immobilizer OPEL FRONTERA 1998 Repair Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 1356 of 6000

6E–239 ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0563 System Voltage High

Circuit Description

The powertrain control module (PCM) monitors the

system voltage on the ignition feed terminals to the PCM.

A system voltage DTC will set whenever the voltage is

above a calibrated value.

Conditions for Setting the DTC

Ignition “ON.”

System voltage is above 16 volts for 15 minutes.

Action Taken When the DTC Sets

The PCM will not illuminate the malfunction indicator

lamp (MIL).

The PCM will store as Failure Records only conditions

which were present when the DTC was set. This

information will not be stored as Freeze Frame data.

Conditions for Clearing the MIL/DTC

A history DTC P0563 will clear after 40 consecutive

warm-up cycles have occurred without a fault.

DTC P0563 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the PCM battery

feed.

Diagnostic Aids

If the DTC sets when an accessory is operated, check for

a poor connection or excessive current draw.

DTC P0563 – System Voltage High

StepActionVa l u e ( s )Ye sNo

1Was the “ON-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

2Using a Tech 2, measure the battery voltage at the

battery.

Is the battery voltage less than the specified value?

11 . 5 VGo to Step 3Go to Step 4

31. Charge the battery and clean the battery terminals.

2. Clean the battery ground cable connection if

corrosion is indicated.

Is the battery voltage less than the specified value?

11 . 5 V

Replace

battery

Go to Step 4

41. Turn “OFF” all the accessories.

2. Install a Tech 2.

3. Select the ignition voltage parameter on the Tech 2.

4. Start the engine and raise the engine RPM to the

specified value.

Is the voltage more than 2.5 volts greater than the

measurement taken in step 2 or 3?

2000 RPM

Go to

Starting/Char

ging

Go to Step 5

5Replace the PCM.

IMPORTANT:The replacement PCM must be

programmed. Refer to

UBS 98 model year Immobilizer

Workshop Manual.

Is the action complete?—Verify repair—

Page 1357 of 6000

6E–240

ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0601 PCM Memory

Circuit Description

The powertrain control module (PCM) used in this vehicle

utilizes an electrically erasable programmable read-only

memory (EEPROM). The EEPROM contains program

information and the calibrations required for engine,

transmission, and powertrain diagnostics operation.

Unlike the PROM used in past applications, the EEPROM

is not replaceable.

Conditions for Setting the DTC

The PCM detects an internal program fault (check sum

error).

Action Taken When the DTC Sets

The PCM will not illuminate the malfunction indicator

lamp (MIL).

The PCM will store conditions which were present

when the DTC was set in the Failure Records data only.

Conditions for Clearing the MIL/DTC

DTC P0601 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the PCM battery

feed.

Diagnostic Aids

DTC P0601 indicates that the contents of the

EEPROM have changed since the PCM was

programmed. The only possible repair is PCM

replacement.

DTC P0601 – PCM Memory

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

2Replace the PCM.

IMPORTANT:The replacement PCM must be

programmed. Refer to

UBS 98model year Immobilizer

Workshop Manual.

Is the action complete?—Verify repair—

Page 1361 of 6000

6E–244

ENGINE DRIVEABILITY AND EMISSIONS

DTC P1154 – HO2S Transition Time Ratio Bank 2 Sensor 1

StepNo Ye s Va l u e ( s ) Action

21Replace Bank 2 HO2S 1.

Is the action complete?

—Verify repair—

22Replace the PCM.

IMPORTANT:The replacement PCM must be

programmed. Refer to

UBS 98model year Immobilizer

Workshop Manual.

Is the action complete?—Verify repair—

Page 1365 of 6000

6E–248

ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P1380 ABS Rough Road ABS System Fault

Circuit Description

The powertrain control module (PCM) monitors ABS fault

signal. When PCM receives fault signal, PCM will set

DTC P1380.

Conditions for Setting the DTC

Vehicle speed is more than 5 mph.

Load is less than 99%.

Engine revolution is less than 6250 rpm.

PCM receives ABS fault signals from ABS unit.

Ignition on.

Misfire DTCs exist.

100 test failures within 120 test samples.

Action Taken When the DTC Sets

The PCM will store DTC 1380 only, no MIL turn on.

Conditions for Clearing the MIL/DTC

A history DTC P1380 will clear after 40 consecutive

warm-up cycles have occurred without a fault.

DTC 1380 can be cleared by using Tech-2 or

disconnecting the PCM battery feed.

Diagnostic Aids

Check for the following conditions:

PCM and ABS communication line short circuit to other

line may cause faulty signal. Inspect communication

line.

