air condition OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 5419 of 6000

6D – 16 ENGINE ELECTRICAL

DIAGNOSIS

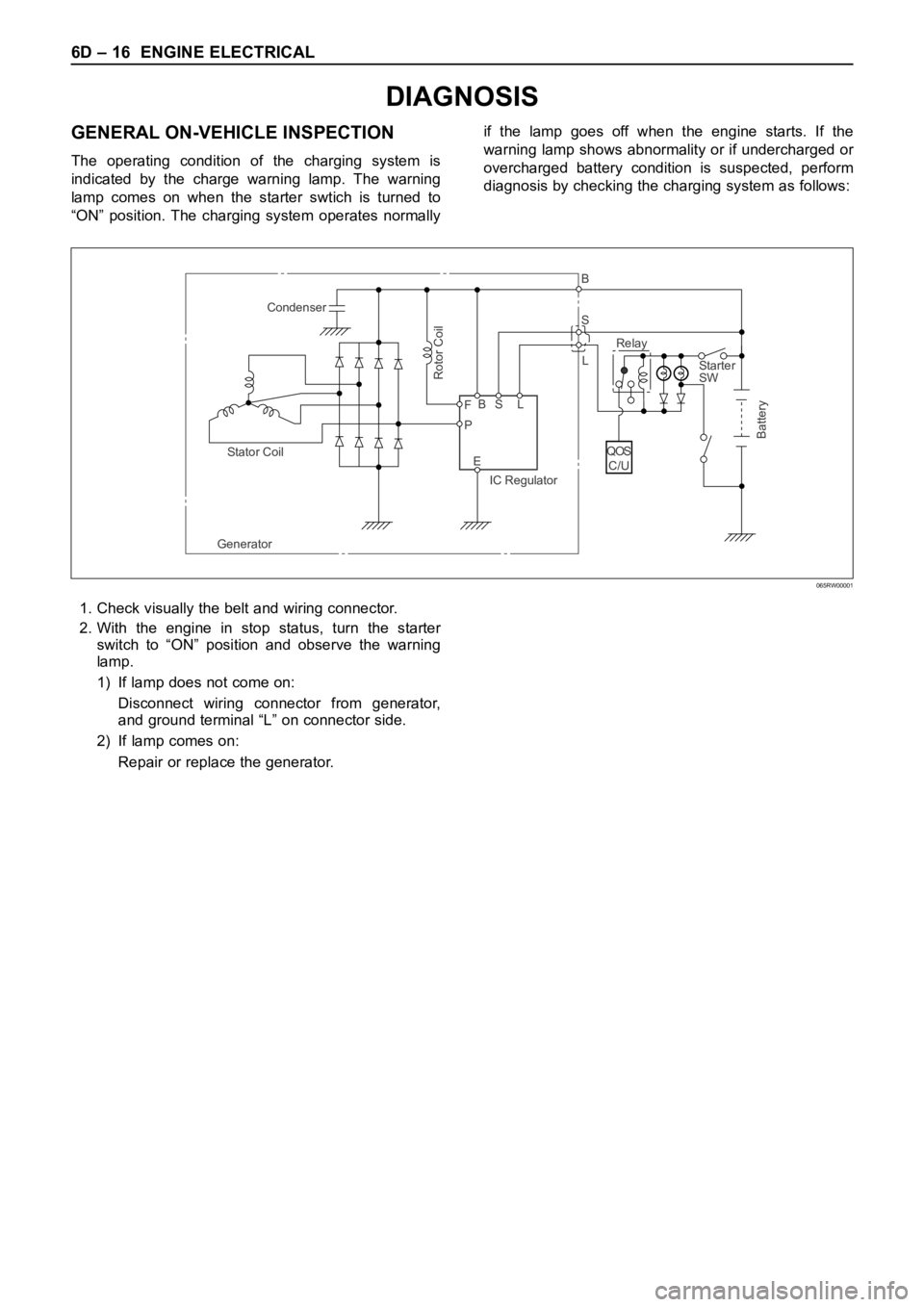

GENERAL ON-VEHICLE INSPECTION

The operating condition of the charging system is

indicated by the charge warning lamp. The warning

lamp comes on when the starter swtich is turned to

“ON” position. The charging system operates normallyif the lamp goes off when the engine starts. If the

warning lamp shows abnormality or if undercharged or

overcharged battery condition is suspected, perform

diagnosis by checking the charging system as follows:

Condenser

GeneratorStator Coil

IC RegulatorStarter

SW

Rotor Coil

Battery

P F

EBS LRelay B

S

L

QOS

C/U

065RW00001

1. Check visually the belt and wiring connector.

2. With the engine in stop status, turn the starter

switch to “ON” position and observe the warning

lamp.

1) If lamp does not come on:

Disconnect wiring connector from generator,

and ground terminal “L” on connector side.

2) If lamp comes on:

Repair or replace the generator.

Page 5430 of 6000

6E–1 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

4JX1–TC 3.0L ENGINE

DRIVEABILITY AND EMISSIONS

CONTENTS

Specification 6E–7. . . . . . . . . . . . . . . . . . . . . . . . . .

Tightening Specifications 6E–7. . . . . . . . . . . . . . .

Diagrams and Schematics 6E–8. . . . . . . . . . . . . . . .

ECM Wiring Diagram (1 of 6) 6E–8. . . . . . . . . . . .

ECM Wiring Diagram (2 of 6) 6E–9. . . . . . . . . . . .

ECM Wiring Diagram (3 of 6) 6E–10. . . . . . . . . . . .

ECM Wiring Diagram (4 of 6) 6E–11. . . . . . . . . . . .

ECM Wiring Diagram (5 of 6) 6E–12. . . . . . . . . . . .

ECM Wiring Diagram (6 of 6) 6E–13. . . . . . . . . . . .

ECM Pinouts 6E–14. . . . . . . . . . . . . . . . . . . . . . . . . . .

ECM Pinout Table, 32-Way Connector – J1

RED – Upper 6E–14. . . . . . . . . . . . . . . . . . . . . . . . .

ECM Pinout Table, 32-Way Connector – J1

RED – Lower 6E–15. . . . . . . . . . . . . . . . . . . . . . . . .

ECM Pinout Table, 32-Way Connector – J2

BLUE – Upper 6E–16. . . . . . . . . . . . . . . . . . . . . . . .

ECM Pinout Table, 32-Way Connector – J2

BLUE – Lower 6E–17. . . . . . . . . . . . . . . . . . . . . . . .

ECM Pinout Table, 5-Way Connector – J3 6E–18

Component Locator 6E–19. . . . . . . . . . . . . . . . . . . . .

Sensors and Miscellaneous Component

Locators 6E–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Abbreviations Charts 6E–23. . . . . . . . . . . . . . . . . . . .

