coolant temperature OPEL FRONTERA 1998 Manual PDF

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 1799 of 6000

6A – 66 ENGINE MECHANICAL

INSTALLATION

1. Valve stem seal

1) Use the special tool to install the stem seal to the

valve guide.

Stem Seal Installer: 5-8840-2033-0

2. Valve spring.

1) Install the lower valve seat spring, valve spring,

then the upper valve spring seat.

2) Use valve spring compressor to compress the

spring then install the split collar.

Valve spring compressor: 5-8840-2441-0

NOTE: Make sure the split collar installs completely.

3. Install cylinder head assembly.

Refer to “Cylinder Head” in this manual.

4. Install the camshaft carrier with camshaft.

Refer to “Camshaft” in this manual.

5. Install oil rail assembly.

Refer to “Oil rail and injector” in this manual.

6. Install injector assembly.

Refer to “Oil rail and injector” in this manual.

7. Install the injector harness assembly.

Refer to “Injector” in this manual.

8. Reconnect harness connecter to oil pressure

sensor and oil temperature sensor on the oil rail.

9. Reconnect Injector harness connecter to injector.

Refer to “Injector” in this manual.

10. Install cylinder head cover with gasket.

Refer to “Cylinder Head Cover” in this manual.

11. Install glow plug with specified torque.

Torque: 15 Nꞏm (1.5 kgꞏm / 10.8 lb ft)

12. Install the intake manifold assembly.

Refer to “Intake Manifold” in this manual.

13. Install the fuel pipe.14. Install the water pipe between the cylinder head

and water pump.

Torque: 20 Nꞏm (2.0 kꞏm / 14.5 lb ft)

15. Install the front plate.

16. Install the camshaft pulley.

Refer to “Timing Gear” in this manual.

17. Install timing belt and set the tensioner.

Refer to “Timing Belt” in this manual.

18. Install CMP sensor bracket.

Torque: 20 Nꞏm (2.0 kgꞏm / 14.5 lb ft)

19. Install timing belt cover.

Torque: 9 Nꞏm (0.9 kgꞏm / 6.5 lb ft)

20. Fill the oil rail with engine oil then immediately

install the high pressure oil pipe with the specified

torque.

Torque: 80 Nꞏm (8.1 kgꞏm / 57.9 lb ft)

21. Install the noise insulator cover.

22. Reconnect hose between thermostat and radiator.

23. Install turbocharger assembly.

Refer to “Turbocharger” in this manual.

24. Install water hose and oil pipe for turbocharger.

Refer to “Turbocharger” in this manual.

25. Install the valve assembly and install heat protector.

26. Install generator and set the fan belts.

27. Install A/C compressor bracket, compressor

assembly and set drive belt.

28. Reconnect harness connector around cylinder

head.

29. Reconnect vacuum hose to EGR valve.

30. Reconnect PCV hose.

31. Install oil level gauge guide assembly.

32. Install intercooler assembly.

Refer to “Intercooler” in this manual.

