tire type OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 469 of 6000

4A2A–2

DIFFERENTIAL (REAR 220mm)

General Description

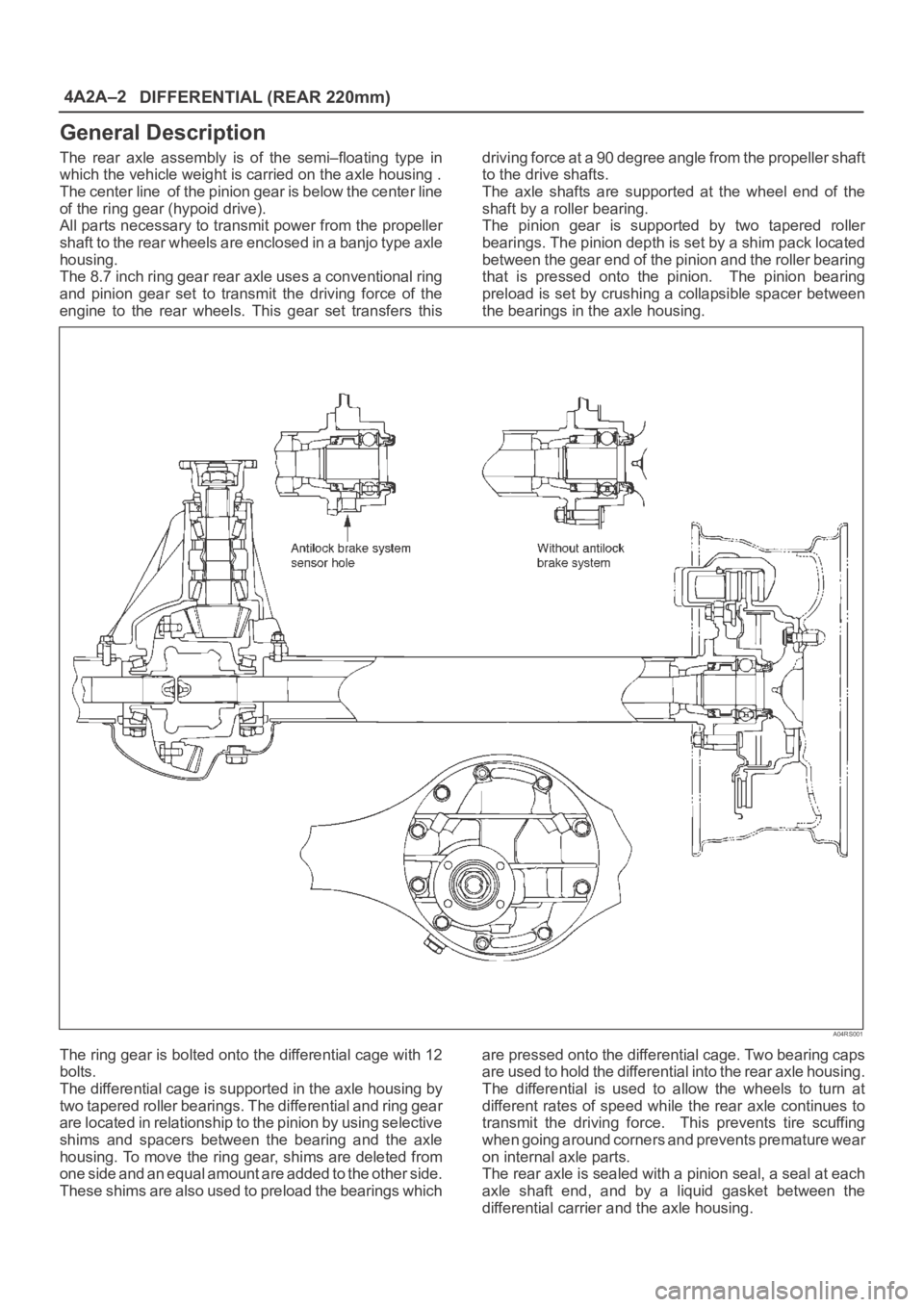

The rear axle assembly is of the semi–floating type in

which the vehicle weight is carried on the axle housing .

