coolant temperature OPEL FRONTERA 1998 Repair Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 1460 of 6000

6E–343 ENGINE DRIVEABILITY AND EMISSIONS

constant measuring and adjusting of the air/fuel ratio, the

fuel injection system is called a “closed loop” system.

The PCM monitors signals from several sensors in order

to determine the fuel needs of the engine. Fuel is

delivered under one of several conditions called “modes.”

All modes are controlled by the PCM.

Fuel Pressure Regulator

The fuel pressure regulator is a diaphragm-operated

relief valve mounted on the fuel rail with fuel pump

pressure on one side and manifold pressure on the other

side. The fuel pressure regulator maintains the fuel

pressure available to the injector at three times

barometric pressure adjusted for engine load. It may be

serviced separate.

If the pressure is too low, poor performance and a DTC

P0131, DTC P0151,DTC P0171 or DTC P1171 will be the

result. If the pressure is too high, excessive odor and/or a

DTC P0132, DTC P0152,DTC P0172 or DTC P0175 will

be the result. Refer to

Fuel System Diagnosis for

information on diagnosing fuel pressure conditions.

0011

Fuel Pump Electrical Circuit

When the key is first turned “ON,” the PCM energizes the

fuel pump relay for two seconds to build up the fuel

pressure quickly. If the engine is not started within two

seconds, the PCM shuts the fuel pump off and waits until

the engine is cranked. When the engine is cranked and

the 58 X crankshaft position signal has been detected by

the PCM, the PCM supplies 12 volts to the fuel pump relay

to energize the electric in-tank fuel pump.

An inoperative fuel pump will cause a “no-start” condition.

A fuel pump which does not provide enough pressure will

result in poor performance.

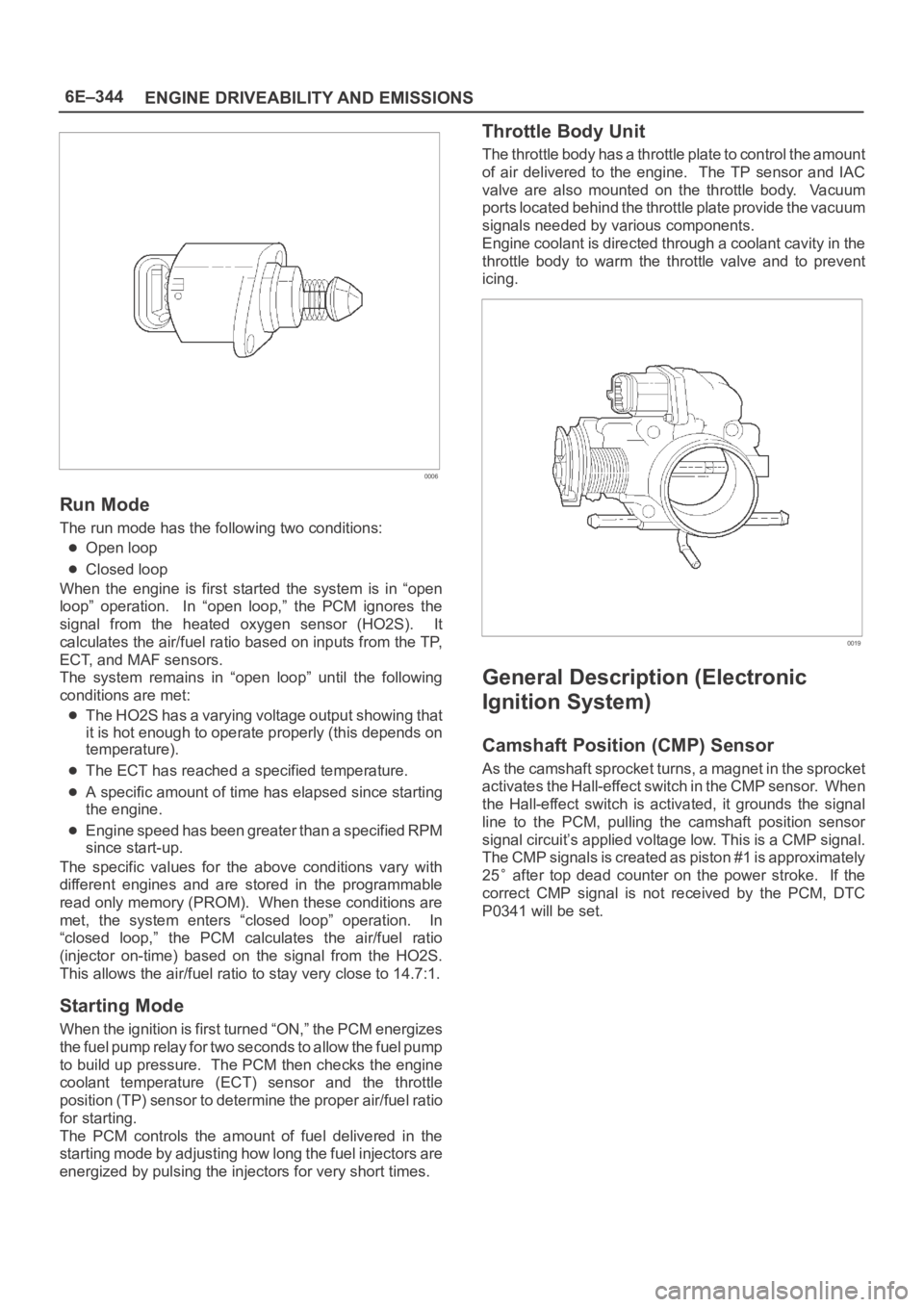

Fuel Rail

The fuel rail is mounted to the top of the engine and

distributes fuel to the individual injectors. Fuel is

delivered to the fuel inlet tube of the fuel rail by the fuel

lines. The fuel goes through the fuel rail to the fuel

pressure regulator. The fuel pressure regulator maintainsa constant fuel pressure at the injectors. Remaining fuel

is then returned to the fuel tank.

