wiring OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 3536 of 6000

9J1–49

RESTRAINT CONTROL SYSTEM

DTC 33 Passenger Pretensioner Loop Short To Voltage

D09RW014

Circuit Description:

When the ignition switch is turned “ON”, the SDM will

perform tests to diagnose critical malfunctions within

itself. Upon passing these tests, “Ignition 1”, and

pretensioner loop voltages are measured to ensure they

are within their respective normal voltage ranges.

The SDM monitors the voltages at “Driver Belt Low”

terminal “10” and “Passenger Belt Low” terminal “22” to

detect short to B+ in the pretensioner assembly circuits.

DTC Will Set When:

“Ignition 1” is within the normal operating voltage range.

Once these conditions are met and the voltage at

“Passenger pretensioner Low” is above a specified value,

DTC 33 will set. This test is run once each ignition cycle

and “Continuous Monitoring”.

Action Taken:

SDM turns “ON” the “AIR BAG” warning lamp and sets

DTC 33.

DTC Will Clear When:

The malfunction is no longer occurring and the ignition is

turned “OFF”.

DTC Chart Test Description:

Number(s) below refer to step number(s) on the

diagnostic chart:

2. This test determines whether the malfunction is in

the SDM.

3. This test isolates the malfunction to one side of the

passenger pretensioner assembly yellow 2–pin

connector at the base of the passenger seat.

4. This test determines whether the malfunction is in

IB15–BLU/BLK.

5. This test determines whether the malfunction is in

IB16–BLU/ORG.

Diagnostic Aids:

An intermittent condition is likely to be caused by a short

to B+ in the passenger pretensioner assembly circuit.

Inspect IB15–BLU/BLK and IB16–BLU/ORG carefully for

cutting or chafing. If the wiring pigtail of the passenger

pretensioner assembly is damaged, the component must

be replaced. A careful inspection of IB15–BLU/BLK and

IB16–BLU/ORG, including the passenger pretensioner

assembly pigtail is essential to ensure that the

replacement SDM will not be damaged.

Page 3538 of 6000

9J1–51

RESTRAINT CONTROL SYSTEM

DTC 34 Passenger Pretensioner Loop Open

D09RW014

Circuit Description:

When the ignition switch is turned “ON”, the SDM will

perform tests to diagnose critical malfunctions within

itself. Upon passing these tests, “Ignition 1”, and

pretensioner loop voltages are measured to ensure they

are within their respective normal voltage ranges. During

“Continuous Monitoring” diagnostics, a fixed amount of

current is flowing in the deployment loop. This produces

proportional voltage drops in the loop. By monitoring the

voltage difference between “Passenger Belt High” and

“Passenger Belt Low”, the SDM calculates the combined

resistance of the passenger pretensioner assembly,

harness wiring IB15–BLU/BLK AND IB16–BLU/ORG,

and connector terminal contact.

DTC Will Set When:

The voltage difference between “Passenger pretensioner

High” terminal “9” and “Passenger pretensioner Low”

terminal “10” is above or equal to a specified value for 500

milliseconds during “Continuous Monitoring”.

Action Taken:

SDM turns “ON” the “AIR BAG” warning lamp and sets a

diagnostic trouble code.

DTC Will Clear When:

The voltage difference between “Passenger Belt High”

terminal “9” and “Passenger Belt Low” terminal “10” isbelow a specified value for 500 milliseconds during

“Continuous Monitoring”.

DTC Chart Test Description:

Number(s) below refer to step number(s) on the

diagnostic chart:

2. This test determines whether the malfunction is in

the SDM.

3. This test verifies proper connection of the yellow

2–pin connector.

4. This test cheeks for proper contact and/or corrosion

of the shorting clip in the yellow 2–pin connector

terminals.

5. The test checks for a malfunctioning passenger

pretensioner assembly.

6. This test determines whether the open in the wiring.

Diagnostic Aids:

An intermittent condition is likely to be caused by a poor

connection at the passenger pretensioner assembly

harness connector terminals“1” and “2”, SDM terminals

“9” and “10”, or an open in IB15–BLU/BLK and

IB16–BLU/ORG.

