immobilizer OPEL FRONTERA 1998 Manual PDF

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 4735 of 6000

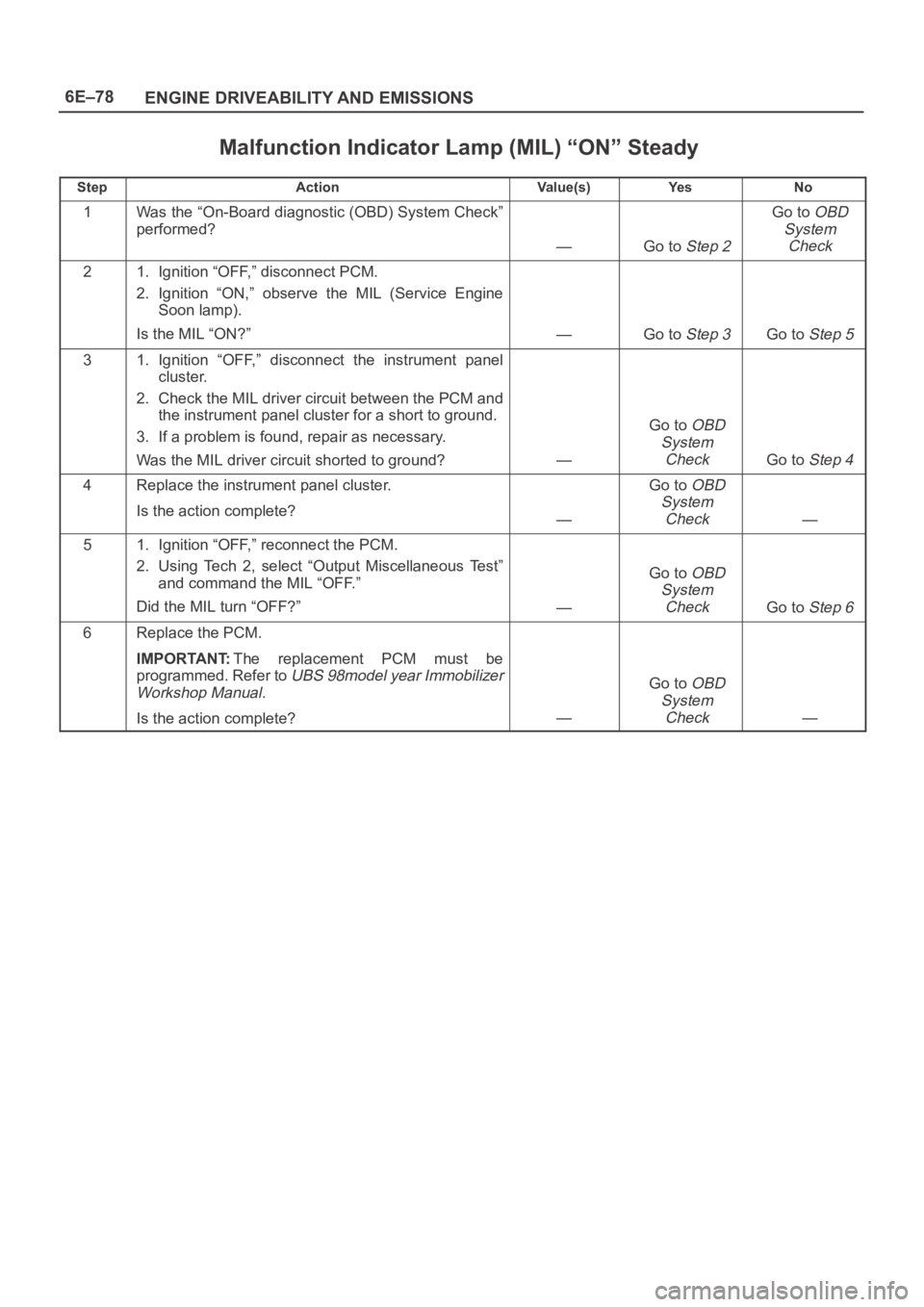

6E–78

ENGINE DRIVEABILITY AND EMISSIONS

Malfunction Indicator Lamp (MIL) “ON” Steady

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

21. Ignition “OFF,” disconnect PCM.

2. Ignition “ON,” observe the MIL (Service Engine

Soon lamp).

Is the MIL “ON?”

—Go to Step 3Go to Step 5

31. Ignition “OFF,” disconnect the instrument panel

cluster.

2. Check the MIL driver circuit between the PCM and

the instrument panel cluster for a short to ground.

