTC set. The Fail Counter and Pass Counter

can also be used to determine how many ignition

cycles the diagnostic reported a pass and/or a fail.

Operate the vehicle within the same Freeze Frame

conditions (RPM, load, vehicle speed , temperature,

etc.) that were noted. This will isolate when the

DTC failed.For any test that requires back probing the PCM or

component harness connectors, use the Connector

Test Adapter Kit J 35616-A. Using this kit will

prevent any damage to the harness connector

terminals.

7. Any un-metered air may cause this DTC to set.

Check the PVC system for vacuum leaks. Also

inspect the dip stick for being pulled out. Check the

oil fill cap for being loose.

8. Verifies the signal circuit from the MAF sensor

electrical connector to the PCM.

9. Verifies whether a ground and B+ circuit is available.

10. Checks a signal circuit for an open.

11. Checks for a signal circuit shorted to B+.

DTC P0101 – MAF System Performance

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

21. Ignition “ON,” engine “OFF.”

2. Using a Tech 2, select “MAP” from the Engine 1

Data List.

Is the value displayed greater than the value shown?

85 kPaGo to Step 3Go toStep 13

31. Remove the MAP sensor from the intake manifold

but leave the electrical harness connected.

2. Connect a hand operated vacuum pump to the MAP

sensor.

3. Observe the MAP display while slowly applying

vacuum up to 20” Hg as indicated on the pump

gauge.

Each 1” of vacuum applied should result in a 3 to 4 kPa

drop in the MAP sensor value on the Tech 2 and the

value should change smoothly with each increase in

vacuum.

Did the MAP value change smoothly through the entire

range of the test without any erratic readings?

—Go to Step 13Go to Step 4

4With 20” Hg vacuum applied to the MAP sensor, is the

MAF sensor reading the same or less than the value

shown?

34 kPaGo to Step 5Go to Step 13

5Disconnect the vacuum source from the MAP sensor.

Does the MAP sensor reading return to its original

value?

—Go to Step 6Go to Step 13

Page 4827 of 6000

6E–170

ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0201 Injector 1 Control Circuit

D06RW034

Circuit Description

The powertrain control module (PCM) has six individual

injector driver circuits. Each controls an injector. When a

driver circuit is grounded by the PCM, the injector is

activated. The PCM monitors the current in each driver

circuit. The voltage on each driver is monitored to detect

a fault. If the voltage is not what the PCM expects to

m o n i t o r o n t h e c i r c u i t , a D T C i s s e t . T h i s D T C i s a l s o s e t i f

an injector driver is shorted to voltage or if there is an open

circuit.

Conditions for Setting the DTC

The battery voltage is more than 9 volts.

The engine is turning, determined by 58X crankshaft

position input signal.

The injector voltage does not equal the ignition voltage

when the injector is commanded “OFF” or the injector

voltage does not equal 0 volts when the injector is

commanded “ON.”

The above conditions are met for 15 seconds.

Action Taken When the DTC Sets

The PCM will illuminate the malfunction indicator lamp

(MIL) the first time the fault is detected.

The PCM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

DTC P0201 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the PCM battery

feed.

Diagnostic Aids

An injector driver circuit that is open or shorted to voltage

will cause a DTC P0201 to set. It will also cause a misfire

due to an inoperative injector. A misfire DTC will also be

set indicating which cylinder is inoperative.

Long term and short term fuel trims that are excessively

high or low are a good indication that an injector is faulty.

Use Fuel Injector Coil Test Procedure to check for faulty

injectors.

Test Description

The number(s) below refer to the step number(s) on the

Diagnostic Chart.

3. This step determines if DTC P0201 is the result of a

hard failure or an intermittent condition.

5. A special injector test connector is provided so that

the injectors can be electrically tested without

removal of the manifold. On the Trooper, the

special 7-way gray connector is located at the front

of the charcoal canister. The test connector can be

identified by the blue connector lock which is

tethered to the wiring harness. If the light for

cylinder 1 is “ON” steady before cranking the engine

as well as while cranking the engine, then the

injector driver circuit is shorted to ground.

Page 4828 of 6000

6E–171 ENGINE DRIVEABILITY AND EMISSIONS

If the test light blinks while cranking, the PCM and

the wiring to the injectors are OK. The Fuel Injector

Coil Test Procedure will check if the injectors are

faulty.