Page 3540 of 6000

9J1–53

RESTRAINT CONTROL SYSTEM

DTC 41 Driver Pretensioner Loop Resistance High

D09RW014

Circuit Description:

When the ignition switch is turned “ON”, the SDM will

perform tests to diagnose critical malfunctions within

itself. Upon passing these tests, “Ignition 1”, and

pretensioner loop voltages are measured to ensure they

are within their respective normal voltage ranges.

The SDM then proceeds with the “Resistance

Measurement Test” “Driver Belt Low” terminal “22” is

grounded through a current sink and the driver current

source connected to “Driver Belt High” terminal “21”

allows a known amount of current to flow. By monitoring

the voltage difference between “Driver Belt High” and

“Driver Belt Low”, the SDM calculates the combined

resistance of the driver pretensioner assembly, harness

wiring IB13–BLU/RED and IB14–BLU/YEL, and

connector terminal contact.

DTC Will Set When:

The combined resistance of the driver pretensioner

assembly, harness wiring IB13–BLU/RED and

IB14–BLU/YEL, and connector terminal contact is above

a specified value. This test run once each ignition cycle

during the “Resistance Measurement Test” when:

1. No “higher priority faults” are detected during

“Turn–ON”

2. “Ignition 1” voltage is in the specified value.

Action Taken:

SDM turns “ON” the “AIR BAG” warning lamp and sets

DTC 41.

DTC Will Clear When:

The ignition switch is turned “OFF”.

DTC Chart Test Description:

Number(s) below refer to step number(s) on the

diagnostic chart:

2. This test determines whether the malfunction is in

the SDM.

3. This test verifies proper connection of the yellow

2–pin connector at the base of the driver seat.

4. This test checks for proper contact and/or corrosion

of the 2–pin connector terminals at the base of the

driver seat.

5. This test isolate the malfunction to one side of the

pretensioner assembly yellow 2–pin connector

located at the base of the driver seat.

6. This test determines whether the malfunction is due

to high resistance in the wiring.

Page 3542 of 6000

9J1–55

RESTRAINT CONTROL SYSTEM

DTC 42 Driver Pretensioner Loop Resistance Low

D09RW014

Circuit Description:

When the ignition switch is turned “ON”, the SDM will

perform tests to diagnose critical malfunctions within

itself. Upon passing these tests “Ignition 1”, and

pretensioner loop voltages are measured to ensure they

are within their respective normal voltage ranges.

The SDM then proceeds with the “Resistance

Measurement Test” “Driver Belt Low” terminal “22” is

grounded through a current sink and the driver current

source connected to “Driver Belt High” terminal “21”

allows a known amount of current to flow. By monitoring

the voltage difference between “Driver Belt High” and

“Driver Belt Low” the SDM calculates the combined

resistance of the driver pretensioner assembly, harness

wiring IB13–BLU/RED and IB14–BLU/YEL and

connector terminal contact.

DTC Will Set When:

The combined resistance of the driver pretensioner

assembly, harness wiring IB13–BLU/RED and

IB14–BLU/YEL and connector terminal contact is above

a specified value. This test is run once each ignition cycle

during the “Resistance Measurement Test” when:

1. No “higher priority faults” are detected during

“Turn–ON”

2. “Ignition 1” voltage is in the specified value.

Action Taken:

SDM turns “ON” the “AIR BAG” warning lamp and sets

DTC 42.

DTC Will Clear When:

The ignition switch is turned “OFF.”

DTC Chart Test Description:

Number(s) below refer to circled number(s) on the

diagnostic chart:

2. This test determines whether the malfunction is in

the SDM.

3. This test verifies proper connection of the yellow

2–pin connector at the base of the driver seat.

4. This test checks for proper operation of the shorting

clip in the yellow 2–pin connector.

5. This test isolate the malfunction to one side of the

pretensioner assembly yellow 2–pin connector

located at the base of driver seat.

6. This test determines whether the malfunction is due

to shortening in the wiring.

