clutch OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 5610 of 6000

6E–181 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Lack of Power, Sluggish or Spongy Symptom

StepActionVa l u e ( s )Ye sNo

1DEFINITION:

Engine delivers less than expected power. Little or no

increase in speed when accelerator pedal is pushed

down part-way.

Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

21. Perform a bulletin search.

2. If a bulletin that addresses the symptom is found,

correct the condition as instructed in the bulletin.

Was a bulletin found that addresses the symptom?

—Verify repairGo to Step 3

3Was a visual/physical check performed?

—Go to Step 4

Go to Visual/

Physical

Check

41. Remove and check the air filter element for dirt or

restrictions. Refer to

Air Intake System in

On-Vehicle Service.

2. Replace the air filter element if necessary.

Was a repair required?

—Verify repairGo to Step 5

51. Check AP sensor system. Refer to AP sensor

diagnostic

.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 6

61. Check for water-or alcohol-contaminated fuel.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 7

71. Using a Tech 2, Injector test.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 8

81. Check the ECM grounds for the cleanliness,

tightness and proper locations. Refer to the ECM

wiring diagrams in

Electrical Diagnosis.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 9

91. Check the exhaust system for possible restriction:

Inspect the exhaust system for damaged or

collapsed pipes.

Inspect the muffler for heat distress or possible

internal failure.