The center line of the pinion gear is below the center line

of the ring gear (hypoid drive).

All parts necessary to transmit power from the propeller

shaft to the rear wheels are enclosed in a banjo type axle

housing.

The 8.7 inch ring gear rear axle uses a conventional ring

and pinion gear set to transmit the driving force of the

engine to the rear wheels. This gear set transfers thisdriving force at a 90 degree angle from the propeller shaft

to the drive shafts.

The axle shafts are supported at the wheel end of the

shaft by a roller bearing.

The pinion gear is supported by two tapered roller

bearings. The pinion depth is set by a shim pack located

between the gear end of the pinion and the roller bearing

that is pressed onto the pinion. The pinion bearing

preload is set by crushing a collapsible spacer between

the bearings in the axle housing.

A04RS001

The ring gear is bolted onto the differential cage with 12

bolts.

The differential cage is supported in the axle housing by

two tapered roller bearings. The differential and ring gear

are located in relationship to the pinion by using selective

shims and spacers between the bearing and the axle

housing. To move the ring gear, shims are deleted from

one side and an equal amount are added to the other side.

These shims are also used to preload the bearings whichare pressed onto the differential cage. Two bearing caps

are used to hold the differential into the rear axle housing.

The differential is used to allow the wheels to turn at

different rates of speed while the rear axle continues to

transmit the driving force. This prevents tire scuffing

when going around corners and prevents premature wear

on internal axle parts.

The rear axle is sealed with a pinion seal, a seal at each

axle shaft end, and by a liquid gasket between the

differential carrier and the axle housing.

Page 470 of 6000

DIFFERENTIAL (REAR 220mm)

4A2A–3

Diagnosis

Many noises that seem to come from the rear axle

actually originate from other sources such as tires, road

surface, wheel bearings, engine, transmission, muffler, or

body drumming. Investigate to find the source of the

noise before disassembling the rear axle. Rear axles, like

any other mechanical device, are not absolutely quiet but

should be considered quiet unless some abnormal noise

is present.

To make a systematic check for axle noise, observe the

following:

1. Select a level asphalt road to reduce tire noise and

body drumming.

2. Check rear axle lubricant level to assure correct level,

and then drive the vehicle far enough to thoroughly

warm up the rear axle lubricant.

3. Note the speed at which noise occurs. Stop the

vehicle and put the transmission in neutral. Run the

engine speed slowly up and down to determine if the

noise is caused by exhaust, muffler noise, or other

engine conditions.

4. Tire noise changes with different road surfaces; axle

noises do not. Temporarily inflate all tires to 344 kPa

(3.5kg/cm

2, 50 psi) (for test purposes only). This will

change noise caused by tires but will not affect noise

caused by the rear axle.

Rear axle noise usually stops when coasting at

speeds under 48 km/h (30 mph); however, tire noise

continues with a lower tone. Rear axle noise usually

changes when comparing pull and coast, but tire

noise stays about the same.

Distinguish between tire noise and rear axle noise by

noting if the noise changes with various speeds or

sudden acceleration and deceleration. Exhaust and

axle noise vary under these conditions, while tire

noise remains constant and is more pronounced at

speeds of 32 to 48 km/h (20 to 30 mph). Further check

for tire noise by driving the vehicle over smooth

pavements or dirt roads (not gravel) with the tires at

normal pressure. If the noise is caused by tires, it will

change noticeably with changes in road surface.

5. Loose or rough front wheel bearings will cause noise

which may be confused with rear axle noise; however,

front wheel bearing noise does not change when

comparing drive and coast. Light application of the

brake while holding vehicle speed steady will often

cause wheel bearing noise to diminish. Front wheel

bearings may be checked for noise by jacking up the

wheels and spinning them or by shaking the wheels to

determine if bearings are loose.

6. Rear suspension rubber bushings and spring

insulators dampen out rear axle noise when correctly

installed. Check to see that there is no link or rod

loosened or metal–to–metal contact.

7. Make sure that there is no metal–to–metal contact

between the floor and the frame.

After the noise has been determined to be in the axle, the

type of axle noise should be determined, in order to make

any necessary repairs.

