fuel type OPEL FRONTERA 1998 Service Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 4997 of 6000

6E–340

ENGINE DRIVEABILITY AND EMISSIONS

the TP sensor is low. As the throttle valve opens, the

output increases so that at wide open throttle (WOT), the

output voltage should be above 4 volts.

The PCM calculates fuel delivery based on throttle valve

angle (driver demand). A broken or loose TP sensor may

cause intermittent bursts of fuel from an injector and

unstable idle because the PCM thinks the throttle is

moving. A hard failure in the TP sensor 5-volt reference

or signal circuits will set a DTC P0123. A hard failure with

the TP sensor ground circuit may set DTC P0123. Once

a DTC is set, the PCM will use an artificial default value

based on engine RPM and mass air flow for the throttle

position, and some vehicle performance will return. A

high idle may result when DTC P0123 is set. The PCM

can also detect a shifted TP sensor. The PCM monitors

throttle position and compares the actual TP sensor

reading to a predicted TP value calculated from engine

speed. If the PCM detects an out-of-range condition,

DTC P0121 will be set.

0021

Transmission Fluid Temperature (TFT)

Sensor

The transmission fluid temperature sensor is a thermistor

which changes its resistance based on the temperature of

the transmission fluid. For a complete description of the

TFT sensor, refer to

4L30-E Automatic Transmission

Diagnosis

.

A failure in the TFT sensor or associated wiring will cause

DTC P0712 or DTC P0713 to set. In this case, engine

coolant temperature will be substituted for the TFT

sensor value and the transmission will operate normally.

Transmission Range Switch

IMPORTANT:The vehicle should not be driven with the

transmission range switch disconnected; idle quality will

be affected.

The four inputs from the transmission range switch

indicate to the PCM which position is selected by the

transmission selector lever. This information is used for

ignition timing, EVAP canister purge, EGR and IAC valve

operation.For more information on the transmission on the

transmission range switch, refer to

4L30-E Automatic

Transmission

.