Check for a possible plugged catalytic

converter by checking the exhaust system

back pressure. Refer to

Restricted Exhaust

System Check

.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 10

101. Check the torque converter clutch (TCC) for proper

operation. Refer to

Transmission Diagnosis.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 11

Page 5629 of 6000

6E–200

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

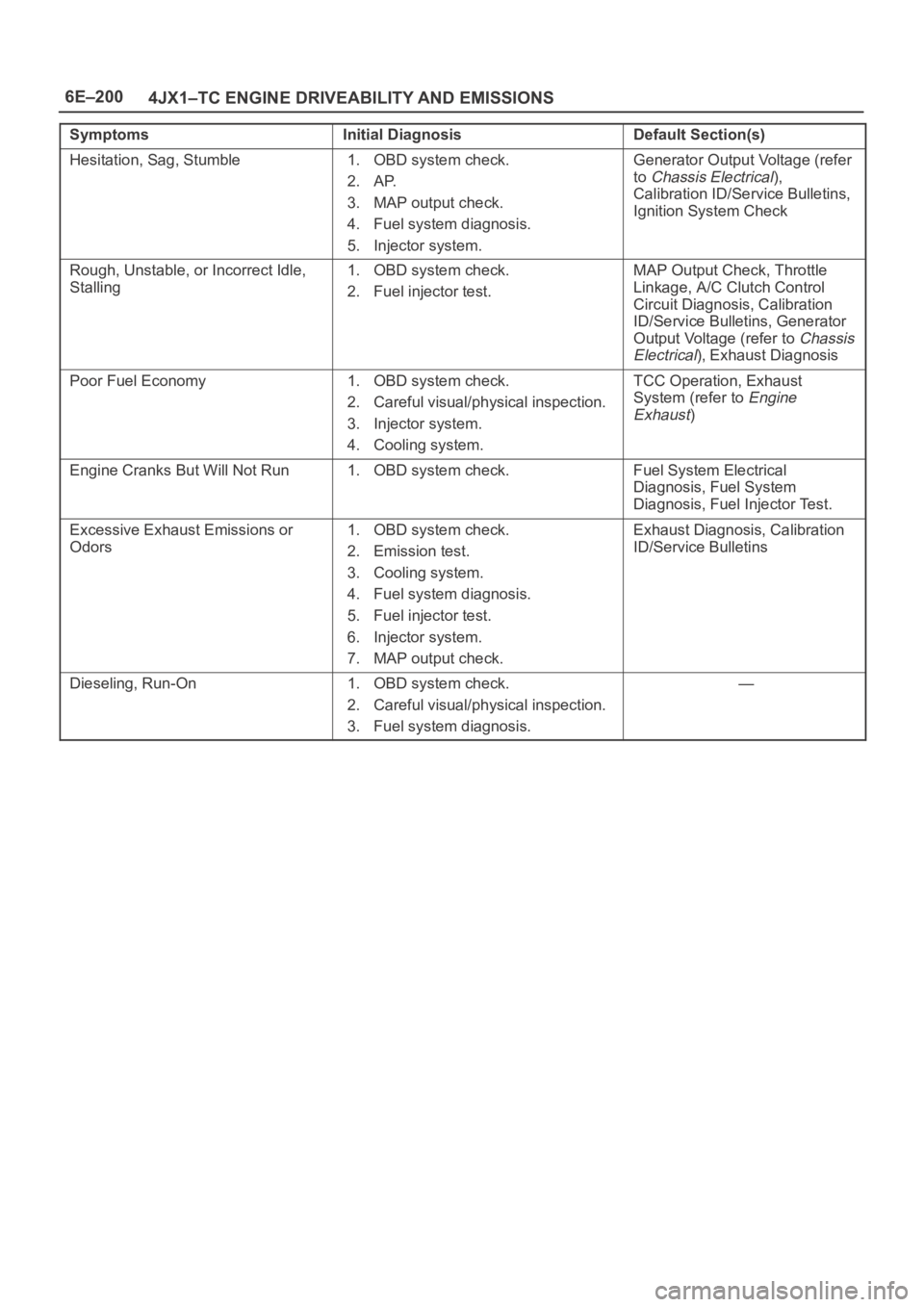

SymptomsInitial DiagnosisDefault Section(s)

Hesitation, Sag, Stumble1. OBD system check.

2. AP.

3. MAP output check.

4. Fuel system diagnosis.

5. Injector system.Generator Output Voltage (refer

to

Chassis Electrical),

Calibration ID/Service Bulletins,

Ignition System Check

Rough, Unstable, or Incorrect Idle,

Stalling1. OBD system check.

2. Fuel injector test.MAP Output Check, Throttle

Linkage, A/C Clutch Control

Circuit Diagnosis, Calibration

ID/Service Bulletins, Generator

Output Voltage (refer to

Chassis

Electrical

), Exhaust Diagnosis

Poor Fuel Economy1. OBD system check.

2. Careful visual/physical inspection.

3. Injector system.

4. Cooling system.TCC Operation, Exhaust

System (refer to

Engine

Exhaust

)

Engine Cranks But Will Not Run1. OBD system check.Fuel System Electrical

Diagnosis, Fuel System

Diagnosis, Fuel Injector Test.

Excessive Exhaust Emissions or

Odors1. OBD system check.

2. Emission test.

3. Cooling system.

4. Fuel system diagnosis.

5. Fuel injector test.

6. Injector system.

7. MAP output check.Exhaust Diagnosis, Calibration

ID/Service Bulletins

Dieseling, Run-On1. OBD system check.

2. Careful visual/physical inspection.

3. Fuel system diagnosis.—

Page 5654 of 6000

6E–225 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

General Description

(ECM and Sensors)

57X Reference ECM Input

The engine control module (ECM) uses this signal from

the crankshaft position (CKP) sensor to calculate engine

RPM and crankshaft position at all engine speeds. The

ECM also uses the pulses on this circuit to initiate injector

pulses. If the ECM receives no pulses on this circuit, DTC

P0337 will set. The engine will not start and run without

using the 57X reference signal.

A/C Request Signal

This signal tells the ECM when the A/C mode is selected

at the A/C control head.

Refer to

A/C Clutch Circuit Diagnosis for A/C wiring

diagrams and diagnosis for the A/C electrical system.

Crankshaft Position (CKP) Sensor

The crankshaft position (CKP) sensor provides a signal

used by the engine control module (ECM) to calculate the

ignition sequence. The CKP sensor initiates the 57X

reference pulses which the ECM uses to calculate RPM

and crankshaft position.

Refer to

Electronic Ignition System for additional

information.

Camshaft Position (CMP) Sensor and

Signal

The camshaft position (CMP) sensor sends a CMP signal

to the ECM. The ECM uses this signal as a “cylinder

distinction” to trigger the injectors in the power order. If the

ECM detects an incorrect CMP signal while the engine is

running, DTC P0341 will set, and the ECM triggers the

injectors in the power order.