33. Install the air duct assembly.

34. Fill engine coolant.

35. Connect battery ground cable.

014RW042

Page 1837 of 6000

6B – 4 ENGINE COOLING

ANTI-FREEZE SOLUTION

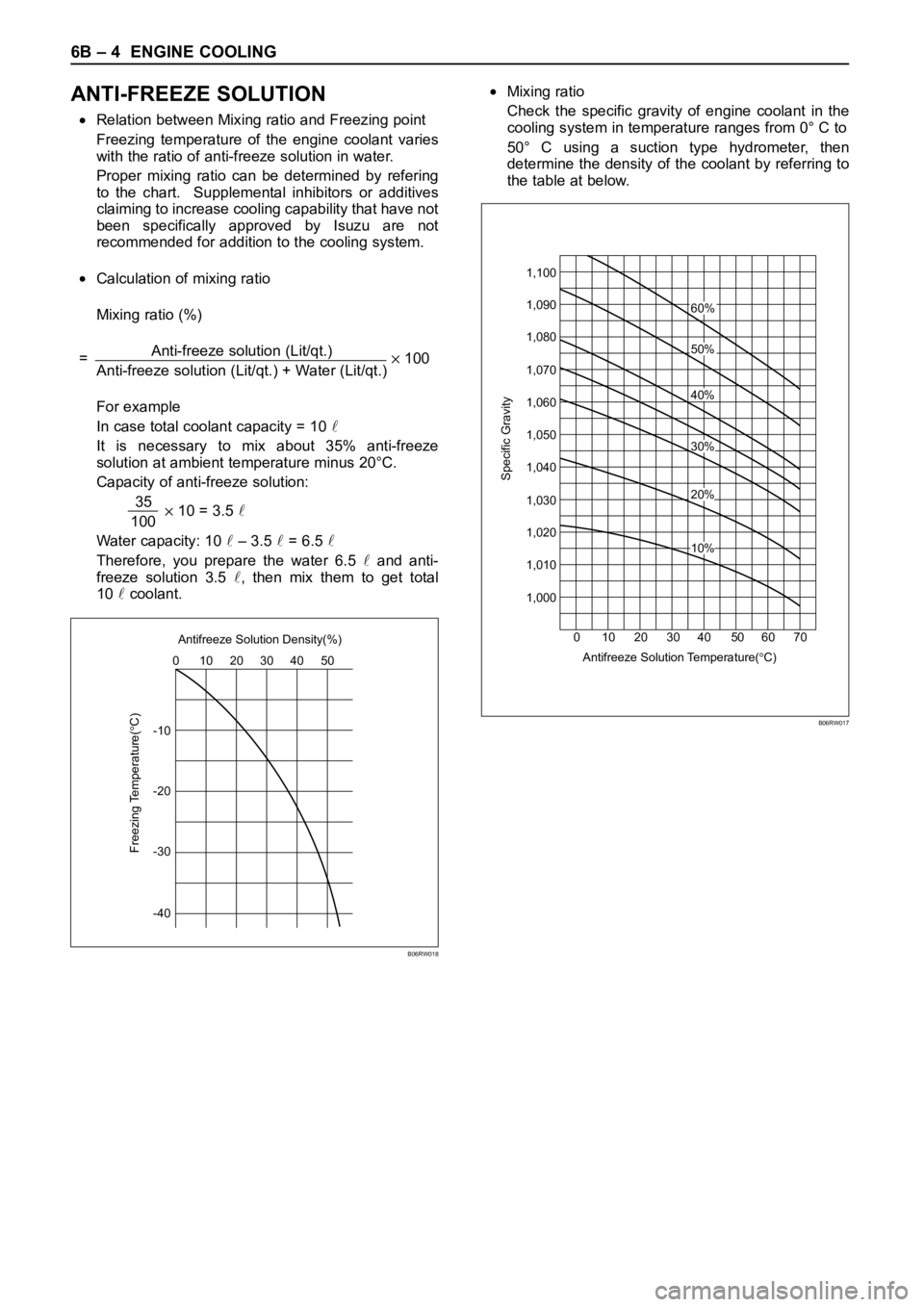

Relation between Mixing ratio and Freezing point

Freezing temperature of the engine coolant varies

with the ratio of anti-freeze solution in water.

Proper mixing ratio can be determined by refering

to the chart. Supplemental inhibitors or additives

claiming to increase cooling capability that have not

been specifically approved by Isuzu are not

recommended for addition to the cooling system.

Calculation of mixing ratio

Mixing ratio (%)

=Anti-freeze solution (Lit/qt.)

100

Anti-freeze solution (Lit/qt.) + Water (Lit/qt.)

For example

In case total coolant capacity = 10

It is necessary to mix about 35% anti-freeze

solution at ambient temperature minus 20°C.

Capacity of anti-freeze solution:

35

10 = 3.5 100

Water capacity: 10

– 3.5 = 6.5

Therefore, you prepare the water 6.5 and anti-

freeze solution 3.5

, then mix them to get total

10

coolant.

Mixing ratio

Check the specific gravity of engine coolant in the

cooling system in temperature ranges from 0° C to

50° C using a suction type hydrometer, then

determine the density of the coolant by referring to

the table at below.

-1010 0

Freezing Temperature(

C)

20 30 Antifreeze Solution Density(%)

40 50

-20

-30

-40

B06RW018

1,100

20 10 30 4060%

50%

40%

20%

10%

30%

Antifreeze Solution Temperature(

C) 50 60 70 0

Specific Gravity

1,090

1,080

1,070

1,060

1,050

1,040

1,030

1,020

1,010

1,000

B06RW017

Page 1838 of 6000

ENGINE COOLING 6B – 5

ENGINE COOLANT CHANGE

PROCEDURE

1. To change engine coolant, make sure that the

engine is cool.

WARNING:

When the coolant is heated to a high temperature,

be sure not to loosen or remove the radiator cap.

Otherwise you might get scalded by hot vapor or

boiling water. To open the radiator cap, put a piece

of thick cloth on the cap and loosen the cap slowly

to reduce the pressure once the coolant has

become cooler.

2. Open radiator cap and drain the cooling system by

loosening the drain valve on the radiator and on the

cylinder body.

NOTE: For best results it is suggested that the engine

cooling system be flushed at least once a year. It is

advisable to flush the interior of the cooling system

including the radiator before using anti-freeze

(ethylene-glycol based).

Replace damaged rubber hoses as the engine anti-

freeze coolant is liable to leak out even minor cracks.

Isuzu recommends using Isuzu genuine anti-freeze

(ethylene-glycol based) or equivalent, for the cooling

system and not add any inhibitors or additives.

CAUTION:

A failure to correctly fill the engine cooling system

in changing or topping off coolant may sometimes

cause the coolant to overflow from the filler neck

even before the engine and radiator are completely

full.

If the engine runs under this condition, shortage of

coolant may possibly result in engine overheating.

To avoid such trouble, the following precautions

should be taken in filling the system.

3. To refill engine coolant, pour coolant up to filler neck

using a filling hose which is smaller in outside

diameter than the filler neck. Otherwise air between

the filler neck and the filling hose will block entry,

preventing the system from completely filling up.

4. Keep a filling rate of 9 liter/min. or less. Filling over

this maximum rate may force air inside the engine

and radiator.

And also, the coolant overflow will increase, making

it difficult to determine whether or not the system is

completely full.

5. After filling the system full, pull out the filling hose

and check to see if air trapped in the system is

dislodged and the coolant level goes down. Should

the coolant level go down, repeat topping-off until

there is no more drop in the coolant level.