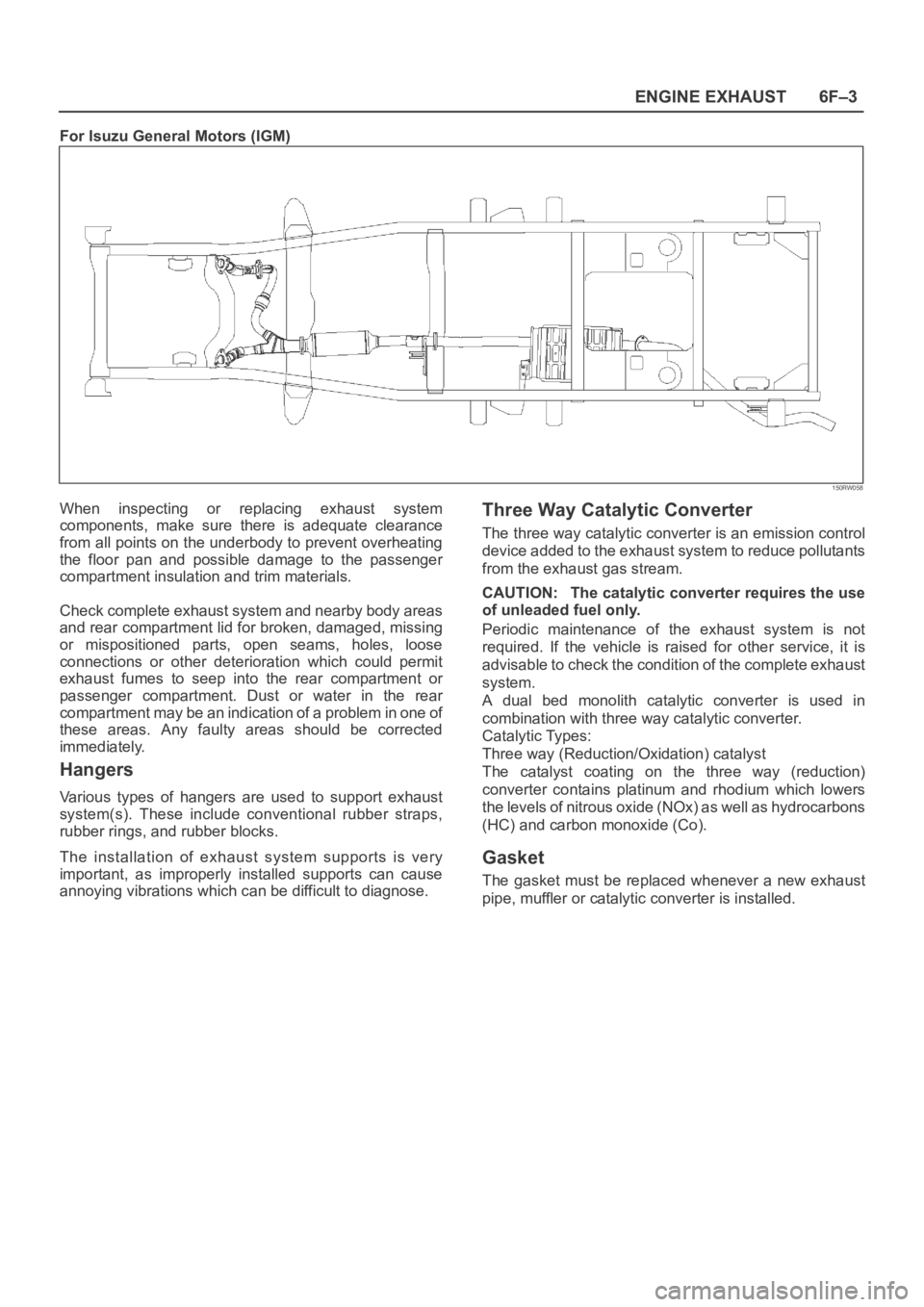

Vehicle Speed Sensor (VSS)

The PCM determines the speed of the vehicle by

converting a plusing voltage signal from the vehicle speed

sensor (VSS) into miles per hour. The PCM uses this

signal to operate the cruise control, speedometer, and the

TCC and shift solenoids in the transmission. For more

information on the TCC and shift solenoids, refer to

4L30-E Automatic Transmission.

0008

Use of Circuit Testing Tools

Do not use a test light to diagnose the powertrain

electrical systems unless specifically instructed by the

diagnostic procedures. Use Connector Test Adapter Kit J

35616 whenever diagnostic procedures call for probing

connectors.

Aftermarket Electrical and Vacuum

Equipment

Aftermarket (add-on) electrical and vacuum equipment is

defined as any equipment which connects to the vehicle’s

electrical or vacuum systems that is installed on a vehicle

after it leaves the factory. No allowances have been

made in the vehicle design for this type of equipment.

NOTE: No add-on vacuum equipment should be added

to this vehicle.

NOTE: Add-on electrical equipment must only be

connected to the vehicle’s electrical system at the battery

(power and ground).

Add-on electrical equipment, even when installed to

these guidelines, may still cause the powertrain system to

malfunction. This may also include equipment not

connected to the vehicle electrical system such as

portable telephones and radios. Therefore, the first step

in diagnosing any powertrain problem is to eliminate all

aftermarket electrical equipment from the vehicle. After

Page 4998 of 6000

6E–341 ENGINE DRIVEABILITY AND EMISSIONS

this is done, if the problem still exists, it may be diagnosed

in the normal manner.

Electrostatic Discharge Damage

Electronic components used in the PCM are often

designed to carry very low voltage. Electronic

components are susceptible to damage caused by

electrostatic discharge. Less than 100 volts of static

electricity can cause damage to some electronic

components. By comparison, it takes as much as 4000

volts for a person to feel even the zap of a static

discharge.

TS23793

There are several ways for a person to become statically

charged. The most common methods of charging are by

friction and induction.

An example of charging by friction is a person sliding

across a vehicle seat.

