air filter OPEL FRONTERA 1998 Repair Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 2173 of 6000

7A–19 AUTOMATIC TRANSMISSION (4L30–E)

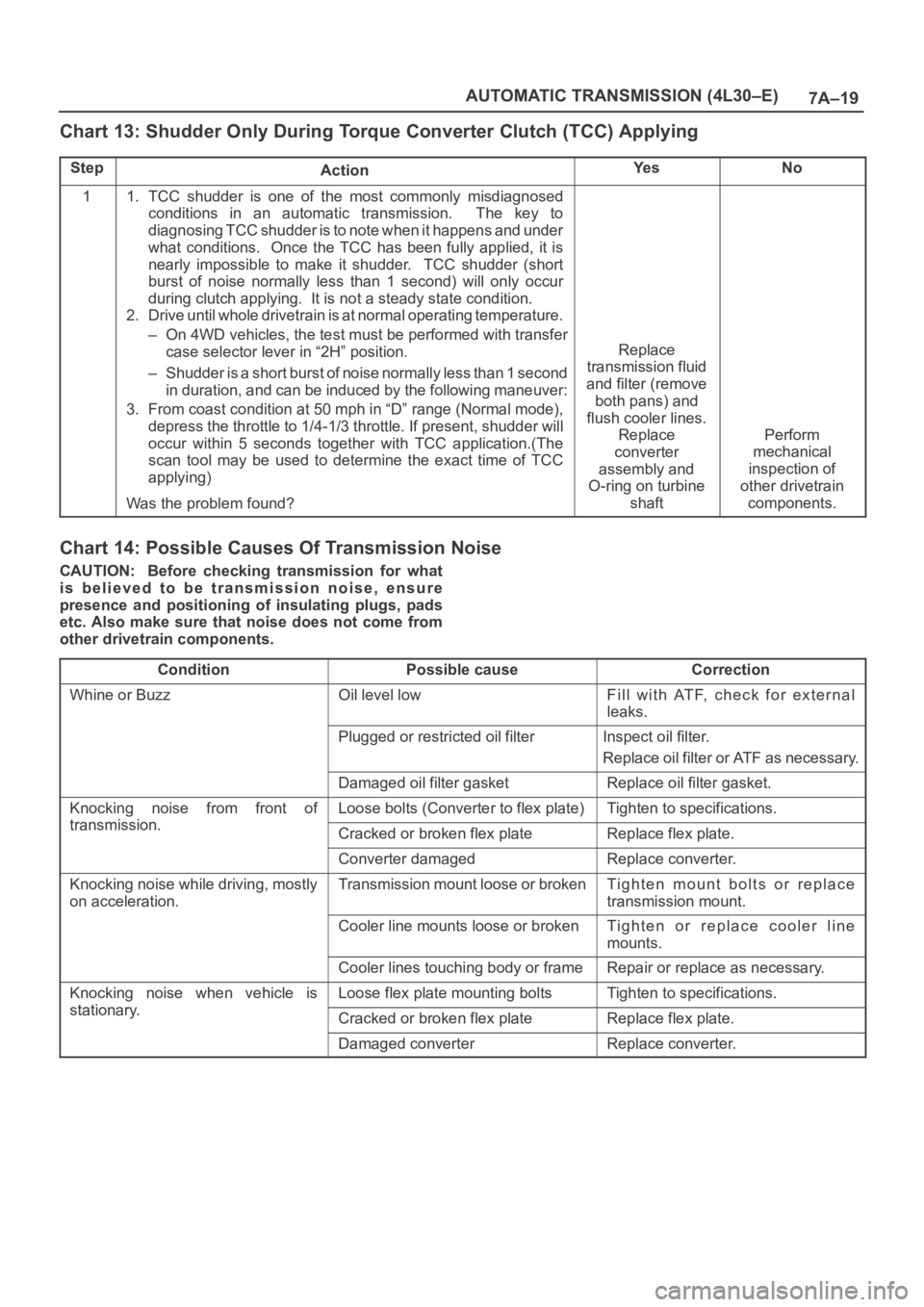

Chart 13: Shudder Only During Torque Converter Clutch (TCC) Applying

StepActionYe sNo

11. TCC shudder is one of the most commonly misdiagnosed

conditions in an automatic transmission. The key to

diagnosing TCC shudder is to note when it happens and under

what conditions. Once the TCC has been fully applied, it is

nearly impossible to make it shudder. TCC shudder (short

burst of noise normally less than 1 second) will only occur

during clutch applying. It is not a steady state condition.

2. Drive until whole drivetrain is at normal operating temperature.

– On 4WD vehicles, the test must be performed with transfer

case selector lever in “2H” position.

– Shudder is a short burst of noise normally less than 1 second

in duration, and can be induced by the following maneuver:

3. From coast condition at 50 mph in “D” range (Normal mode),

depress the throttle to 1/4-1/3 throttle. If present, shudder will

occur within 5 seconds together with TCC application.(The

scan tool may be used to determine the exact time of TCC

applying)

Was the problem found?