6. Directly after filling the radiator, fill the reservoir to

the maximum level.

7. Install and tighten radiator cap and start the engine.

After idling for 2 to 3 minutes, stop the engine and

reopen radiator cap. If the water level is lower,

replenish.WARNING:

When the coolant is heated to a high temperature,

be sure not to loosen or remove the radiator cap.

Otherwise you might get scalded by hot vapor or

boiling water. To open the radiator cap, put a piece

of thick cloth on the cap and loosen the cap slowly

to reduce the pressure once the coolant has

become cooler.

8. After tightening radiator cap, warm up the engine at

about 2,000 rpm.

Set heater adjustment to the highest temperature

position, and let the coolant circulate also into

heater water system.

9. Check to see the thermostat has opened by the

needle position of a water thermometer, conduct a

5-minute idle again and stop the engine.

10. When the engine has been cooled, check filler neck

for water level and replenish if required. Should

extreme shortage of coolant be found, check the

coolant system and reservoir tank hose for leakage.

11. Fill the coolant into the reservoir tank up to “MAX”

line.

Page 1840 of 6000

ENGINE COOLING 6B – 7

THERMOSTAT

REMOVAL

1. Disconnect battery ground cable.

2. Drain coolant from the radiator and engine.

3. Thermostat housing

1) Remove mounting bolt and remove thermostat

housing together with radiator hose.

4. Gasket

5. Thermostat

INSPECTION

Make necessary repair and parts replacement if

excessive wear or damage is found during inspection.

Submerge the thermostat assembly in the water.

Place wooden blocks on the bottom of the water

container.

Do not heat the thermostat directly.

Gradually increase the water temperature. Stir the

water so that the entire water is the same temperature.

1) Make sure that valve begins to open at the

specified temperature.

Valve Opening Temperature: 85°C (185°F)

2) Make sure that valve opens fully at the specified

temperature.

Valve Full Open Temperature: 100°C (212°F)

1

2

3

4

Legend

(1) Bolt

(2) Thermostat Housing

(3) Thermostat

(4) Intake Manifold

035RW002

031RS003

Page 1850 of 6000

ENGINE FUEL 6C – 5

FUEL FILTER

Legend

(1) Priming Pump

(2) Fuel Filter Cartridge

A cartridge type fuel filter is used along with the piston

type fuel pump on the high pressure oil pump.

The fuel filter removes foreign material from the fuel

before it reaches the fuel pump.

A diaphragm type priming pump is installed at the top of

the fuel filter. It is used during the air bleeding

procedures.

INJECTOR ASSEMBLY

Legend

(1) Oil Passage

(2) Fuel Passage

1. Construction of Fuel Injector

The fuel injector is comprised of the solenoid

section, hydraulic line, and fuel line. Fuel injection is

controlled by the continuity time signal and

continuity start timing signal sent by the ECM

(Electronic Control Module) to the solenoid.

2. Working of Fuel Injector

1) The ECM detects the working of the engine from

its input signals, such as engine speed

accelerator throttle opening, and engine coolant

temperature, sending the optimal signals to the

solenoid.

