wiring OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 4065 of 6000

4B1–20

DRIVE LINE CONTROL SYSTEM (SHIFT ON THE FLY)

Wiring Diagram (RHD / Diesel Engine Model)

D08RW842

Page 4066 of 6000

4B1–21 DRIVE LINE CONTROL SYSTEM (SHIFT ON THE FLY)

Wiring Diagram (RHD / Gasoline Engine Model)

D08RW638

Page 4071 of 6000

4B1–26

DRIVE LINE CONTROL SYSTEM (SHIFT ON THE FLY)

3.Case that the indicator keeps blinking by 2Hz

after aforementioned Solution 2 is carried out.

Step

ActionYe sNo

1Check the air pressure and wear of all tires.

Were problems found?Try Solution 2

after adjust the

air pressure and

replace worn

tires.

Go to Step 2

2

Can the transfer lever be operated from High to 4L or vice versa?

Go to Step 3

Disconnection of

the motor

actuator harness

wiring. Trace this

chart from the

start after repair

or replace.

Faults on the

motor actuator.

Trace this chart

from the start

after replace.

Internal faults of

transfer case.

Disassemble the

transfer case for

check. Trace this

chart from the

start after repair

or replace.

3Pull out the hoses from vacuum actuator and operate 4WD

switch.

Is there negative pressure on either of hoses?

Go to Step 4

Faults on the

transfer position

switch or its

harness. Trace

this chart from

the start after

repair or replace.

Faults on the

VSV main body,

its harness or

vacuuming

system. Trace

the front axle

diagnosis chart in

this section.

After that, trace

this chart from

the start.

4Check the axle switch.

Were problems found?

Internal faults on

axle switch.

Trace this chart

from the start

after replace.

Disconnection on

the axle harness.

Trace this chart

from the start

after repair or

replace.

Faults on Front

Axle ASM. Trace

the front axle

diagnosis chart in

this section.

After that, trace

this chart from

the start.

Page 4073 of 6000

4B1–28

DRIVE LINE CONTROL SYSTEM (SHIFT ON THE FLY)

2.Case that indicator keeps 2Hz blinking after

aforementioned Solution 3 is carried out.

Step

ActionYe sNo

1Check the air pressure and wear of all tires.

Were problems found?Try Solution 3

after adjust the

air pressure and

replace worn

tires.

Go to Step 2

2

Can the transfer lever be operated from High to 4L or vice versa?

Faults on the

harness wiring of

motor actuator.

Trace this chart

from the start

after repair or

replace.

Internal faults on

transfer case.

Disassemble the

transfer case for

check. Trace this

chart from the

start after repair

or replace.

Faults on the

motor actuator.

Trace this chart

from the start

after or replace.

Go to Step 3

3Pull out the hoses from vacuum actuator and operate 4WD

switch.

Is there negative pressure on either of hoses?

Go to Step 4

Faults on the

transfer position

switch or its

harness. Trace

this chart from

the start after

repair or replace.

Faults on the

VSV main body,

its harness or

vacuuming

system. Trace

the front axle

diagnosis chart in

this section.

After that, trace

this chart from

the start.

4Check the axle switch.

Were problems found?Internal faults on

axle switch.

Trace this chart

from the start

after replace.

Faults on Front

Axle ASM. Trace

the front axle

diagnosis chart in

this section.

After that, trace

this chart from

the start.

Short circuit

(body short) or

disconnection of

the axle harness.

Trace this chart

from the start

after repair or

replace.

Page 4074 of 6000

4B1–29 DRIVE LINE CONTROL SYSTEM (SHIFT ON THE FLY)

3.Case that indicator’s blinking changes to 4Hz

after aforementioned Solution 4 is carried out.

Step

ActionYe sNo

1

Can the transfer lever be operated from High to 4L or vice versa?

Faults on the

harness wiring of

motor actuator.

Trace this chart

from the start

after repair or

replace.

Faults on the

motor actuator.

Trace this chart

from the start

after replace.

Internal faults on

transfer case.

Disassemble the

transfer case for

check. Trace this

chart from the

start after repair

or replace.

Faults on the

4WD control unit.

Trace this chart

from the start

after replace.