Replace

transmission fluid

and filter (remove

both pans) and

flush cooler lines.

Replace

converter

assembly and

O-ring on turbine

shaft

Perform

mechanical

inspection of

other drivetrain

components.

Chart 14: Possible Causes Of Transmission Noise

CAUTION: Before checking transmission for what

is believed to be transmission noise, ensure

presence and positioning of insulating plugs, pads

etc. Also make sure that noise does not come from

other drivetrain components.

Condition

Possible causeCorrection

Whine or BuzzOil level lowFill with ATF, check for external

leaks.

Plugged or restricted oil filterInspect oil filter.

Replace oil filter or ATF as necessary.

Damaged oil filter gasketReplace oil filter gasket.

Knocking noise from front of

transmission

Loose bolts (Converter to flex plate)Tighten to specifications.

transmission.Cracked or broken flex plateReplace flex plate.

Converter damagedReplace converter.

Knocking noise while driving, mostly

on acceleration.Transmission mount loose or brokenTighten mount bolts or replace

transmission mount.

Cooler line mounts loose or brokenTighten or replace cooler line

mounts.

Cooler lines touching body or frameRepair or replace as necessary.

Knocking noise when vehicle is

stationary

Loose flex plate mounting boltsTighten to specifications.

stationary.Cracked or broken flex plateReplace flex plate.

Damaged converterReplace converter.

Page 4049 of 6000

4B1–4

DRIVE LINE CONTROL SYSTEM (SHIFT ON THE FLY)

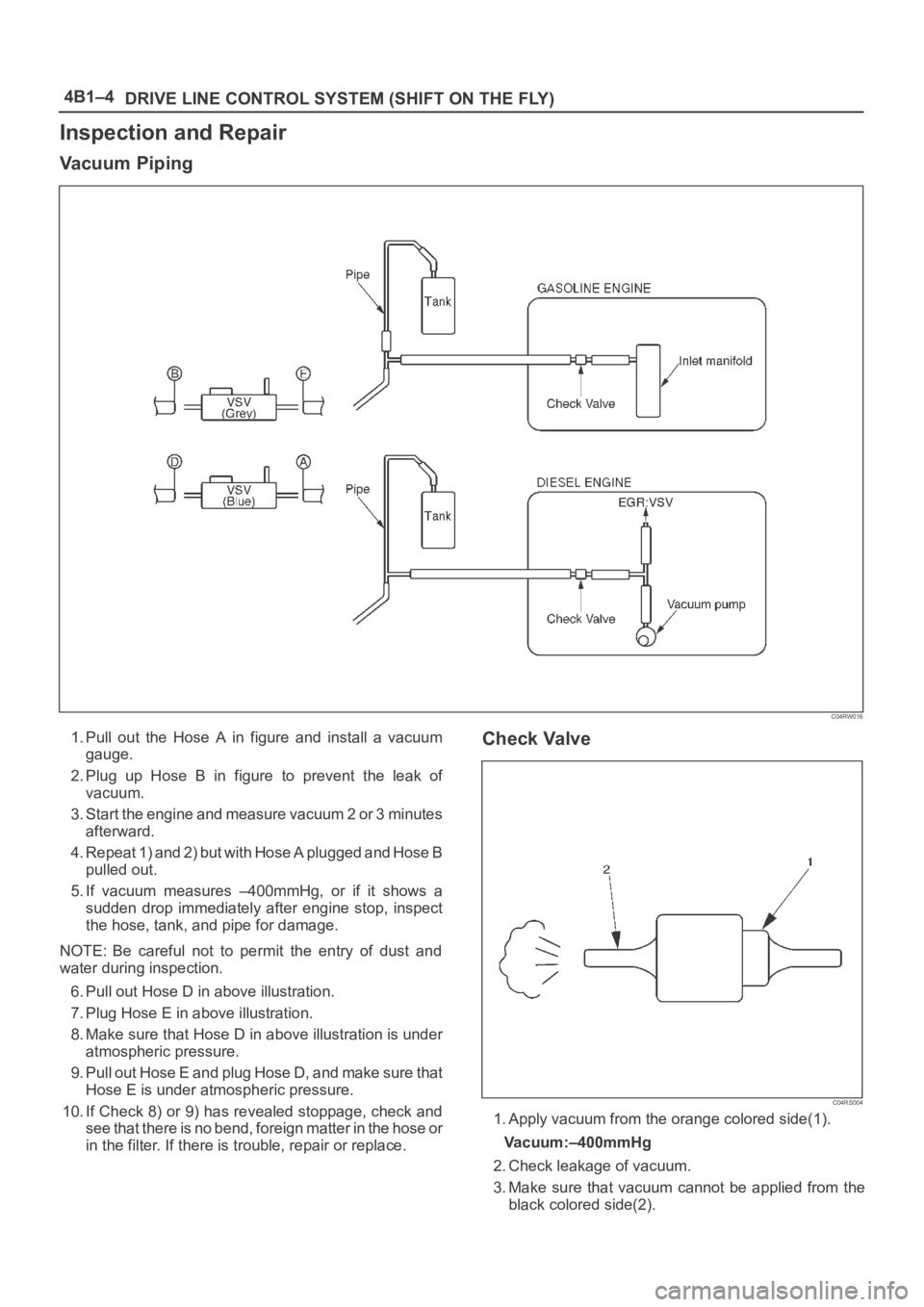

Inspection and Repair

Va c u u m P i p i n g

C04RW016

1. Pull out the Hose A in figure and install a vacuum

gauge.