1

2

041RW017

1

2

055RW018

Page 1890 of 6000

ENGINE ELECTRICAL 6D – 23

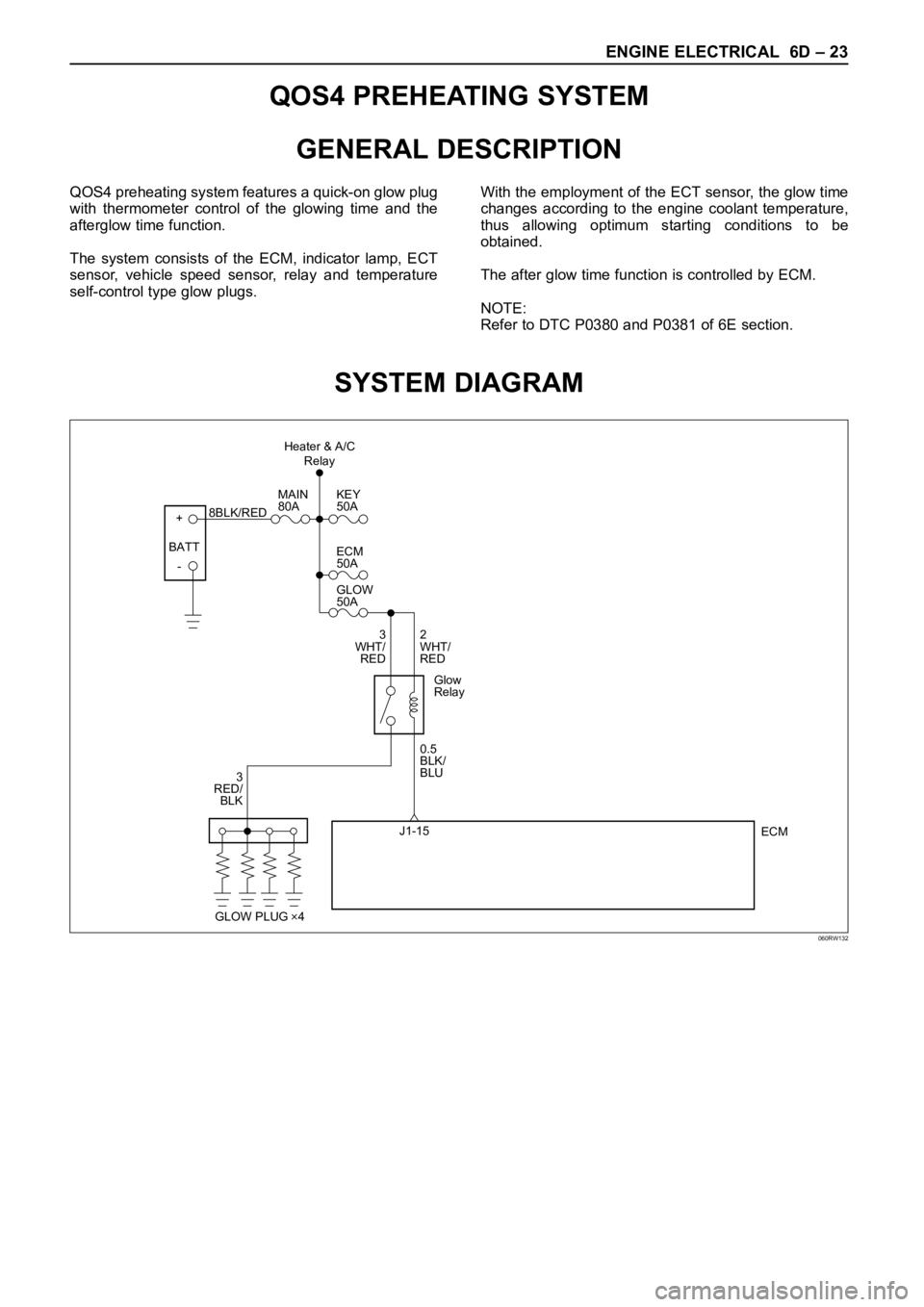

QOS4 PREHEATING SYSTEM

GENERAL DESCRIPTION

QOS4 preheating system features a quick-on glow plug

with thermometer control of the glowing time and the

afterglow time function.

The system consists of the ECM, indicator lamp, ECT

sensor, vehicle speed sensor, relay and temperature

self-control type glow plugs.With the employment of the ECT sensor, the glow time

changes according to the engine coolant temperature,

thus allowing optimum starting conditions to be

obtained.

The after glow time function is controlled by ECM.

NOTE:

Refer to DTC P0380 and P0381 of 6E section.

SYSTEM DIAGRAM

+

-KEY

50A

ECM

50A

GLOW

50A

2

WHT/

RED

0.5

BLK/

BLU

ECM J1-15 3

WHT/

RED

3

RED/

BLKMAIN

80A

8BLK/RED

Glow

Relay

GLOW PLUG 4

BATTHeater & A/C

Relay

060RW132

Page 1895 of 6000

6E–2

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Circuit Description 6E–56. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–56. . . . . . .

Conditions for Clearing the MIL/DTC 6E–56. . . . .

Diagnostic Aids 6E–56. . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0108

(Flash DTC 34)

MAP Sensor Circuit High Voltage 6E–58. . . . . . . . .

Circuit Description 6E–58. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–58. . . . . . .

Conditions for Clearing the MIL/DTC 6E–58. . . . .

Diagnostic Aids 6E–58. . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0112

(Flash DTC 23) IAT Sensor Circuit Low

Voltage 6E–60. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Description 6E–60. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–60. . . . . . .

Conditions for Clearing the MIL/DTC 6E–60. . . . .

Diagnostic Aids 6E–60. . . . . . . . . . . . . . . . . . . . . . . .

Test Description 6E–61. . . . . . . . . . . . . . . . . . . . . . .

Intake Air Temperature Sensor 6E–61. . . . . . . . . .

Diagnostic Trouble Code (DTC) P0113

(Flash DTC 23) IAT Sensor Circuit High

Voltage 6E–62. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Description 6E–62. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–62. . . . . . .

Conditions for Clearing the MIL/DTC 6E–62. . . . .

Diagnostic Aids 6E–62. . . . . . . . . . . . . . . . . . . . . . . .

Test Description 6E–63. . . . . . . . . . . . . . . . . . . . . . .

Manifold Air Temperature Sensor 6E–63. . . . . . . .

Diagnostic Trouble Code (DTC) P0117

(Flash DTC 14) ECT Sensor Low Voltage 6E–65.

Circuit Description 6E–65. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–65. . . . . . .

Conditions for Clearing the MIL/DTC 6E–65. . . . .

Diagnostic Aids 6E–65. . . . . . . . . . . . . . . . . . . . . . . .

Test Description 6E–65. . . . . . . . . . . . . . . . . . . . . . .

Engine Coolant Temperature Sensor 6E–66. . . . .

Diagnostic Trouble Code (DTC) P0118

(Flash DTC 14) ECT Sensor High Voltage 6E–67.

Circuit Description 6E–67. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–67. . . . . . .

Conditions for Clearing the MIL/DTC 6E–67. . . . .

Diagnostic Aids 6E–67. . . . . . . . . . . . . . . . . . . . . . . .

Test Description 6E–68. . . . . . . . . . . . . . . . . . . . . . .

Engine Coolant Temperature Sensor 6E–68. . . . .

Diagnostic Trouble Code (DTC) P0121

(Flash DTC 33) AP Sensor Rationality 6E–70. . . . .