Diagnosis 6E–24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Strategy-Based Diagnostics 6E–24. . . . . . . . . . . . .

Strategy-Based Diagnostics 6E–24. . . . . . . . . . . . .

DTC Stored 6E–24. . . . . . . . . . . . . . . . . . . . . . . . . . .

No DTC 6E–24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

No Matching Symptom 6E–24. . . . . . . . . . . . . . . . .

Intermittents 6E–24. . . . . . . . . . . . . . . . . . . . . . . . . .

No Trouble Found 6E–24. . . . . . . . . . . . . . . . . . . . .

Verifying Vehicle Repair 6E–24. . . . . . . . . . . . . . . .

General Service Information 6E–25. . . . . . . . . . . . . .

Serviceability Issues 6E–25. . . . . . . . . . . . . . . . . . .

Visual/Physical Engine Compartment

Inspection 6E–25. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Basic Knowledge of Tools Required 6E–25. . . . . .

Serial Data Communications 6E–25. . . . . . . . . . . . . .

Class II Serial Data Communications 6E–25. . . . .

On-Board Diagnostic (OBD) 6E–25. . . . . . . . . . . . . .

On-Board Diagnostic Tests 6E–25. . . . . . . . . . . . .

Comprehensive Component Monitor

Diagnostic Operation 6E–25. . . . . . . . . . . . . . . . . .

Common OBD Terms 6E–26. . . . . . . . . . . . . . . . . .

The Diagnostic Executive 6E–26. . . . . . . . . . . . . . .

DTC Types 6E–26. . . . . . . . . . . . . . . . . . . . . . . . . . .

Verifying Vehicle Repair 6E–27. . . . . . . . . . . . . . . . Reading Flash Diagnostic Trouble Codes 6E–27.

Reading Diagnostic Trouble Codes Using

a TECH 2 6E–28. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tech 2 Scan Tool 6E–29. . . . . . . . . . . . . . . . . . . . . .

Getting Started 6E–30. . . . . . . . . . . . . . . . . . . . . . . .

DTC Modes 6E–32. . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC Information Mode 6E–32. . . . . . . . . . . . . . . . .

Injector Test 6E–32. . . . . . . . . . . . . . . . . . . . . . . . . .

EGR Valve Test 6E–32. . . . . . . . . . . . . . . . . . . . . . .

Rail Pressure Control Valve Test 6E–32. . . . . . . . .

Injector Balance Test 6E–32. . . . . . . . . . . . . . . . . . .

Data Programming in Case of ECM Change 6E–32

Rail Pressure Sensor Programming 6E–33. . . . . .

Injector Group Sign Programming

(Injector Change) 6E–33. . . . . . . . . . . . . . . . . . . . .

On-Board Diagnostic (OBD) System Check 6E–35.

Circuit Description 6E–37. . . . . . . . . . . . . . . . . . . . .

Diagnostic Aids 6E–37. . . . . . . . . . . . . . . . . . . . . . . .

Engine Control Module ECM Diagnosis 6E–39. . . .

Multiple ECM Information Sensor DTCS Set 6E–39

Circuit Description 6E–39. . . . . . . . . . . . . . . . . . . . .

Diagnostic Aids 6E–39. . . . . . . . . . . . . . . . . . . . . . . .

EGR (Exhaust Gas Recirculation) Diagnosis 6E–41

Tech 2 Data Definitions and Ranges 6E–41. . . . . . .

Typical Scan Data Values 6E–41. . . . . . . . . . . . . . . .

Test Conditions 6E–41. . . . . . . . . . . . . . . . . . . . . . . .

4JX1-TC Engine (Automatic and Manual

Transmission) 6E–42. . . . . . . . . . . . . . . . . . . . . . . .

No Malfunction Indicator Lamp (MIL) 6E–44. . . . . . .

Circuit Description 6E–44. . . . . . . . . . . . . . . . . . . . .

Diagnostic Aids 6E–44. . . . . . . . . . . . . . . . . . . . . . . .

Malfunction Indicator Lamp (MIL) “ON”

Steady 6E–47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit description 6E–47. . . . . . . . . . . . . . . . . . . . .

Diagnostic Aids 6E–47. . . . . . . . . . . . . . . . . . . . . . . .

Engine Cranks But Will Not Run 6E–49. . . . . . . . . . .

Circuit Description 6E–49. . . . . . . . . . . . . . . . . . . . .

Diagnostic Aids 6E–49. . . . . . . . . . . . . . . . . . . . . . . .

Exhaust Gas Recirculation (EGR) System

Check 6E–52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Description 6E–52. . . . . . . . . . . . . . . . . . . . .

ECM Diagnostic Trouble Codes 6E–54. . . . . . . . . . .

ECM Diagnostic Trouble Codes 6E–54. . . . . . . . .

Diagnostic Trouble Code (DTC) P0107

(Flash DTC 34)

MAP Sensor Circuit Low Voltage 6E–56. . . . . . . . . .

Page 5431 of 6000

6E–2

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Circuit Description 6E–56. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–56. . . . . . .

Conditions for Clearing the MIL/DTC 6E–56. . . . .

Diagnostic Aids 6E–56. . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0108

(Flash DTC 34)

MAP Sensor Circuit High Voltage 6E–58. . . . . . . . .

Circuit Description 6E–58. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–58. . . . . . .

Conditions for Clearing the MIL/DTC 6E–58. . . . .

Diagnostic Aids 6E–58. . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0112

(Flash DTC 23) IAT Sensor Circuit Low

Voltage 6E–60. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Description 6E–60. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–60. . . . . . .

Conditions for Clearing the MIL/DTC 6E–60. . . . .

Diagnostic Aids 6E–60. . . . . . . . . . . . . . . . . . . . . . . .

Test Description 6E–61. . . . . . . . . . . . . . . . . . . . . . .

Intake Air Temperature Sensor 6E–61. . . . . . . . . .

Diagnostic Trouble Code (DTC) P0113

(Flash DTC 23) IAT Sensor Circuit High

Voltage 6E–62. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Description 6E–62. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–62. . . . . . .

Conditions for Clearing the MIL/DTC 6E–62. . . . .

Diagnostic Aids 6E–62. . . . . . . . . . . . . . . . . . . . . . . .

Test Description 6E–63. . . . . . . . . . . . . . . . . . . . . . .

Manifold Air Temperature Sensor 6E–63. . . . . . . .

Diagnostic Trouble Code (DTC) P0117

(Flash DTC 14) ECT Sensor Low Voltage 6E–65.

Circuit Description 6E–65. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–65. . . . . . .

Conditions for Clearing the MIL/DTC 6E–65. . . . .

Diagnostic Aids 6E–65. . . . . . . . . . . . . . . . . . . . . . . .