2. Plug up Hose B in figure to prevent the leak of

vacuum.

3. Start the engine and measure vacuum 2 or 3 minutes

afterward.

4. Repeat 1) and 2) but with Hose A plugged and Hose B

pulled out.

5. If vacuum measures –400mmHg, or if it shows a

sudden drop immediately after engine stop, inspect

the hose, tank, and pipe for damage.

NOTE: Be careful not to permit the entry of dust and

water during inspection.

6. Pull out Hose D in above illustration.

7. Plug Hose E in above illustration.

8. Make sure that Hose D in above illustration is under

atmospheric pressure.

9. Pull out Hose E and plug Hose D, and make sure that

Hose E is under atmospheric pressure.

10. If Check 8) or 9) has revealed stoppage, check and

see that there is no bend, foreign matter in the hose or

in the filter. If there is trouble, repair or replace.Check Valve

C04RS004

1. Apply vacuum from the orange colored side(1).

Vacuum:–400mmHg

2. Check leakage of vacuum.

3. Make sure that vacuum cannot be applied from the

black colored side(2).

Page 4078 of 6000

4B1–33 DRIVE LINE CONTROL SYSTEM (SHIFT ON THE FLY)

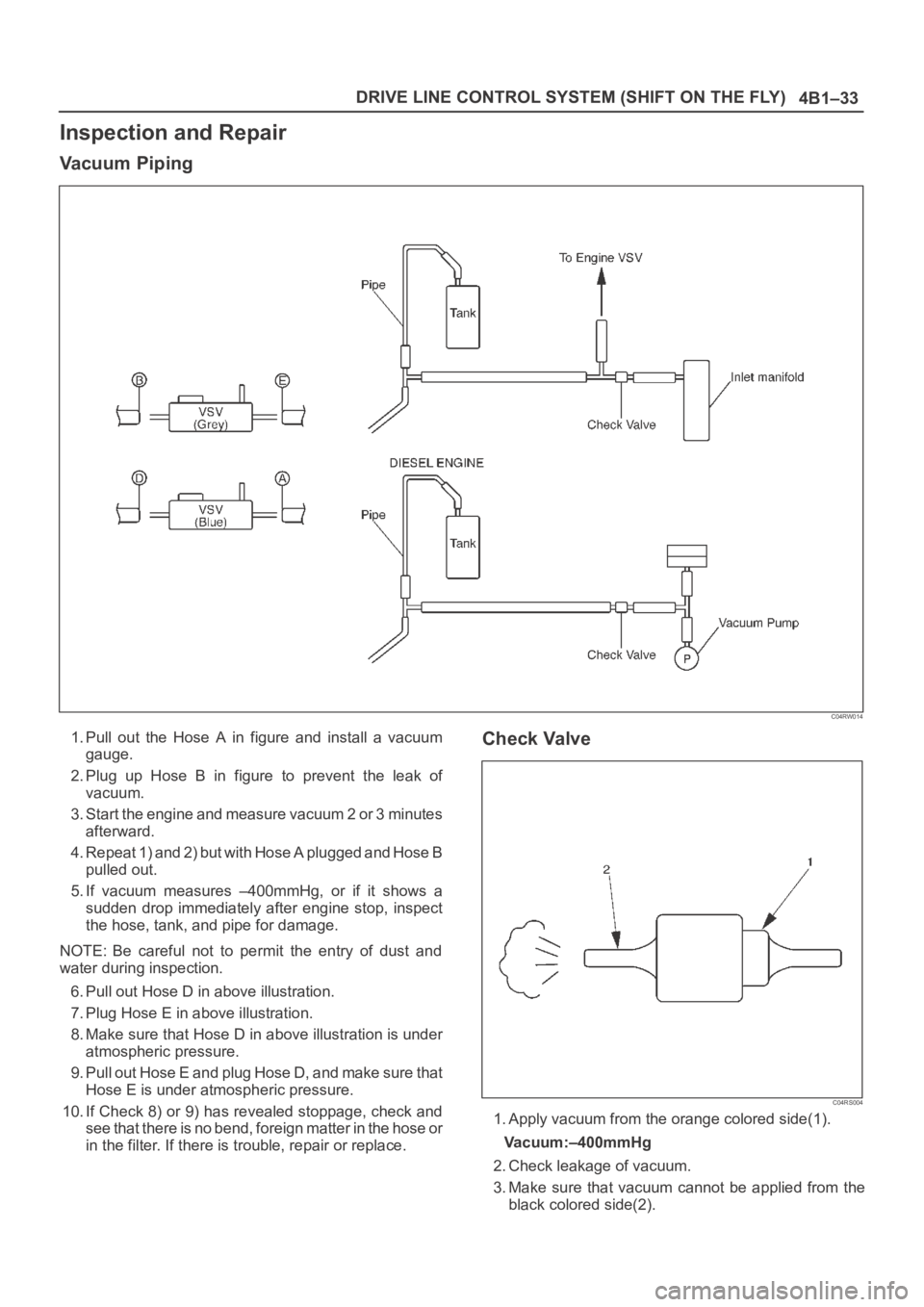

Inspection and Repair

Va c u u m P i p i n g

C04RW014

1. Pull out the Hose A in figure and install a vacuum

gauge.

2. Plug up Hose B in figure to prevent the leak of

vacuum.

3. Start the engine and measure vacuum 2 or 3 minutes

afterward.

4. Repeat 1) and 2) but with Hose A plugged and Hose B

pulled out.

5. If vacuum measures –400mmHg, or if it shows a

sudden drop immediately after engine stop, inspect

the hose, tank, and pipe for damage.

NOTE: Be careful not to permit the entry of dust and

water during inspection.

6. Pull out Hose D in above illustration.

7. Plug Hose E in above illustration.

8. Make sure that Hose D in above illustration is under

atmospheric pressure.

9. Pull out Hose E and plug Hose D, and make sure that

Hose E is under atmospheric pressure.

10. If Check 8) or 9) has revealed stoppage, check and

see that there is no bend, foreign matter in the hose or

in the filter. If there is trouble, repair or replace.Check Valve

C04RS004

1. Apply vacuum from the orange colored side(1).

Vacuum:–400mmHg

2. Check leakage of vacuum.

3. Make sure that vacuum cannot be applied from the

black colored side(2).

Page 4499 of 6000

6A–3

ENGINE MECHANICAL

General Description

Engine Cleanliness And Care

An automobile engine is a combination of many

machined, honed, polished and lapped surfaces with

tolerances that are measured in the thousandths of a

millimeter (ten thousandths of an inch). Accordingly,

when any internal engine parts are serviced, care and

cleanliness are important. Throughout this section, it

should be understood that proper cleaning and protection

of machined surfaces and friction areas is part of the

repair procedure. This is considered standard shop

practice even if not specifically stated.