Refer to

DTC P0341.

Engine Coolant Temperature (ECT) Sensor

The engine coolant temperature (ECT) sensor is a

thermistor (a resistor which changes value based on

temperature) mounted in the engine coolant stream. Low

coolant temperature produces a high resistance of

100,000 ohms at –40

C (–40F). High temperature

causes a low resistance of 70 ohms at 130

C (266F).

The ECM supplies a 5-volt signal to the ECT sensor

through resistors in the ECM and measures the voltage.

The signal voltage will be high when the engine is cold and

low when the engine is hot. By measuring the voltage, the

ECM calculates the engine coolant temperature. Engine

coolant temperature affects most of the systems that the

ECM controls.

The Tech 2 displays engine coolant temperature in

degrees. After engine start-up, the temperature should

rise steadily to about 85

C (185F). It then stabilizes

when the thermostat opens. If the engine has not been

run for several hours (overnight), the engine coolanttemperature and intake air temperature displays should

be close to each other. A hard fault in the engine coolant

sensor circuit will set DTC P0117 or DTC P0118.

0016

Electrically Erasable Programmable Read

Only Memory (EEPROM)

The electrically erasable programmable read only

memory (EEPROM) is a permanent memory chip that is

physically soldered within the ECM. The EEPROM

contains the program and the calibration information that

the ECM needs to control powertrain operation.

Unlike the PROM used in past applications, the EEPROM

is not replaceable. If the ECM is replaced, the new ECM

will need to be programmed. Equipment containing the

correct program and calibration for the vehicle is required

to program the ECM.

Intake Air Temperature (IAT) Sensor

The intake air temperature (IAT) sensor is a thermistor

which changes its resistance based on the temperature of

air entering the engine. Low temperature produces a high

resistance of 100,000 ohms at –40

C (–40F). High

temperature causes low resistance of 70 ohms at 130

C

(266

F) . The ECM supplies a 5-volt signal to the sensor

through a resistor in the ECM and monitors the signal

voltage. The voltage will be high when the incoming air is

cold. The voltage will be low when the incoming air is hot.

By measuring the voltage, the ECM calculates the

incoming air temperature.

The Tech 2 displays the temperature of the air entering

the engine. The temperature should read close to the

ambient air temperature when the engine is cold and rise

as underhood temperature increases. If the engine has

not been run for several hours (overnight), the IAT sensor

temperature and engine coolant temperature should read

close to each other. A fault in the IAT sensor circuit will set

DTC P0112 or DTC P0113.

Page 5657 of 6000

6E–228

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

General Description (Air Induction)

Air Induction System

The air induction system filters contaminants from the

outside air, and directs the progress of the air as it is

drawn into the engine. A remote-mounted air cleaner

prevents dirt and debris in the air from entering the

engine. The air duct assembly routes filtered air to the

throttle body. Air enters the engine by to following steps:

1. Through the throttle body.

2. Into the intake manifold.

3. Through the cylinder head intake ports.

4. Into the cylinders.

General Description (Fuel Metering)

Deceleration Mode

The ECM reduces the amount of fuel injected when it

detects a decrease in the Accelerator position.

Fuel Injector

Fuel injector comprises the solenoid, hydraulic line, and

fuel line. Fuel injection is controlled by the continuity time

signal and continuity start timing signal from ECM to the

solenoid

ECM determines the running conditions of engine by

input signals such as engine speed. Accelerator throttle

valve opening, and engine coolant temperature, thereby

to send the solenoid the best suited signal to the engine

status. When current is carried to the solenoid, the

armature opens the poppet valve to alow high pressure oil

to run into the injector. Under the pressure of the oil, the

piston and plunger are depressed to compress the fuel in

the combustion chamber of the plunger. Specifically, the

pressure of the fuel compressed is increased by a piston

top/ plunger bottom area ratio over the pressure of high

pressure oil, thereby lifting the fuel nozzle end needle for

injecting fuel.

Fuel Metering System Components

The fuel metering system is made up of the following

parts:

The fuel injectors.