055RW009

Idle Air Control (IAC) Valve

The purpose of the idle air control (IAC) valve is to control

engine idle speed, while preventing stalls due to changes

in engine load. The IAC valve, mounted in the throttle

body, controls bypass air around the throttle plate. By

moving the conical valve (pintle) in (to decrease air flow)

or out (to increase air flow), a controlled amount of air can

move around the throttle plate. If the RPM is too low, the

PCM will retract the IAC pintle, resulting in more air

moving past the throttle plate to increase the RPM. If the

RPM is too high, the PCM will extend the IAC pintle,

allowing less air to move past the throttle plate,

decreasing the RPM.

The IAC pintle valve moves in small steps called counts.

During idle, the proper position of the IAC pintle is

calculated by the PCM based on battery voltage, coolant

temperature, engine load, and engine RPM. If the RPM

drops below a specified value, and the throttle plate is

closed, the PCM senses a near-stall condition. The PCM

will then calculate a new IAC pintle valve position to

prevent stalls.

If the IAC valve is disconnected and reconnected with the

engine running, the idle RPM will be wrong. In this case,

the IAC must be reset. The IAC resets when the key is

cycled “ON” then “OFF.” When servicing the IAC, it

should only be disconnected or connected with the

ignition “OFF.”

The position of the IAC pintle valve affects engine start-up

and the idle characteristics of the vehicle. If the IAC pintle

is fully open, too much air will be allowed into the manifold.

This results in high idle speed, along with possible hard

starting and a lean air/fuel ratio. DTC P0507 or DTC

P1509 may set. If the IAC pintle is stuck closed, too little

air will be allowed in the manifold. This results in a low idle

speed, along with possible hard starting and a rich air/fuel

ratio. DTC P0506 or DTC P1508 may set. If the IAC

pintle is stuck part-way open, the idle may be high or low

and will not respond to changes in the engine load.

Page 1461 of 6000

6E–344

ENGINE DRIVEABILITY AND EMISSIONS

0006

Run Mode

The run mode has the following two conditions:

Open loop

Closed loop

When the engine is first started the system is in “open

loop” operation. In “open loop,” the PCM ignores the

signal from the heated oxygen sensor (HO2S). It

calculates the air/fuel ratio based on inputs from the TP,

ECT, and MAF sensors.

The system remains in “open loop” until the following

conditions are met:

The HO2S has a varying voltage output showing that

it is hot enough to operate properly (this depends on

temperature).

The ECT has reached a specified temperature.

A specific amount of time has elapsed since starting

the engine.

Engine speed has been greater than a specified RPM

since start-up.

The specific values for the above conditions vary with

different engines and are stored in the programmable

read only memory (PROM). When these conditions are

met, the system enters “closed loop” operation. In

“closed loop,” the PCM calculates the air/fuel ratio

(injector on-time) based on the signal from the HO2S.

This allows the air/fuel ratio to stay very close to 14.7:1.

Starting Mode

When the ignition is first turned “ON,” the PCM energizes

the fuel pump relay for two seconds to allow the fuel pump

to build up pressure. The PCM then checks the engine

coolant temperature (ECT) sensor and the throttle

position (TP) sensor to determine the proper air/fuel ratio

for starting.

The PCM controls the amount of fuel delivered in the

starting mode by adjusting how long the fuel injectors are

energized by pulsing the injectors for very short times.