A liberal coating of engine oil should be applied to all

friction areas during assembly to protect and lubricate

the surfaces on initial operation.

Whenever valve train components, pistons, piston

rings, connecting rods, rod bearings, and crankshaft

journal bearings are removed for service, they should

be retained in order.

At the time of installation, they should be installed in

the same locations and with the same mating

surfaces as when removed.

Battery cables should be disconnected before any

major work is performed on the engine. Failure to

disconnect cables may result in damage to wire

harness or other electrical parts.

The six cylinders of this engine are identified by

numbers; Right side cylinders 1, 3 and 5, Left side

cylinders 2, 4 and 6, as counted from crankshaft

pulley side to flywheel side.

General Information on Engine Service

The following information on engine service should be

noted carefully, as it is important in preventing damage

and contributing to reliable engine performance:

When raising or supporting the engine for any reason,

do not use a jack under the oil pan. Due to the small

clearance between the oil pan and the oil pump

strainer, jacking against the oil pan may cause

damage to the oil pick–up unit.

The 12–volt electrical system is capable of damaging

circuits. When performing any work where electrical

terminals could possibly be grounded, the ground

cable of the battery should be disconnected at the

battery.

Any time the intake air duct or air cleaner is removed,

the intake opening should be covered. This will

protect against accidental entrance of foreign

material into the cylinder which could cause extensive

damage when the engine is started.

Cylinder Block

The cylinder block is made of aluminum die–cast casting

for 75

V–type six cylinders. It has a rear plate integrated

structure and employs a deep skint. The cylinder liner is

cast and the liner inner diameter and crankshaft journal

diameter are classified into grades. The crankshaft is

supported by four bearings of which width of No.3 bearing

on the body side is different in order to support the thrust

bearing. The bearing cap is made of nodular cast iron and

each bearing cap uses four bolts and two side bolts.

Cylinder Head

The cylinder head, made of aluminum alloy casting

employs a pent–roof type combustion chamber with a

spark plug in the center. The intake and exhaust valves

are placed in V–type design. The ports are cross–flow

type.

Va l v e Tr a i n

Intake and exhaust camshaft on the both side of banks

are driven through an camshaft drive gear by timing belt.

The valves are operated by the camshaft and the valve

clearance is adjusted to select suitable thickness shim.

Intake Manifold

The intake manifold system is composed of the aluminum

cast common chamber and intake manifold attached with

six fuel injectors.

