immobilizer OPEL FRONTERA 1998 Repair Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 1456 of 6000

6E–339 ENGINE DRIVEABILITY AND EMISSIONS

0005

PCM Components

The PCM is designed to maintain exhaust emission levels

to government mandated standards while providing

excellent driveability and fuel efficiency. The PCM

monitors numerous engine and vehicle functions via

electronic sensors such as the throttle position (TP)

sensor, heated oxygen sensor (HO2S), and vehicle

speed sensor (VSS). The PCM also controls certain

engine operations through the following:

Fuel injector control

Ignition control module

Knock sensor

Automatic transmission shift functions

Cruise control

A/C clutch control

PCM Voltage Description

The PCM supplies a buffered voltage to various switches

and sensors. It can do this because resistance in the

PCM is so high in value that a test light may not illuminate

when connected to the circuit. An ordinary shop

voltmeter may not give an accurate reading because the

voltmeter input impedance is too low. Use a 10-megohm

input impedance digital voltmeter (such as J 39200) to

assure accurate voltage readings.

The input/output devices in the PCM include

analog-to-digital converters, signal buffers, counters,

and special drivers. The PCM controls most components

with electronic switches which complete a ground circuit

when turned “ON.” These switches are arranged in

groups of 4 and 7, called either a surface-mounted quad

driver module (QDM), which can independently control up

to 4 output terminals, or QDMs which can independently

control up to 7 outputs. Not all outputs are always used.

PCM Input/Outputs

Inputs – Operating Conditions Read

Air Conditioning “ON” or “OFF”

Engine Coolant Temperature

Crankshaft Position

Exhaust Oxygen Content

Electronic Ignition

Manifold Absolute Pressure

Battery Voltage

Throttle Position

Vehicle Speed

Fuel Pump Voltage

Power Steering Pressure

Intake Air Temperature

Mass Air Flow

Engine Knock

Camshaft Position

Outputs – Systems Controlled

Exhaust Gas Recirculation (EGR)

Ignition Control

Fuel Control

Idle Air Control

Electric Fuel Pump

Air Conditioning

Diagnostics

– Malfunction Indicator Lamp (Service Engine Soon

lamp)

– Data Link Connector (DLC)

– Data Output

Transmission Control Module

Alternator Gain Control

PCM Service Precautions

The PCM is designed to withstand normal current draws

associated with vehicle operation. Avoid overloading any

circuit. When testing for opens and shorts, do not ground

or apply voltage to any of the PCM’s circuits unless

instructed to do so. These circuits should only be tested

Tech-2. The PCM should remain connected to the PCM

or to a recommended breakout box.

Reprogramming The PCM

The Trooper allow reprogramming of the PCM without

removing it from the vehicle . This provides a flexible and

cost-effective method of making changes in software

calibrations.

The service programming system (SPS) will not allow

incorrect software programming or incorrect calibration

changes.

Refer to the UBS 98model year Immobilizer Workshop

Manual.

Throttle Position (TP) Sensor

The throttle position (TP) sensor is a potentiometer

connected to the throttle shaft on the throttle body. The

PCM monitors the voltage on the signal line and

calculates throttle position. As the throttle valve angle is

changed (accelerator pedal moved), the TP sensor signal

also changes. At a closed throttle position, the output of

Page 1873 of 6000

6D – 6 ENGINE ELECTRICAL

RELATION BETWEEN STARTER SWITCH AND STARTER

M

Key

PositionB1 B2 ACCIG1 IG2 ST

LOCKKey

Removed

Inserted OFF

ACC

ON

START

BSBattery

+-

2

17

3

4

5

6

Legend

(1) Starter Switch

(2) To Generator

(3) To QOS4 Control(4) Starter Relay

(5) Immobilizer Relay (for Europe)