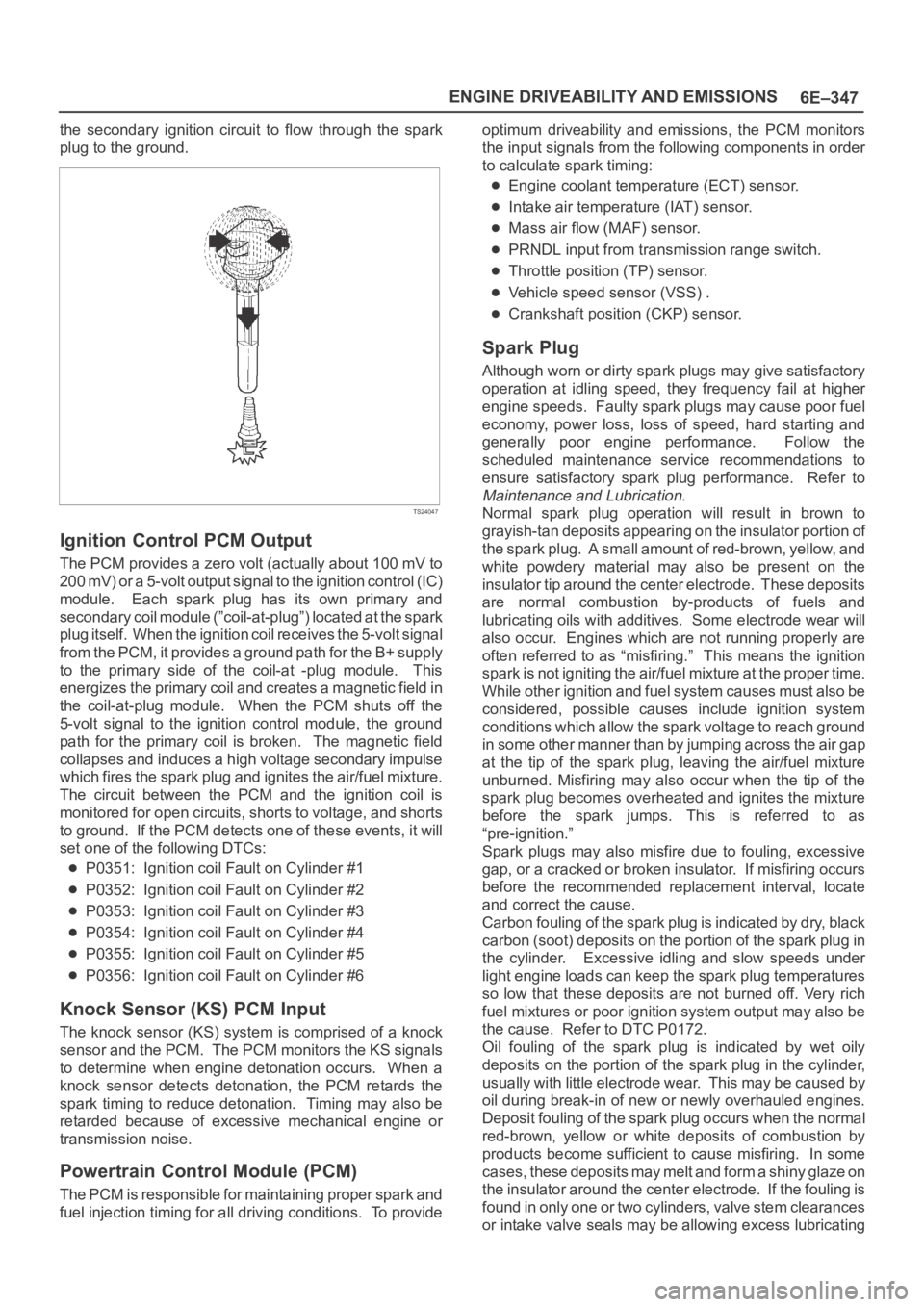

Throttle Body Unit

The throttle body has a throttle plate to control the amount

of air delivered to the engine. The TP sensor and IAC

valve are also mounted on the throttle body. Vacuum

ports located behind the throttle plate provide the vacuum

signals needed by various components.

Engine coolant is directed through a coolant cavity in the

throttle body to warm the throttle valve and to prevent

icing.

0019

General Description (Electronic

Ignition System)

Camshaft Position (CMP) Sensor

As the camshaft sprocket turns, a magnet in the sprocket

activates the Hall-effect switch in the CMP sensor. When

the Hall-effect switch is activated, it grounds the signal

line to the PCM, pulling the camshaft position sensor

signal circuit’s applied voltage low. This is a CMP signal.

The CMP signals is created as piston #1 is approximately

25

after top dead counter on the power stroke. If the

correct CMP signal is not received by the PCM, DTC

P0341 will be set.

Page 1463 of 6000

6E–346

ENGINE DRIVEABILITY AND EMISSIONS

Crankshaft position (58X reference).

Camshaft position (CMP) sensor.

Engine coolant temperature (ECT) sensor.

Throttle position (TP) sensor.

Knock signal (knock sensor).

Park/Neutral position (PRNDL input).

Vehicle speed (vehicle speed sensor).

PCM and ignition system supply voltage.

The crankshaft positron (CKP) sensor sends the

PCM a 58X signal related to the exact position of the

crankshaft.

TS22909

The camshaft position (CMP) sensor sends a signal

related to the position of the camshaft.

TS22910

The knock sensor tells the PCM if there is any

problem with pre-ignition or detonation. This

information allows the PCM to retard timing, if

necessary.

TS24037

Based on these sensor signals and engine load

information, the PCM sends 5V to each ignition coil.

060RW015

The PCM applies 5V signal voltage to the ignition coil

requiring ignition. This signal sets on the power transistor

of the ignition coil to establish a grounding circuit for the

primary coil, applying battery voltage to the primary coil.

At the ignition timing, the PCM stops sending the 5V

signal voltage. Under this condition the power transistor

of the ignition coil is set off to cut the battery voltage to the

primary coil, thereby causing a magnetic field generated

in the primary coil to collapse. On this moment a line of

magnetic force flows to the secondary coil, and when this

magnetic line crosses the coil, high voltage induced by

Page 1464 of 6000

6E–347 ENGINE DRIVEABILITY AND EMISSIONS

the secondary ignition circuit to flow through the spark

plug to the ground.