Test Description 6E–65. . . . . . . . . . . . . . . . . . . . . . .

Engine Coolant Temperature Sensor 6E–66. . . . .

Diagnostic Trouble Code (DTC) P0118

(Flash DTC 14) ECT Sensor High Voltage 6E–67.

Circuit Description 6E–67. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–67. . . . . . .

Conditions for Clearing the MIL/DTC 6E–67. . . . .

Diagnostic Aids 6E–67. . . . . . . . . . . . . . . . . . . . . . . .

Test Description 6E–68. . . . . . . . . . . . . . . . . . . . . . .

Engine Coolant Temperature Sensor 6E–68. . . . .

Diagnostic Trouble Code (DTC) P0121

(Flash DTC 33) AP Sensor Rationality 6E–70. . . . .

Circuit Description 6E–70. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–70. . . . . . .

Conditions for Clearing the MIL/DTC 6E–70. . . . .

Diagnostic Aids 6E–70. . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0122

(Flash DTC 21) AP Sensor Low Voltage 6E–72. . .

Circuit Description 6E–72. . . . . . . . . . . . . . . . . . . . . Action Taken When the DTC Sets 6E–72. . . . . . .

Conditions for Clearing the MIL/DTC 6E–72. . . . .

Diagnostic Aids 6E–72. . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0123

(Flash DTC 21) AP Sensor High Voltage 6E–75. . .

Circuit Description 6E–75. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–75. . . . . . .

Conditions for Clearing the MIL/DTC 6E–75. . . . .

Diagnostic Aids 6E–75. . . . . . . . . . . . . . . . . . . . . . . .

Test Description 6E–75. . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0182

(Flash DTC 15) FT Sensor Low Voltage 6E–78. . .

Circuit Description 6E–78. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–78. . . . . . .

Conditions for Clearing the MIL/DTC 6E–78. . . . .

Diagnostic Aids 6E–78. . . . . . . . . . . . . . . . . . . . . . . .

Test Description 6E–78. . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0183

(Flash DTC 15) FT Sensor High Voltage 6E–80. . .

Circuit Description 6E–80. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–80. . . . . . .

Conditions for Clearing the MIL/DTC 6E–80. . . . .

Diagnostic Aids 6E–80. . . . . . . . . . . . . . . . . . . . . . . .

Test Description 6E–80. . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0192

(Flash DTC 63) Rail Pressure Sensor Low

Voltage 6E–82. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Description 6E–82. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–82. . . . . . .

Conditions for Clearing the MIL/DTC 6E–82. . . . .

Diagnostic Aids 6E–82. . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0193

(Flash DTC 63) Rail Pressure Sensor

High Voltage 6E–84. . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Description 6E–84. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–84. . . . . . .

Conditions for Clearing the MIL/DTC 6E–84. . . . .

Diagnostic Aids 6E–84. . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P1193

(Flash DTC 64) RPCV Circuit Open/Short 6E–86. .

Circuit Description 6E–86. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–86. . . . . . .

Conditions for Clearing the MIL/DTC 6E–86. . . . .

Diagnostic Aids 6E–86. . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P1194

(Flash DTC 61) Rail Pressure System

Low Voltage 6E–88. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Description 6E–88. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–88. . . . . . .

Conditions for Clearing the MIL/DTC 6E–88. . . . .

Diagnostic Aids 6E–88. . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P1195

(Flash DTC 61) Rail Pressure System

High Voltage 6E–90. . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Description 6E–90. . . . . . . . . . . . . . . . . . . . .

Page 5434 of 6000

6E–5 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Conditions for Clearing the MIL/DTC 6E–159. . . . .

Diagnostic Aids 6E–159. . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P1562

(Flash DTC 35) System Voltage Too Low

at Cranking 6E–160. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Description 6E–160. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–160. . . . . . .

Conditions for Clearing the MIL/DTC 6E–160. . . . .

Diagnostic Aids 6E–160. . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P1587

(Flash DTC 25) Brake SW Malfunction 6E–161. . . .

Circuit Description 6E–161. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–161. . . . . . .

Conditions for Clearing the MIL/DTC 6E–161. . . . .

Diagnostic Aids 6E–161. . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P1588

(Flash DTC 25) Brake SW Malfunction 6E–163. . . .

Circuit Description 6E–163. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–163. . . . . . .

Conditions for Clearing the MIL/DTC 6E–163. . . . .

Diagnostic Aids 6E–163. . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0601

(Flash DTC 55) ECM Checksum Error 6E–165. . . . .

Action Taken When the DTC Sets 6E–165. . . . . . .

Conditions for Clearing the MIL/DTC 6E–165. . . . .

Diagnostic Aids 6E–165. . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0650

(Flash DTC 77) Check Engine Lam Circuit

Open/Short 6E–166. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Description 6E–166. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–166. . . . . . .

Conditions for Clearing the MIL/DTC 6E–166. . . . .

Diagnostic Aids 6E–166. . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0654

(Flash DTC 27) Tachometer Circuit

Open/Short 6E–168. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Description 6E–168. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–168. . . . . . .

Conditions for Clearing the MIL/DTC 6E–168. . . . .

Diagnostic Aids 6E–168. . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P1655

(Flash DTC 17) Thermo Relay Circuit

Open/Short 6E–170. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Description 6E–170. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–170. . . . . . .

Conditions for Clearing the MIL/DTC 6E–170. . . . .

Diagnostic Aids 6E–170. . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P1657

(Flash DTC 76) ECM Main Relay Circuit

Open/Short 6E–172. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Description 6E–172. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–172. . . . . . .

Conditions for Clearing the MIL/DTC 6E–172. . . . .

Diagnostic Aids 6E–172. . . . . . . . . . . . . . . . . . . . . . . . Diagnostic Trouble Code (DTC) P1589

(Flash DTC 47) Transmission SW Circuit

Open/Short 6E–174. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Description 6E–174. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–174. . . . . . .

Conditions for Clearing the MIL/DTC 6E–174. . . . .

Diagnostic Aids 6E–174. . . . . . . . . . . . . . . . . . . . . . . .

Symptom Diagnosis 6E–176. . . . . . . . . . . . . . . . . . . . .

Default Matrix Table 6E–199. . . . . . . . . . . . . . . . . . . . .

On–Vehicle Service Camshaft Position

(CMP) Sensor 6E–201. . . . . . . . . . . . . . . . . . . . . . . . . .

Removal Procedure 6E–201. . . . . . . . . . . . . . . . . . . .

Inspection Procedure 6E–201. . . . . . . . . . . . . . . . . .

Installation Procedure 6E–201. . . . . . . . . . . . . . . . . .

Crankshaft Position (CKP) Sensor 6E–202. . . . . . . . .