Exhaust Manifold

The exhaust manifold is made of nodular cast iron.

Pistons and Connecting Rods

Aluminum pistons are used after selecting the grade that

meets the cylinder bore diameter. Each piston has two

compression rings and one oil ring. The piston pin is made

of chromium steel is offset 1mm toward the thrust side,

and the thrust pressure of piston to the cylinder wall varies

gradually as the piston travels. The connecting rods are

made of forged steel. The connecting rod bearings are

graded for correct seze selection.

Crankshaft and Bearings

The crankshaft is made of Ductile cast–iron. Pins and

journals are graded for correct size selection for their

bearing.

Engine Lubrication

The oil discharged by a trochoid–type oil pump driven by

the crankshaft is fed through full–flow oil filter and to the oil

gallery provided under the crankshaft bearing cap. The oil

is then led to the crankshaft journals and cylinder head.

The crank pins are lubricated with oil from crankshaft

journals through oil holes. Also, an oil jet is fed to each

cylinder from crankshaft juornals on the connecting rod

for piston cleaning. The oil pan flange is dealed with liquid

packing only; do not deform or damage the flange surface

during removal or installation.

Page 4503 of 6000

6A–7

ENGINE MECHANICAL

Condition CorrectionPossible cause

OthersEngine lacks compressionRefer to “Hard Start”

Valve incorrectly seatedLap valve

Air Cleaner Filter cloggedReplace filter element

Valve timing incorrectReadjust

Idle air control valve brokenReplace

Fast idle solenoid defectiveReplace

Positive Crankcase Ventilation valve

defective or cloggedReplace

Rough Engine Running

ConditionPossible causeCorrection

Engine misfires periodicallyIgnition coil layer shortedReplace

Spark plugs foulingClean or install hotter type plug

Spark plug(s) insulator nose leakingReplace

Fuel injector(s) defectiveReplace

Powertrain control module faultyReplace

Engine knocks periodicallySpark plugs running too hotInstall colder type spark plugs

Powertrain control module faultyReplace

Engine lacks powerSpark plugs fouledClean

Fuel injectors defectiveReplace

Mass Airflow Sensor or Intake

Airflow Sensor circuit defectiveCorrect or replace

Manifold Absolute Pressure (MAP)