Gear Noise

Gear noise (whine) is audible from 32 to 89 km/h (20 to 55

mph) under four driving conditions.

1. Driving under acceleration or heavy pull.

2. Driving under load or under constant speed.

3. When using enough throttle to keep the vehicle from

driving the engine while the vehicle slows down

gradually (engine still pulls slightly).

4. When coasting with the vehicle in gear and the throttle

closed. The gear noise is usually more noticeable

between 48 and 64 km/h (30 and 40 mph) and 80 and

89 km/h (50 and 55 mph).

Bearing Noise

Bad bearings generally produce a rough growl or grating

sound, rather than the whine typical of gear noise.

Bearing noise frequently “wow–wows” at bearing rpm,

indicating a bad pinion or rear axle side bearing. This

noise can be confused with rear wheel bearing noise.

Rear Wheel Bearing Noise

Rear wheel bearing noise continues to be heard while

coasting at low speed with transmission in neutral. Noise

may diminish by gentle braking. Jack up the rear wheels,

spin them by hand and listen for noise at the hubs.

Replace any faulty wheel bearings.

Knock At Low Speeds

Low speed knock can be caused by worn universal joints

or a side gear hub counter bore in the cage that is worn

oversize. Inspect and replace universal joints or cage and

side gears as required.

Backlash Clunk

Excessive clunk on acceleration and deceleration can be

caused by a worn rear axle pinion shaft, a worn cage,

excessive clearance between the axle and the side gear

splines, excessive clearance between the side gear hub

and the counterbore in the cage, worn pinion and side

gear teeth, worn thrust washers, or excessive drive pinion

and ring gear backlash. Remove worn parts and replace

as required. Select close–fitting parts when possible.

Adjust pinion and ring gear backlash.

Page 505 of 6000

4A2B–2DIFFERENTIAL (REAR 244mm)

General Description

The rear axle assembly is of the semi–floating type in

which the vehicle weight is carried on the axle housing .

The center line of the pinion gear is below the center line

of the ring gear (hypoid drive).

All parts necessary to transmit power from the propeller

shaft to the rear wheels are enclosed in a banjo type axle

housing.

The 9.61 inch ring gear rear axle uses a conventional ring

and pinion gear set to transmit the driving force of the

engine to the rear wheels. This gear set transfers thisdriving force at a 90 degree angle from the propeller shaft

to the drive shafts.

The axle shafts are supported at the wheel end of the

shaft by a roller bearing.

The pinion gear is supported by two tapered roller

bearings. The pinion depth is set by a shim pack located

between the gear end of the pinion and the roller bearing

that is pressed onto the pinion. The pinion bearing

preload is set by crushing a collapsible spacer between

the bearings in the axle housing.

A04RW001

The ring gear is bolted onto the differential cage with 12

bolts.

The differential cage is supported in the axle housing by

two tapered roller bearings. The differential and ring gear

are located in relationship to the pinion by using selective

shims and spacers between the bearing and the axle

housing. To move the ring gear, shims are deleted from

one side and an equal amount are added to the other side.

These shims are also used to preload the bearings whichare pressed onto the differential cage. Two bearing caps

are used to hold the differential into the rear axle housing.

The differential is used to allow the wheels to turn at

different rates of speed while the rear axle continues to

transmit the driving force. This prevents tire scuffing

when going around corners and prevents premature wear

on internal axle parts.

The rear axle is sealed with a pinion seal, a seal at each

axle shaft end, and by a liquid gasket between the

differential carrier and the axle housing.

Page 506 of 6000

DIFFERENTIAL (REAR 244mm)

4A2B–3

Diagnosis

Many noises that seem to come from the rear axle

actually originate from other sources such as tires, road

surface, wheel bearings, engine, transmission, muffler, or

body drumming. Investigate to find the source of the

noise before disassembling the rear axle. Rear axles, like

any other mechanical device, are not absolutely quiet but

should be considered quiet unless some abnormal noise

is present.

To make a systematic check for axle noise, observe the

following:

1. Select a level asphalt road to reduce tire noise and

body drumming.