Circuit Description 6E–70. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–70. . . . . . .

Conditions for Clearing the MIL/DTC 6E–70. . . . .

Diagnostic Aids 6E–70. . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0122

(Flash DTC 21) AP Sensor Low Voltage 6E–72. . .

Circuit Description 6E–72. . . . . . . . . . . . . . . . . . . . . Action Taken When the DTC Sets 6E–72. . . . . . .

Conditions for Clearing the MIL/DTC 6E–72. . . . .

Diagnostic Aids 6E–72. . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0123

(Flash DTC 21) AP Sensor High Voltage 6E–75. . .

Circuit Description 6E–75. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–75. . . . . . .

Conditions for Clearing the MIL/DTC 6E–75. . . . .

Diagnostic Aids 6E–75. . . . . . . . . . . . . . . . . . . . . . . .

Test Description 6E–75. . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0182

(Flash DTC 15) FT Sensor Low Voltage 6E–78. . .

Circuit Description 6E–78. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–78. . . . . . .

Conditions for Clearing the MIL/DTC 6E–78. . . . .

Diagnostic Aids 6E–78. . . . . . . . . . . . . . . . . . . . . . . .

Test Description 6E–78. . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0183

(Flash DTC 15) FT Sensor High Voltage 6E–80. . .

Circuit Description 6E–80. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–80. . . . . . .

Conditions for Clearing the MIL/DTC 6E–80. . . . .

Diagnostic Aids 6E–80. . . . . . . . . . . . . . . . . . . . . . . .

Test Description 6E–80. . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0192

(Flash DTC 63) Rail Pressure Sensor Low

Voltage 6E–82. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Description 6E–82. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–82. . . . . . .

Conditions for Clearing the MIL/DTC 6E–82. . . . .

Diagnostic Aids 6E–82. . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0193

(Flash DTC 63) Rail Pressure Sensor

High Voltage 6E–84. . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Description 6E–84. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–84. . . . . . .

Conditions for Clearing the MIL/DTC 6E–84. . . . .

Diagnostic Aids 6E–84. . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P1193

(Flash DTC 64) RPCV Circuit Open/Short 6E–86. .

Circuit Description 6E–86. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–86. . . . . . .

Conditions for Clearing the MIL/DTC 6E–86. . . . .

Diagnostic Aids 6E–86. . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P1194

(Flash DTC 61) Rail Pressure System

Low Voltage 6E–88. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Description 6E–88. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–88. . . . . . .

Conditions for Clearing the MIL/DTC 6E–88. . . . .

Diagnostic Aids 6E–88. . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P1195

(Flash DTC 61) Rail Pressure System

High Voltage 6E–90. . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Description 6E–90. . . . . . . . . . . . . . . . . . . . .

Page 1896 of 6000

6E–3 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Action Taken When the DTC Sets 6E–90. . . . . . .

Conditions for Clearing the MIL/DTC 6E–90. . . . .

Diagnostic Aids 6E–90. . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P1196

(Flash DTC 62) Rail Pressure System

High Warning 6E–92. . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Description 6E–93. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–93. . . . . . .

Conditions for Clearing the MIL/DTC 6E–93. . . . .

Diagnostic Aids 6E–93. . . . . . . . . . . . . . . . . . . . . . . .

Test Description 6E–93. . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0197

(Flash DTC 16) Oil Temp Sensor Low

Voltage 6E–94. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Description 6E–94. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–94. . . . . . .

Conditions for Clearing the MIL/DTC 6E–94. . . . .

Diagnostic Aids 6E–94. . . . . . . . . . . . . . . . . . . . . . . .

Test Description 6E–95. . . . . . . . . . . . . . . . . . . . . . .

Engine Oil Temperature Sensor 6E–95. . . . . . . . .

Diagnostic Trouble Code (DTC) P0198

(Flash DTC 16) Oil Temp Sensor High

Voltage 6E–96. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Description 6E–96. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–96. . . . . . .

Conditions for Clearing the MIL/DTC 6E–96. . . . .

Diagnostic Aids 6E–96. . . . . . . . . . . . . . . . . . . . . . . .

Test Description 6E–97. . . . . . . . . . . . . . . . . . . . . . .

Engine Oil Temperature Sensor 6E–97. . . . . . . . .

Diagnostic Trouble Code (DTC) P0201

(Flash DTC 51) Injector # 1 Circuit Fault 6E–99. . .

Circuit Description 6E–99. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–99. . . . . . .

Conditions for Clearing the MIL/DTC 6E–99. . . . .

Diagnostic Aids 6E–99. . . . . . . . . . . . . . . . . . . . . . . .

Test Description 6E–99. . . . . . . . . . . . . . . . . . . . . . .

Injector Test 6E–99. . . . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0202

(Flash DTC 52) Injector # 2 Circuit Fault 6E–101. . .

Circuit Description 6E–101. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–101. . . . . . .

Conditions for Clearing the MIL/DTC 6E–101. . . . .

Diagnostic Aids 6E–101. . . . . . . . . . . . . . . . . . . . . . . .

Test Description 6E–101. . . . . . . . . . . . . . . . . . . . . . .

Injector Test 6E–101. . . . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0203

(Flash DTC 52) Injector # 3 Circuit Fault 6E–103. . .

Circuit Description 6E–103. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–103. . . . . . .