Page 4079 of 6000

4B1–34

DRIVE LINE CONTROL SYSTEM (SHIFT ON THE FLY)

4. If vacuum is not applicable as much as –400mmHg,

and if there is resistance on the intake side, replace

with a new check valve.

VSV Assembly

Inspect the vehicle side harness as follows:

412RS071

Legend

(1) Grey

(2) Blue

1. Remove connector.

2. Shift transfer lever to 2H and start the engine.

NOTE: Do not move the vehicle while inspection.

3. Make sure that there is continuity in the vehicle side of

harness. If there is no continuity, check transfer shift

switch and wiring.

Inspect both VSVs as follows:

F04RS004

1. With battery not connected (Usual).

A–C:There is continuity

B:Closed

2. With battery connected

A – B:There is continuity

C:Closed

3. If 1) and 2) fail, replace with a new VSV.

Axle Position Switch

412RS048

1. With ball (1) being free

A – B:There is continuity

2. With ball forced into the switch

A – B:No continuity

3. If 1) and 2) fail, replace with a new switch.

Motor Actuator Assembly

Inspect the function of the motor actuator assembly as

follows:

Page 4084 of 6000

4B2–1 DRIVE LINE CONTROL SYSTEM (TOD)

DRIVELINE/AXLE

DRIVELINE CONTROL SYSTEM (TOD)

CONTENTS

Service Precaution 4B2–1. . . . . . . . . . . . . . . . . . . . . .

General Description 4B2–2. . . . . . . . . . . . . . . . . . . . .

System Components 4B2–4. . . . . . . . . . . . . . . . . . . .

Parts Location 4B2–4. . . . . . . . . . . . . . . . . . . . . . . .

Functions of Indicator Lamp 4B2–8. . . . . . . . . . . . . .

Diagnosis 4B2–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Basic Diagnostic Flow Chart 4B2–17. . . . . . . . . . . . . .

Parts Location 4B2–18. . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Diagram 4B2–22. . . . . . . . . . . . . . . . . . . . . . . . . Connector List 4B2–34. . . . . . . . . . . . . . . . . . . . . . . . . .

Checking Failed Pin 4B2–36. . . . . . . . . . . . . . . . . . . . .

Checking Failed TOD Control Unit Pin 4B2–39. . . . .

Diagnostic Trouble Codes 4B2–43. . . . . . . . . . . . . . . .

Diagnosis from Trouble Codes 4B2–44. . . . . . . . . . . .

Trouble Diagnosis Depending on The Status

of TOD Indicator 4B2–74. . . . . . . . . . . . . . . . . . . . . . . .

Diagnosis from Symptom 4B2–114. . . . . . . . . . . . . . . . .

Service Precaution

WARNING: IF SO EQUIPPED WITH A

SUPPLEMENTAL RESTRAINT SYSTEM (SRS),

REFER TO THE SRS COMPONENT AND WIRING

LOCATION VIEW IN ORDER TO DETERMINE

WHETHER YOU ARE PERFORMING SERVICE ON OR

NEAR THE SRS COMPONENTS OR THE SRS

WIRING. WHEN YOU ARE PERFORMING SERVICE

ON OR NEAR THE SRS COMPONENTS OR THE SRS

WIRING, REFER TO THE SRS SERVICE

INFORMATION. FAILURE TO FOLLOW WARNINGS

COULD RESULT IN POSSIBLE AIR BAG

DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU will call out those fasteners that require a

replacement after removal. ISUZU will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED, do not

use supplemental coatings (Paints, greases, or other

corrosion inhibitors) on threaded fasteners or

fastener joint interfaces. Generally, such coatings

adversely affect the fastener torque and the joint

clamping force, and may damage the fastener. When

you install fasteners, use the correct tightening

sequence and specifications. Following these

instructions can help you avoid damage to parts and

systems.