3. If a problem is found, repair as necessary.

Was the MIL driver circuit shorted to ground?

—

Go to OBD

System

Check

Go to Step 4

4Replace the instrument panel cluster.

Is the action complete?

—

Go to OBD

System

Check

—

51. Ignition “OFF,” reconnect the PCM.

2. Using Tech 2, select “Output Miscellaneous Test”

and command the MIL “OFF.”

Did the MIL turn “OFF?”

—

Go to OBD

System

Check

Go to Step 6

6Replace the PCM.

IMPORTANT:The replacement PCM must be

programmed. Refer to

UBS 98model year Immobilizer

Workshop Manual.

Is the action complete?—

Go to OBD

System

Check

—

Page 4740 of 6000

6E–83 ENGINE DRIVEABILITY AND EMISSIONS

Engine Cranks But Will Not Run

StepNo Ye s Va l u e ( s ) Action

201. At the PCM (female) side of the connector, connect

a test light between the ignition + terminal and one

of the injector driver circuits at the same connector.

2. Ignition “ON.”

3. Observe the test light, and repeat the test for each

injector driver circuit.

Did the test light stay on when checking any of the 6

injector driver circuits?

—Go to Step 21Go to Step 23

211. Ignition “OFF,” disconnect the PCM.

2. Ignition “ON,” observe the test light.

Is the test light “ON?”

—Go to Step 22Go to Step 27

22Locate and repair the short to ground in the injector

driver circuit.

Is the action complete?

—Verify repair—

231. Using the same test location as in step 20, connect

a test light between the ignition terminal and one of

the driver circuits.

2. Crank the engine and observe the test light.

3. Repeat for each injector driver circuit.

Did the light blink during the test for each circuit?

—Go to Step 25Go to Step 24

24Check for an open injector driver circuit.

Was a problem found?

—Verify repairGo to Step 27

251. At the injector (male) side of the gray connector,

connect an ohmmeter between the ignition pin and

one of the driver circuit pins.

2. Check for continuity in the circuit.

3. Repeat for each injector circuit. The readings

should be approximately equal to the specified

value for injector resistance.

Was a problem found?

12.5 ohmsVerify repairGo to Step 8

26Repair the ignition feed circuit.

Is the action complete?

—Verify repair—

27Replace the PCM.

IMPORTANT:The replacement PCM must be

programmed. Refer to

UBS 98model year Immobilizer

Workshop Manual.

Is the action complete?—Verify repair—

281. Raise the vehicle and disconnect the CKP sensor

harness.

2. Ignition “ON.”

3. With a test light to ground, probe the harness

ignition feed terminal.

Did the light illuminate?

—Go to Step 30Go to Step 29

29Check the ignition feed wire between the sensor and

the PCM for a short to ground or open circuit.

Is the action complete?

—Verify repair—

Page 4744 of 6000

6E–87 ENGINE DRIVEABILITY AND EMISSIONS

Fuel System Electrical Test

StepNo Ye s Va l u e ( s ) Action

9Check for short or open between the PCM and the fuel

pump relay.

Was a problem found?

—Verify repairGo to Step 10

101. Check the fuel pump relay circuit for a poor terminal

connection at the PCM.

2. If a problem is found, replace terminal as necessary.

Was a problem found?

—Verify repairGo to Step 11

11Replace the PCM.

IMPORTANT:The replacement PCM must be

programmed. Refer to

UBS 98model year Immobilizer

Workshop Manual.

Is the action complete?—Verify repair—

121. Reconnect the fuel pump relay.

2. Disconnect the fuel pump electrical connector at the

fuel tank.

3. Using a test light connected to ground, probe the

fuel pump feed wire (harness side).

4. Command the fuel pump “ON” with Tech 2.

Did the light illuminate for 2 seconds?

—Go to Step 15Go to Step 13

131. Honk the horn to verify that the horn relay is

functioning.

2. Substitute the horn relay for the fuel pump relay.

3. Leave the test light connected as in step 12.

4. Command the fuel pump “ON” with Tech 2.

Did the test light illuminate for 2 seconds when the fuel

pump was commanded “ON?”

—Go to Step 17Go to Step 14

141. Re-connect the horn relay in its proper location.

2. Check for a short circuit, blown fuse or open circuit

between the relay and the fuel tank.

Is the action complete?

—Verify repair—

151. With the fuel pump electrical connector at the fuel

tank disconnected, connect a test light between the

feed wire and the ground wire (harness side).