Follow ABS ECU diagnosis procedure, refer to ABS

procedure page.

DTC P1380 – ABS Rough Road ABS System Fault

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

21. Ignition “ON,” engine “OFF”, review and record

Tech 2 Failure Records Data.

2. Operate the vehicle within Failure Records

conditions as noted.

3. Using a Tech 2, monitor “Specific DTC” info for DTC

P1380 and Misfire DTCs until the DTC P1380 and

Misfire DTCs test runs. Note the result.

Does the Tech 2 indicates DTC P1380 and Misfire

DTCs failed this ignition?

—

Refer to ABS

diagnosis

After inspect

ABS, unit re-

peat

Step 2

Still problem

exists, go to

Step 3

Clear DTC by

Te c h 2

3Check short circuit among communication line of

PCM/ABS and others.

Was short circuit?

—

Repair wiring

Verify repair

Go to Step 4

4Replace the PCM.

IMPORTANT:The replacement PCM must be

programmed. Refer to

UBS 98model year Immobilizer

Workshop Manual.

Is the action complete?—Verify repair—

Page 1367 of 6000

6E–250

ENGINE DRIVEABILITY AND EMISSIONS

DTC P1404 – EGR Closed Stuck

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

21. Ignition “ON,” engine “OFF”, review and record

Tech 2 Failure Records Data.

2. Operate the vehicle within Failure Records

conditions as noted.

3. Using a Tech 2, monitor “DTC inf. for DTC P1404

until the DTC P1404 test runs. Note the result.

Does the Tech 2 indicates DTC P1404 failed this

ignition?

—Go to Step 3

Refer to

Diagnostic

Aids

31. Disconnect the EGR valve harness connector.

2. Inspect the EGR valve and connectors for damaged

pin or terminals.

Were there any damaged pins or terminals?

—Go to Step 4Go to Step 5

4Repair the damaged pin or terminal.

Is the action complete?

—Verify repair—

51. Remove EGR valve from Engine.

2. Inspect EGR valve whether there is any excessive

carbon deposit on EGR shaft.

3. Inspect any foreign material inside of EGR valve.

Was excessive carbon deposit on EGR valve shaft

or/and foreign material in EGR valve ?

—Go to Step 6Go to Step 7

61. Clean up EGR valve shaft and inside of EGR valve.

2. Remove foreign material from EGR valve.

3. Visually inspect damage of pintle and seat whether

there is bent, leakage may occur.

Was there any severe damage which affects function?

3–6 ohmsGo to Step 8

Verify repair

Go to

Step 7

71. Reconnect.

2. Ignition “OFF”.

3. Install the Tech 2.

4. Run the engine at idle.

5. On the Tech 2, select F3:Misc. Test F5:EGR.

6. Use the “UP” arrow to increase the EGR from 0% to

40%.

Did EGR work properly?

——Go to Step 8

81. Reset the learned zero EGR valve position.

2. Repeat step 7.

Did EGR work properly?

—Verify repairGo to Step 9

9Replace the EGR valve.

Replace the EGR valve. Does DTC P1404 still fail

“specific DTC” test on the Tech 2?

—Go to Step 10Verify repair

10Replace the PCM.

IMPORTANT:The replacement PCM must be

programmed. Refer to

UBS 98model year Immobilizer

Workshop Manual.

Is the action complete?—Verify repair—

Page 1370 of 6000

6E–253 ENGINE DRIVEABILITY AND EMISSIONS

DTC P1508 – IAC System Low RPM

StepNo Ye s Va l u e ( s ) Action

5Visually/physically inspect for following conditions:

Restricted air intake system. Check for a possible

collapsed air intake duct, restricted air filter

element, or foreign objects blocking the air intake

system.

T h r o t t l e b o d y. C h e c k f o r o b j e c t s b l o c k i n g t h e I A C

passage or throttle bore, excessive deposits in

the IAC passage and on the IAC pintle, and

excessive deposits in the throttle bore and on the

throttle plate.

Do any of the above require a repair?

—

Refer to

appropriate

section for

on-vehicle

service

Go to Step 6

61. Check for a poor connection at the IAC harness

connector.

2. If a problem is found, replace faulty terminals as

necessary.

Was a problem found?

—Verify repairGo to Step 7

7Replace the IAC valve.

Is the action complete?

—Verify repair—

8Replace the PCM.

IMPORTANT:The replacement PCM must be

programmed. Refer to

UBS 98model year Immobilizer

Workshop Manual.

Is the action complete?—Verify repair—

Page 1373 of 6000

6E–256

ENGINE DRIVEABILITY AND EMISSIONS

DTC P1509 – IAC System High RPM

StepNo Ye s Va l u e ( s ) Action

61. Check for a poor connection at the IAC harness

connector.