Page 4126 of 6000

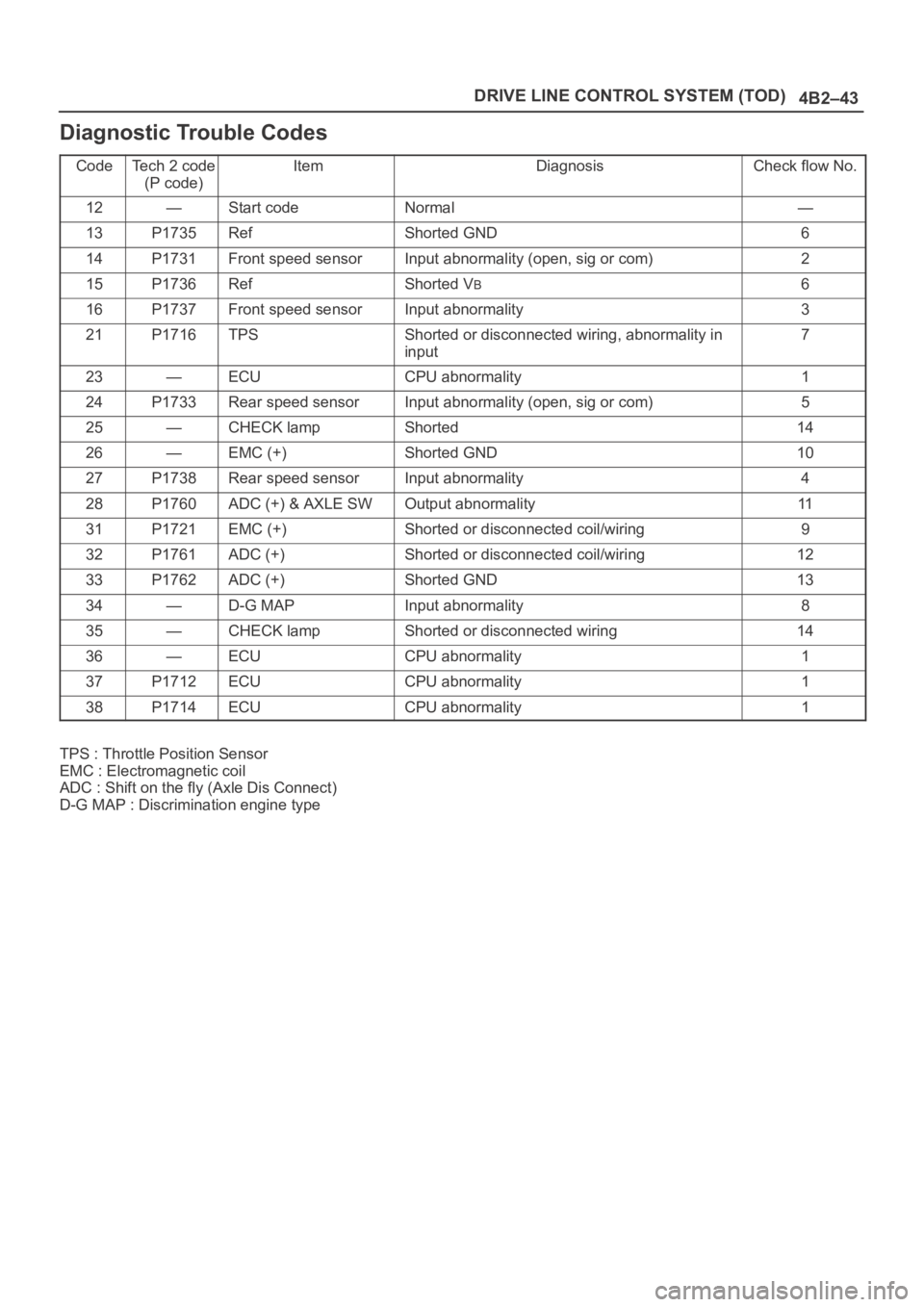

4B2–43 DRIVE LINE CONTROL SYSTEM (TOD)

Diagnostic Trouble Codes

CodeTe c h 2 c o d e

(P code)ItemDiagnosisCheck flow No.