Charge by induction occurs when a person with well

insulated shoes stands near a highly charged object

and momentary touches ground. Charges of the

same polarity are drained off leaving the person

highly charged with the opposite polarity. Static

charges can cause damage, therefore it is important

to use care when handling and testing electronic

components.

NOTE: To prevent possible electrostatic discharge

damage, follow these guidelines:

Do not touch the PCM connector pins or soldered

components on the PCM circuit board.

Do not touch the knock sensor module component

leads.

Do not open the replacement part package until the

part is ready to be installed.

Before removing the part from the package, ground

the package to a known good ground on the vehicle.

If the part has been handled while sliding across the

seat, while sitting down from a standing position, or

while walking a distance, touch a known good ground

before installing the part.

Upshift Lamp

Refer to Manual Transmission.

General Description (Air Induction)

Air Induction System

The air induction system filters contaminants from the

outside air, and directs the progress of the air as it is

drawn into the engine. A remote-mounted air cleaner

prevents dirt and debris in the air from entering the

engine. The air duct assembly routes filtered air to the

throttle body. Air enters the engine by to following steps:

1. Through the throttle body.

2. Into the common chamber.

3. Through the cylinder head intake ports.

4. Into the cylinders.

055RV010

General Description (Fuel Metering)

Acceleration Mode

The PCM provides extra fuel when it detects a rapid

increase in the throttle position and the air flow.

Accelerator Controls

The accelerator control system is a cable-type system

with specific linkage adjustments.

Refer to

Cable Adjustment.

Battery Voltage Correction Mode

When battery voltage is low, the PCM will compensate for

the weak spark by increasing the following:

The amount of fuel delivered.

The idle RPM.

Ignition dwell time.

CMP Signal

The PCM uses this signal to determine the position of the

number 1 piston during its power stroke, allowing the

Page 5014 of 6000

6F–3 ENGINE EXHAUST

For Isuzu General Motors (IGM)

150RW058

When inspecting or replacing exhaust system

components, make sure there is adequate clearance

from all points on the underbody to prevent overheating

the floor pan and possible damage to the passenger

compartment insulation and trim materials.

Check complete exhaust system and nearby body areas

and rear compartment lid for broken, damaged, missing

or mispositioned parts, open seams, holes, loose

connections or other deterioration which could permit

exhaust fumes to seep into the rear compartment or

passenger compartment. Dust or water in the rear

compartment may be an indication of a problem in one of

these areas. Any faulty areas should be corrected

immediately.

Hangers

Various types of hangers are used to support exhaust

system(s). These include conventional rubber straps,

rubber rings, and rubber blocks.

The installation of exhaust system supports is very

important, as improperly installed supports can cause

annoying vibrations which can be difficult to diagnose.

Three Way Catalytic Converter

The three way catalytic converter is an emission control

device added to the exhaust system to reduce pollutants

from the exhaust gas stream.

CAUTION: The catalytic converter requires the use

of unleaded fuel only.

Periodic maintenance of the exhaust system is not

required. If the vehicle is raised for other service, it is

advisable to check the condition of the complete exhaust

system.

A dual bed monolith catalytic converter is used in

combination with three way catalytic converter.

Catalytic Types:

Three way (Reduction/Oxidation) catalyst

The catalyst coating on the three way (reduction)

converter contains platinum and rhodium which lowers

the levels of nitrous oxide (NOx) as well as hydrocarbons

(HC) and carbon monoxide (Co).

Gasket

The gasket must be replaced whenever a new exhaust

pipe, muffler or catalytic converter is installed.