The intake throttle body.

The Accelerator position (AP) sensor

The ECM.

The crankshaft position (CKP) sensor.

The camshaft position (CMP) sensor.

Basic System Operation

Fuel is supplied through fuel filter to the fuel pump.

The fuel pump is installed to the oil pump, and fuel is

forced, through the fuel pump outlet, pipe and cylinder

head inside, into the fuel injector.

An orifice is provided at the rear fuel outlet of cylinder

head to control the pressure of oil.The injector is controlled by ECM which gives

opening/closing commands to the solenoid installed on

the top of the injector. Opening/closing operation of the

pressurized engine oil circuit of the injector controls fuel

injection quantity, fuel injection timing, etc.

A/C Clutch Diagnosis

A/C Request Signal

This signal tells the ECM when the A/C mode is selected

at the A/C control head. The ECM uses this to adjust the

idle speed.

Refer to

A/C Clutch Circuit Diagnosis for A/C wiring

diagrams and diagnosis for A/C electrical system.

General Description Exhaust Gas

Recirculation (EGR) System

EGR Purpose

The exhaust gas recirculation (EGR) system is use to

reduce emission levels of oxides of nitrogen (NOx). NOx

emission levels are caused by a high combustion

temperature. The EGR system lowers the NOx emission

levels by decreasing the combustion temperature.

The ECM uses information from the following sensors to

control EGR valve boost pressure.

ECT

ITP

Engine Speed

AP sensor

Page 5690 of 6000

7A–1 AUTOMATIC TRANSMISSION (4L30–E)

TRANSMISSION

AUTOMATIC TRANSMISSION (4L30–E)

CONTENTS

Service Precaution 7A–3. . . . . . . . . . . . . . . . . . . . . .

Construction 7A–3. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Range Reference Chart 7A–4. . . . . . . . . . . . . . . . . .

Normal Operation Of 2000 4L30–E

Transmission 7A–5. . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagnosis 7A–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Driver Information 7A–5. . . . . . . . . . . . . . . . . . . . . . .

General Diagnosis Procedure 7A–8. . . . . . . . . . . . .

Preliminary Inspection Chart 7A–9. . . . . . . . . . . . . .

Checking Transmission Fluid Level and

Condition 7A–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test Driving 7A–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mechanical / Hydraulic Diagnosis Check Trans

Indicator Chart 7A–12. . . . . . . . . . . . . . . . . . . . . . . . . .

Mechanical / Hydraulic Diagnosis

Symptoms Index 7A–13. . . . . . . . . . . . . . . . . . . . . . . .

Stall Test 7A–23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Line Pressure Test 7A–23. . . . . . . . . . . . . . . . . . . . . .

Shift Speed Chart (V6 3.2L 6VD1 Model) 7A–24. . .

Shift Speed Chart (V6 3.5L 6VE1 Model) 7A–26. .

Lockup Speed Chart (V6 3.2L 6VD1 Model) 7A–28

Lockup Speed Chart (V6 3.5L 6VE1 Model) 7A–28

Changing Transmission Fluid 7A–29. . . . . . . . . . . . .

Selector Lever 7A–29. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection 7A–29. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 7A–30. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 7A–30. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mode Switch 7A–31. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 7A–31. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 7A–31. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transmission (With Transfer Case) 7A–33. . . . . . . .

Transmission And Associated Parts 7A–33. . . . . .

Removal 7A–33. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 7A–35. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Solenoid (Main Case Valve Body) 7A–39. . . . . . . . .

Removal 7A–39. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 7A–39. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Solenoid (Adapter Case Valve Body) 7A–40. . . . . . .

Removal 7A–40. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 7A–40. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Valve Body Assembly (Main Case) 7A–41. . . . . . . .

Removal 7A–41. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 7A–41. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Valve Body Assembly (Adapter Case) 7A–43. . . . . .

Removal 7A–43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . Installation 7A–43. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Powertrain Control Module (PCM) 7A–43. . . . . . . . .

Removal 7A–43. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 7A–43. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Speed Sensor (Extension Housing) 7A–44. . . . . . . .