2. Check rear axle lubricant level to assure correct level,

and then drive the vehicle far enough to thoroughly

warm up the rear axle lubricant.

3. Note the speed at which noise occurs. Stop the

vehicle and put the transmission in neutral. Run the

engine speed slowly up and down to determine if the

noise is caused by exhaust, muffler noise, or other

engine conditions.

4. Tire noise changes with different road surfaces; axle

noises do not. Temporarily inflate all tires to 344 kPa

(3.5kg/cm

2, 50 psi) (for test purposes only). This will

change noise caused by tires but will not affect noise

caused by the rear axle.

Rear axle noise usually stops when coasting at

speeds under 48 km/h (30 mph); however, tire noise

continues with a lower tone. Rear axle noise usually

changes when comparing pull and coast, but tire

noise stays about the same.

Distinguish between tire noise and rear axle noise by

noting if the noise changes with various speeds or

sudden acceleration and deceleration. Exhaust and

axle noise vary under these conditions, while tire

noise remains constant and is more pronounced at

speeds of 32 to 48 km/h (20 to 30 mph). Further check

for tire noise by driving the vehicle over smooth

pavements or dirt roads (not gravel) with the tires at

normal pressure. If the noise is caused by tires, it will

change noticeably with changes in road surface.

5. Loose or rough front wheel bearings will cause noise

which may be confused with rear axle noise; however,

front wheel bearing noise does not change when

comparing drive and coast. Light application of the

brake while holding vehicle speed steady will often

cause wheel bearing noise to diminish. Front wheel

bearings may be checked for noise by jacking up the

wheels and spinning them or by shaking the wheels to

determine if bearings are loose.

6. Rear suspension rubber bushings and spring

insulators dampen out rear axle noise when correctly

installed. Check to see that there is no link or rod

loosened or metal–to–metal contact.

7. Make sure that there is no metal–to–metal contact

between the floor and the frame.

After the noise has been determined to be in the axle, the

type of axle noise should be determined, in order to make

any necessary repairs.

Gear Noise

Gear noise (whine) is audible from 32 to 89 km/h (20 to 55

mph) under four driving conditions.

1. Driving under acceleration or heavy pull.

2. Driving under load or under constant speed.

3. When using enough throttle to keep the vehicle from

driving the engine while the vehicle slows down

gradually (engine still pulls slightly).

4. When coasting with the vehicle in gear and the throttle

closed. The gear noise is usually more noticeable

between 48 and 64 km/h (30 and 40 mph) and 80 and

89 km/h (50 and 55 mph).

Bearing Noise

Bad bearings generally produce a rough growl or grating

sound, rather than the whine typical of gear noise.

Bearing noise frequently “wow–wows” at bearing rpm,

indicating a bad pinion or rear axle side bearing. This

noise can be confused with rear wheel bearing noise.

Rear Wheel Bearing Noise

Rear wheel bearing noise continues to be heard while

coasting at low speed with transmission in neutral. Noise

may diminish by gentle braking. Jack up the rear wheels,

spin them by hand and listen for noise at the hubs.

Replace any faulty wheel bearings.

Knock At Low Speeds

Low speed knock can be caused by worn universal joints

or a side gear hub counter bore in the cage that is worn

oversize. Inspect and replace universal joints or cage and

side gears as required.

Backlash Clunk

Excessive clunk on acceleration and deceleration can be

caused by a worn rear axle pinion shaft, a worn cage,

excessive clearance between the axle and the side gear

splines, excessive clearance between the side gear hub

and the counterbore in the cage, worn pinion and side

gear teeth, worn thrust washers, or excessive drive pinion

and ring gear backlash. Remove worn parts and replace

as required. Select close–fitting parts when possible.

Adjust pinion and ring gear backlash.