Page 5275 of 6000

6A – 2 ENGINE MECHANICAL

GENERAL DESCRIPTION

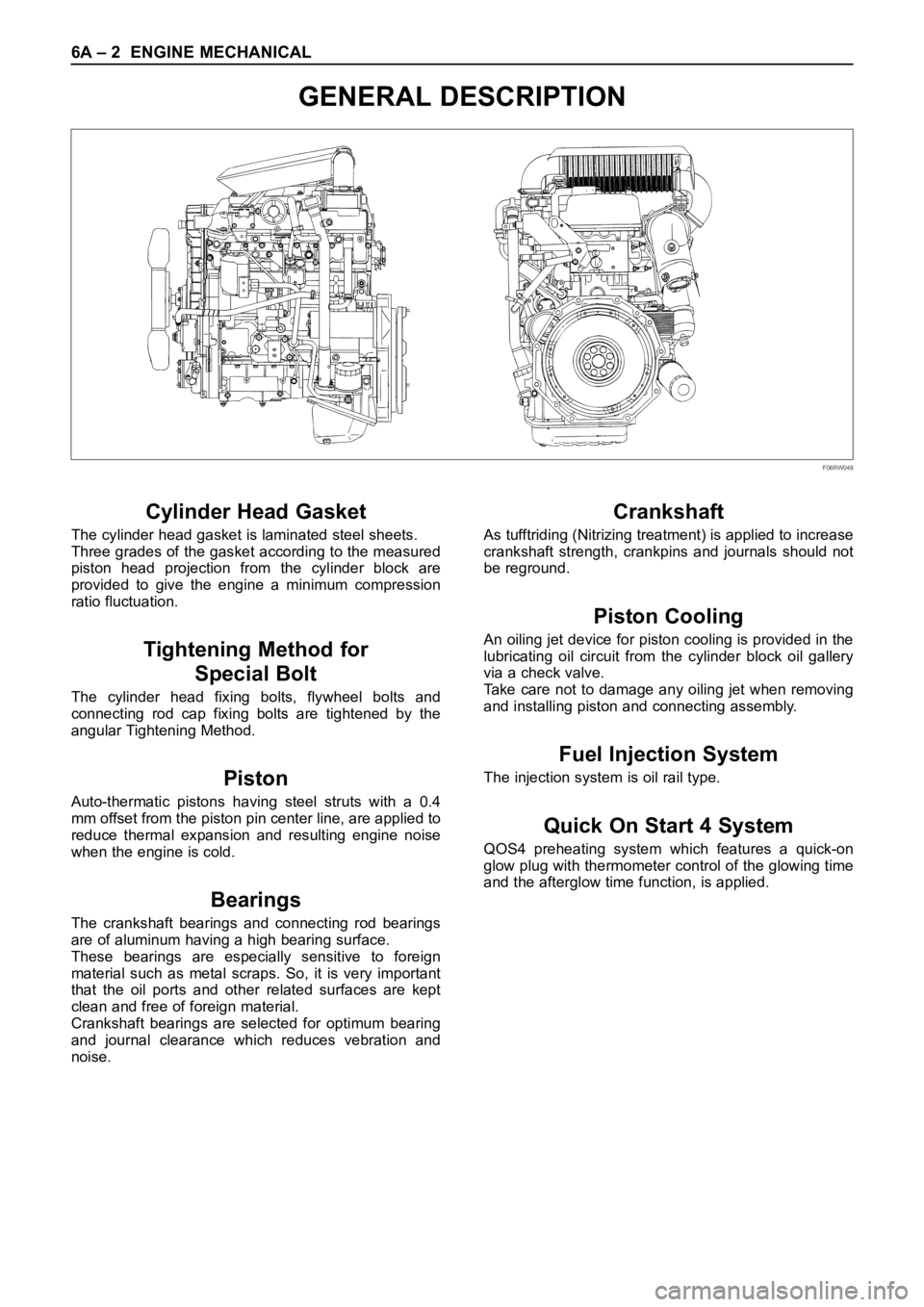

Cylinder Head Gasket

The cylinder head gasket is laminated steel sheets.

Three grades of the gasket according to the measured

piston head projection from the cylinder block are

provided to give the engine a minimum compression

ratio fluctuation.

Tightening Method for

Special Bolt

The cylinder head fixing bolts, flywheel bolts and

connecting rod cap fixing bolts are tightened by the

angular Tightening Method.

Piston

Auto-thermatic pistons having steel struts with a 0.4

mm offset from the piston pin center line, are applied to

reduce thermal expansion and resulting engine noise

when the engine is cold.