2. Command the fuel pump “ON” with Tech 2.

Did the test light illuminate for 2 seconds?

—Go to Step 18Go to Step 16

16Repair the open circuit in the fuel pump ground wire.

Is the action complete?

—Verify repair—

171. Re-connect the horn relay in its proper location.

2. Replace the fuel pump relay.

Is the action complete?

—Verify repair—

18Replace the fuel pump.

Is the action complete?

—Verify repair—

Page 4753 of 6000

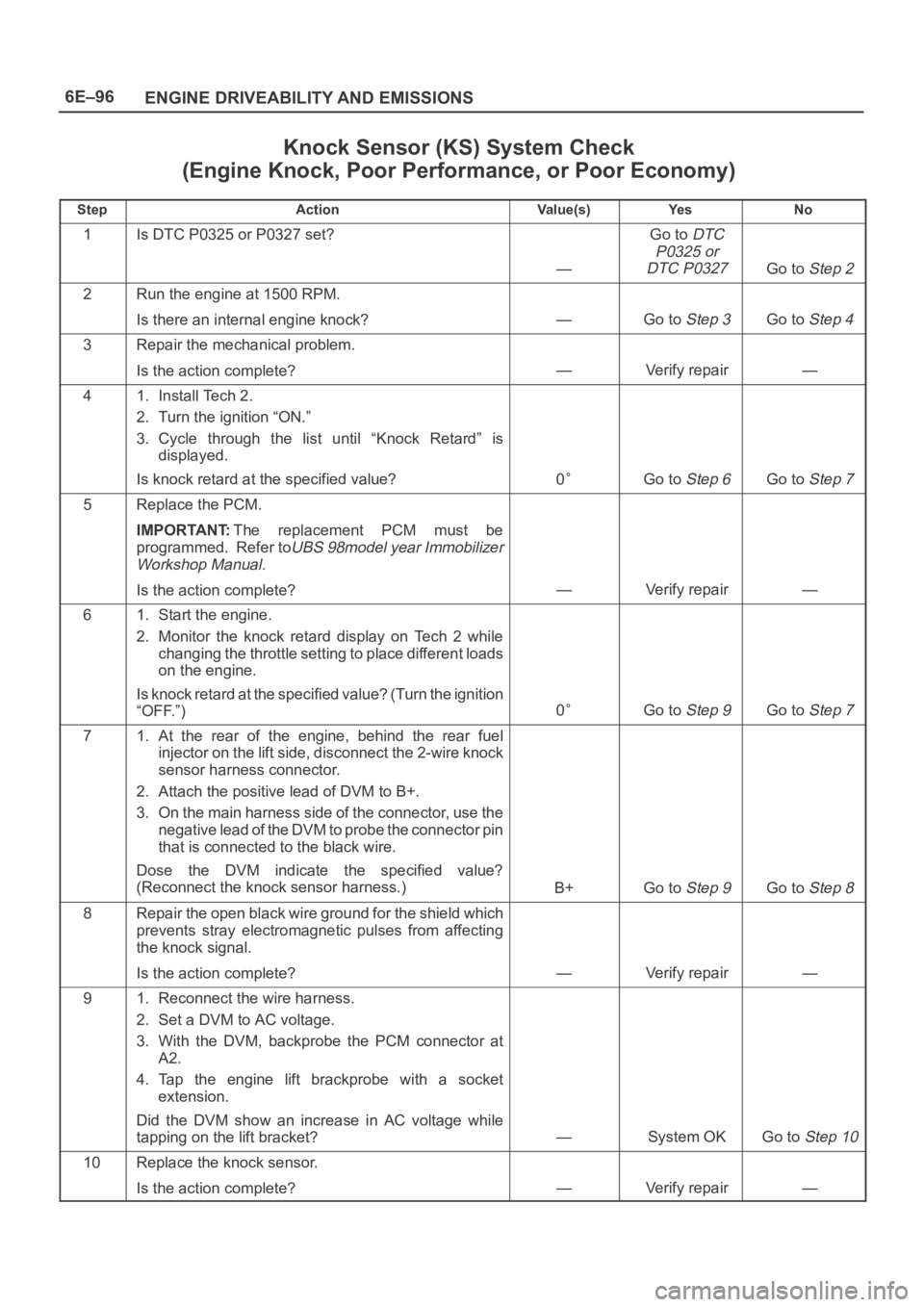

6E–96

ENGINE DRIVEABILITY AND EMISSIONS

Knock Sensor (KS) System Check

(Engine Knock, Poor Performance, or Poor Economy)

StepActionVa l u e ( s )Ye sNo

1Is DTC P0325 or P0327 set?