R321054

7. Because the test light was “ON” steady, voltage to

the injector is OK, but the driver circuit is grounded

at all times. This step determines if the circuit is

shorted to ground or the PCM is faulty.

9. The reading should be about 12-14

.

10.Locating the open in the harness or in the injector

will require removal of the manifold to provide

access.

DTC P0201 – Injector 1 Control Circuit

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

2Will the engine start?

—Go to Step 3

Go to Engine

Cranks But

Will Not Run

chart

31. Install the Tech 2. Clear the DTC.

2. Idle the engine for one minute.

Does DTC P0201 reset?

—Go to Step 5Go to Step 4

41. Review the Freeze Frame data with the ignition

“ON” and the engine “OFF” and note the

parameters.

2. Operate the vehicle within the Freeze Frame

conditions as noted.

Does P0201 reset?

—Go to Step 5

Go to

Diagnostic

Aids

51. Engine “OFF.”

2. Disconnect the injector connector.

3. Install an injector test light 5-8840-2636-0 on the

injector test connector.

4. Crank the engine and note the light.

Does the injector test light blink?

—

Go to Fuel

Injector Coil

Te s t

Procedure

Go to Step 6

6Note whether the injector test light for cylinder 1 was

“OFF” or “ON” steady in step 5.

Was the test light “ON” steady while cranking the

engine?