Page 657 of 6000

DRIVE LINE CONTROL SYSTEM (TOD) 4B2–86

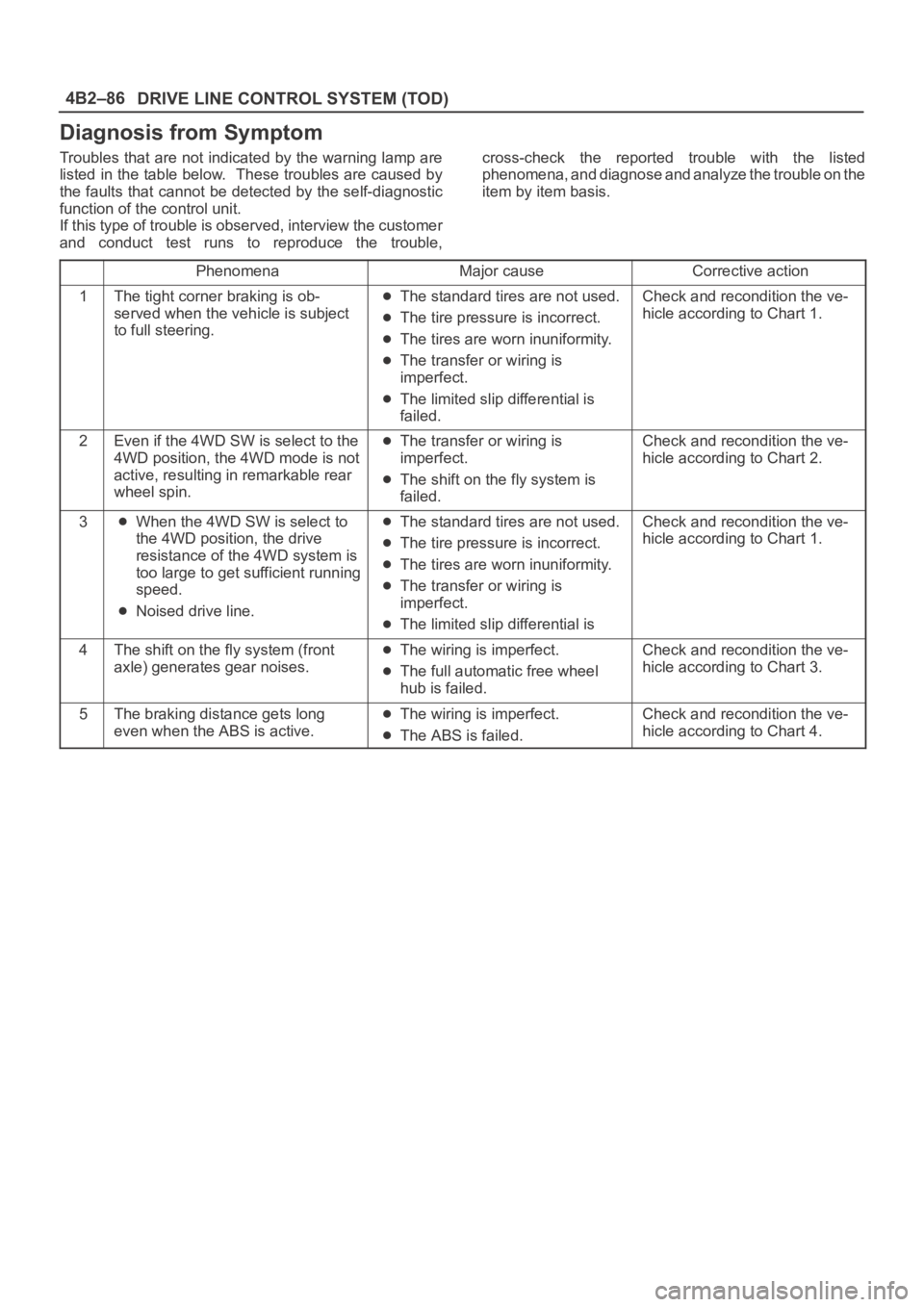

Diagnosis from Symptom

Troubles that are not indicated by the warning lamp are

listed in the table below. These troubles are caused by

the faults that cannot be detected by the self-diagnostic

function of the control unit.

If this type of trouble is observed, interview the customer

and conduct test runs to reproduce the trouble,cross-check the reported trouble with the listed

phenomena, and diagnose and analyze the trouble on the

item by item basis.