Bearings

The crankshaft bearings and connecting rod bearings

are of aluminum having a high bearing surface.

These bearings are especially sensitive to foreign

material such as metal scraps. So, it is very important

that the oil ports and other related surfaces are kept

clean and free of foreign material.

Crankshaft bearings are selected for optimum bearing

and journal clearance which reduces vebration and

noise.

Crankshaft

As tufftriding (Nitrizing treatment) is applied to increase

crankshaft strength, crankpins and journals should not

be reground.

Piston Cooling

An oiling jet device for piston cooling is provided in the

lubricating oil circuit from the cylinder block oil gallery

via a check valve.

Take care not to damage any oiling jet when removing

and installing piston and connecting assembly.

Fuel Injection System

The injection system is oil rail type.

Quick On Start 4 System

QOS4 preheating system which features a quick-on

glow plug with thermometer control of the glowing time

and the afterglow time function, is applied.

F06RW048

Page 5387 of 6000

6C – 6 ENGINE FUEL

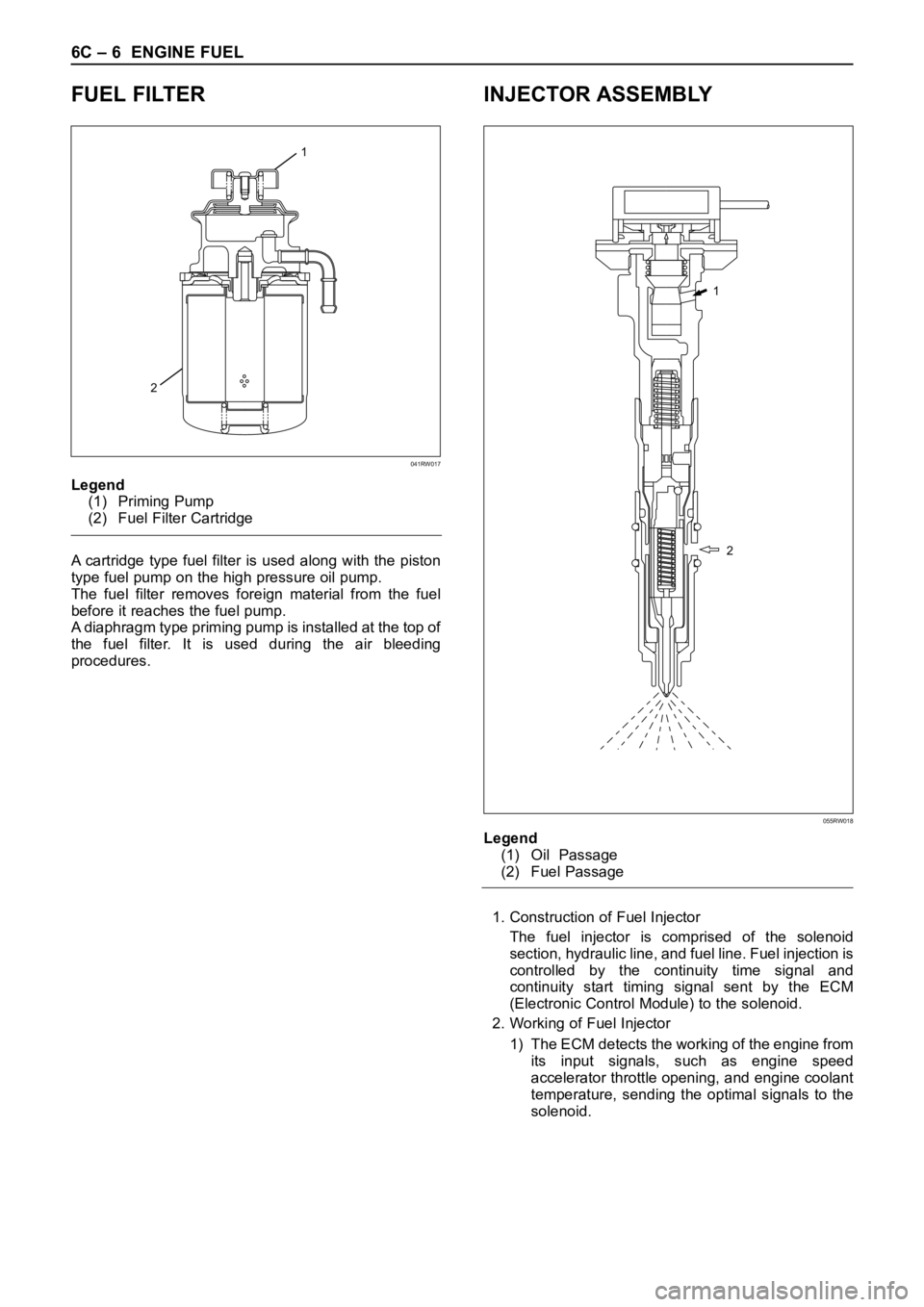

FUEL FILTER

Legend

(1) Priming Pump

(2) Fuel Filter Cartridge

A cartridge type fuel filter is used along with the piston

type fuel pump on the high pressure oil pump.

The fuel filter removes foreign material from the fuel

before it reaches the fuel pump.

A diaphragm type priming pump is installed at the top of

the fuel filter. It is used during the air bleeding

procedures.

INJECTOR ASSEMBLY

Legend

(1) Oil Passage

(2) Fuel Passage

1. Construction of Fuel Injector

The fuel injector is comprised of the solenoid

section, hydraulic line, and fuel line. Fuel injection is

controlled by the continuity time signal and

continuity start timing signal sent by the ECM

(Electronic Control Module) to the solenoid.

2. Working of Fuel Injector

1) The ECM detects the working of the engine from

its input signals, such as engine speed

accelerator throttle opening, and engine coolant

temperature, sending the optimal signals to the

solenoid.

1

2

041RW017

1

2

055RW018

Page 5455 of 6000

6E–26

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Output Components:

Output components are diagnosed for proper response to

control module commands. Components where

functional monitoring is not feasible will be monitored for

circuit continuity and out-of-range values if applicable.

Output components to be monitored include, but are not

limited to, the following circuit:

EGR VSV

EGR EVRV

Electronic Transmission controls

Injector

Intake throttle

Glow plug

MIL control