—

Go to DTC

P0325 or

DTC P0327

Go to Step 2

2Run the engine at 1500 RPM.

Is there an internal engine knock?

—Go to Step 3Go to Step 4

3Repair the mechanical problem.

Is the action complete?

—Verify repair—

41. Install Tech 2.

2. Turn the ignition “ON.”

3. Cycle through the list until “Knock Retard” is

displayed.

Is knock retard at the specified value?

0Go to Step 6Go to Step 7

5Replace the PCM.

IMPORTANT:The replacement PCM must be

programmed. Refer to

UBS 98model year Immobilizer

Workshop Manual.

Is the action complete?—Verify repair—

61. Start the engine.

2. Monitor the knock retard display on Tech 2 while

changing the throttle setting to place different loads

on the engine.

Is knock retard at the specified value? (Turn the ignition

“OFF.”)

0Go to Step 9Go to Step 7

71. At the rear of the engine, behind the rear fuel

injector on the lift side, disconnect the 2-wire knock

sensor harness connector.

2. Attach the positive lead of DVM to B+.

3. On the m ain harness side of the connector, use th e

negative lead of the DVM to probe the connector pin

that is connected to the black wire.

Dose the DVM indicate the specified value?

(Reconnect the knock sensor harness.)

B+Go to Step 9Go to Step 8

8Repair the open black wire ground for the shield which

prevents stray electromagnetic pulses from affecting

the knock signal.

Is the action complete?

—Verify repair—

91. Reconnect the wire harness.

2. Set a DVM to AC voltage.

3. With the DVM, backprobe the PCM connector at

A2.

4. Tap the engine lift brackprobe with a socket

extension.

Did the DVM show an increase in AC voltage while

tapping on the lift bracket?

—System OKGo to Step 10

10Replace the knock sensor.

Is the action complete?

—Verify repair—

Page 4766 of 6000

6E–109 ENGINE DRIVEABILITY AND EMISSIONS

DTC P0102 – MAF Sensor Circuit Low Frequency

StepNo Ye s Va l u e ( s ) Action

91. Ignition “OFF.”

2. Disconnect the PCM white connector.

3. Ignition “ON.”

4. Check the MAF sensor signal circuit for a short to 5

volts.

Is the action complete?

—Verify repair—

101. Ignition “OFF.”

2. Disconnect the PCM white connector.

3. Ignition “ON.”

4. Check the MAF sensor signal circuit between the

PCM and the MAF sensor for an open, short to

ground, or short to the MAF ground circuit.

Is the action complete?

—Verify repairGo to Step 13

11Locate and repair the open in the ground circuit to the

MAF sensor.

Is the action complete?

—Verify repair—

12Locate and repair the open in the ignition feed circuit to

the MAF sensor.

Is the action complete?

—Verify repair—

13Replace the MAF sensor.

Is the action complete?

—Verify repairGo to Step 14

14Replace the PCM.

IMPORTANT:The replacement PCM must be

programmed. Refer to

UBS 98model year Immobilizer

Workshop Manual.

Is the action complete?—Verify repair—

Page 4768 of 6000

6E–111 ENGINE DRIVEABILITY AND EMISSIONS

DTC P0103 – MAF Sensor Circuit High Frequency

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

21. Ignition “ON,” engine “OFF.”

2. Review and record Tech 2 Failure Records data.

3. Operate the vehicle within Failure Records

conditions as noted.

4. Using a Tech 2, monitor “DTC” info for DTC P0103.

Does the Tech 2 indicate DTC P0103 failed this

ignition?

—Go to Step 3

Refer to

Diagnostic

Aids

31. Start the engine.

2. With the engine idling, monitor “MAF Frequency”

display on the Tech 2.

Is “MAF Frequency” above the specified value?

219 g/SecGo to Step 4Go to Step 7

41. Ignition “OFF.”

2. Disconnect the MAF sensor connector.

3. Ignition “ON,” engine idling.

4. Using a Tech 2, monitor “MAF Frequency.”

Does the Tech 2 indicate a “MAF Frequency” at the

specified value?

0.0 g/SecGo to Step 5Go to Step 6

5Replace the MAF sensor.

Is the action complete?

—Verify repairGo to Step 8

61. Check the MAF harness for incorrect routing near

high voltage components (solenoids, relays,

motors).

2. If incorrect routing is found, correct the harness

routing.

Was a problem found?