Removal Procedure 6E–202. . . . . . . . . . . . . . . . . . . .

Installation Procedure 6E–202. . . . . . . . . . . . . . . . . .

Engine Coolant Temperature (ECT) Sensor 6E–203.

Removal Procedure 6E–203. . . . . . . . . . . . . . . . . . . .

Installation Procedure 6E–203. . . . . . . . . . . . . . . . . .

Intake Air Temperature (IAT) Sensor 6E–203. . . . . . .

Removal Procedure 6E–203. . . . . . . . . . . . . . . . . . . .

Installation Procedure 6E–204. . . . . . . . . . . . . . . . . .

Manifold Absolute Pressure (MAP) Sensor 6E–204.

Removal Procedure 6E–204. . . . . . . . . . . . . . . . . . . .

Installation Procedure 6E–205. . . . . . . . . . . . . . . . . .

Oil Temperature (OT) Sensor 6E–205. . . . . . . . . . . . .

Removal Procedure 6E–205. . . . . . . . . . . . . . . . . . . .

Installation Procedure 6E–206. . . . . . . . . . . . . . . . . .

Malfunction Indicator Lamp (MIL) 6E–206. . . . . . . . . .

Removal and Installation Procedure 6E–206. . . . . .

Engine Control Module (ECM) 6E–206. . . . . . . . . . . .

Service Precaution 6E–206. . . . . . . . . . . . . . . . . . . .

Electrostatic Discharge (ESD) Damage 6E–206. . .

Removal Procedure 6E–207. . . . . . . . . . . . . . . . . . . .

Installation Procedure 6E–208. . . . . . . . . . . . . . . . . .

EEPROM 6E–208. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Description 6E–208. . . . . . . . . . . . . . . . . . . .

Functional Check 6E–208. . . . . . . . . . . . . . . . . . . . . .

Intake Throttle Position (ITP) Sensor 6E–208. . . . . . .

Removal Procedure 6E–208. . . . . . . . . . . . . . . . . . . .

Function Check 6E–209. . . . . . . . . . . . . . . . . . . . . . .

Installation Procedure 6E–209. . . . . . . . . . . . . . . . . .

Vehicle Speed Sensor (VSS) 6E–210. . . . . . . . . . . . .

Removal Procedure 6E–210. . . . . . . . . . . . . . . . . . . .

Inspection Procedure 6E–210. . . . . . . . . . . . . . . . . .

Installation Procedure 6E–210. . . . . . . . . . . . . . . . . .

Air Cleaner/Air Filter 6E–211. . . . . . . . . . . . . . . . . . . . .

Removal Procedure 6E–211. . . . . . . . . . . . . . . . . . . .

Installation Procedure 6E–211. . . . . . . . . . . . . . . . . .

Accel Position (AP) Sensor 6E–211. . . . . . . . . . . . . . .

Removal Procedure 6E–211. . . . . . . . . . . . . . . . . . . .

Installation Procedure 6E–212. . . . . . . . . . . . . . . . . .

Accelerator Pedal Replacement 6E–212. . . . . . . . . . .

Page 5435 of 6000

6E–6

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Removal Procedure 6E–212. . . . . . . . . . . . . . . . . . . .

Installation Procedure 6E–212. . . . . . . . . . . . . . . . . .

Fuel Filter Cap 6E–213. . . . . . . . . . . . . . . . . . . . . . . . . .

General Description 6E–213. . . . . . . . . . . . . . . . . . . .

Inspection Procedure 6E–213. . . . . . . . . . . . . . . . . .

Fuel Filter 6E–213. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal and Installation Procedure 6E–213. . . . . .

Fuel Gauge Unit 6E–213. . . . . . . . . . . . . . . . . . . . . . . .

Removal Procedure 6E–213. . . . . . . . . . . . . . . . . . . .

Installation Procedure 6E–214. . . . . . . . . . . . . . . . . .

Fuel Injectors 6E–214. . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal and Installation Procedure 6E–214. . . . . .

Fuel Temperature Sensor 6E–214. . . . . . . . . . . . . . . .

Removal Procedure 6E–214. . . . . . . . . . . . . . . . . . . .

Installation Procedure 6E–215. . . . . . . . . . . . . . . . . .

Rail Pressure (RP) Sensor 6E–216. . . . . . . . . . . . . . .

Removal Procedure 6E–216. . . . . . . . . . . . . . . . . . . .

Installation Procedure 6E–216. . . . . . . . . . . . . . . . . .

Fuel Tank 6E–216. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal Procedure 6E–216. . . . . . . . . . . . . . . . . . . .

Throttle Body (TB) 6E–217. . . . . . . . . . . . . . . . . . . . . . .

Removal Procedure 6E–217. . . . . . . . . . . . . . . . . . . .

Installation Procedure 6E–217. . . . . . . . . . . . . . . . . .

Air Conditioning (A/C) Relay 6E–217. . . . . . . . . . . . . .

Removal Procedure 6E–217. . . . . . . . . . . . . . . . . . . .

Installation Procedure 6E–217. . . . . . . . . . . . . . . . . .

Exhaust Gas Recirculation (EGR) Vacuum

Switch Valve (VSV) 6E–217. . . . . . . . . . . . . . . . . . . . .

Removal Procedure 6E–217. . . . . . . . . . . . . . . . . . . .

Installation Procedure 6E–218. . . . . . . . . . . . . . . . . .

Electronic Vacuum Regurating Valve (EVRV) 6E–219

Removal Procedure 6E–219. . . . . . . . . . . . . . . . . . . .

Installation Procedure 6E–220. . . . . . . . . . . . . . . . . .

Wiring and Connectors 6E–220. . . . . . . . . . . . . . . . . . .

Wiring Harness Service 6E–220. . . . . . . . . . . . . . . .

Connectors and Terminals 6E–220. . . . . . . . . . . . . .

Wire Harness Repair: Twisted Shielded

Cable 6E–220. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal Procedure 6E–220. . . . . . . . . . . . . . . . . . . .

Installation Procedure 6E–221. . . . . . . . . . . . . . . . . .

Twisted Leads 6E–221. . . . . . . . . . . . . . . . . . . . . . . . . .

Removal Procedure 6E–221. . . . . . . . . . . . . . . . . . . .

Installation Procedure 6E–222. . . . . . . . . . . . . . . . . .

Weather-Pack Connector 6E–223. . . . . . . . . . . . . . . . .

Tools Required 6E–223. . . . . . . . . . . . . . . . . . . . . . . .

Removal Procedure 6E–223. . . . . . . . . . . . . . . . . . . . Installation Procedure 6E–223. . . . . . . . . . . . . . . . . .

Com-Pack III 6E–224. . . . . . . . . . . . . . . . . . . . . . . . . . .