2. If a problem is found, replace faulty terminals as

necessary.

Was a problem found?

—Verify repairGo to Step 7

7Replace the IAC valve.

Is the action complete?

—Verify repair—

8Replace the PCM.

IMPORTANT:The replacement PCM must be

programmed, Refer to

UBS 98model year Immobilizer

Workshop Manual.

Is the action complete?—Verify repair—

Page 1374 of 6000

6E–257 ENGINE DRIVEABILITY AND EMISSIONS

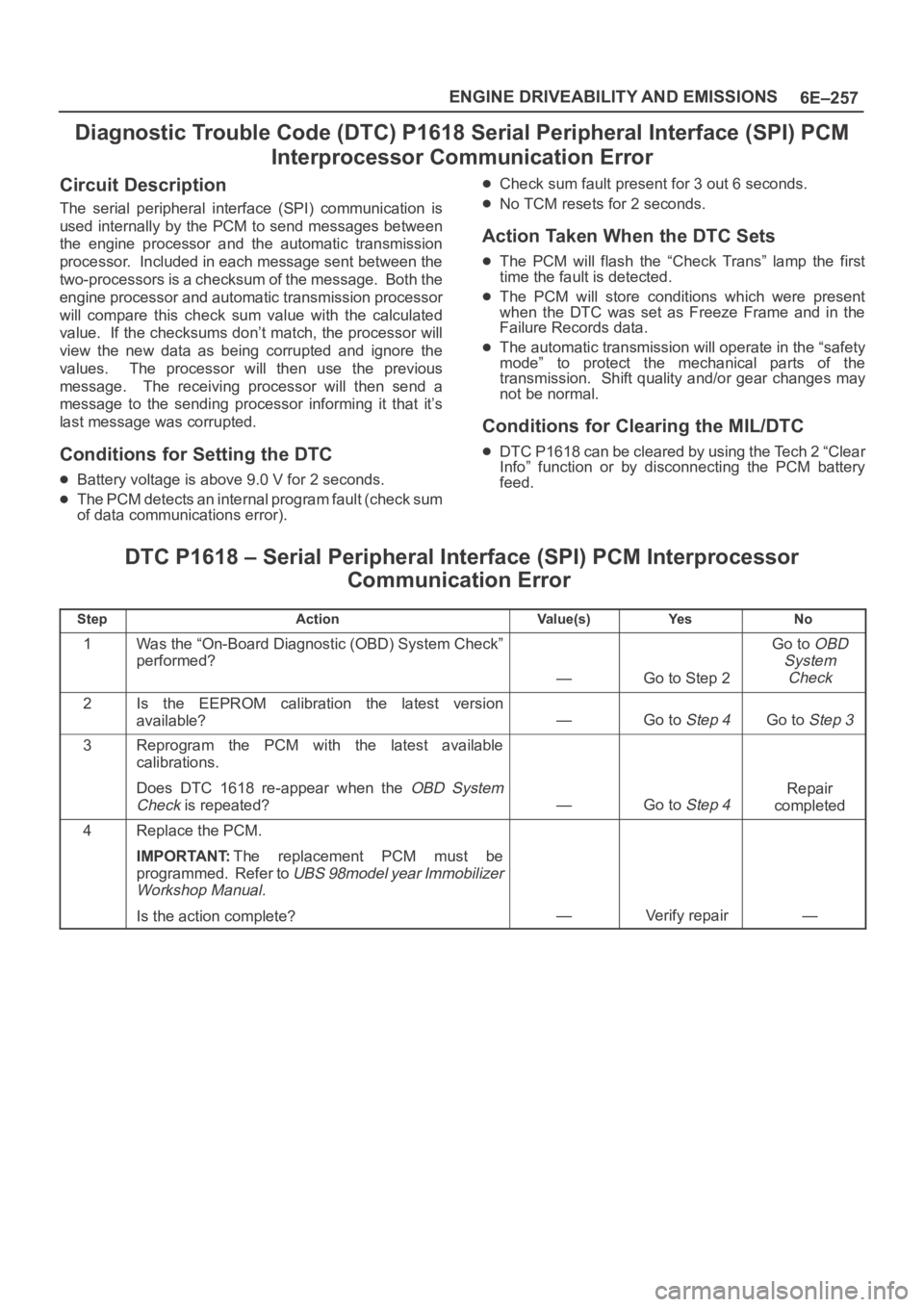

Diagnostic Trouble Code (DTC) P1618 Serial Peripheral Interface (SPI) PCM

Interprocessor Communication Error

Circuit Description

The serial peripheral interface (SPI) communication is

used internally by the PCM to send messages between

the engine processor and the automatic transmission

processor. Included in each message sent between the

two-processors is a checksum of the message. Both the

engine processor and automatic transmission processor

will compare this check sum value with the calculated

value. If the checksums don’t match, the processor will

view the new data as being corrupted and ignore the

values. The processor will then use the previous

message. The receiving processor will then send a

message to the sending processor informing it that it’s

last message was corrupted.