TS24047

Ignition Control PCM Output

The PCM provides a zero volt (actually about 100 mV to

200 mV) or a 5-volt output signal to the ignition control (IC)

module. Each spark plug has its own primary and

secondary coil module (”coil-at-plug”) located at the spark

plug itself. When the ignition coil receives the 5-volt signal

from the PCM, it provides a ground path for the B+ supply

to the primary side of the coil-at -plug module. This

energizes the primary coil and creates a magnetic field in

the coil-at-plug module. When the PCM shuts off the

5-volt signal to the ignition control module, the ground

path for the primary coil is broken. The magnetic field

collapses and induces a high voltage secondary impulse

which fires the spark plug and ignites the air/fuel mixture.

The circuit between the PCM and the ignition coil is

monitored for open circuits, shorts to voltage, and shorts

to ground. If the PCM detects one of these events, it will

set one of the following DTCs:

P0351: Ignition coil Fault on Cylinder #1

P0352: Ignition coil Fault on Cylinder #2

P0353: Ignition coil Fault on Cylinder #3

P0354: Ignition coil Fault on Cylinder #4

P0355: Ignition coil Fault on Cylinder #5

P0356: Ignition coil Fault on Cylinder #6

Knock Sensor (KS) PCM Input

The knock sensor (KS) system is comprised of a knock

sensor and the PCM. The PCM monitors the KS signals

to determine when engine detonation occurs. When a

knock sensor detects detonation, the PCM retards the

spark timing to reduce detonation. Timing may also be

retarded because of excessive mechanical engine or

transmission noise.

Powertrain Control Module (PCM)

The PCM is responsible for maintaining proper spark and

fuel injection timing for all driving conditions. To provideoptimum driveability and emissions, the PCM monitors

the input signals from the following components in order

to calculate spark timing:

Engine coolant temperature (ECT) sensor.

Intake air temperature (IAT) sensor.

Mass air flow (MAF) sensor.

PRNDL input from transmission range switch.

Throttle position (TP) sensor.

Vehicle speed sensor (VSS) .

Crankshaft position (CKP) sensor.

Spark Plug

Although worn or dirty spark plugs may give satisfactory

operation at idling speed, they frequency fail at higher

engine speeds. Faulty spark plugs may cause poor fuel

economy, power loss, loss of speed, hard starting and

generally poor engine performance. Follow the

scheduled maintenance service recommendations to

ensure satisfactory spark plug performance. Refer to

Maintenance and Lubrication.

Normal spark plug operation will result in brown to

grayish-tan deposits appearing on the insulator portion of

the spark plug. A small amount of red-brown, yellow, and

white powdery material may also be present on the

insulator tip around the center electrode. These deposits

are normal combustion by-products of fuels and

lubricating oils with additives. Some electrode wear will

also occur. Engines which are not running properly are

often referred to as “misfiring.” This means the ignition

spark is not igniting the air/fuel mixture at the proper time.

While other ignition and fuel system causes must also be

considered, possible causes include ignition system

conditions which allow the spark voltage to reach ground

in some other manner than by jumping across the air gap

at the tip of the spark plug, leaving the air/fuel mixture

unburned. Misfiring may also occur when the tip of the

spark plug becomes overheated and ignites the mixture

before the spark jumps. This is referred to as

“pre-ignition.”

Spark plugs may also misfire due to fouling, excessive

gap, or a cracked or broken insulator. If misfiring occurs

before the recommended replacement interval, locate

and correct the cause.

Carbon fouling of the spark plug is indicated by dry, black

carbon (soot) deposits on the portion of the spark plug in

the cylinder. Excessive idling and slow speeds under

light engine loads can keep the spark plug temperatures

so low that these deposits are not burned off. Very rich

fuel mixtures or poor ignition system output may also be

the cause. Refer to DTC P0172.

Oil fouling of the spark plug is indicated by wet oily

deposits on the portion of the spark plug in the cylinder,

usually with little electrode wear. This may be caused by

oil during break-in of new or newly overhauled engines.

Deposit fouling of the spark plug occurs when the normal

red-brown, yellow or white deposits of combustion by

products become sufficient to cause misfiring. In some

c a s e s , t h e s e d e p o s i t s m a y m e l t a n d f o r m a s h i n y g l a z e o n

the insulator around the center electrode. If the fouling is

found in only one or two cylinders, valve stem clearances

or intake valve seals may be allowing excess lubricating

Page 1466 of 6000

6E–349 ENGINE DRIVEABILITY AND EMISSIONS

Damage during re-gapping can happen if the gapping

tool is pushed against the center electrode or the

insulator around it, causing the insulator to crack.

When re-gapping a spark plug, make the adjustment

by bending only the ground side terminal, keeping the

tool clear of other parts.

”Heat shock” breakage in the lower insulator tip

generally occurs during several engine operating

conditions (high speeds or heavy loading) and may be

caused by over-advanced timing or low grade fuels.

Heat shock refers to a rapid increase in the tip

temperature that causes the insulator material to

crack.

Spark plugs with less than the recommended amount of

service can sometimes be cleaned and re-gapped , then

returned to service. However, if there is any doubt about

the serviceability of a spark plug, replace it. Spark plugs

with cracked or broken insulators should always be

replaced.

A/C Clutch Diagnosis

A/C Clutch Circuit Operation

A 12-volt signal is supplied to the A/C request input of the

PCM when the A/C is selected through the A/C control

switch.