General Information 6E–224. . . . . . . . . . . . . . . . . . . .

Metri-Pack 6E–224. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tools Required 6E–224. . . . . . . . . . . . . . . . . . . . . . . .

Removal Procedure 6E–224

. . . . . . . . . . . . . . . . . . . .

Installation Procedure 6E–224. . . . . . . . . . . . . . . . . .

General Description

(ECM and Sensors) 6E–225. . . . . . . . . . . . . . . . . . . . .

57X Reference ECM Input 6E–225. . . . . . . . . . . . . .

A/C Request Signal 6E–225. . . . . . . . . . . . . . . . . . . .

Crankshaft Position (CKP) Sensor 6E–225. . . . . . .

Camshaft Position (CMP) Sensor and

Signal 6E–225. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine Coolant Temperature (ECT) Sensor 6E–225

Electrically Erasable Programmable Read

Only Memory (EEPROM) 6E–225. . . . . . . . . . . . . .

Intake Air Temperature (IAT) Sensor 6E–225. . . . .

Manifold Absolute Pressure (MAP) Sensor 6E–226

Engine Control Module (ECM) 6E–226. . . . . . . . . . .

ECM Function 6E–226. . . . . . . . . . . . . . . . . . . . . . . . .

ECM Components 6E–226. . . . . . . . . . . . . . . . . . . . .

ECM Voltage Description 6E–226. . . . . . . . . . . . . . .

ECM Input/Outputs 6E–226. . . . . . . . . . . . . . . . . . . .

ECM Service Precautions 6E–227. . . . . . . . . . . . . .

Intake Throttle Position (ITP) Sensor 6E–227. . . . .

Transmission Range Switch 6E–227. . . . . . . . . . . . .

Accelerator Position Sensor (AP) 6E–227. . . . . . . .

Aftermarket Electrical and Vacuum

Equipment 6E–227. . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrostatic Discharge Damage 6E–227. . . . . . . . .

General Description (Air Induction) 6E–228. . . . . . . .

Air Induction System 6E–228. . . . . . . . . . . . . . . . . . .

General Description (Fuel Metering) 6E–228. . . . . . .

Deceleration Mode 6E–228. . . . . . . . . . . . . . . . . . . .

Fuel Injector 6E–228. . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Metering System Components 6E–228. . . . . .

A/C Clutch Diagnosis 6E–228. . . . . . . . . . . . . . . . . . . .

A/C Request Signal 6E–228. . . . . . . . . . . . . . . . . . . .

General Description Exhaust Gas

Recirculation (EGR) System 6E–228. . . . . . . . . . . . .

EGR Purpose 6E–228. . . . . . . . . . . . . . . . . . . . . . . . .

Fuse and Relay Panel

(Underhood Electrical Center) RHD 6E–229. . . . . . .

Fuse and Relay Panel

(Underhood Electrical Center) LHD 6E–230. . . . . . .

Page 5452 of 6000

6E–23 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

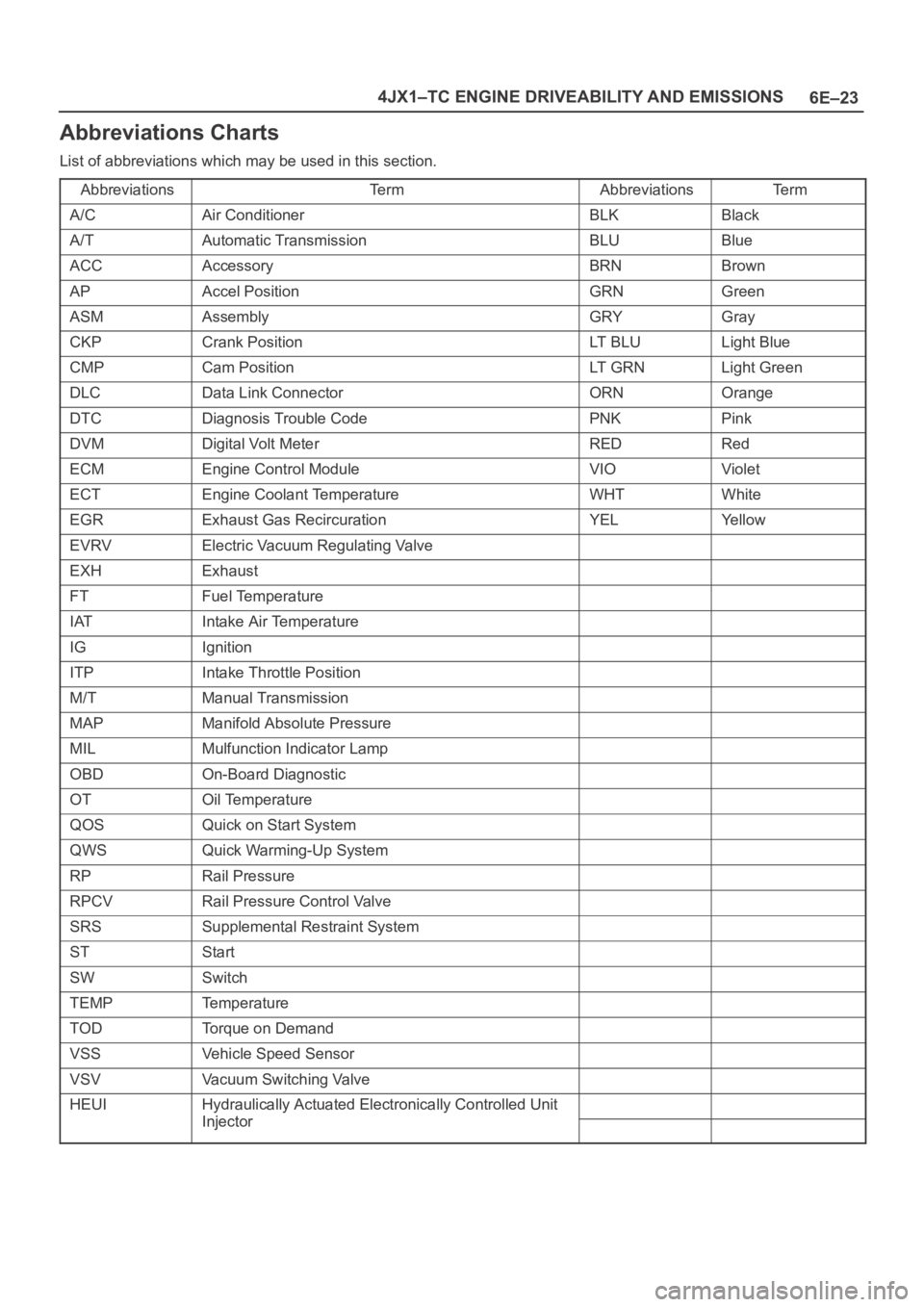

Abbreviations Charts

List of abbreviations which may be used in this section.