PhenomenaMajor causeCorrective action

1The tight corner braking is ob-

served when the vehicle is subject

to full steering.The standard tires are not used.

The tire pressure is incorrect.

The tires are worn inuniformity.

The transfer or wiring is

imperfect.

The limited slip differential is

failed.

Check and recondition the ve-

hicle according to Chart 1.

2Even if the 4WD SW is select to the

4WD position, the 4WD mode is not

active, resulting in remarkable rear

wheel spin.The transfer or wiring is

imperfect.

The shift on the fly system is

failed.

Check and recondition the ve-

hicle according to Chart 2.

3When the 4WD SW is select to

the 4WD position, the drive

resistance of the 4WD system is

too large to get sufficient running

speed.

Noised drive line.

The standard tires are not used.

The tire pressure is incorrect.

The tires are worn inuniformity.

The transfer or wiring is

imperfect.

The limited slip differential is

Check and recondition the ve-

hicle according to Chart 1.

4The shift on the fly system (front

axle) generates gear noises.The wiring is imperfect.

The full automatic free wheel

hub is failed.

Check and recondition the ve-

hicle according to Chart 3.

5The braking distance gets long

even when the ABS is active.The wiring is imperfect.

The ABS is failed.

Check and recondition the ve-

hicle according to Chart 4.