The A/C compressor clutch relay is controlled through the

PCM. This allows the PCM to modify the idle air control

position prior to the A/C clutch engagement for better idle

quality. If the engine operating conditions are within their

specified calibrated acceptable ranges, the PCM will

enable the A/C compressor relay. This is done by

providing a ground path for the A/C relay coil within the

PCM. When the A/C compressor relay is enabled,

battery voltage is supplied to the compressor clutch coil.

The PCM will enable the A/C compressor clutch

whenever the engine is running and the A/C has been

requested. The PCM will not enable the A/C compressor

clutch if any of the following conditions are met:

The throttle is greater than 90%.

The engine speed is greater than 6315 RPM.

The ECT is greater than 119C (246F).

The IAT is less than 5C (41F).

The throttle is more than 80% open.

A/C Clutch Circuit Purpose

The A/C compressor operation is controlled by the

powertrain control module (PCM) for the following

reasons:

It improvises idle quality during compressor clutch

engagement.

It improvises wide open throttle (WOT) performance.

It provides A/C compressor protection from operation

with incorrect refrigerant pressures.

The A/C electrical system consists of the following

components:

The A/C control head.

The A/C refrigerant pressure switches.

The A/C compressor clutch.

The A/C compressor clutch relay.

The PCM.

A/C Request Signal

This signal tells the PCM when the A/C mode is selected

at the A/C control head. The PCM uses this to adjust the

idle speed before turning on the A/C clutch. The A/C

compressor will be inoperative if this signal is not

available to the PCM.

Refer to

A/C Clutch Circuit Diagnosis for A/C wiring

diagrams and diagnosis for A/C electrical system.

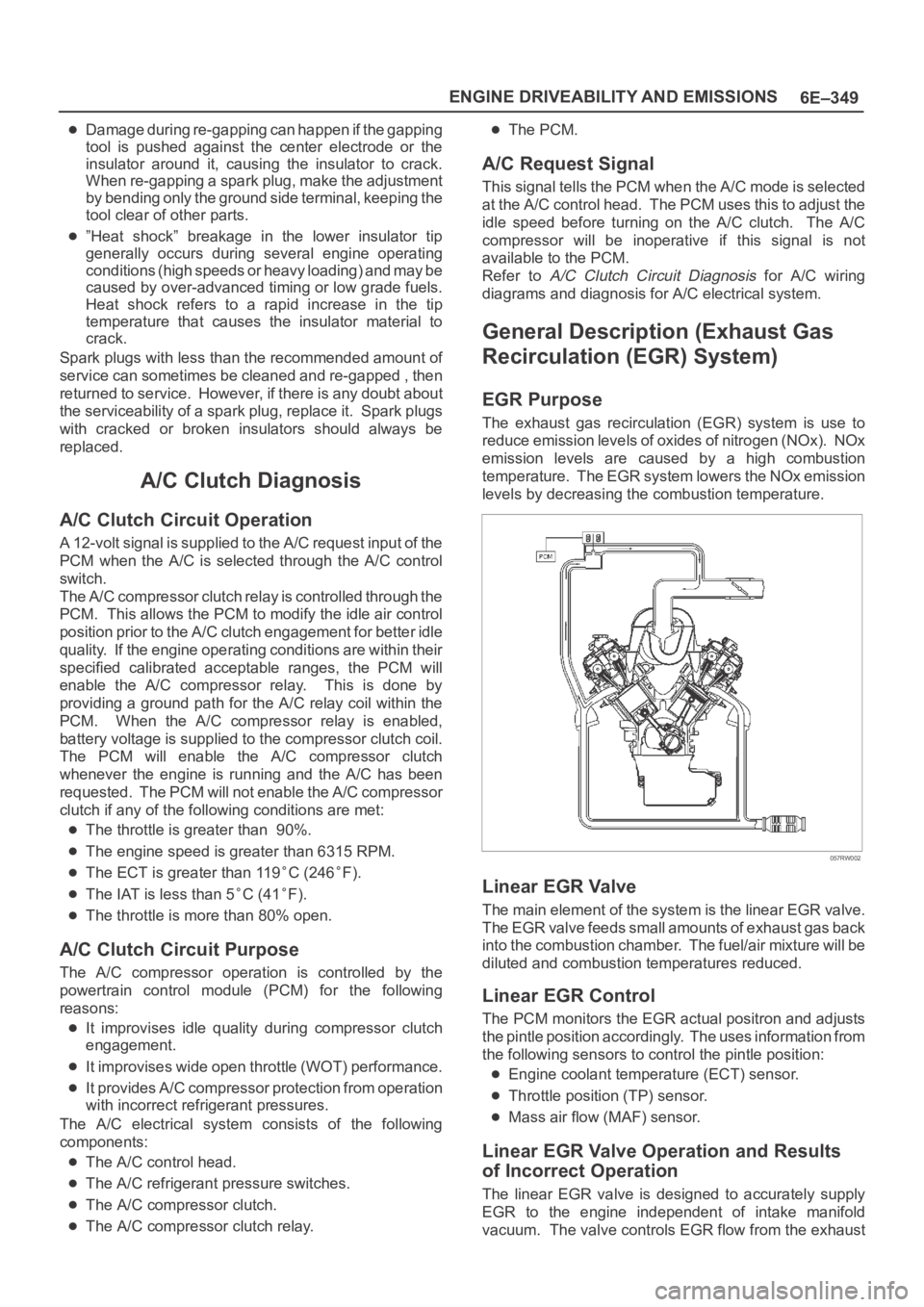

General Description (Exhaust Gas

Recirculation (EGR) System)

EGR Purpose

The exhaust gas recirculation (EGR) system is use to

reduce emission levels of oxides of nitrogen (NOx). NOx

emission levels are caused by a high combustion

temperature. The EGR system lowers the NOx emission

levels by decreasing the combustion temperature.