Diagnostic Aids:

An intermittent condition is likely to be caused by a short

between IB13–BLU/RED or IB14–BLU/YEL or a

malfunctioning shorting clip on the driver pretensioner

assembly which would require replacement of the

component. The test for this diagnostic trouble code is

Page 3544 of 6000

9J1–57

RESTRAINT CONTROL SYSTEM

DTC 44 Driver Pretensioner Loop Open

D09RW014

Circuit Description:

When the ignition switch is turned “ON”, the SDM will

perform tests to diagnose critical malfunctions within

itself. Upon passing these tests, “Ignition 1”, and

pretensioner loop voltages are measured to ensure they

are within their respective normal voltage ranges.

During “Continuous Monitoring” diagnostics, a fixed

amount of current is following in the pretensioner loop.

This produces proportional voltage drops in the loop. By

monitoring the voltage difference between “Driver Belt

High” and “Driver Belt Low”, the SDM calculates the

combined resistance of the driver pretensioner assembly,

harness wiring IB13–BLU/RED and IB14–BLU/YEL, and

connector terminal contact.

DTC Will Set When:

The voltage difference between “Driver Belt High”

terminal “21” and “Driver Belt Low” terminal “22” is above

or equal to a specified value for 500 milliseconds during

“Continuous Monitoring”.

Action Taken:

SDM turns “ON” the “AIR BAG” warning lamp and sets a

diagnostic trouble code.

DTC Will Clear When:

The voltage difference between “Driver Belt High”

terminal “21” and “Driver Belt Low” terminal “22” is belowa specified value for 500 milliseconds during “Continuous

Monitoring”.

DTC Chart Test Description:

Number(s) below refer to step number(s) on the

diagnostic chart:

2. This test determines whether the malfunction is in

the SDM.

3. This test verifies proper connection of the yellow

2–pin connector at the base of the driver seat.

4. This test checks for proper contact and/or corrosion

of the yellow 2–pin connector at the base of the

driver seat.

5. This test isolates the malfunction to one side of the

driver pretensioner assembly yellow 2–pin

connector located at the base of driver seat.

6. This test determines whether the open is in the

wiring.

Diagnostic Aids:

An intermittent condition is likely to be caused by a poor

connection at the driver pretensioner assembly harness

2–pin connector terminals “3” and “4” at the top of the

steering column, SDM terminals “21” and “22”, or an open

in IB13–BLU/RED and IB14–BLU/YEL.

Page 3548 of 6000

9J1–61

RESTRAINT CONTROL SYSTEM

DTC 46 Driver Pretensioner Loop Short To Voltage

D09RW014

Circuit Description:

When the ignition switch is turned “ON”, the SDM will

perform tests to diagnose critical malfunctions within

itself. Upon passing these tests, “Ignition 1”, and

pretensioner loop voltages are measured to ensure they

are within their respective normal voltage ranges.

The SDM monitors the voltage at “Driver Belt Low”

terminal “22” and “Passenger Belt Low” terminal “10” to

detect shorts to B+ in the pretensioner assembly circuits.

DTC Will Set When:

“Ignition 1” is in the normal operating voltage range. This

test is run once each ignition cycle and “Continuous

monitoring”. Once these conditions are met and the

voltage at “Driver Belt Low” is above a specified value,

DTC 46 will set.

Action Taken:

SDM turns “ON” the “AIR BAG” warning lamp and sets

DTC 46.

DTC Will Clear When:

The malfunction is no longer occurring and the ignition is

turned “OFF”.

DTC Chart Test Description:

Number(s) below refer to step number(s) on the

diagnostic chart:

2. This test determines whether the SDM is

malfunctioning.

3. This test isolates the malfunction to one side of the

driver pretensioner assembly yellow 2–pin

connector at the base of the driver seat.

4. This test determines whether the malfunction is in

IB13–BLU/RED.

5. This test determines whether the malfunction is in

IB14–BLU/YEL.

Diagnostic Aids:

An intermittent condition is likely to be caused by a short

to B+ in the driver pretensioner assembly circuit. Inspect

IB13–BLU/RED and IB14–BLU/YEL carefully for cutting

or chafing. If the wiring pigtail of the driver pretensioner

assembly is damaged, the components must be

replaced. A careful inspection of IB13–BLU/RED and

IB14–BLU/YEL, including the driver pretensioner

assembly is essential to ensure that the replacement

SDM will not be damaged.