Sensor or Manifold Absolute

Pressure Sensor circuit defectiveCorrect or replace

Engine Coolant Temperature Sensor

or Engine Coolant Temperature

Sensor circuit defectiveCorrect or replace

Powertrain Control Module faultyReplace

Intake Air Temperature Sensor or

Intake Air Temperature Sensor

circuit defectiveCorrect or replace

Throttle Position Sensor or Throttle

Position Sensor circuit defectiveCorrect or replace

Knock Sensor or Knock Sensor

circuits defectiveCorrect or replace

Knock Sensor Module or Knock

Sensor Module circuits defectiveCorrect or replace

Page 4504 of 6000

6A–8

ENGINE MECHANICAL

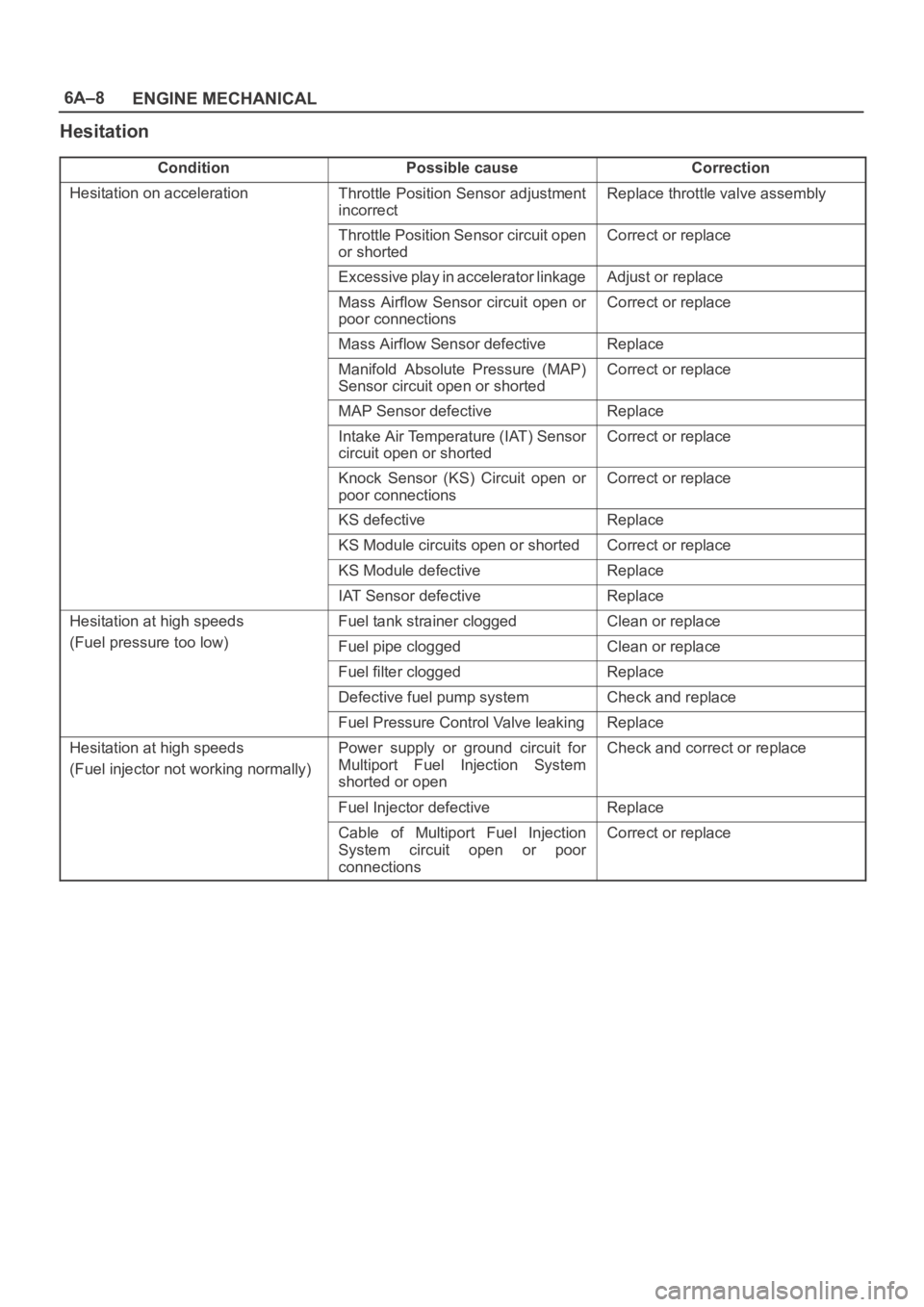

Hesitation

ConditionPossible causeCorrection

Hesitation on accelerationThrottle Position Sensor adjustment

incorrectReplace throttle valve assembly

Throttle Position Sensor circuit open

or shortedCorrect or replace

Excessive play in accelerator linkageAdjust or replace

Mass Airflow Sensor circuit open or

poor connectionsCorrect or replace

Mass Airflow Sensor defectiveReplace

Manifold Absolute Pressure (MAP)

Sensor circuit open or shortedCorrect or replace

MAP Sensor defectiveReplace

Intake Air Temperature (IAT) Sensor

circuit open or shortedCorrect or replace

Knock Sensor (KS) Circuit open or

poor connectionsCorrect or replace

KS defectiveReplace

KS Module circuits open or shortedCorrect or replace

KS Module defectiveReplace

IAT Sensor defectiveReplace

Hesitation at high speedsFuel tank strainer cloggedClean or replace

(Fuel pressure too low)Fuel pipe cloggedClean or replace

Fuel filter cloggedReplace

Defective fuel pump systemCheck and replace

Fuel Pressure Control Valve leakingReplace

Hesitation at high speeds

(Fuel injector not working normally)Power supply or ground circuit for

Multiport Fuel Injection System

shorted or openCheck and correct or replace

Fuel Injector defectiveReplace

Cable of Multiport Fuel Injection

System circuit open or poor

connectionsCorrect or replace

Page 4505 of 6000

6A–9

ENGINE MECHANICAL

Condition CorrectionPossible cause

Hesitation at high speedsPowertrain Control Module defectiveReplace

Throttle Position Sensor cable

broken or poor connectionsCorrect or replace

Throttle Position Sensor defectiveReplace

Engine Coolant Temperature Sensor

circuit open or shortedCorrect or replace

Engine Coolant Temperature Sensor

defectiveReplace

Mass Airflow Sensor circuit open or

poor connectionsCorrect or replace

Mass Airflow Sensor defectiveReplace

MAP Sensor cable broken or poor

connectionsCorrect or replace

MAP Sensor defectiveReplace

IAT Sensor circuit open or poor

connectionsCorrect or replace

IAT Sensor defectiveReplace

KS circuit open or poor connectionsCorrect or replace

KS defectiveReplace

KS Module circuit open or shortedCorrect or replace

KS Module defectiveReplace

Throttle valve not fully openedCheck and correct or replace

Air Cleaner Filter cloggedReplace filter element

Power supply voltage too lowCheck and correct or replace

Page 4506 of 6000

6A–10

ENGINE MECHANICAL

Engine Lacks Power

ConditionPossible causeCorrection

Trouble in fuel systemFuel Pressure Control Valve not

working normallyReplace

Fuel injector cloggedClean or replace

Fuel pipe cloggedClean

Fuel filter clogged or fouledReplace

Fuel pump drive circuit not working

normallyCorrect or replace

Fuel tank not sufficiently breathing

due to clogged Evaporative

Emission Control System circuitClean or replace

Water in fuel systemClean

Inferior quality fuel in fuel systemUse fuel of specified octane rating

Powertrain Control Module supplied

poor voltageCorrect circuit

Throttle Position Sensor cable

broken or poor connectionsCorrect or replace

Throttle Position Sensor defectiveReplace

Mass Airflow Sensor not working

normallyReplace

Manifold Absolute Pressure Sensor

not working normallyReplace

Intake Air Temperature Sensor not

working normallyReplace

Engine Coolant Temperature Sensor

circuit open or shortedCorrect or replace

Engine Coolant Temperature Sensor

defectiveReplace

Powertrain Control Module defectiveReplace

Trouble in intake or exhaust systemAir Cleaner Filter cloggedReplace filter element