(6) Magnetic Switch

(7) Battery

065R200029

Page 1948 of 6000

6E–55 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

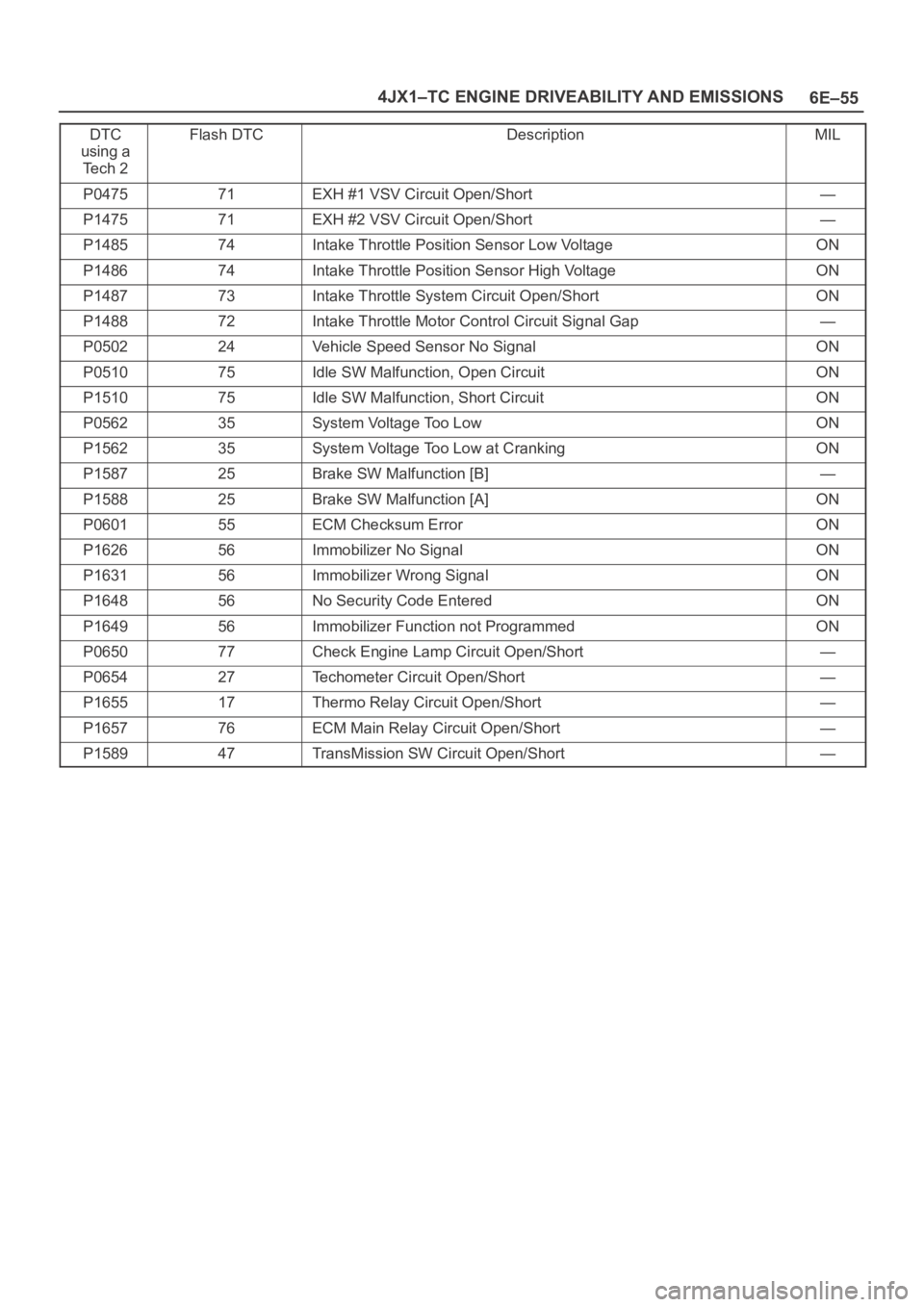

DTC

using a

Te c h 2Flash DTCDescriptionMIL

P047571EXH #1 VSV Circuit Open/Short—

P147571EXH #2 VSV Circuit Open/Short—

P148574Intake Throttle Position Sensor Low VoltageON

P148674Intake Throttle Position Sensor High VoltageON

P148773Intake Throttle System Circuit Open/ShortON

P148872Intake Throttle Motor Control Circuit Signal Gap—

P050224Vehicle Speed Sensor No SignalON

P051075Idle SW Malfunction, Open CircuitON

P151075Idle SW Malfunction, Short CircuitON

P056235System Voltage Too LowON

P156235System Voltage Too Low at CrankingON

P158725Brake SW Malfunction [B]—

P158825Brake SW Malfunction [A]ON

P060155ECM Checksum ErrorON

P162656Immobilizer No SignalON

P163156Immobilizer Wrong SignalON

P164856No Security Code EnteredON

P164956Immobilizer Function not ProgrammedON

P065077Check Engine Lamp Circuit Open/Short—

P065427Techometer Circuit Open/Short—

P165517Thermo Relay Circuit Open/Short—

P165776ECM Main Relay Circuit Open/Short—

P158947TransMission SW Circuit Open/Short—

Page 2662 of 6000

B-22B-36

22

H-1512

17 B-22

B-19 1.25

B2.0

B 0.5

B

ANTI-THEFT & KEYLESS

ENTRY CONTROL UNITHEATER &

A/C RELAY

STARTER

(W/O ANTI-THEFT)IMMOBILIZER

CONTROL UNIT

(10)