Abbreviations

Te r mAbbreviationsTe r m

A/CAir ConditionerBLKBlack

A/TAutomatic TransmissionBLUBlue

ACCAccessoryBRNBrown

APAccel PositionGRNGreen

ASMAssemblyGRYGray

CKPCrank PositionLT B L ULight Blue

CMPCam PositionLT G R NLight Green

DLCData Link ConnectorORNOrange

DTCDiagnosis Trouble CodePNKPink

DVMDigital Volt MeterREDRed

ECMEngine Control ModuleVIOViolet

ECTEngine Coolant TemperatureWHTWhite

EGRExhaust Gas RecircurationYELYe l l o w

EVRVElectric Vacuum Regulating Valve

EXHExhaust

FTFuel Temperature

IATIntake Air Temperature

IGIgnition

ITPIntake Throttle Position

M/TManual Transmission

MAPManifold Absolute Pressure

MILMulfunction Indicator Lamp

OBDOn-Board Diagnostic

OTOil Temperature

QOSQuick on Start System

QWSQuick Warming-Up System

RPRail Pressure

RPCVRail Pressure Control Valve

SRSSupplemental Restraint System

STStart

SWSwitch

TEMPTemperature

TODTorque on Demand

VSSVehicle Speed Sensor

VSVVacuum Switching Valve

HEUIHydraulically Actuated Electronically Controlled Unit

InjectorInjector

Page 5453 of 6000

6E–24

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Diagnosis

Strategy-Based Diagnostics

Strategy-Based Diagnostics

The strategy-based diagnostic is a uniform approach to

repair all Electrical/Electronic (E/E) systems. The

diagnostic flow can always be used to resolve an E/E

system problem and is a starting point when repairs are

necessary. The following steps will instruct the technician

how to proceed with a diagnosis:

1. Verify the customer complaint.

To verify the customer complaint, the technician

should know the normal operation of the system.

2. Perform preliminary checks.

Conduct a thorough visual inspection.

Review the service history.

Detect unusual sounds or odors.

Gather diagnostic trouble code information to

achieve an effective repair.

3. Check bulletins and other service information.

This includes videos, newsletters, etc.

4. Refer to service information (manual) system

check(s).

“System checks” contain information on a system

that may not be supported by one or more DTCs.

System checks verify proper operation of the

system. This will lead the technician in an

organized approach to diagnostics.

5. Refer to service diagnostics.

DTC Stored

Follow the designated DTC chart exactly to make an

effective repair.

No DTC

Select the symptom from the symptom tables. Follow the

diagnostic paths or suggestions to complete the repair.

You may refer to the applicable component/system check

in the system checks.

No Matching Symptom

1. Analyze the complaint.

2. Develop a plan for diagnostics.

3. Utilize the wiring diagrams and the theory of

operation.

Call technical assistance for similar cases where repair

history may be available. Combine technician knowledge

with efficient use of the available service information.

Intermittents

Conditions that are not always present are called

intermittents. To resolve intermittents, perform the

following steps:

1. Observe history DTCs, DTC modes, and freezeframe

data.2. Evaluate the symptoms and the conditions described

by the customer.

3. Use a check sheet or other method to identify the

circuit or electrical system component.

4. Follow the suggestions for intermittent diagnosis

found in the service documentation.

Most scan tools, such as the Tech 2 and the DVM, have

data-capturing capabilities that can assist in detecting

intermittents.

No Trouble Found

This condition exists when the vehicle is found to operate

normally. The condition described by the customer may

be normal. Verify the customer complaint against another

vehicle that is operating normally. The condition may be

intermittent. Verify the complaint under the conditions

described by the customer before releasing the vehicle.

1. Re-examine the complaint.

When the complaint cannot be successfully found or

isolated, a re-evaluation is necessary. The complaint

should be re-verified and could be intermittent as

defined in

Intermittents, or could be normal.

2. Repair and verify.

After isolating the cause, the repairs should be made.

Validate for proper operation and verify that the

symptom has been corrected. This may involve road

testing or other methods to verify that the complaint

has been resolved under the following conditions:

Conditions noted by the customer.

If a DTC was diagnosed, verify a repair by

duplicating conditions present when the DTC was

set as noted in the Failure Records or Freeze

Frame data.

Verifying Vehicle Repair

Verification of the vehicle repair will be more

comprehensive for vehicles with OBD system

diagnostics. Following a repair, the technician should

perform the following steps:

IMPORTANT:Follow the steps below when you verify

repairs on OBD systems. Failure to follow these steps

could result in unnecessary repairs.

1. Review and record the Failure Records and the

Freeze Frame data for the DTC which has been

diagnosed (Freeze Frame data will only be stored for

the MIL (“Check Engine” lamp) has been requested).

2. Clear the DTC(s).

3. Operate the vehicle within conditions noted in the

Failure Records and Freeze Frame data.

4. Monitor the DTC status information for the specific

DTC which has been diagnosed until the diagnostic

test associated with that DTC runs.

Page 5454 of 6000

6E–25 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

General Service Information

Serviceability Issues

Non-OEM Parts

All of the OBD diagnostics have been calibrated to run

with OEM parts. Accordingly, if commercially sold sensor

or switch is installed, it makes a wrong diagnosis and turn

on the MIL (“Check Engine” lamp).

Aftermarket electronics, such as cellular phones,

stereos, and anti-theft devices, may radiate EMI into the

control system if they are improperly installed. This may

cause a false sensor reading and turn on the MIL (“Check

Engine” lamp).

Poor Vehicle Maintenance

The sensitivity of OBD diagnostics will cause the MIL

(“Check Engine” lamp) to turn on if the vehicle is not

maintained properly. Restricted oil filters, fuel filters, and

crankcase deposits due to lack of oil changes or improper

oil viscosity can trigger actual vehicle faults that were not

previously monitored prior to OBD. Poor vehicle

maintenance can not be classified as a “non-vehicle

fault”, but with the sensitivity of OBD diagnostics, vehicle

maintenance schedules must be more closely followed.

Related System Faults

Many of the OBD system diagnostics will not run if the

ECM detects a fault on a related system or component.

Visual/Physical Engine Compartment

Inspection

Perform a careful visual and physical engine

compartment inspection when performing any diagnostic

procedure or diagnosing the cause of an emission test

failure. This can often lead to repairing a problem without

further steps. Use the following guidelines when

performing a visual/physical inspection:

Inspect all vacuum hoses for punches, cuts,

disconnects, and correct routing.

Inspect hoses that are difficult to see behind other

components.