Page 3552 of 6000

10A–1

CRUISE CONTROL SYSTEM

CONTROL SYSTEM

CRUISE CONTROL SYSTEM

CONTENTS

Service Precaution 10A–1. . . . . . . . . . . . . . . . . . . . . .

General Description 10A–1. . . . . . . . . . . . . . . . . . . . .

Diagnosis 10A–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Brake Switch 10A–2. . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 10A–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 10A–2. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjustment 10A–3. . . . . . . . . . . . . . . . . . . . . . . . . . .

Clutch Switch 10A–3. . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal and Installation 10A–3. . . . . . . . . . . . . . .

Adjustment 10A–3. . . . . . . . . . . . . . . . . . . . . . . . . . .

Starter Switch 10A–4. . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 10A–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 10A–4. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cruise Control Main Switch 10A–5. . . . . . . . . . . . . . . Removal 10A–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 10A–5. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cruise Control Switch (Combination Switch) 10A–5

Removal and Installation 10A–5. . . . . . . . . . . . . . .

Cruise Control Unit 10A–6. . . . . . . . . . . . . . . . . . . . . .

Removal 10A–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 10A–6. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cruise Actuator 10A–7. . . . . . . . . . . . . . . . . . . . . . . . .

Actuator Cable Diagram (LHD) 10A–7. . . . . . . . . .

Actuator Cable Diagram (RHD) 10A–7. . . . . . . . . .

Removal 10A–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 10A–8. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mode Switch 10A–8. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal and Installation 10A–8. . . . . . . . . . . . . . .

Service Precaution

WARNING: IF SO EQUIPPED WITH A

SUPPLEMENTAL RESTRAINT SYSTEM (SRS),

REFER TO THE SRS COMPONENT AND WIRING

LOCATION VIEW IN ORDER TO DETERMINE

WHETHER YOU ARE PERFORMING SERVICE ON OR

NEAR THE SRS COMPONENTS OR THE SRS

WIRING. WHEN YOU ARE PERFORMING SERVICE

ON OR NEAR THE SRS COMPONENTS OR THE SRS

WIRING, REFER TO THE SRS SERVICE

INFORMATION. FAILURE TO FOLLOW WARNINGS

COULD RESULT IN POSSIBLE AIR BAG

DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU will call out those fasteners that require a

replacement after removal. ISUZU will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED, do not

use supplemental coatings (Paints, greases, or other

corrosion inhibitors) on threaded fasteners or

fastener joint interfaces. Generally, such coatings

adversely affect the fastener torque and the joint

clamping force, and may damage the fastener. When

you install fasteners, use the correct tightening

sequence and specifications. Following these

instructions can help you avoid damage to parts and

systems.

General Description

The cruise control keeps the vehicle running at a fixed

speed until a signal canceling this fixed speed is received .

When the main switch “AUTO CRUISE” is turned on with

the vehicle in the running mode, the battery voltage is

applied to the control unit. When a signal from the control

switch is input to the control unit while the vehicle is in this

state, the cruise control actuator is activated to operate

the system. Also, while the system is operating, the

“AUTO CRUISE” indicator light in the meter assembly

lights up.

1. SET/COAST Switch Function

1.Set Function: When the SET/COAST switch is

pressed and released with the main switch on, the

speed at which the vehicle is running at that moment

is stored in the memory, and the vehicle automatically

runs at the stored speed.

2.Coast-down Function: When the SET/COAST

switch is kept on while the vehicle in running, the

vehicle decelerates during that time. The speed at

which vehicle is running when the control switch is

turned off is stored in the memory, and the vehicle

automatically returns to the stored speed.

3.Tap-down Function: When the SET/COAST switch

is turned on and off instantaneously while the vehicle

is running, the vehicle decelerates a mile for each

on/off operation. The vehicle speed at which the

vehicle was running when the SET/COAST was

turned off last is stored in the memory, and the vehicle

automatically returns to this stored speed.