057RW002

Linear EGR Valve

The main element of the system is the linear EGR valve.

The EGR valve feeds small amounts of exhaust gas back

into the combustion chamber. The fuel/air mixture will be

diluted and combustion temperatures reduced.

Linear EGR Control

The PCM monitors the EGR actual positron and adjusts

the pintle position accordingly. The uses information from

the following sensors to control the pintle position:

Engine coolant temperature (ECT) sensor.

Throttle position (TP) sensor.

Mass air flow (MAF) sensor.

Linear EGR Valve Operation and Results

of Incorrect Operation

The linear EGR valve is designed to accurately supply

EGR to the engine independent of intake manifold

vacuum. The valve controls EGR flow from the exhaust

Page 1744 of 6000

ENGINE MECHANICAL 6A – 11

Remove the radiator filler cap only when absolutely

necessary.

Always check the coolant level when the engine is cold.

Always refer to the chart at the left to determine the

correct cooling water to antifreeze solution mixing ratio.

Cooling System Inspection

Install a radiator filler cap tester to the radiator. Apply

testing pressure to the cooling system to check for

leakage.

The testing pressure must not exceed the specified

pressure.

Testing Pressure: 196 kPa (2 kg/cm

2/28.45 psi)

Radiator Cap Inspection

The radiator filler cap is designed to maintain coolant

pressure in the cooling system at 103 kPa (1.05

kg/cm

2/15 psi).

Check the radiator filler cap with a radiator filler cap

tester.The radiator filler cap must be replaced if it fails to hold

the specified pressure during the test procedure.

Radiator Filler Cap Pressure Valve: 88.2 – 117.6 kPa

(0.899 – 1.199 kg/cm

2/12.8 – 17.1 psi)

Negative Valve (Reference): 1.0 – 3.9 kPa

(0.01 – 0.04 kg/cm

2/0.14 – 0.57 psi)

Thermostat Operating Test

1. Completely submerge the thermostat in water.

2. Heat the water.

Stir the water constantly to avoid direct heat being

applied to the thermostat.

3. Check the thermostat initial opening temperature.

Thermostat Initial Opening Temperature:

83 – 87°C (181 – 189°F)

4. Check the thermostat full opening temperature.

Thermostat Full Opening Temperature:

100°C (212°F)

Valve Lift at Fully Open Position: 9.5 mm (0.374

in)0

-10

-20

-30

-40

-50

-60

10 20 30

Mixing ratio (%)

Freezing point (

C)