Page 659 of 6000

DRIVE LINE CONTROL SYSTEM (TOD) 4B2–88

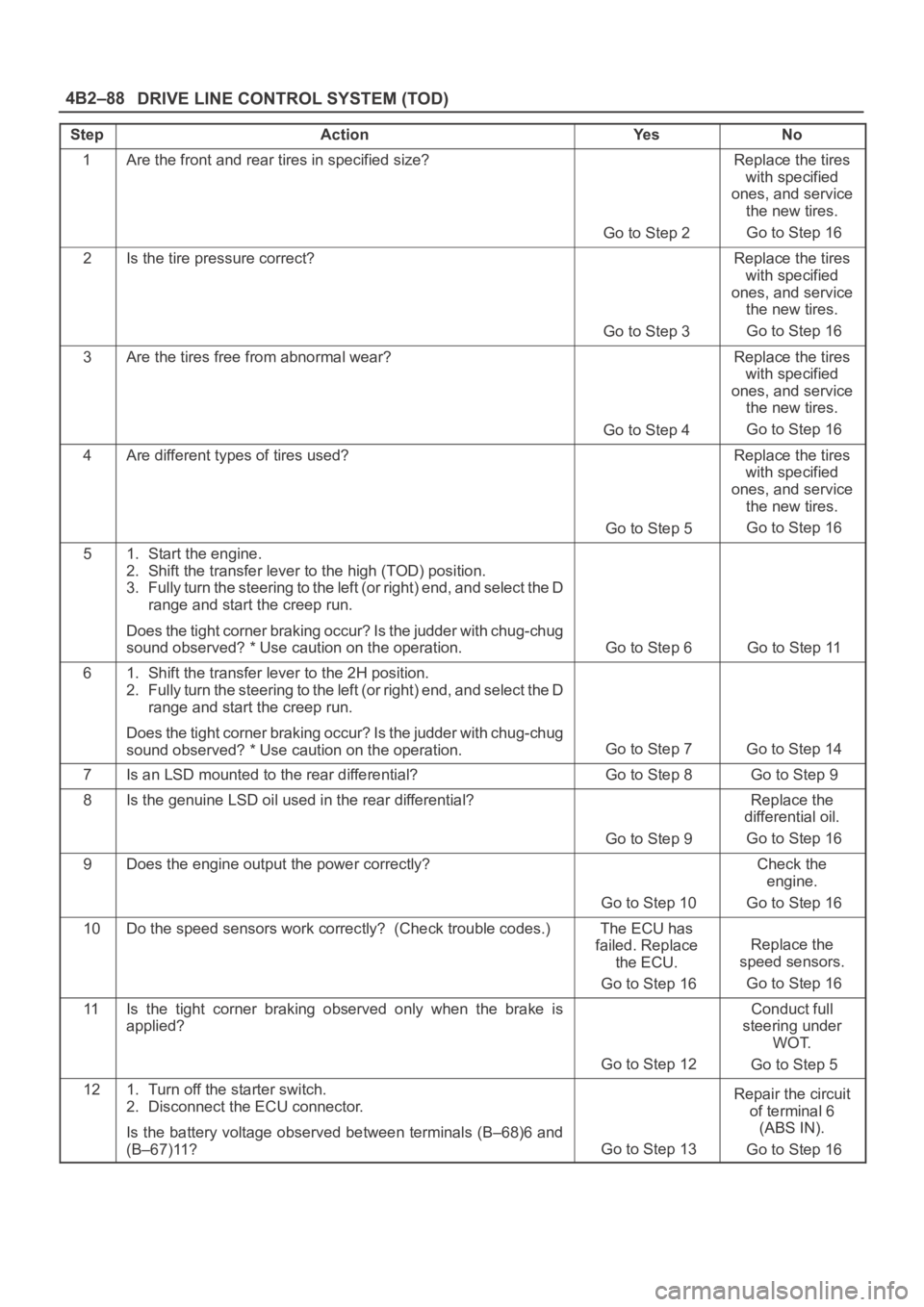

StepActionYe sNo

1Are the front and rear tires in specified size?

Go to Step 2

Replace the tires

with specified

ones, and service

the new tires.

Go to Step 16

2Is the tire pressure correct?

Go to Step 3

Replace the tires

with specified

ones, and service

the new tires.

Go to Step 16

3Are the tires free from abnormal wear?

Go to Step 4

Replace the tires

with specified

ones, and service

the new tires.

Go to Step 16

4Are different types of tires used?

Go to Step 5

Replace the tires

with specified

ones, and service

the new tires.

Go to Step 16

51. Start the engine.

2. Shift the transfer lever to the high (TOD) position.

3. Fully turn the steering to the left (or right) end, and select the D

range and start the creep run.

Does the tight corner braking occur? Is the judder with chug-chug

sound observed? * Use caution on the operation.

Go to Step 6 Go to Step 11

61. Shift the transfer lever to the 2H position.

2. Fully turn the steering to the left (or right) end, and select the D

range and start the creep run.

Does the tight corner braking occur? Is the judder with chug-chug

sound observed? * Use caution on the operation.

Go to Step 7 Go to Step 14

7Is an LSD mounted to the rear differential? Go to Step 8 Go to Step 9

8Is the genuine LSD oil used in the rear differential?

Go to Step 9

Replace the

differential oil.

Go to Step 16

9Does the engine output the power correctly?

Go to Step 10

Check the

engine.

Go to Step 16

10Do the speed sensors work correctly? (Check trouble codes.)The ECU has

failed. Replace

the ECU.

Go to Step 16

Replace the

speed sensors.

Go to Step 16

11Is the tight corner braking observed only when the brake is

applied?

Go to Step 12

Conduct full

steering under

WOT.

Go to Step 5

121. Turn off the starter switch.

2. Disconnect the ECU connector.

Is the battery voltage observed between terminals (B–68)6 and

(B–67)11?

Go to Step 13

Repair the circuit

of terminal 6

(ABS IN).

Go to Step 16

Page 1081 of 6000

6D1–2

ENGINE ELECTRICAL

Battery

General Description

There are six battery fluid caps on top of the battery.

These are covered by a paper label.

The battery is completely sealed except for the six small

vent holes on the side. These vent holes permit the

escape of small amounts of gas generated by the battery.

This type of battery has the following advantages over

conventional batteries:

1. There is no need to add water during the entire

service life of the battery.

2. The battery protects itself against overcharging.

The battery will refuse to accept an extensive charge.

(A conventional battery will accept an excessive

charge, resulting in gassing and loss of battery fluid.)

3. The battery is much less vulnerable to self discharge

than a conventional type battery.

Diagnosis

1. Visual Inspection

Inspect the battery for obvious physical damage, such as

a cracked or broken case, which would permit electrolyte

loss.

Replace the battery if obvious physical damage is

discovered during inspection.

Check for any other physical damage and correct it as

necessary.