Conditions for Clearing the MIL/DTC 6E–103. . . . .

Diagnostic Aids 6E–103. . . . . . . . . . . . . . . . . . . . . . . .

Test Description 6E–103. . . . . . . . . . . . . . . . . . . . . . .

Injector Test 6E–103. . . . . . . . . . . . . . . . . . . . . . . . . . Diagnostic Trouble Code (DTC) P0204

(Flash DTC 54) Injector # 4 Circuit Fault 6E–105

. . .

Circuit Description 6E–105. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–105. . . . . . .

Conditions for Clearing the MIL/DTC 6E–105. . . . .

Diagnostic Aids 6E–105. . . . . . . . . . . . . . . . . . . . . . . .

Test Description 6E–105. . . . . . . . . . . . . . . . . . . . . . .

Injector Test 6E–105. . . . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0217

(Flash DTC 22) High Coolant Temp Waring 6E–107

Circuit Description 6E–107. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–107. . . . . . .

Conditions for Clearing the MIL/DTC 6E–107. . . . .

Diagnostic Aids 6E–107. . . . . . . . . . . . . . . . . . . . . . . .

Test Description 6E–107. . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P1217

(Flash DTC 36) High Oil Temp Warning 6E–109. . . .

Circuit Description 6E–109. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–109. . . . . . .

Conditions for Clearing the MIL/DTC 6E–109. . . . .

Diagnostic Aids 6E–109. . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0219

(Flash DTC 11) Engine Over Speed Warning 6E–111

Circuit Description 6E–111. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–111. . . . . . .

Conditions for Clearing the MIL/DTC 6E–111. . . . .

Diagnostic Aids 6E–111. . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0336

(Flash DTC 43) CKP (Crank Position)

Sensor Out of Synchro 6E–114. . . . . . . . . . . . . . . . . .

Circuit Description 6E–114. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–114. . . . . . .

Conditions for Clearing the MIL/DTC 6E–114. . . . .

Diagnostic Aids 6E–114. . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0337

(Flash DTC 43) CKP (Crank Position)

Sensor No Signal 6E–116. . . . . . . . . . . . . . . . . . . . . . .

Circuit Description 6E–116. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–116. . . . . . .

Conditions for Clearing the MIL/DTC 6E–116. . . . .

Diagnostic Aids 6E–116. . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0341

(Flash DTC 41) CMP (Cam Position)

Sensor Out of Synchro 6E–119. . . . . . . . . . . . . . . . . .

Circuit Description 6E–119. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–119. . . . . . .

Conditions for Clearing the MIL/DTC 6E–119. . . . .

Diagnostic Aids 6E–119. . . . . . . . . . . . . . . . . . . . . . . .

Test Description 6E–119. . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0342

(Flash DTC 41) CMP (Cam Position)

Sensor No Signal 6E–122. . . . . . . . . . . . . . . . . . . . . . .

Circuit Description 6E–122. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–122. . . . . . .

Conditions for Clearing the MIL/DTC 6E–122. . . . .

Page 1898 of 6000

6E–5 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Conditions for Clearing the MIL/DTC 6E–159. . . . .

Diagnostic Aids 6E–159. . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P1562

(Flash DTC 35) System Voltage Too Low

at Cranking 6E–160. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Description 6E–160. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–160. . . . . . .

Conditions for Clearing the MIL/DTC 6E–160. . . . .

Diagnostic Aids 6E–160. . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P1587

(Flash DTC 25) Brake SW Malfunction 6E–161. . . .

Circuit Description 6E–161. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–161. . . . . . .

Conditions for Clearing the MIL/DTC 6E–161. . . . .

Diagnostic Aids 6E–161. . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P1588

(Flash DTC 25) Brake SW Malfunction 6E–163. . . .

Circuit Description 6E–163. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–163. . . . . . .

Conditions for Clearing the MIL/DTC 6E–163. . . . .

Diagnostic Aids 6E–163. . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0601

(Flash DTC 55) ECM Checksum Error 6E–165. . . . .

Action Taken When the DTC Sets 6E–165. . . . . . .

Conditions for Clearing the MIL/DTC 6E–165. . . . .

Diagnostic Aids 6E–165. . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0650

(Flash DTC 77) Check Engine Lam Circuit

Open/Short 6E–166. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Description 6E–166. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–166. . . . . . .

Conditions for Clearing the MIL/DTC 6E–166. . . . .

Diagnostic Aids 6E–166. . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0654

(Flash DTC 27) Tachometer Circuit

Open/Short 6E–168. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Description 6E–168. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–168. . . . . . .

Conditions for Clearing the MIL/DTC 6E–168. . . . .

Diagnostic Aids 6E–168. . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P1655

(Flash DTC 17) Thermo Relay Circuit

Open/Short 6E–170. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Description 6E–170. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–170. . . . . . .

Conditions for Clearing the MIL/DTC 6E–170. . . . .

Diagnostic Aids 6E–170. . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P1657

(Flash DTC 76) ECM Main Relay Circuit

Open/Short 6E–172. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Description 6E–172. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–172. . . . . . .

Conditions for Clearing the MIL/DTC 6E–172. . . . .

Diagnostic Aids 6E–172. . . . . . . . . . . . . . . . . . . . . . . . Diagnostic Trouble Code (DTC) P1589

(Flash DTC 47) Transmission SW Circuit

Open/Short 6E–174. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Description 6E–174. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–174. . . . . . .