Inspect all wires in the engine compartment for proper

connections, burned or chafed spots, pinched wires,

contact with sharp edges or contact with hot exhaust

manifolds or pipes.

Basic Knowledge of Tools Required

NOTE: Lack of basic knowledge of this powertrain when

performing diagnostic procedures could result in an

incorrect diagnosis or damage to powertrain

components. Do not attempt to diagnose a powertrain

problem without this basic knowledge.

A basic understanding of hand tools is necessary to effec-

tively use this section of the Service Manual.

Serial Data Communications

Class II Serial Data Communications

This vehicle utilizes the “Class II” communication system.

Each bit of information can have one of two lengths: longor short. This allows vehicle wiring to be reduced by

transmitting and receiving multiple signals over a single

wire. The messages carried on Class II data streams are

also prioritized. If two messages attempt to establish

communications on the data line at the same time, only

the message with higher priority will continue. The device

with the lower priority message must wait.

On this vehicle the Tech 2 displays the actual values for

vehicle parameters. It will not be necessary to perform

any conversions from coded values to actual values.

On-Board Diagnostic (OBD)

On-Board Diagnostic Tests

A diagnostic test is a series of steps, the result of which is

a pass or fail reported to the diagnostic executive. When

a diagnostic test reports a pass result, the diagnostic

executive records the following data:

The diagnostic test has been completed since the last

ignition cycle.

The diagnostic test has passed during the current

ignition cycle.

The fault identified by the diagnostic test is not

currently active.

When a diagnostic test reports a fail result, the diagnostic

executive records the following data:

The diagnostic test has been completed since the last

ignition cycle.

The fault identified by the diagnostic test is currently

active.

The fault has been active during this ignition cycle.

The operating conditions at the time of the failure.

Comprehensive Component Monitor

Diagnostic Operation

Comprehensive component monitoring diagnostics are

required to operate engine properly.

Input Components:

Input components are monitored for circuit continuity and

out-of-range values. This includes rationality checking.

Rationality checking refers to indicating a fault when the

signal from a sensor does not seem reasonable. Accel

Position (AP) sensor that indicates high throttle position

at low engine loads or MAP voltage. Input components

may include, but are not limited to the following sensors:

Intake Air Temperature (IAT) Sensor

Crankshaft Position (CKP) Sensor

Intake throttle Position (ITP) Sensor

Engine Coolant Temperature (ECT) Sensor

Camshaft Position (CMP) Sensor

Manifold absolute Pressure (MAP) Sensor

Accel Position Sensor

Fuel Temp Sensor

Rail Pressure Sensor

Oil Temp Sensor

EGR Pressure Sensor

Vehicle Speed Sensor

Page 5456 of 6000

6E–27 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Non-Emissions related

Dose not request illumination of any lamp

Stores a History DTC on the first trip with a fail

Stores Fail Record when test fails

Updates the Fail Record each time the diagnostic test

fails

Storing and Erasing Freeze Frame Data and Failure

Records

The data captured is called Freeze Frame data. The

Freeze Frame data is very similar to a single record of

operating conditions. Whenever the MIL is illuminated,

the corresponding record of operating conditions is

recorded to the Freeze Frame buffer.

Data from these faults take precedence over data

associated with any other fault. The Freeze Frame data

will not be erased unless the associated history DTC is

cleared.

Each time a diagnostic test reports a failure, the current

engine operating conditions are recorded in the

Failure

Records

buffer. A subsequent failure will update the

recorded operating conditions. The following operating

conditions for the diagnostic test which failed

typically

include the following parameters:

Engine Speed

Engine Load

Engine Coolant Temperature

Vehicle Speed

Intake Throttle Position

MAP

Injector Base Pulse Width

Loop Status

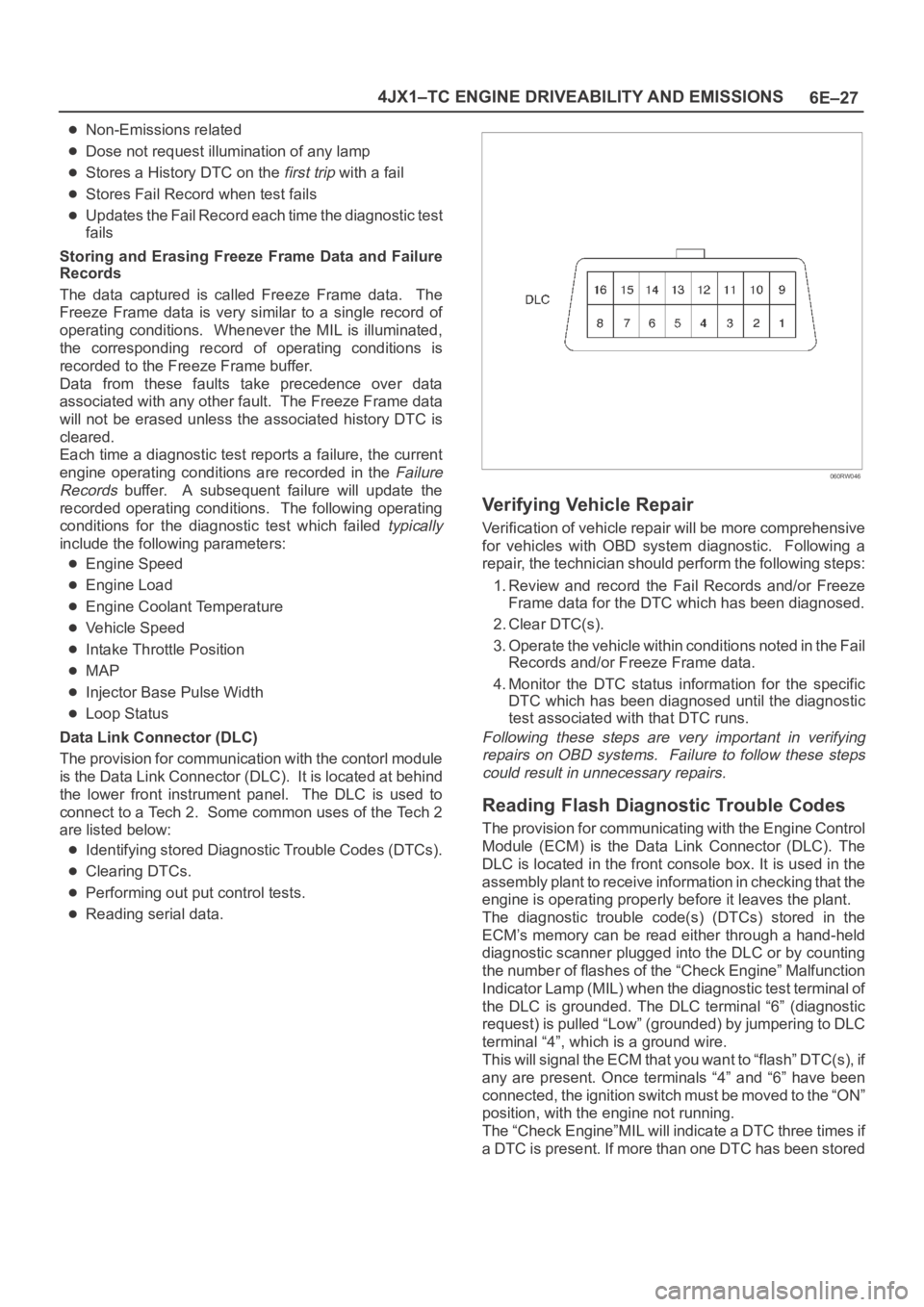

Data Link Connector (DLC)