Removal 7A–44. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 7A–44. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transmission Oil Temperature Sensor

(Adapter Case) 7A–44. . . . . . . . . . . . . . . . . . . . . . . . .

Removal 7A–44. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 7A–45. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Oil Seal (Converter Housing) 7A–45. . . . . . . .

Removal 7A–45. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 7A–45. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rear Oil Seal (Extension Housing) 7A–46. . . . . . . . .

Removal 7A–46. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 7A–46. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transmission (4L30–E) 7A–46. . . . . . . . . . . . . . . . . .

Disassembly 7A–46. . . . . . . . . . . . . . . . . . . . . . . . . .

Reassembly 7A–50. . . . . . . . . . . . . . . . . . . . . . . . . .

Converter Housing And Oil Pump Assembly 7A–60

Disassembled View 7A–60. . . . . . . . . . . . . . . . . . . .

Disassembly 7A–60. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection And Repair 7A–60. . . . . . . . . . . . . . . . . .

Reassembly 7A–60. . . . . . . . . . . . . . . . . . . . . . . . . .

Oil Pump 7A–61. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disassembled View 7A–61. . . . . . . . . . . . . . . . . . . .

Disassembly 7A–61. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection And Repair 7A–61. . . . . . . . . . . . . . . . . .

Reassembly 7A–61. . . . . . . . . . . . . . . . . . . . . . . . . .

Main Case Valve Body 7A–62. . . . . . . . . . . . . . . . . . .

Disassembled View 7A–62. . . . . . . . . . . . . . . . . . . .

Disassembly 7A–62. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection And Repair 7A–63. . . . . . . . . . . . . . . . . .

Reassembly 7A–63. . . . . . . . . . . . . . . . . . . . . . . . . .

Adapter Case Valve Body 7A–64. . . . . . . . . . . . . . . .

Disassembled View 7A–64. . . . . . . . . . . . . . . . . . . .

Disassembly 7A–64. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection And Repair 7A–64. . . . . . . . . . . . . . . . . .

Reassembly 7A–64. . . . . . . . . . . . . . . . . . . . . . . . . .

Third Clutch And Sprag Unit 7A–65. . . . . . . . . . . . . .

Disassembled View 7A–65. . . . . . . . . . . . . . . . . . . .

Disassembly 7A–65. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection And Repair 7A–66. . . . . . . . . . . . . . . . . .

Page 5691 of 6000

7A–2

AUTOMATIC TRANSMISSION (4L30–E)

Reassembly 7A–66. . . . . . . . . . . . . . . . . . . . . . . . . .

Third Clutch 7A–67. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disassembled View 7A–67. . . . . . . . . . . . . . . . . . . .

Disassemble 7A–67. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection And Repair 7A–67. . . . . . . . . . . . . . . . . .

Reassembly 7A–67. . . . . . . . . . . . . . . . . . . . . . . . . .

Sprag Unit 7A–69. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disassembled View 7A–69. . . . . . . . . . . . . . . . . . . .

Disassembly 7A–69. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection And Repair 7A–69. . . . . . . . . . . . . . . . . .

Reassembly 7A–69. . . . . . . . . . . . . . . . . . . . . . . . . .

Second Clutch 7A–70. . . . . . . . . . . . . . . . . . . . . . . . . .

Disassembled View 7A–70. . . . . . . . . . . . . . . . . . . .

Disassembly 7A–70. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection And Repair 7A–71. . . . . . . . . . . . . . . . . .

Reassembly 7A–71. . . . . . . . . . . . . . . . . . . . . . . . . .

3–4 Accumulator Piston 7A–72. . . . . . . . . . . . . . . . . .

Disassembled View 7A–72. . . . . . . . . . . . . . . . . . . .

Disassembly 7A–72. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection And Repair 7A–73. . . . . . . . . . . . . . . . . .

Reassembly 7A–73. . . . . . . . . . . . . . . . . . . . . . . . . .

Reverse Clutch Piston And Center Support 7A–74.

Disassembled View 7A–74. . . . . . . . . . . . . . . . . . . .