0.85

B0.5

L/B0.5

G/Y 0.5

L 0.5

L

0.5

L/B

BODY-RH

B-2

BODY-LHB-18

BODY-RHB-19

BODY-RH

B-36

B-36

3.0

L/R5.0

W

0.3

B 0.85

W/R

3.0

B/W 30.0

B/R

C-19 25A

BLOWER

BLOWER

MOTORPRESSURE SW

(A/C)C-20 10A

AIR CON B-3612

1

34

BATT.(+) FUSE

C-8

1.25

B3.0

W

P-4

P-3

X-20IMMOBILIZER

RELAYX-20

X-20 X-2021

43

0.5

B/Y

D08RW586

Page 3572 of 6000

PA G E B A C K

THIS MALUAL INCLUDES THE FOLLOWING SECTIONS:

SECTION No. CONTRNTS

Sec.- IMMOBILIZER SYSTEM

HOME

-

Page 4709 of 6000

6E–52

ENGINE DRIVEABILITY AND EMISSIONS

10.This vehicle is equipped with a PCM which utilizes

an electrically erasable programmable read only

memory (EEPROM). When the PCM is replaced,

the new PCM must be programmed.

Refer to UBS

98 model year Immobilizer Workshop Manual.

Page 4714 of 6000

6E–57 ENGINE DRIVEABILITY AND EMISSIONS

A/C Clutch Control Circuit Diagnosis

StepNo Ye s Va l u e ( s ) Action

19Replace the A/C switch.

Is the action complete?

—Verify repair—

20Use an ohmmeter to check continuity between the

electronic A/C thermostat and the blower switch.

Was there an open circuit?

—Go to Step 21Go to Step 22

21Repair the open wire (GRN/YEL) between the

thermostat and the blower switch.

Is the action complete?

—Verify repair—

22Replace the electronic A/C thermostat.

Is the an action complete?

—Verify repair—

23Check for an open circuit between A/C thermostat relay

and PCM A/C request terminal (E-15).

Was there an open circuit?

—Go to Step 24Go to Step 25

24Repair the open circuit between the PCM and A/C

thermostat relay.

Is the action complete?

—Verify repair—

25Check for an open circuit between the A/C switch (LT

GRN) and the A/C thermostat relay (LT GRN).

Was there an open circuit?

—Go to Step 26Go to Step 27

26Repair the open circuit between the A/C switch and the

A/C thermostat relay.

Is the action complete?

—Verify repair—

271. Ignition “ON.”

2. Use a DVM to check voltage at the A/C pressure

switch (BRN).

Was voltage equal to the specified value?

+BGo to Step 29Go to Step 28

28Repair the open circuit between the 10A A/C fuse and

the pressure switch.

Is the action complete?

—Verify repair—

29Use an ohmmeter to check continuity between the

pressure switch (GRN/WHT) and the A/C thermostat

relay (GRN/WHT).

Was the circuit open?

—Go to Step 30Go to Step 31

30Repair the open circuit between the pressure switch

and the A/C thermostat relay.

Is the action complete?

—Verify repair—

31Check for damaged pin or terminal at E-15 of the PCM.

Was a damaged pin or terminal found?

—Go to Step 32Go to Step 33

32Repair the damaged pin or terminal.

Is the action complete?

—Verify repair—

33Replace the PCM.

IMPORTANT:The replacement PCM must be

programmed. Refer to

UBS 98model year Immobilizer

Workshop Manual.

Is the action complete?—Verify repair—

Page 4724 of 6000

6E–67 ENGINE DRIVEABILITY AND EMISSIONS

Multiple PCM Information Sensor DTCs Set

StepNo Ye s Va l u e ( s ) Action

111. Disconnect the EGR valve.

2. Measure the voltage between the EGR pintle

position sensor signal circuit at the PCM harness

connector and ground.