40 50 60

111RW002

110RS005

110RS006

031RS003

Page 1746 of 6000

ENGINE MECHANICAL 6A – 13

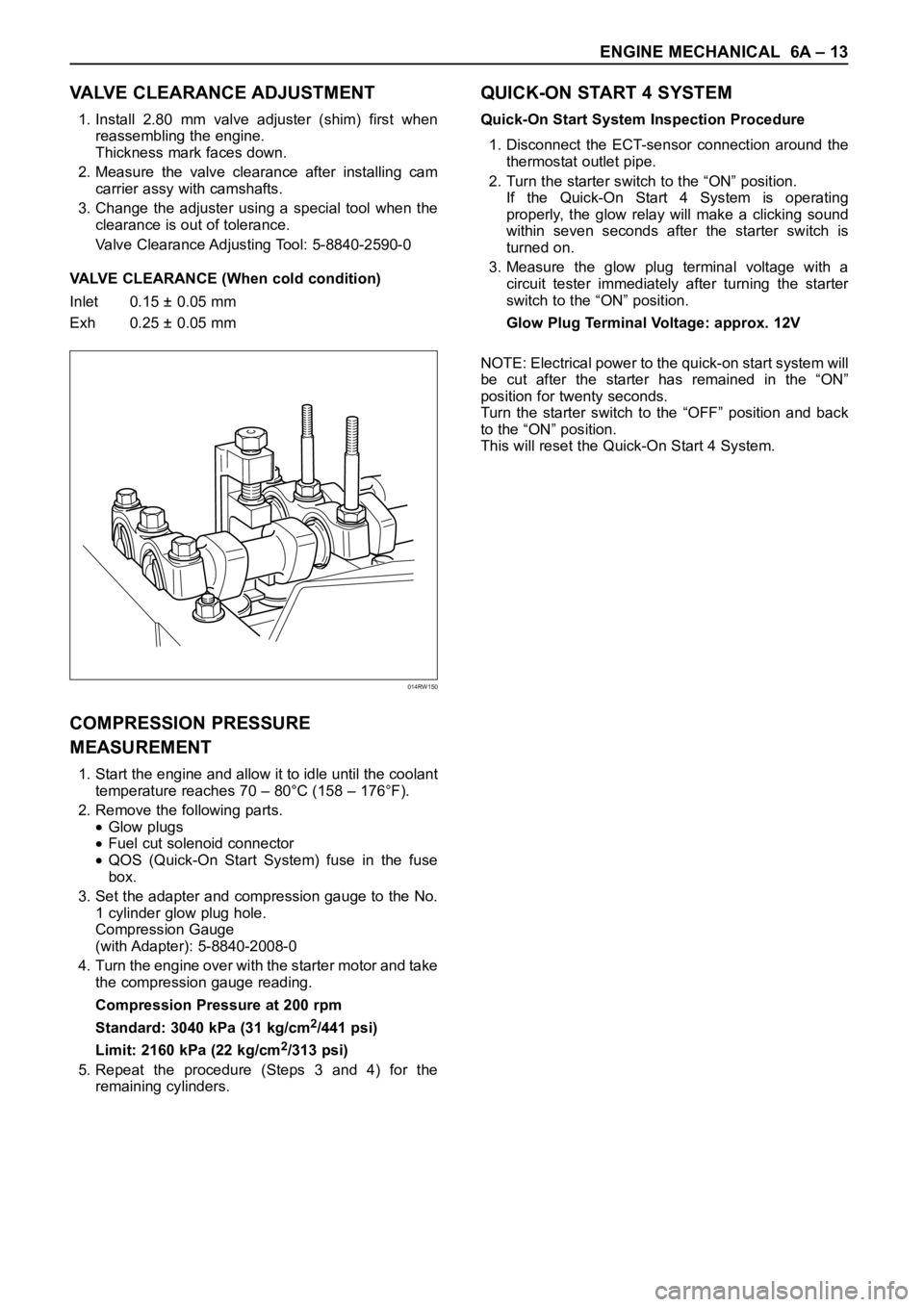

VALVE CLEARANCE ADJUSTMENT

1. Install 2.80 mm valve adjuster (shim) first when

reassembling the engine.

Thickness mark faces down.

2. Measure the valve clearance after installing cam

carrier assy with camshafts.

3. Change the adjuster using a special tool when the

clearance is out of tolerance.

Valve Clearance Adjusting Tool: 5-8840-2590-0

VALVE CLEARANCE (When cold condition)

Inlet 0.15 ± 0.05 mm

Exh 0.25 ± 0.05 mm

COMPRESSION PRESSURE

MEASUREMENT

1. Start the engine and allow it to idle until the coolant

temperature reaches 70 – 80°C (158 – 176°F).

2. Remove the following parts.

Glow plugs

Fuel cut solenoid connector

QOS (Quick-On Start System) fuse in the fuse

box.

3. Set the adapter and compression gauge to the No.

1 cylinder glow plug hole.

Compression Gauge

(with Adapter): 5-8840-2008-0

4. Turn the engine over with the starter motor and take

the compression gauge reading.

Compression Pressure at 200 rpm

Standard: 3040 kPa (31 kg/cm

2/441 psi)

Limit: 2160 kPa (22 kg/cm

2/313 psi)

5. Repeat the procedure (Steps 3 and 4) for the

remaining cylinders.

QUICK-ON START 4 SYSTEM

Quick-On Start System Inspection Procedure

1. Disconnect the ECT-sensor connection around the

thermostat outlet pipe.

2. Turn the starter switch to the “ON” position.

If the Quick-On Start 4 System is operating

properly, the glow relay will make a clicking sound

within seven seconds after the starter switch is

turned on.

3. Measure the glow plug terminal voltage with a

circuit tester immediately after turning the starter

switch to the “ON” position.

Glow Plug Terminal Voltage: approx. 12V

NOTE: Electrical power to the quick-on start system will

be cut after the starter has remained in the “ON”

position for twenty seconds.

Turn the starter switch to the “OFF” position and back

to the “ON” position.

This will reset the Quick-On Start 4 System.

014RW150

Page 1768 of 6000

ENGINE MECHANICAL 6A – 35

INTAKE MANIFOLD

REMOVAL

1. Drain engine coolant and disconnect water hose

from thermostat hosing.

2. Remove intercooler assembly

Refer to “Intercooler” in this manual.

3. Remove bracket bolt of oil level gauge guide tube.

4. Remove PCV Hose.

5. Remove hoses from EGR, EGR vacuum sensor

and inlet/outlet of heater.

6. Disconnect harness connector form MAP sensor,

EGR vacuum sensor, ETC sensor, water

temperature unit, IAT sensor and EVRV.

7. Remove high pressure oil pipe.

8. Remove the two way valve.

9. Remove fuel pipe from between intake manifold

and high pressure oil pump.

10. Remove fixing bolts and nuts on the intake

manifold, then remove the intake manifold

assembly.

INSTALLATION

1. Install the intake manifold, tighten bolts and nuts to

the specified torque.

Torque : 20 Nꞏm (2.0 kgꞏm/14.5 lb ft) for bolt and nut

2. Install the fuel pipe and tighten to the specified

torque.To r q u e :

M16 bolt (apply engine oil) 4 Nꞏm (0.4 kgꞏm/2.9

lb ft)

Cap nut (M10) 13Nꞏm (1.3 kgꞏm/9.4 lb ft)

Fuel pipe (M10 apply engine oil) 14 Nꞏm (1.4

kgꞏm/10 lb ft)

3. Install two way valve.

Torque : 20 Nꞏm (2.0 kgꞏm/14.5 lb ft)

4. Fill with about 300 cc of engine oil from the high

pressure oil pipe installation port of the oil rail using

an oil filler. If assembled without filling the oil rail

with oil, the time for starting the engine will be

longer.