Disassembly 7A–75. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection And Repair 7A–75. . . . . . . . . . . . . . . . . .

Reassembly 7A–75. . . . . . . . . . . . . . . . . . . . . . . . . .

Overrun Clutch And Turbine Shaft 7A–76. . . . . . . . .

Disassembled View 7A–76. . . . . . . . . . . . . . . . . . . .

Disassembly 7A–77. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection And Repair 7A–77. . . . . . . . . . . . . . . . . .

Reassembly 7A–77. . . . . . . . . . . . . . . . . . . . . . . . . .

Main Data And Specification 7A–79. . . . . . . . . . . . . .

Special Tools 7A–83. . . . . . . . . . . . . . . . . . . . . . . . . . .

4L30–E Parts List 7A–86. . . . . . . . . . . . . . . . . . . . . . .

Page 5692 of 6000

7A–3 AUTOMATIC TRANSMISSION (4L30–E)

Service Precaution

WARNING: IF SO EQUIPPED WITH A

SUPPLEMENTAL RESTRAINT SYSTEM (SRS),

REFER TO THE SRS COMPONENT AND WIRING

LOCATION VIEW IN ORDER TO DETERMINE

WHETHER YOU ARE PERFORMING SERVICE ON OR

NEAR THE SRS COMPONENTS OR THE SRS

WIRING. WHEN YOU ARE PERFORMING SERVICE

ON OR NEAR THE SRS COMPONENTS OR THE SRS

WIRING, REFER TO THE SRS SERVICE

INFORMATION. FAILURE TO FOLLOW WARNINGS

COULD RESULT IN POSSIBLE AIR BAG

DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU will call out those fasteners that require a

replacement after removal. ISUZU will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED, do not

use supplemental coatings (Paints, greases, or other

corrosion inhibitors) on threaded fasteners or

fastener joint interfaces. Generally, such coatings

adversely affect the fastener torque and the joint

clamping force, and may damage the fastener. When

you install fasteners, use the correct tightening

sequence and specifications. Following these

instructions can help you avoid damage to parts and

systems.

Construction

A07RS001

Legend

(1) Torque Converter Clutch (TCC)

(2) Fourth Clutch (C4)

(3) Overrun Clutch (OC)

(4) Overdrive Unit

(5) Reverse Clutch (RC)

(6) Second Clutch (C2)(7) Third Clutch (C3)

(8) Ravigneaux Planetary Gear Set

(9) Brake Band (B)

(10) Overdrive Free Wheel (One Way Clutch)

(OFW)

(11) Principle Sprag Assembly (One Way Clutch)

(PFW)

Page 5694 of 6000

7A–5 AUTOMATIC TRANSMISSION (4L30–E)

Normal Operation Of 2000 4L30–E

Tr a n s m i s s i o n

Torque Converter Clutch (TCC)

Application Conditions:

The TCC is normally applied in 2nd, 3rd and 4th gears

only when all of the following conditions exist:

— The engine coolant temperature is above 70

C

(158

F).

— The brake pedal is released.

— The shift pattern requests TCC apply.

Moreover, TCC is always applied in 2nd, 3rd and 4th

gears when the transmission oil temperature is above

135

C (275F).

This mode should be canceled at 125

C (257F).

ATF Warning Lamp

The ATF warning lamp will be constantly on (not flashing)

if the transmission oil temperature is above 145

C

(293

F).

The ATF warning lamp goes off again when the

transmission oil temperature is below 125

C (257F).

Special Shift Pattern When The Engine Is

Cold:

A special shift pattern is activated when the engine

coolant temperature is below 70

C (158F). (3–4 shifts,

for example, are delayed for small throttle openings and

will occur a few MPH higher.)

Diagnosis

Introduction

The systematic troubleshooting information covered by

this Section offers a practical and systematic approach to

diagnosing 4L30–E transmission, using information that

can be obtained from road tests, electrical diagnosis, oil

pressure checks or noise evaluation.

The key to correcting a complaint is to make use of all of

the available symptoms and logically letting them direct

you to the cause.

When dealing with automatic transmission complaints, it

is best to gather as many symptoms as possible before

making the decision to remove the transmission from the

vehicle.