Refer to ECM and Sensors in General Descriptions.

Passive and Active Diagnostic Tests

A passive test is a diagnostic test which simply monitors a

vehicle system or component. Conversely, an active test,

actually takes some sort of action when performing

diagnostic functions, often in response to a failed passive

test.

Intrusive Diagnostic Tests

This is any on-board test run by the Diagnostic

Management System which may have an effect on

vehicle performance or emission levels.

Warm-Up Cycle

A warm-up cycle means that engine at temperature must

reach a minimum of 70

C (160F) and rise at least 22C

(40

F) over the course of a trip.

Freeze Frame

Freeze Frame is an element of the Diagnostic

Management System which stores various vehicle

information at the moment an emissions-related fault is

stored in memory and when the MIL is commanded on.

These data can help to identify the cause of a fault. Refer

to

Storing And Erasing Freeze Fame Data for more

detailed information.

Failure Records

Failure Records data is an enhancement of the OBD

Freeze Frame feature. Failure Records store the same

vehicle information as does Freeze Frame, but it will store

that information for any fault which is stored in on-board

memory, while Freeze Frame stores information only for

emission-related faults that command the MIL on.

Common OBD Terms

Diagnostic

When used as a noun, the word diagnostic refers to any

on-board test run by the vehicle’s Diagnostic

Management System. A diagnostic is simply a test run on

a system or component to determine if the system or

component is operating according to specification. There

are many diagnostics, shown in the following list:

EGR

engine speed

vehicle speed

ECT

MAP

VSV

IAT

ITP

AP

FT (Fuel Temp)

RP (Rail Pressure)

OT (Oil Temp)

EGR EVRV

Idle SW

Brake SW

The Diagnostic Executive

The Diagnostic Executive is a unique segment of

software which is designed to coordinate and prioritize

the diagnostic procedures as well as define the protocol

for recording and displaying their results. The main

responsibilities of the Diagnostic Executive are listed as

follows:

Commanding the MIL (“Check Engine” lamp) on and

off

DTC logging and clearing

Freeze Frame data for the first emission related DTC

recorded

Current status information on each diagnostic

Diagnostic Information

The diagnostic charts and functional checks are designed

to locate a faulty circuit or component through a process

of logical decisions. The charts are prepared with the

requirement that the vehicle functioned correctly at the

time of assembly and that there are not multiple faults

present.