5. Install the high pressure oil pipe immediately and

tighten the sleeve nut to the specified torque.

Torque : 80 Nꞏm (8 kgꞏm/57.9 lb ft)

6. Reconnect harness connector to MAP sensor, EGR

vacuum sensor, ETC sensor, Water temperature

unit, IAT sensor and EVRV.

7. Connect the hoses to EGR valve, EGR vacuum

sensor, and water inlet/outlet pipe for heater.

8. Connect PCV hose.

9. Install the oil level gauge guide tube and tighten

bracket bolt.

10. Install the intercooler assembly.

Refer to “Intercooler” in this manual.

11. Connect the hose to the thermostat housing and fill

with engine coolant.

For Europe

2

1

3

3 1 42

025R200005

Legend

(1) Intake Manifold

(2) Throttle Valve Assembly

(3) EGR Valve

(4) Gasket

Page 1777 of 6000

6A – 44 ENGINE MECHANICAL

REMOVAL

1. Disconnect battery ground cable.

2. Drain engine coolant.

3. Remove air cleaner and air duct.

4. Remove intercooler assembly.

Refer to “Intercooler” in this manual.

5. Remove oil level gauge guide assembly.

6. Remove PCV hose.

7. Remove EGR vacuum hose.

8. Disconnect harness connector around the cylinder

head.

9. Remove A/C compressor assembly.

10. Remove A/C compressor bracket.

11. Remove generator assembly and take out fan belt.

12. Remove heat protector and remove valve

assembly.

13. Remove water hose and oil pipe from turbocharger.

14. Remove turbocharger assembly.

15. Remove water hose between thermostat and

radiator.

16. Remove cylinder head noise insulator cover.

NOTE: Do not make damage to the harness.

17. Remove high pressure pipe.

18. Remove timing belt cover.

19. Remove CMP sensor bracket.

20. Remove timing belt tensioner and remove timing

belt.

21. Remove camshaft pulley.

22. Remove front plate.

23. Remove water pipe between cylinder head and

water pump.

24. Remove fuel pipe between fuel pump and intake

manifold.

25. Remove fuel return pipe.

26. Remove intake manifold assembly.

27. Disconnect glow plug wiring and remove glow plug.

28. Remove cylinder head cover.

29. Drain oil from oil rail.

30. Disconnect injector harness connector.

31. Disconnect harness connector from oil pressure

sensor and oil temperature sensor on the oil rail.

32. Disconnect injector harness assembly.

33. Remove injector clamp.

34. Remove injector spacer (If equipped.).

35. Remove injector assembly.

36. Remove oil rail assembly.

37. Remove camshaft carrier.

38. Remove cylinder head assembly.

39. Remove cylinder gasket.

INSTALLATION

1. Install cylinder head gasket with top mark up.

NOTE: Determine cylinder head gasket grade by

measuring projection of piston head.2. Selection cylinder head gasket.

1) Measure the piston head projection by dial

gauge.

2) Measure the projection of piston head at the

nearest possible point to the cylinder bore.

3) Obtain the largest measurement from among all

cylinders.

4) Determine cylinder head gasket grade by

maximum value of measuring projection of

piston head.

Legend

(1) Top Mark

(2) Grade Mark

012RW073

2 1

011RW043

Page 1793 of 6000

6A – 60 ENGINE MECHANICAL

VALVE STEM SEAL, VALVE SPRING AND ADJUSTER

REMOVAL

1. Disconnect battery ground cable.

2. Drain engine coolant.

3. Remove the air duct from between air cleaner and

turbocharger.

4. Remove intercooler assembly.

Refer to “Intercooler” in this manual.

5. Remove oil level gauge guide assembly.

6. Disconnect PCV hose.

7. Disconnect EGR vacuum hose.

8. Disconnect harness connectors around the cylinder

head such as the injector, CMP sensor, MAP

sensor, EGR sensor, EVRV, IAT sensor, A/C

compressor, TP stepping motor, TP sensor and fuel

temperature sensor etc.

9. Remove A/C compressor assembly.

10. Remove A/C compressor bracket.

11. Remove generator assembly and take out drivebelt.

12. Remove heat protector, remove exhaust valve

assembly.

13. Remove water cooling hose and lubrication pipe for

turbocharger.

14. Remove turbocharger assembly.

15. Remove hose between thermostat and radiator.

16. Remove noise insulator cover of cylinder head.

NOTE: Do not damage injector harness.

17. Remove high pressure oil pipe.

18. Remove timing belt cover.

19. Remove CMP sensor bracket.

20. Remove timing belt tensioner then remove timing

belt.

21. Remove camshaft pulley.

22. Remove front plate.

23. Remove engine coolant pipe between cylinder

head and water pump.

1

2

3

4

5

6

9

10

7

8

011RW031

Legend

(1) Adjuster

(2) Tappet

(3) Split Collar

(4) Spring Seat Upper

(5) Valve Spring(6) Spring Seat Lower

(7) Valve Stem Seal

(8) Valve Guide

(9) Valve Seat

(10) Valve