Air duct kinked or flattenedCorrect or replace

Ignition failure————Refer to Hard Start Troubleshooting

Guide

Heat range of spark plug inadequateInstall spark plugs of adequate heat

range

Ignition coil defectiveReplace

Page 4509 of 6000

6A–13

ENGINE MECHANICAL

Condition CorrectionPossible cause

Engine knockingPreignition due to use of spark plugs

of inadequate heat rangeInstall Spark Plugs of adequate heat

range

Carbon deposits in combustion

chambersClean

Fuel too low in octane ratingReplace fuel

Wide Open Throttle enrichment

system failureRefer to Section 6E

Selection of transmission gear

incorrectCaution operator of incorrect gear

selection

Engine overheatingRefer to “Engine Lacks Power”

OthersWater pump defectiveReplace

Drive belt slippingReplace auto tentioner or drive belt

Abnormal Combustion

ConditionPossible causeCorrection

Trouble in fuel systemFuel pressure control valve defectiveReplace

Fuel filter cloggedReplace

Fuel pump cloggedClean or replace

Fuel tank or fuel pipe cloggedClean or replace

Fuel injector cloggedClean or replace

Fuel pump relay defectiveReplace

Power supply cable for fuel pump

broken or poor connectionsReconnect, correct or replace

Mass Airflow (MAF) sensor circuit

open or defectiveCorrect or replace

MAF Sensor defectiveReplace

Manifold Absolute Pressure Sensor

circuit open or shortedCorrect or replace

Manifold Absolute Pressure Sensor

defectiveReplace

Engine Coolant Temperature (ECT)