Page 3553 of 6000

10A–2

CRUISE CONTROL SYSTEM

2. RESUME/ACCEL Switch Function

1.Resume Function: When the RESUME/ACCEL

switch is turned on/off after the system is temporarily

deactivated by pressing the brake or clutch pedal

while the vehicle is running, the vehicle resumes the

speed stored before the system was released, and

the vehicle automatically runs at the stored speed .

2.Accelerate Function: When the RESUME/ACCEL

switch is kept on after the system is released

completely, the vehicle accelerates its speed during

t h a t t i m e . T h e v e h i c l e s p e e d a t w h i c h t h e v e h i c l e w a s

running when the switch was turned off is stored in the

memory, and the vehicle automatically returns to this

speed.

3.Tap-up Function: When the RESUME/ACCEL

switch is turned on and off instantaneously while the

vehicle is running, the vehicle decelerates a mile for

each on/off operation. The vehicle speed at which the

vehicle was running when the switch was turned off

last is stored in the memory, and the vehicle

automatically returns to this stored speed.

3. CANCEL Function

1.Temporary Cancellation:

When the brake pedal is pressed.

When the clutch pedal is pressed. (M/T)

When the select lever is shifted to any position other

than “D”, “3”, “2” or “L”. (A/T)

When the cancel switch is operated.

When the vehicle speed exceeds about 20 km/h

over the vehicle speed stored in the memory.

Turning the RESUME/ACCEL switch will return the

vehicle to the speed stored in the cruise control

memory.

2.Complete Cancellation:

When the starter switch or the main switch is turned

off.

When the fail-safe function is activated.

When the vehicle speed is about 38.5 km/h.

Diagnosis

Refer to the Cruise Control System Diagnosis in Wiring

System section.

Brake Switch

Removal

1. Disconnect the battery ground cable.

2. Remove the brake switch (1).

Disconnect the connector.

Loosen the lock nuts of the switch.

Remove the switch by turning it.

310RS004

Installation

To install, follow the removal steps in the reverse order,

noting the following points.

1. Check to see if the brake pedal has been returned by

the return spring to the specified position.2. Turn the switch clockwise until the tip of the threaded

portion of the brake switch contacts the pedal arm.

3. Turn the switch counterclockwise until the space

between the tip of the threaded portion and the pedal

arm is 0.5 to 1.0 mm (0.02-0.04 in.) as shown in the

figure.