Conditions for Clearing the MIL/DTC 6E–174. . . . .

Diagnostic Aids 6E–174. . . . . . . . . . . . . . . . . . . . . . . .

Symptom Diagnosis 6E–176. . . . . . . . . . . . . . . . . . . . .

Default Matrix Table 6E–199. . . . . . . . . . . . . . . . . . . . .

On–Vehicle Service Camshaft Position

(CMP) Sensor 6E–201. . . . . . . . . . . . . . . . . . . . . . . . . .

Removal Procedure 6E–201. . . . . . . . . . . . . . . . . . . .

Inspection Procedure 6E–201. . . . . . . . . . . . . . . . . .

Installation Procedure 6E–201. . . . . . . . . . . . . . . . . .

Crankshaft Position (CKP) Sensor 6E–202. . . . . . . . .

Removal Procedure 6E–202. . . . . . . . . . . . . . . . . . . .

Installation Procedure 6E–202. . . . . . . . . . . . . . . . . .

Engine Coolant Temperature (ECT) Sensor 6E–203.

Removal Procedure 6E–203. . . . . . . . . . . . . . . . . . . .

Installation Procedure 6E–203. . . . . . . . . . . . . . . . . .

Intake Air Temperature (IAT) Sensor 6E–203. . . . . . .

Removal Procedure 6E–203. . . . . . . . . . . . . . . . . . . .

Installation Procedure 6E–204. . . . . . . . . . . . . . . . . .

Manifold Absolute Pressure (MAP) Sensor 6E–204.

Removal Procedure 6E–204. . . . . . . . . . . . . . . . . . . .

Installation Procedure 6E–205. . . . . . . . . . . . . . . . . .

Oil Temperature (OT) Sensor 6E–205. . . . . . . . . . . . .

Removal Procedure 6E–205. . . . . . . . . . . . . . . . . . . .

Installation Procedure 6E–206. . . . . . . . . . . . . . . . . .

Malfunction Indicator Lamp (MIL) 6E–206. . . . . . . . . .

Removal and Installation Procedure 6E–206. . . . . .

Engine Control Module (ECM) 6E–206. . . . . . . . . . . .

Service Precaution 6E–206. . . . . . . . . . . . . . . . . . . .

Electrostatic Discharge (ESD) Damage 6E–206. . .

Removal Procedure 6E–207. . . . . . . . . . . . . . . . . . . .

Installation Procedure 6E–208. . . . . . . . . . . . . . . . . .

EEPROM 6E–208. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Description 6E–208. . . . . . . . . . . . . . . . . . . .

Functional Check 6E–208. . . . . . . . . . . . . . . . . . . . . .

Intake Throttle Position (ITP) Sensor 6E–208. . . . . . .

Removal Procedure 6E–208. . . . . . . . . . . . . . . . . . . .

Function Check 6E–209. . . . . . . . . . . . . . . . . . . . . . .

Installation Procedure 6E–209. . . . . . . . . . . . . . . . . .

Vehicle Speed Sensor (VSS) 6E–210. . . . . . . . . . . . .

Removal Procedure 6E–210. . . . . . . . . . . . . . . . . . . .

Inspection Procedure 6E–210. . . . . . . . . . . . . . . . . .

Installation Procedure 6E–210. . . . . . . . . . . . . . . . . .

Air Cleaner/Air Filter 6E–211. . . . . . . . . . . . . . . . . . . . .

Removal Procedure 6E–211. . . . . . . . . . . . . . . . . . . .

Installation Procedure 6E–211. . . . . . . . . . . . . . . . . .

Accel Position (AP) Sensor 6E–211. . . . . . . . . . . . . . .

Removal Procedure 6E–211. . . . . . . . . . . . . . . . . . . .

Installation Procedure 6E–212. . . . . . . . . . . . . . . . . .

Accelerator Pedal Replacement 6E–212. . . . . . . . . . .

Page 1899 of 6000

6E–6

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Removal Procedure 6E–212. . . . . . . . . . . . . . . . . . . .

Installation Procedure 6E–212. . . . . . . . . . . . . . . . . .

Fuel Filter Cap 6E–213. . . . . . . . . . . . . . . . . . . . . . . . . .

General Description 6E–213. . . . . . . . . . . . . . . . . . . .

Inspection Procedure 6E–213. . . . . . . . . . . . . . . . . .

Fuel Filter 6E–213. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal and Installation Procedure 6E–213. . . . . .

Fuel Gauge Unit 6E–213. . . . . . . . . . . . . . . . . . . . . . . .

Removal Procedure 6E–213. . . . . . . . . . . . . . . . . . . .

Installation Procedure 6E–214. . . . . . . . . . . . . . . . . .

Fuel Injectors 6E–214. . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal and Installation Procedure 6E–214. . . . . .

Fuel Temperature Sensor 6E–214. . . . . . . . . . . . . . . .

Removal Procedure 6E–214. . . . . . . . . . . . . . . . . . . .

Installation Procedure 6E–215. . . . . . . . . . . . . . . . . .

Rail Pressure (RP) Sensor 6E–216. . . . . . . . . . . . . . .

Removal Procedure 6E–216. . . . . . . . . . . . . . . . . . . .