There is a continuous self-diagnosis on certain control

functions. This diagnostic capability is complemented by

the diagnostic procedures contained in this manual. The

language of communicating the source of the malfunction

is a system of diagnostic trouble codes. When a

malfunction is detected by the control module, a

diagnostic trouble code is set and the Malfunction

Indicator Lamp (MIL) (“Check Engine” lamp) is

illuminated.

Malfunction Indicator Lamp (MIL)

The Malfunction Indicator Lamp (MIL) looks the same as

the MIL you are already familiar with “Check Engine”

lamp.

Basically, the MIL is turned on when the ECM detects a

DTC that will impact the vehicle emissions.

When the MIL remains “ON” while the engine is

running, or when a malfunction is suspected due to a

driveability or emissions problem, a Powertrain

On-Board Diagnostic (OBD) System Check must be

performed. The procedures for these checks are

given in On-Board Diagnostic (OBD) System Check.

These checks will expose faults which may not be

detected if other diagnostics are performed first.

DTC Types

Characteristic of Code

Page 5464 of 6000

6E–35 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Guid to the System

Fuel Injection system is an HEUI (Hydraulically

Actuated, Electronically Controlled, Unit, Injector)

type. In this type of injector system, the oil

pressurized by means of High Pressure Oil Pump

(16) is fed through Rail Pressure Control Valve (10)

and Oil Rail (7) to Injector (29) from which fuel is

injected under this oil pressure.

For diagnosis, therefore, the Rail Pressure as well as

the Electric Circuit must be inspected.

On-Board Diagnostic (OBD) System Check

A Group

060RW135

Page 5478 of 6000

6E–49 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Engine Cranks But Will Not Run

Circuit Description

In this type of injector system, the Engine Control Module

(ECM) triggers the correct driver inside the injector, which

then triggers the correct injector based on the 57X signal

received from the crankshaft position sensor (CKP).

During crank, the ECM monitors the CKP 57X signal. The

CKP signal is used to determine which cylinder will fire

first. After the CKP 57X signal has been processed by the

ECM, it will command all four injectors to allow a priming

shot of fuel for all the cylinders. After the priming, the

injectors are left “OFF” during the next four 57X reference

pulses from the CKP. This allows each cylinder a chance

to use the fuel from the priming shot. During this waiting

period, a camshaft position (CMP) signal pulse will have

been received by the ECM. The CMP signal allows the

ECM to operate the injectors sequentially based on

camshaft position. If the camshaft position signal is not

present at start-up, the ECM will begin sequential fuel

delivery with a 1-in-4 chance that fuel delivery is correct.

The engine will run without a CMP signal, but will set a

DTC code.

Diagnostic Aids

An intermittent problem may be caused by a poor

connection, rubbed-through wire insulation or a wirebroken inside the insulation. Check for the following

items:

Poor connection or damaged harness – Inspect the

ECM harness and connectors for improper mating,

broken locks, improperly formed or damaged

terminals, poor terminal-to-wore connection, and

damaged harness.

Faulty engine coolant temperature sensor – Using a

Tech 2, compare engine coolant temperature with

manifold air temperature on a completely cool engine.

Test Description

Number(s) below refer to the step number(s) on the

Diagnostic Chart.

4. An obvious cause of low fuel pressure would be an

empty fuel tank.

5. The engine will easily start and run if a few injectors

are disabled. It is not necessary to test all injectors

at this time since this step is only a test to verify that

all of the injectors have not been disabled by fuel

contamination.