Does the voltage measure near the specified value?

0 VGo to Step 13Go to Step 18

12Measure the voltage between the TFT sensor signal

circuit at the PCM harness connector and ground.

Does the voltage measure near the specified value?

0 VGo to Step 20Go to Step 19

13Replace the EGR valve.

Is the action complete?

—Verify repair—

14Locate and repair the short to voltage in the MAP

sensor signal circuit.

Is the action complete?

—Verify repair—

15Locate and repair the short to voltage in the TP sensor

signal circuit.

Is the action complete?

—Verify repair—

16Locate and repair the short to voltage in the IAT sensor

signal circuit.

Is the action complete?

—Verify repair—

17Locate and repair the short to voltage in the ECT

sensor signal circuit.

Is the action complete?

—Verify repair—

18Locate and repair the short to voltage in the EGR pintle

position sensor signal circuit.

Is the action complete?

—Verify repair—

19Locate and repair the short to voltage in the TFT sensor

signal circuit.

Is the action complete?

—Verify repair—

20Replace the PCM.

IMPORTANT:The replacement PCM must be

programmed. Refer to

UBS 98model year Immobilizer

Workshop Manual.

Is the action complete?—

Go to OBD

System

Check

—

Page 4732 of 6000

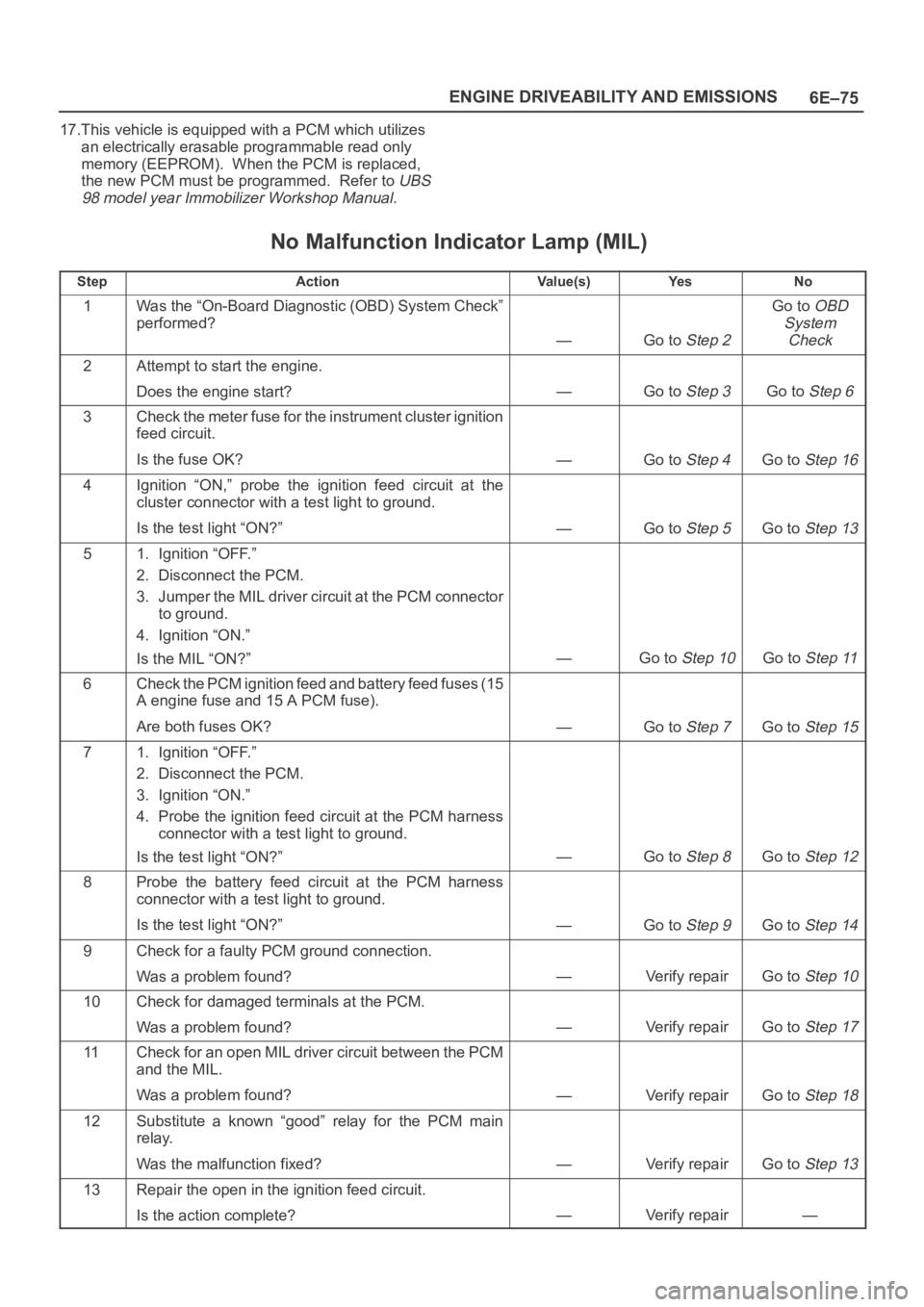

6E–75 ENGINE DRIVEABILITY AND EMISSIONS

17.This vehicle is equipped with a PCM which utilizes

an electrically erasable programmable read only

memory (EEPROM). When the PCM is replaced,

the new PCM must be programmed. Refer to

UBS

98 model year Immobilizer Workshop Manual.

No Malfunction Indicator Lamp (MIL)

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

2Attempt to start the engine.

Does the engine start?

—Go to Step 3Go to Step 6

3Check the meter fuse for the instrument cluster ignition

feed circuit.

Is the fuse OK?

—Go to Step 4Go to Step 16

4Ignition “ON,” probe the ignition feed circuit at the

cluster connector with a test light to ground.

Is the test light “ON?”

—Go to Step 5Go to Step 13

51. Ignition “OFF.”

2. Disconnect the PCM.

3. Jumper the MIL driver circuit at the PCM connector

to ground.

4. Ignition “ON.”

Is the MIL “ON?”

—Go to Step 10Go to Step 11

6Check the PCM ignition feed and battery feed fuses (15

A engine fuse and 15 A PCM fuse).

Are both fuses OK?

—Go to Step 7Go to Step 15