—Verify repairGo to Step 7

71. With the engine idling, monitor “MAF Frequency”

display on the Tech 2.

2. Quickly snap open throttle to wide open throttle

while under a road load and record value.

Does the Tech 2 indicate “MAF Frequency” above the

specified value?

219 g/SecGo to Step 5Go to Step 8

8Replace the PCM.

IMPORTANT:The replacement PCM must be

programmed. Refer to

UBS 98model year Immobilizer

Workshop Manual.

Is the action complete?—Verify repair—

Page 4771 of 6000

6E–114

ENGINE DRIVEABILITY AND EMISSIONS

DTC P0107 – MAP Sensor Circuit Low Voltage

StepNo Ye s Va l u e ( s ) Action

9Check the MAP sensor signal circuit for a poor

connection at the PCM and the MAP sensor; replace

the terminal if necessary.

Did the terminal require replacement?

—Verify repairGo to Step 11

10Replace the MAP sensor.

Is the action complete?

—Verify repair—

11Replace the PCM.

IMPORTANT:The replacement PCM must be

programmed. Refer to

UBS 98model year Immobilizer

Workshop Manual.

Is the action complete?—Verify repair—

Page 4774 of 6000

6E–117 ENGINE DRIVEABILITY AND EMISSIONS

DTC P0108 – MAP Sensor Circuit High Voltage

StepNo Ye s Va l u e ( s ) Action

11Replace the PCM.

IMPORTANT:The replacement PCM must be

programmed. Refer to

UBS 98model year Immobilizer

Workshop Manual.

Is the action complete?—Verify Repair—

12Replace the MAP sensor.

Is the action complete?

—Verify repair—

Page 4777 of 6000

6E–120

ENGINE DRIVEABILITY AND EMISSIONS

DTC P0112–IAT Sensor Circuit Low Voltage

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

21. Ignition “ON,” engine “OFF.”

2. Using a Tech 2, monitor the intake air temperature

(IAT).

Is the intake air temperature greater than the specified

value?

148C

(283

F)Go to Step 4Go to Step 3

31. Ignition “ON,” engine “OFF.” Review and record

Tech 2 Failure Records data.

2. Operate the vehicle within Failure Records

conditions as noted.

3. Using a Tech 2, monitor the “Specific DTC” info for

DTC P0112.

Does the Tech 2 indicate DTC P0112 failed this

ignition?

—

Refer to Te s t

Description

Refer to

Diagnostic

Aids

41. Ignition “OFF.”

2. Disconnect the IAT sensor electrical connector.

3. Ignition “ON.”

4. Observe the intake air temperature on the Tech 2.

Is the intake air temperature below the specified value?

–38C

(–36

F)Go to Step 6Go to Step 5

51. Ignition “OFF.”

2. Disconnect the PCM electrical connectors.

3. Check the IAT sensor signal circuit for a short to

ground.

Is the IAT sensor signal circuit shorted to ground?

—Verify repairGo to Step 7

6Replace the IAT sensor.

Is the action complete?

—Verify repair—

7Replace the PCM.

IMPORTANT:The replacement PCM must be

programmed. Refer to

UBS 98model year Immobilizer

Workshop Manual.

Is the action complete?—Verify repair—

Page 4780 of 6000

6E–123 ENGINE DRIVEABILITY AND EMISSIONS

DTC P0113 –IAT Sensor Circuit High Voltage

StepNo Ye s Va l u e ( s ) Action

6Check for poor connections at the IAT sensor and

replace terminals if necessary.

Did any terminals require replacement?

—Verify repairGo to Step 10

71. Ignition “OFF.”

2. Disconnect the PCM, and check the IAT sensor

ground circuit for an open.

3. If the IAT sensor ground circuit is open, repair it as

necessary.

Was the IAT sensor ground circuit open?

—Verify repairGo to Step 9

81. Ignition “OFF.”

2. Disconnect the PCM, and check the IAT signal

circuit for an open.

3. If the IAT sensor signal circuit is open, repair it as

necessary.

Was the IAT signal circuit open?

—Verify repairGo to Step 9

9Check for a poor sensor ground or IAT signal circuit

terminal connection at the PCM and replace

terminal(s) if necessary.

Did any of the terminals need to be replaced?

—Verify repairGo to Step 11

10Replace the IAT sensor.

Is the action complete?

—Verify repair—

11Replace the PCM.

IMPORTANT:The replacement PCM must be

programmed. Refer to

UBS 98model year Immobilizer

Workshop Manual.

Is the action complete?—Verify repair—