—Go to Step 7Go to Step 9

Page 4830 of 6000

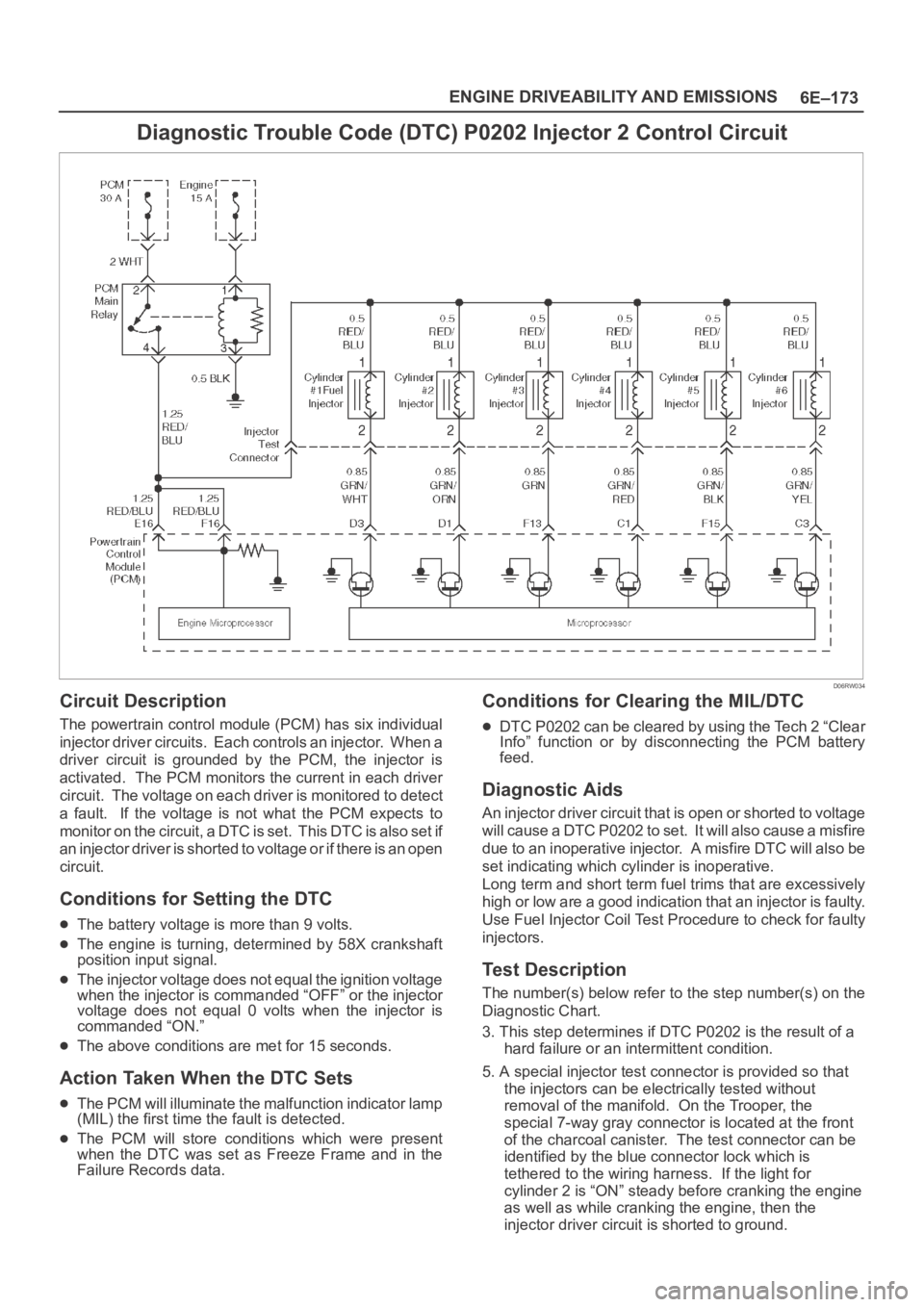

6E–173 ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0202 Injector 2 Control Circuit

D06RW034

Circuit Description

The powertrain control module (PCM) has six individual

injector driver circuits. Each controls an injector. When a

driver circuit is grounded by the PCM, the injector is

activated. The PCM monitors the current in each driver

circuit. The voltage on each driver is monitored to detect

a fault. If the voltage is not what the PCM expects to

m o n i t o r o n t h e c i r c u i t , a D T C i s s e t . T h i s D T C i s a l s o s e t i f

an injector driver is shorted to voltage or if there is an open

circuit.

Conditions for Setting the DTC

The battery voltage is more than 9 volts.

The engine is turning, determined by 58X crankshaft

position input signal.

The injector voltage does not equal the ignition voltage

when the injector is commanded “OFF” or the injector

voltage does not equal 0 volts when the injector is

commanded “ON.”

The above conditions are met for 15 seconds.

Action Taken When the DTC Sets

The PCM will illuminate the malfunction indicator lamp

(MIL) the first time the fault is detected.

The PCM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

DTC P0202 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the PCM battery

feed.

Diagnostic Aids

An injector driver circuit that is open or shorted to voltage

will cause a DTC P0202 to set. It will also cause a misfire

due to an inoperative injector. A misfire DTC will also be

set indicating which cylinder is inoperative.

Long term and short term fuel trims that are excessively

high or low are a good indication that an injector is faulty.

Use Fuel Injector Coil Test Procedure to check for faulty

injectors.

Test Description

The number(s) below refer to the step number(s) on the

Diagnostic Chart.

3. This step determines if DTC P0202 is the result of a

hard failure or an intermittent condition.

5. A special injector test connector is provided so that

the injectors can be electrically tested without

removal of the manifold. On the Trooper, the

special 7-way gray connector is located at the front

of the charcoal canister. The test connector can be

identified by the blue connector lock which is

tethered to the wiring harness. If the light for

cylinder 2 is “ON” steady before cranking the engine

as well as while cranking the engine, then the

injector driver circuit is shorted to ground.

Page 4831 of 6000

6E–174

ENGINE DRIVEABILITY AND EMISSIONS

If the test light blinks while cranking, the PCM and

the wiring to the injectors are OK. The Fuel Injector

Coil Test Procedure will check if the injectors are

faulty.

R321055

7. Because the test light was “ON” steady, voltage to

the injector is OK, but the driver circuit is grounded

at all times. This step determines if the circuit is

shorted to ground or the PCM is faulty.

9.The reading should be about 12-14

.

10.Locating the open in the harness or in the injector

will require removal of the manifold to provide

access.

DTC P0202 – Injector 2 Control Circuit

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

2Will the engine start?

—Go to Step 3

Go to Engine

Cranks But

Will Not Run

chart

31. Install the Tech 2. Clear the DTC.

2. Idle the engine for one minute.

Does DTC P0202 reset?

—Go to Step 5Go to Step 4

41. Review the Freeze Frame data with the ignition

“ON” and the engine “OFF” and note the

parameters.

2. Operate the vehicle within the Freeze Frame

conditions as noted.

Does P0202 reset?