The provision for communication with the contorl module

is the Data Link Connector (DLC). It is located at behind

the lower front instrument panel. The DLC is used to

connect to a Tech 2. Some common uses of the Tech 2

are listed below:

Identifying stored Diagnostic Trouble Codes (DTCs).

Clearing DTCs.

Performing out put control tests.

Reading serial data.

060RW046

Verifying Vehicle Repair

Verification of vehicle repair will be more comprehensive

for vehicles with OBD system diagnostic. Following a

repair, the technician should perform the following steps:

1. Review and record the Fail Records and/or Freeze

Frame data for the DTC which has been diagnosed.

2. Clear DTC(s).

3. Operate the vehicle within conditions noted in the Fail

Records and/or Freeze Frame data.

4. Monitor the DTC status information for the specific

DTC which has been diagnosed until the diagnostic

test associated with that DTC runs.

Following these steps are very important in verifying

repairs on OBD systems. Failure to follow these steps

could result in unnecessary repairs.

Reading Flash Diagnostic Trouble Codes

The provision for communicating with the Engine Control

Module (ECM) is the Data Link Connector (DLC). The

DLC is located in the front console box. It is used in the

assembly plant to receive information in checking that the

engine is operating properly before it leaves the plant.

The diagnostic trouble code(s) (DTCs) stored in the

ECM’s memory can be read either through a hand-held

diagnostic scanner plugged into the DLC or by counting

the number of flashes of the “Check Engine” Malfunction

Indicator Lamp (MIL) when the diagnostic test terminal of

the DLC is grounded. The DLC terminal “6” (diagnostic

request) is pulled “Low” (grounded) by jumpering to DLC

terminal “4”, which is a ground wire.

This will signal the ECM that you want to “flash” DTC(s), if

any are present. Once terminals “4” and “6” have been

connected, the ignition switch must be moved to the “ON”

position, with the engine not running.

The “Check Engine”MIL will indicate a DTC three times if

a DTC is present. If more than one DTC has been stored

Page 5468 of 6000

6E–39 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Engine Control Module ECM

Diagnosis

To read and clear diagnostic trouble codes, use a Tech 2.

IMPORTANT:Use of a Tech 2 is recommended to clear

diagnostic trouble codes from the ECM memory.

Diagnostic trouble codes can also be cleared by turning

the ignition “OFF” and disconnecting the battery power

from the ECM for 30 seconds. Turning off the ignition and

disconnecting the battery power from the ECM will cause

all diagnostic information in the ECM memory to be

cleared. Therefore, all the diagnostic tests will have to be

re-run.

Since the ECM can have a failure which may affect only

one circuit, following the diagnostic procedures in this

section will determine which circuit has a problem and

where it is.

If a diagnostic chart indicates that the ECM connections

or the ECM is the cause of a problem, and the ECM is

replaced, but this does not correct the problem, one of the

following may be the reason:

There is a problem with the ECM terminal

connections. The terminals may have to be removed

from the connector in order to check them properly.

The problem is intermittent. This means that the

problem is not present at the time the system is being

checked. In this case, refer to the

Symptoms portion

of the manual and make a careful physical inspection

of all components and wiring associated with the

affected system.

There is a shorted solenoid, relay coil, or harness.

Solenoids and relays are turned “ON” and “OFF” by

the ECM using internal electronic switches called

drivers. A shorted solenoid, relay coil, or harness will

not damage the ECM but will cause the solenoid or

relay to be inoperative.

Multiple ECM Information Sensor

DTCS Set

Circuit Description

The Engine Control Module ECM monitors various

sensors to determine the engine operating conditions.

The ECM controls fuel delivery, spark advance,

transmission operation, and emission control device

operation based on the sensor inputs.

The ECM provides a sensor ground to all of the sensors.

The ECM applies 5 volts through a pull-up resistor, and

determines the status of the following sensors by

monitoring the voltage present between the 5-volt supply

and the resistor:

The fuel temperature (FT) sensor

The engine coolant temperature (ECT) sensor

The Intake air temperature (IAT) sensor

The ECM provides the following sensors with a 5-volt

reference and a sensor ground signal:

The Intake throttle position sensor

The manifold absolute pressure sensor

The rail pressure sensor

The accelerator position sensor

The oil temperature sensor

The camshaft position sensor

The crankshaft position sensor

The EGR pressure sensor

The ECM monitors the signals from these sensors in

order to determine their operating status.

Diagnostic Aids

IMPORTANT:Be sure to inspect ECM and engine

grounds for being secure and clean.

A short to voltage in one of the sensor input circuits may

cause one or more of the following DTCs to be set:

P0337

P0342

P1193

P1404

P1405

P1488

IMPORTANT:If a sensor input circuit has been shorted

to voltage, ensure that the sensor is not damaged. A

damaged sensor will continue to indicate a high or low

voltage after the affected circuit has been repaired. If the

sensor has been damaged, replace it.

An open in the sensor ground circuit between the ECM

and the splice will cause one or more of the following

DTCs to be set:

P0337

P0342

P0117

A short to ground in the 5-volt reference A or B circuit will

cause one or more of the following DTCs to be set:

P0112

P0117

P0182

P0197

An open in the 5-volt reference circuit A, between the

ECM and the splice will cause one or more of the following

DTCs to be set:

P0107

P0405

P1194

P0122

An open in the 5-volt reference circuit B, between the

ECM and the splice will cause one or more of the following

DTCs to be set:

P1485

Check for the following conditions:

Poor connection at ECM. Inspect the harness

connectors for backed-out terminals, improper

mating, broken locks, improperly formed or damage

terminals, and a poor terminal-to-wire connection.

Damaged harness. Inspect the wiring harness for

damage. If the harness is not damaged, observe an

affected sensor’s displayed value on the Tech 2 with

the ignition “ON” and the engine “OFF” while you

move the connectors and the wiring harnesses

related to the following sensors:

ECT Sensor