Conditions for Setting the DTC

Battery voltage is above 9.0 V for 2 seconds.

The PCM detects an internal program fault (check sum

of data communications error).

Check sum fault present for 3 out 6 seconds.

No TCM resets for 2 seconds.

Action Taken When the DTC Sets

The PCM will flash the “Check Trans” lamp the first

time the fault is detected.

The PCM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

The automatic transmission will operate in the “safety

mode” to protect the mechanical parts of the

transmission. Shift quality and/or gear changes may

not be normal.

Conditions for Clearing the MIL/DTC

DTC P1618 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the PCM battery

feed.

DTC P1618 – Serial Peripheral Interface (SPI) PCM Interprocessor

Communication Error

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

2Is the EEPROM calibration the latest version

available?

—Go to Step 4Go to Step 3

3Reprogram the PCM with the latest available

calibrations.

Does DTC 1618 re-appear when the

OBD System

Check

is repeated?—Go to Step 4

Repair

completed

4Replace the PCM.

IMPORTANT:The replacement PCM must be

programmed. Refer to

UBS 98model year Immobilizer

Workshop Manual.

Is the action complete?—Verify repair—

Page 1378 of 6000

6E–261 ENGINE DRIVEABILITY AND EMISSIONS

DTC P1640 – Driver-1-Input High Voltage

StepNo Ye s Va l u e ( s ) Action

13Repair the open circuit between the fuse and the PCM

driver terminal for the affected circuit.

Is the action complete?

—Verify repair—

141. Connect the PCM.

2. Start the engine and let it idle.

3. Backprobe the affected terminal at the PCM with a

DVM.

Was the voltage equal to the specified value?

+BGo to Step 16Go to Step 15

151. Run the engine at idle.

2. Check for battery voltage at the fuse for the affected

circuit.

Was battery voltage available at the fuse?

—Go to Step 11Go to Step 10

16Replace the PCM.

IMPORTANT:The replacement PCM must be

programmed. Refer to

UBS 98model year Immobilizer

Workshop Manual.

Is the action complete?—Verify repair—

Page 1417 of 6000

6E–300

ENGINE DRIVEABILITY AND EMISSIONS

4. Disconnect the red, white, and blue electrical

connectors at the PCM.

5. Remove the two screws in the front of the PCM.

6. Remove the one screw at the left rear of the PCM.

7. Pull the PCM straight out from the dashboard.

TS23757

Installation Procedure

1. Insert the PCM into the dashboard.

Line up the holes in front for the mounting screws.

2. Install the PCM with two screws in the front and one

screw at the left rear.

3. Plug the red, white, and blue connectors into the

appropriate sockets.

TS23757

EEPROM

General Description

The Electronically Erasable Programmable Read Only

Memory (EEPROM) is a permanent memory that is

physically soldered within the PCM. The EEPROM

contains program and calibration information that the

PCM needs to control powertrain operation.

EEPROM Programming

1. Step-up – Ensure that the following conditions have

been met:

The battery is fully charged.

The ignition is “ON.”

The Vehicle Interface Module cable connection at

the DLC is secure.

2. Program the PCM using the latest software matching

the vehicle. Refer to up-to-date Techline equipment

user’s instructions.

3. If the PCM fails to program, Refer to

UBS 98 model

year Immobilizer Workshop Manual.

Functional Check

1. Perform the On-Board Diagnostic System Check.

2. Start the engine and run for one minute.

3. Scan for DTCs using the Tech 2.

Power Steering Pressure (PSP)

Switch

General Description

The Power Steering Pressure (PSP) switch closes when

the hydraulic pressure reaches 3920

690 kPa (570

100 psi). This causes the PCM to actuate the idle air

control valve in order to prevent the additional load from

slowing down the engine. The switch opens when the

hydraulic pressure drops to 2970

560 kPa (430 80

psi).

Removal Procedure

1. Disconnect the PSP switch pigtail from the wiring

harness.

The pigtail is permanently attached to the switch.

Do not attempt to remove the wires from the

sensor.

Have a container ready to catch the power steering

fluid that leaks out of the line when the switch is

removed.