Frequently, the correction of the complaint does not

require removal of the transmission from the vehicle.

Driver Information

To analyze the problem fill out a complete description of

the owner’s complaint.

Please draw a circle around the right information and

complete the following form. (The next page is an

example of a completed form). You can draw a circle

around many numbers if you are not sure.

Page 5702 of 6000

7A–13 AUTOMATIC TRANSMISSION (4L30–E)

Mechanical / Hydraulic Diagnosis Symptoms Index

Perform Preliminary Inspection First!

CHART

SYMPTOMS

1NO ENGINE START IN NEUTRAL OR PARK

2NO FORWARD GEARS IN ANY RANGE/NO REVERSE

3NO ENGINE BRAKE IN ANY RANGE

4POOR SHIFTING IN ALL GEARS (ALL HARSH OR ALL SOFT)

5aDELAYS IN DRIVE AND REVERSE

5bDELAYS IN REVERSE ONLY

6DIAGNOSTIC TROUBLE CODE (DTC) P0730

7HARSH 1–2 SHIFT

8HARSH 3–4 SHIFT

9a3–2 DOWNSHIFT COMPLAINT

9bHARSH SHIFT WHEN SHIFTING INTO “D” OR ACCELERATING FROM STOP

9cCOASTDOWN HARSH SHIFT OR CLUNK AT 3–2 DOWNSHIFT

10INTERMITTENT 4TH TO 2ND GEAR DOWNSHIFT AT STEADY SPEED

11ENGINE FLARE AT SHIFTING DURING TURNING ONLY (USUALLY WITH WARM ENGINE)

12ENGINE FLARE DURING 1–2 OR 2–3 SHIFT

13SHUDDER ONLY DURING TORQUE CONVERTER CLUTCH (TCC) APPLYING

14POSSIBLE CAUSES OF TRANSMISSION NOISE

15aPOSSIBLE CAUSES OF LOW LINE PRESSURE

15bPOSSIBLE CAUSES OF HIGH LINE PRESSURE

16POSSIBLE CAUSES OF TRANSMISSION FLUID LEAKS

NOTE: Numbers with parenthesis on the following charts

refer to Parts List at end of this section.

Chart 1: No Engine Start In Neutral Or Park

StepActionYe sNo

1Does engine start when shift lever moved from drive to neutral

mostly in hot condition?

Go to Step 2Go to Step 3

2Does engine start in park at any condition?Re–test vehicleGo to Step 4

3Does engine also not start in neutral when shift lever moved from

park to neutral?

Go to Step 4Go to Step 5

4Check mode switch (63) setting. Readjust if necessary.

Problems fixed?

Re–test vehicleGo to Step 5

5Check start circuit of mode switch (63) open in neutral.

Was open found?Locate and repair

open(s)Replace mode

switch (63)

Page 5703 of 6000

7A–14

AUTOMATIC TRANSMISSION (4L30–E)

Chart 2: No Forward Gears In Any Range/No Reverse

StepActionYe sNo

1Check line pressure. Refer to Line Pressure Test in this section.

Was line pressure normal?

Go to Step 2

Use Chart 15a:

Possible Causes

of Low Line

Pressure in this

section

21. Check internal linkage:

– Manual linkage (58) not moving manual valve (326).

2. Check for internal mechanical damage:

– Turbine shaft (506) broken loose.

– Overrun roller clutch (516) broken loose.

Was the problem found?

Repair or replace—

Chart 3: No Engine Brake In Any Range

StepActionYe sNo

1Check line pressure. Refer to Line Pressure Test in this section.

Was line pressure normal?

Go to Step 2

Use Chart 15a:

Possible Causes

of Low Line

Pressure in this

section

21. Check for overrun clutch leaks caused by:

– Damaged piston lip (513)

– Check ball defective (504)

2. Check for overrun lockout valve (705) stuck by foreign

material.

3. Check for leaks at turbine shaft (506) caused by:

– Teflon seal rings damaged (508)

– Excessive wear of turbine shaft bearing surfaces.

Was the problem found?

Repair or replace—