71. Ignition “OFF.”

2. Disconnect the PCM.

3. Ignition “ON.”

4. Probe the ignition feed circuit at the PCM harness

connector with a test light to ground.

Is the test light “ON?”

—Go to Step 8Go to Step 12

8Probe the battery feed circuit at the PCM harness

connector with a test light to ground.

Is the test light “ON?”

—Go to Step 9Go to Step 14

9Check for a faulty PCM ground connection.

Was a problem found?

—Verify repairGo to Step 10

10Check for damaged terminals at the PCM.

Was a problem found?

—Verify repairGo to Step 17

11Check for an open MIL driver circuit between the PCM

and the MIL.

Was a problem found?

—Verify repairGo to Step 18

12Substitute a known “good” relay for the PCM main

relay.

Was the malfunction fixed?

—Verify repairGo to Step 13

13Repair the open in the ignition feed circuit.

Is the action complete?

—Verify repair—

Page 4734 of 6000

6E–77 ENGINE DRIVEABILITY AND EMISSIONS

Malfunction Indicator Lamp (MIL) “ON” Steady

D06RW00007

Circuit description

The malfunction indicator lamp (MIL) should always be

illuminated and steady with ignition “ON” and the engine

stopped. Ignition feed voltage is supplied directly to the

MIL indicator. The powertrain control module (PCM)

turns the MIL “ON” by grounding the MIL driver circuit.

The MIL should not remain “ON” with the engine running

and no DTC(s) set. A steady MIL with the engine running

and no DTC(s) suggests a short to ground in the MIL

driver circuit.

Diagnostic Aids

An intermittent may be caused by a poor connection,

rubbed-through wire insulation, or a wire broken inside

the insulation. Check for the following items:

Poor connection or damaged harness – Inspect the

PCM harness and connectors for improper mating,

broken locks, improperly formed or damaged

terminals, poor terminal-to-wire connection, and

damaged harness.

Test Description

Number(s) below refer to the step number(s) on the

Diagnostic Chart.

2. If the MIL does not remain “ON” when the PCM is

disconnected, the MIL driver wiring is not faulty.

3. If the MIL driver circuit is OK, the instrument panel

cluster is faulty.

6. This vehicle is equipped with a PCM which utilizes

an electrically erasable programmable read only

memory (EEPROM). When the PCM is replaced,

the new PCM must be programmed. Refer to

UBS

98 model year Immobilizer Workshop Manual.