8.If there is an open or shorted driver circuit, DTCs

0201-0204 should be set.

Engine Cranks But Will Not Run

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

2Check the 15 A injector fuse, the 15 A engine device

fuse, and the 15A ECM fuse.

Was a fuse blown?

—Go to Step 3Go to Step 4

3Check for a short to ground and replace the fuse.

Is the action complete?

—Verify repair—

4Is fuel tank empty?

—

Fill the fuel

tank

Go to Step 5

5Is the right fuel using?

—Go to Step 6

Replace the

fuel

6Is the right engine oil using?

—Go to Step 7

Replace the

engine oil

7Using the Tech–2.

Is DTC P0192 or P0193 set? (Check rail pressure

system)

—

Go to DTC

P0192 or

DTC P0193

Go to Step 8

8Using the Tech–2.

Is DTC P0201 – P0204 set? (Check inject circuit fault)

—

Go to DTC

P0201 –

P0204

Go to Step 9

9Using the Tech–2.

Is DTC P1657 set? (Check ECM Main relay)

—

Go to DTC

P1657

Go to Step 10

Page 5551 of 6000

6E–122

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0342 (Flash DTC 41)

CMP (Cam Position) Sensor No Signal

060RW133

Circuit Description

The CMP signal produced by the camshaft position

(CMP) sensor pulses when the engine is running and

crankshaft position (CKP) synchro pulses are also being

received. The hall type CMP sensor and the CKP sensor

share 5 V and ground connections at the Engine Control

Module ECM. The third wire at the sensor is a signal

c i r c u i t t o t h e E C M . T h e E C M u s e s t h e C M P s i g n a l p u l s e s

to initiate sequential fuel injection. If the ECM does not

receive pulses on the CMP reference circuit, DTC P0342

will set.

Action Taken When the DTC Sets

The ECM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

DTC P0342 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the ECM battery

feed.

Diagnostic Aids

An intermittent may be caused by a poor connection,

rubbed-through wire insulation or a wire broken inside the

insulation. Check for:

Poor connection – Inspect the ECM harness and

connectors for improper mating, broken locks,

improperly formed or damaged terminals, and poor

terminal to wire connection.

Damaged harness – Inspect the wiring harness for

damage. If the harness appears to be OK, disconnect

the ECM, turn the ignition on and observe a voltmeter

connected to the CMP signal circuit at the ECM

harness connector while moving connectors and

wiring harnesses related to the ICM and the CMP

sensor. A change in voltage will indicate the location

of the fault.

Test Description

Number(s) below refer to the step number(s) on the

Diagnostic Chart.

2. Ensures that the fault is present.

14.Determines whether the fault is being caused by a

missing camshaft magnet or a faulty ECM. The

voltage measured in this step should read around 4

volts, toggling to near 0 volts when the CMP sensor

interfaces with the camshaft magnet.

Page 5642 of 6000

6E–213 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

3. Connect the electrical connector to the AP sensor.

035RW060

4. Connect the negative battery cable.

Fuel Filter Cap

General Description

The fuel filler cap includes a vacuum valve and a pressure

valve.

If high vacuum or high pressure occurs in the fuel tank,

each valve works to adjust the pressure in order to

prevent damage to the tank at the EGR valve.

TS23767

Inspection Procedure

NOTE: Replace the fuel filler cap with the same type of

filler cap that was originally installed on the vehicle.

Check the seal ring in the filler cap for any abnormality

and for seal condition.

Replace the filler cap if any abnormality is found.

Fuel Filter

Removal and Installation Procedure

Refer to the Engine fuel in the 4JX1 Engine section.

Fuel Gauge Unit

Removal Procedure

1. Disconnect the negative battery cable.

2. Loosen the fuel filler cap.

3. Drain the fuel from the tank.

Tighten

Tighten the drain plug to 20 Nꞏm (14 lb ft.).

TS22907

4. Disconnect the wiring connector from the fuel gauge

unit.

TS23771

5. Remove the fuel gauge unit retaining screws.