—Go to Step 5

Go to

Diagnostic

Aids

51. Engine “OFF.”

2. Disconnect the injector test connector.

3. Install an injector test light 5-8840-2636-0 on

injector connector.

4. Crank the engine and note the light.

Does the cylinder 2 test light blink?

—

Go to Fuel

Injector Coil

Te s t

Procedure

Go to Step 6

6Note whether the injector test light for cylinder 2 was

“OFF” or “ON” steady in step 5.

Was the test light “ON” steady while cranking the

engine?

—Go to Step 7Go to Step 9

Page 4833 of 6000

6E–176

ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0203 Injector 3 Control Circuit

D06RW034

Circuit Description

The powertrain control module (PCM) has six individual

injector driver circuits. Each controls an injector. When

the driver circuit is grounded by the PCM, the injector is

activated. The PCM monitors the current in each driver

circuit. The voltage on each driver is monitored to detect

a fault. If the voltage is not what the PCM expects to

m o n i t o r o n t h e c i r c u i t , a D T C i s s e t . T h i s D T C i s a l s o s e t i f

an injector driver is shorted to voltage or if there is an open

circuit.

Conditions for Setting the DTC

The battery voltage is more than 9 volts.

The engine is turning, determined by the 58X

crankshaft position input signal.

The injector voltage does not equal the ignition voltage

when the injector is commanded “OFF” or the injector

voltage does not equal 0 volts when the injector is

commanded “ON.”

The above conditions are met for 15 seconds.

Action Taken When the DTC Sets

The PCM will illuminate the malfunction indicator lamp

(MIL) the first time the fault is detected.

The PCM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

DTC P0203 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the PCM battery

feed.

Diagnostic Aids

An injector driver circuit that is open or shorted to voltage

will cause a DTC P0203 to set. It will also cause a misfire

due to an inoperative injector. A misfire DTC will also be

set indicating which cylinder is inoperative.

Long term and short term fuel trims that are excessively

high or low are a good indication that an injector is faulty.

Use Fuel Injector Coil Test Procedure to check for faulty

injectors.

Test Description

The number(s) below refer to the step number(s) on the

Diagnostic Chart.

3. This step determines if DTC P0203 is the result of a

hard failure or an intermittent condition.

5. A special injector test connector is provided so that

the injectors can be electrically tested without

removal of the manifold. On the Trooper, the

special 7-way gray connector is located at the front

of the charcoal canister. The test connector can be

identified by the blue connector lock which is

tethered to the wiring harness. If the light for

cylinder 3 is “ON” steady before cranking the engine

as well as while cranking the engine, then the

injector driver circuit is shorted to ground.

Page 4834 of 6000

6E–177 ENGINE DRIVEABILITY AND EMISSIONS

If the test light blinks while cranking, the PCM and

the wiring to the injectors are OK. The Fuel Injector

Coil Test Procedure will check if the injectors are

faulty.

R321056

7. Because the test light was “ON” steady, voltage to

the injector is OK, but the driver circuit is grounded

at all times. This step determines if the circuit is

shorted to ground or the PCM is faulty.

9. The reading should be about 12-14

.

10.Locating the open in the harness or in the injector

will require removal of the manifold to provide

access.

DTC P0203 – Injector 3 Control Circuit

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

2Will the engine start?

—Go to Step 3

Go to Engine

Cranks But

Will Not Run

chart

31. Install the Tech 2. Clear the DTC.

2. Idle the engine for one minute.

Does DTC P0203 reset?

—Go to Step 5Go to Step 4

41. Review the Freeze Frame data with the ignition

“ON” and the engine “OFF” and note the

parameters.

2. Operate the vehicle within the Freeze Frame

conditions as noted.

Does P0203 reset?

—Go to Step 5

Go to

Diagnostic

Aids

51. Engine “OFF.”

2. Disconnect the injector test connector .

3. Install an injector test light 5-8840-2636-0 on

injector connector.

4. Crank the engine and note the light.

Does the cylinder 3 test light blink?

—

Go to Fuel

Injector Coil

Te s t

Procedure

Go to Step 6

6Note whether the injector test light for cylinder 3 was

“OFF” or “ON” steady in step 5.

Was the test light “ON” steady while cranking the

engine?

—Go to Step 7Go to Step 9