310RS003

Page 3569 of 6000

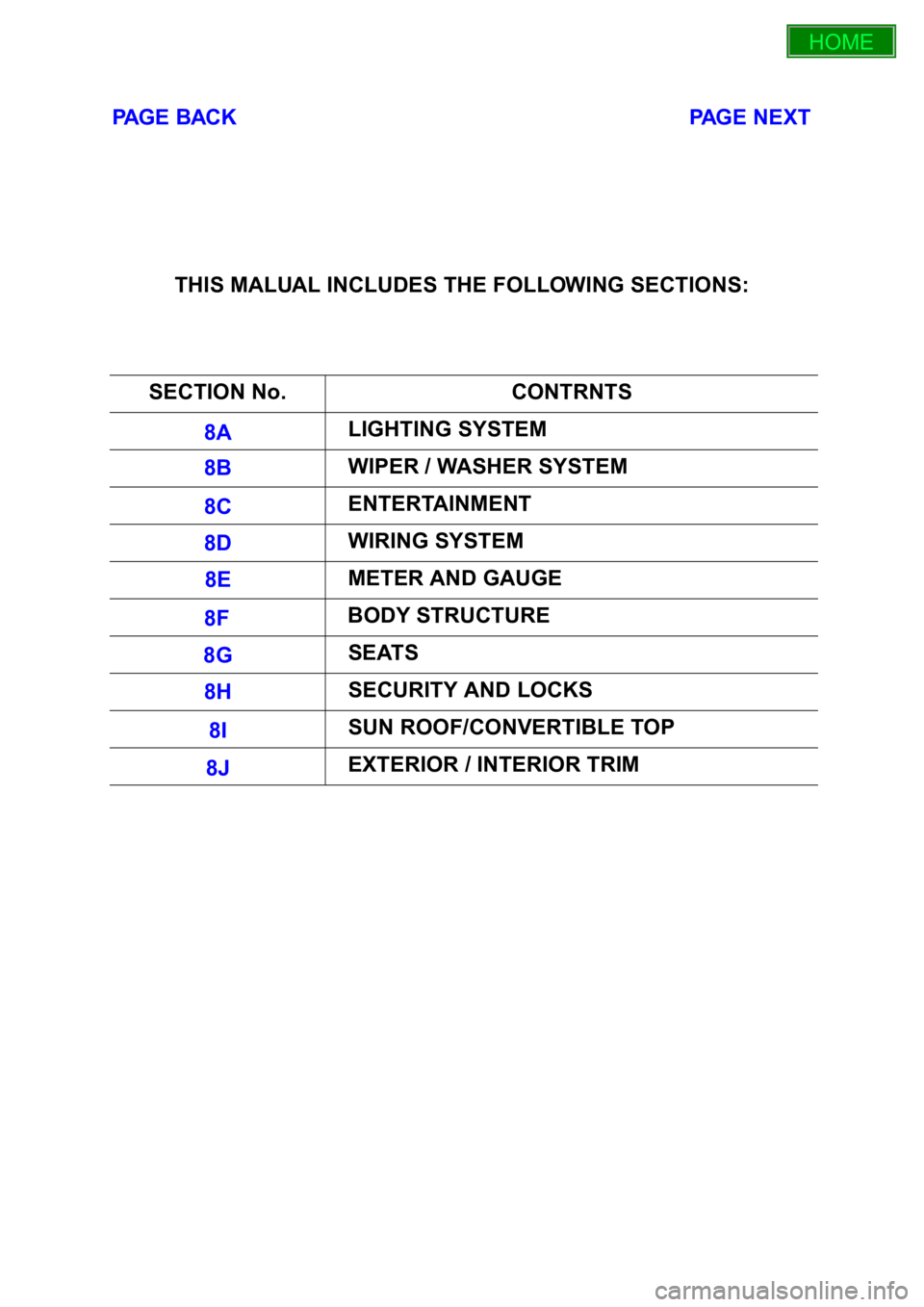

PAGE BACK PAGE NEXT

THIS MALUAL INCLUDES THE FOLLOWING SECTIONS:

SECTION No. CONTRNTS

8A LIGHTING SYSTEM

8B WIPER / WASHER SYSTEM

8C ENTERTAINMENT

8D WIRING SYSTEM

8E METER AND GAUGE

8F BODY STRUCTURE

8G SEATS

8H SECURITY AND LOCKS

8I SUN ROOF/CONVERTIBLE TOP

8J EXTERIOR / INTERIOR TRIM

HOME

8A

8B

8C

8D

8E

8F

8G

8H

8I

8J

Page 3573 of 6000

Service Precaution

WARNING: THIS VEHICLE HAS A SUPPLEMENTAL

RESTRAINT SYSTEM (SRS). REFER TO THE SRS

COMPONENT AND WIRING LOCATION VIEW IN

ORDER TO DETERMINE WHETHER YOU ARE

PERFORMING SERVICE ON OR NEAR THE SRS

COMPONENTS OR THE SRS WIRING. WHEN YOU

ARE PERFORMING SERVICE ON OR NEAR THE

SRS COMPONENTS OR THE SRS WIRING, REFER

TO THE SRS SERVICE INFORMATION. FAILURE

TO FOLLOW WARNINGS COULD RESULT IN

POSSIBLE AIR BAG DEPLOYMENT, PERSONAL

INJURY, OR OTHERWISE UNNEEDED SRS

SYSTEM REPAIRS.CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU will call out those fasteners that require a

replacement after removal. ISUZU will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED, do not

use supplemental coatings (Paints, greases, or

other corrosion inhibitors) on threaded fasteners

or fasteners joint interfaces. Generally, such

coatings adversely affect the fastener torque and

the joint clamping force, and may damage the

fastener. When you install fasteners, use the

correct tightening sequence and specification.

Following these instructions can help you avoid

damage to parts and systems.