Installation Procedure 6E–216. . . . . . . . . . . . . . . . . .

Fuel Tank 6E–216. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal Procedure 6E–216. . . . . . . . . . . . . . . . . . . .

Throttle Body (TB) 6E–217. . . . . . . . . . . . . . . . . . . . . . .

Removal Procedure 6E–217. . . . . . . . . . . . . . . . . . . .

Installation Procedure 6E–217. . . . . . . . . . . . . . . . . .

Air Conditioning (A/C) Relay 6E–217. . . . . . . . . . . . . .

Removal Procedure 6E–217. . . . . . . . . . . . . . . . . . . .

Installation Procedure 6E–217. . . . . . . . . . . . . . . . . .

Exhaust Gas Recirculation (EGR) Vacuum

Switch Valve (VSV) 6E–217. . . . . . . . . . . . . . . . . . . . .

Removal Procedure 6E–217. . . . . . . . . . . . . . . . . . . .

Installation Procedure 6E–218. . . . . . . . . . . . . . . . . .

Electronic Vacuum Regurating Valve (EVRV) 6E–219

Removal Procedure 6E–219. . . . . . . . . . . . . . . . . . . .

Installation Procedure 6E–220. . . . . . . . . . . . . . . . . .

Wiring and Connectors 6E–220. . . . . . . . . . . . . . . . . . .

Wiring Harness Service 6E–220. . . . . . . . . . . . . . . .

Connectors and Terminals 6E–220. . . . . . . . . . . . . .

Wire Harness Repair: Twisted Shielded

Cable 6E–220. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal Procedure 6E–220. . . . . . . . . . . . . . . . . . . .

Installation Procedure 6E–221. . . . . . . . . . . . . . . . . .

Twisted Leads 6E–221. . . . . . . . . . . . . . . . . . . . . . . . . .

Removal Procedure 6E–221. . . . . . . . . . . . . . . . . . . .

Installation Procedure 6E–222. . . . . . . . . . . . . . . . . .

Weather-Pack Connector 6E–223. . . . . . . . . . . . . . . . .

Tools Required 6E–223. . . . . . . . . . . . . . . . . . . . . . . .

Removal Procedure 6E–223. . . . . . . . . . . . . . . . . . . . Installation Procedure 6E–223. . . . . . . . . . . . . . . . . .

Com-Pack III 6E–224. . . . . . . . . . . . . . . . . . . . . . . . . . .

General Information 6E–224. . . . . . . . . . . . . . . . . . . .

Metri-Pack 6E–224. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tools Required 6E–224. . . . . . . . . . . . . . . . . . . . . . . .

Removal Procedure 6E–224

. . . . . . . . . . . . . . . . . . . .

Installation Procedure 6E–224. . . . . . . . . . . . . . . . . .

General Description

(ECM and Sensors) 6E–225. . . . . . . . . . . . . . . . . . . . .

57X Reference ECM Input 6E–225. . . . . . . . . . . . . .

A/C Request Signal 6E–225. . . . . . . . . . . . . . . . . . . .

Crankshaft Position (CKP) Sensor 6E–225. . . . . . .

Camshaft Position (CMP) Sensor and

Signal 6E–225. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine Coolant Temperature (ECT) Sensor 6E–225

Electrically Erasable Programmable Read

Only Memory (EEPROM) 6E–225. . . . . . . . . . . . . .

Intake Air Temperature (IAT) Sensor 6E–225. . . . .

Manifold Absolute Pressure (MAP) Sensor 6E–226

Engine Control Module (ECM) 6E–226. . . . . . . . . . .

ECM Function 6E–226. . . . . . . . . . . . . . . . . . . . . . . . .

ECM Components 6E–226. . . . . . . . . . . . . . . . . . . . .

ECM Voltage Description 6E–226. . . . . . . . . . . . . . .

ECM Input/Outputs 6E–226. . . . . . . . . . . . . . . . . . . .

ECM Service Precautions 6E–227. . . . . . . . . . . . . .

Intake Throttle Position (ITP) Sensor 6E–227. . . . .

Transmission Range Switch 6E–227. . . . . . . . . . . . .

Accelerator Position Sensor (AP) 6E–227. . . . . . . .

Aftermarket Electrical and Vacuum

Equipment 6E–227. . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrostatic Discharge Damage 6E–227. . . . . . . . .

General Description (Air Induction) 6E–228. . . . . . . .

Air Induction System 6E–228. . . . . . . . . . . . . . . . . . .

General Description (Fuel Metering) 6E–228. . . . . . .

Deceleration Mode 6E–228. . . . . . . . . . . . . . . . . . . .

Fuel Injector 6E–228. . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Metering System Components 6E–228. . . . . .

A/C Clutch Diagnosis 6E–228. . . . . . . . . . . . . . . . . . . .

A/C Request Signal 6E–228. . . . . . . . . . . . . . . . . . . .

General Description Exhaust Gas

Recirculation (EGR) System 6E–228. . . . . . . . . . . . .

EGR Purpose 6E–228. . . . . . . . . . . . . . . . . . . . . . . . .

Fuse and Relay Panel

(Underhood Electrical Center) RHD 6E–229. . . . . . .

Fuse and Relay Panel

(Underhood Electrical Center) LHD 6E–230. . . . . . .