Sensor circuit open or shortedCorrect or replace

ECT Sensor defectiveReplace

Throttle Position Sensor adjustment

incorrectReadjust

Throttle Position Sensor defectiveReplace

Throttle Position Sensor connector

poor connectionsReconnect

Vehicle Speed Sensor cable poor

connections or defectiveCorrect or replace

Vehicle Speed Sensor loosely fixedFix tightly

Vehicle Speed Sensor in wrong

contact or defectiveReplace

Powertrain Control Module cable

poor connections or defectiveCorrect or replace

Page 4608 of 6000

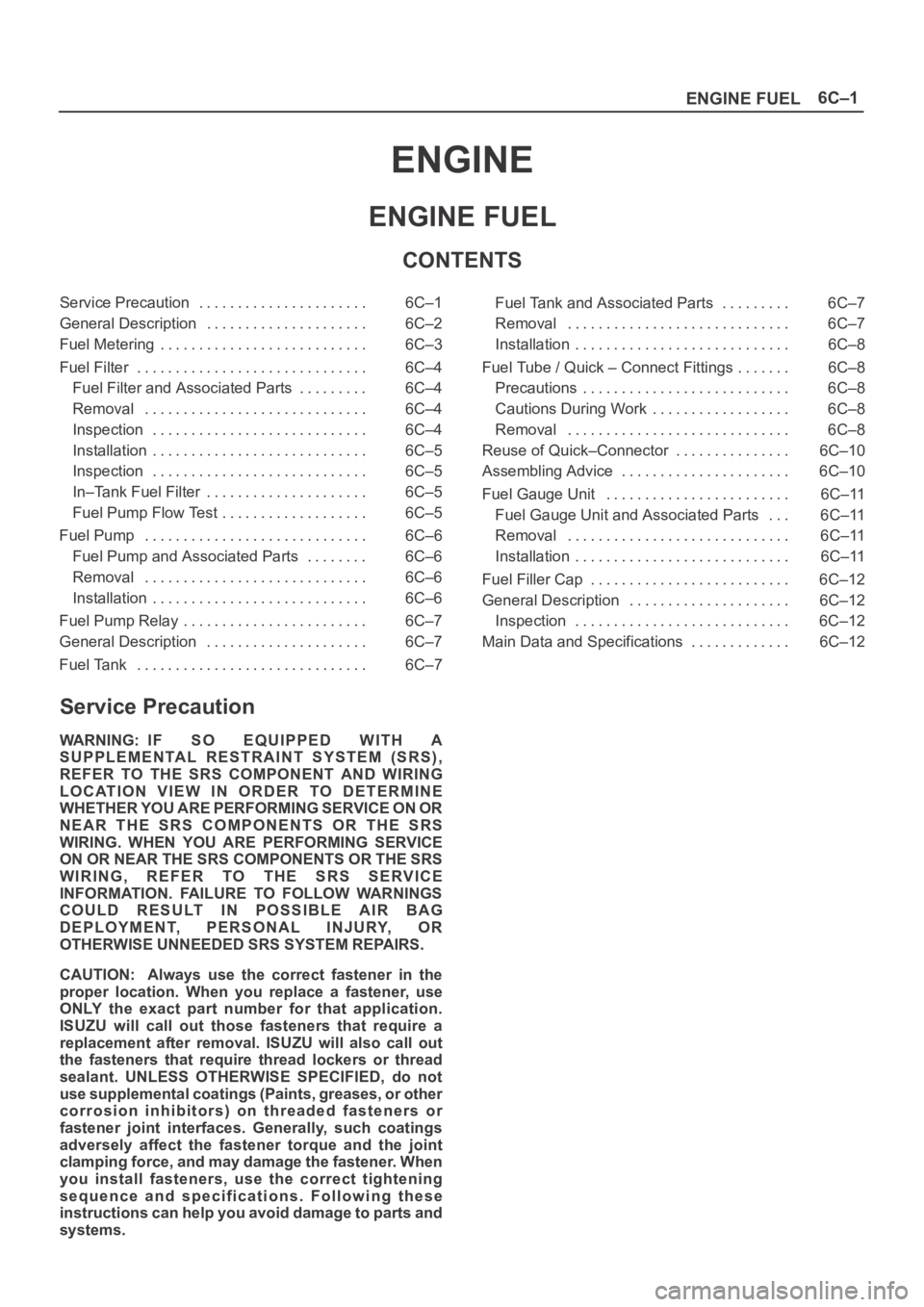

6C–1

ENGINE FUEL

ENGINE

ENGINE FUEL

CONTENTS

Service Precaution 6C–1. . . . . . . . . . . . . . . . . . . . . .

General Description 6C–2. . . . . . . . . . . . . . . . . . . . .

Fuel Metering 6C–3. . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Filter 6C–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Filter and Associated Parts 6C–4. . . . . . . . .

Removal 6C–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection 6C–4. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6C–5. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection 6C–5. . . . . . . . . . . . . . . . . . . . . . . . . . . .

In–Tank Fuel Filter 6C–5. . . . . . . . . . . . . . . . . . . . .

Fuel Pump Flow Test 6C–5. . . . . . . . . . . . . . . . . . .

Fuel Pump 6C–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Pump and Associated Parts 6C–6. . . . . . . .

Removal 6C–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6C–6. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Pump Relay 6C–7. . . . . . . . . . . . . . . . . . . . . . . .

General Description 6C–7. . . . . . . . . . . . . . . . . . . . .

Fuel Tank 6C–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fuel Tank and Associated Parts 6C–7. . . . . . . . .

Removal 6C–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6C–8. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Tube / Quick – Connect Fittings 6C–8. . . . . . .

Precautions 6C–8. . . . . . . . . . . . . . . . . . . . . . . . . . .

Cautions During Work 6C–8. . . . . . . . . . . . . . . . . .

Removal 6C–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reuse of Quick–Connector 6C–10. . . . . . . . . . . . . . .

Assembling Advice 6C–10. . . . . . . . . . . . . . . . . . . . . .

Fuel Gauge Unit 6C–11. . . . . . . . . . . . . . . . . . . . . . . .

Fuel Gauge Unit and Associated Parts 6C–11. . .

Removal 6C–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6C–11. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Filler Cap 6C–12. . . . . . . . . . . . . . . . . . . . . . . . . .

General Description 6C–12. . . . . . . . . . . . . . . . . . . . .

Inspection 6C–12. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Main Data and Specifications 6C–12. . . . . . . . . . . . .

Service Precaution

WARNING: IF SO EQUIPPED WITH A

SUPPLEMENTAL RESTRAINT SYSTEM (SRS),

REFER TO THE SRS COMPONENT AND WIRING

LOCATION VIEW IN ORDER TO DETERMINE

WHETHER YOU ARE PERFORMING SERVICE ON OR

NEAR THE SRS COMPONENTS OR THE SRS

WIRING. WHEN YOU ARE PERFORMING SERVICE

ON OR NEAR THE SRS COMPONENTS OR THE SRS

WIRING, REFER TO THE SRS SERVICE

INFORMATION. FAILURE TO FOLLOW WARNINGS

COULD RESULT IN POSSIBLE AIR BAG

DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU will call out those fasteners that require a

replacement after removal. ISUZU will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED, do not

use supplemental coatings (Paints, greases, or other

corrosion inhibitors) on threaded fasteners or

fastener joint interfaces. Generally, such coatings

adversely affect the fastener torque and the joint

clamping force, and may damage the fastener. When

you install fasteners, use the correct tightening

sequence and specifications. Following these

instructions can help you avoid damage to parts and

systems.