12—Start codeNormal—

13P1735RefShorted GND6

14P1731Front speed sensorInput abnormality (open, sig or com)2

15P1736RefShorted VB6

16P1737Front speed sensorInput abnormality3

21P1716TPSShorted or disconnected wiring, abnormality in

input7

23—ECUCPU abnormality1

24P1733Rear speed sensorInput abnormality (open, sig or com)5

25—CHECK lampShorted14

26—EMC (+)Shorted GND10

27P1738Rear speed sensorInput abnormality4

28P1760ADC (+) & AXLE SWOutput abnormality11

31P1721EMC (+)Shorted or disconnected coil/wiring9

32P1761ADC (+)Shorted or disconnected coil/wiring12

33P1762ADC (+)Shorted GND13

34—D-G MAPInput abnormality8

35—CHECK lampShorted or disconnected wiring14

36—ECUCPU abnormality1

37P1712ECUCPU abnormality1

38P1714ECUCPU abnormality1

TPS : Throttle Position Sensor

EMC : Electromagnetic coil

ADC : Shift on the fly (Axle Dis Connect)

D-G MAP : Discrimination engine type

Page 4197 of 6000

DRIVE LINE CONTROL SYSTEM (TOD) 4B2–114

Diagnosis from Symptom

Troubles that are not indicated by the warning lamp are

listed in the table below. These troubles are caused by

the faults that cannot be detected by the self-diagnostic

function of the control unit.

If this type of trouble is observed, interview the customer

and conduct test runs to reproduce the trouble,

cross-check the reported trouble with the listed

phenomena, and diagnose and analyze the trouble on the

item by item basis.

PhenomenaMajor causeCorrective action

1The tight corner braking is

observed when the vehicle is

subject to full steering.The standard tires are not used.

The tire pressure is incorrect.

The tires are worn inuniformity.

The transfer or wiring is

imperfect.

The limited slip differential is

failed.

Check and recondition the

vehicle according to Chart 1.

2Even if the 4WD AUTO SW is

select to the 4WD position, the

4WD mode is not active, resulting

in remarkable rear wheel spin.The transfer or wiring is

imperfect.

The shift on the fly system is

failed.

Check and recondition the

vehicle according to Chart 2.

3When the 4WD AUTO SW is

selected to the 4WD position,

the drive resistance of the 4WD

system is too large to get

sufficient running speed.

Noised drive line.

The standard tires are not used.

The tire pressure is incorrect.

The tires are worn inuniformity.

The transfer or wiring is

imperfect.

The limited slip differential is

failed.

Check and recondition the

vehicle according to Chart 1.

4The shift on the fly system (front

axle) generates gear noises.The wiring is imperfect.

The shift on the fly system is

failed.

Check and recondition the

vehicle according to Chart 3.

5The braking distance gets long

even when the ABS is active.The wiring is imperfect.

The ABS is failed.

Check and recondition the

vehicle according to Chart 4.

Page 4208 of 6000

4C–2

DRIVE SHAFT SYSTEM

Service Precaution

WARNING: IF SO EQUIPPED WITH A

SUPPLEMENTAL RESTRAINT SYSTEM (SRS),

REFER TO THE SRS COMPONENT AND WIRING

LOCATION VIEW IN ORDER TO DETERMINE

WHETHER YOU ARE PERFORMING SERVICE ON OR

NEAR THE SRS COMPONENTS OR THE SRS

WIRING. WHEN YOU ARE PERFORMING SERVICE

ON OR NEAR THE SRS COMPONENTS OR THE SRS

WIRING, REFER TO THE SRS SERVICE

INFORMATION. FAILURE TO FOLLOW WARNINGS

COULD RESULT IN POSSIBLE AIR BAG

DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU will call out those fasteners that require a

replacement after removal. ISUZU will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED , do not

use supplemental coatings (Paints, greases, or other

corrosion inhibitors) on threaded fasteners or

fastener joint interfaces. Generally, such coatings

adversely affect the fastener torque and the joint

clamping force, and may damage the fastener. When

you install fasteners, use the correct tightening

sequence and specifications. Following these

instructions can help you avoid damage to parts and

systems.

General Description

This publication contains essential removal, installation,

adjustment and maintenance procedures.

The front axle utilizes a central disconnect type front

axle/transfer case system.

The drive axles are completely flexible assemblies,

consisting of inner and outer constant velocity (CV) drive

shaft joints connected by an axle shaft.

For description of propeller shaft and universal joint, refer

to Front/Rear Propeller Shaft in this section.