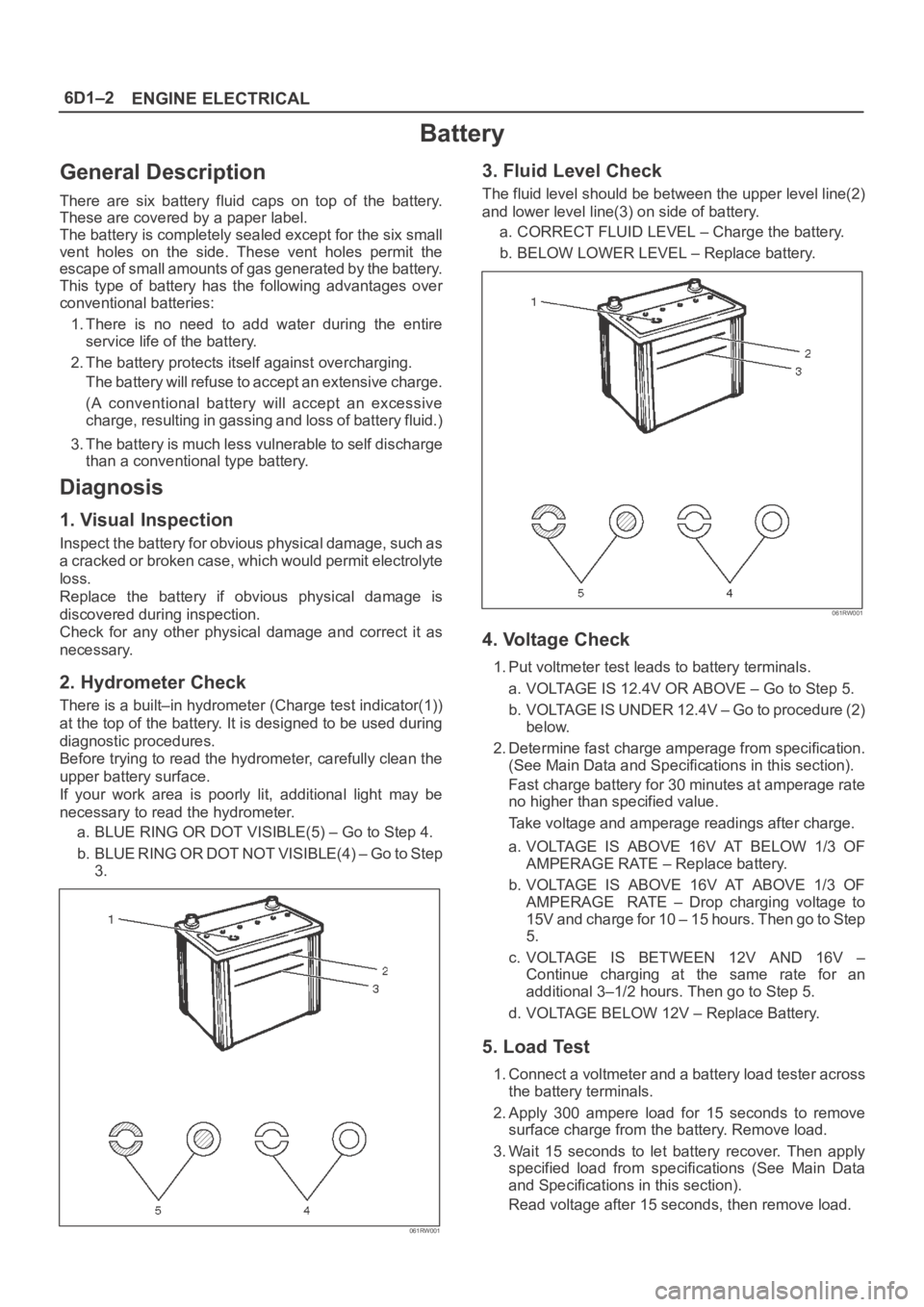

2. Hydrometer Check

There is a built–in hydrometer (Charge test indicator(1))

at the top of the battery. It is designed to be used during

diagnostic procedures.

Before trying to read the hydrometer, carefully clean the

upper battery surface.

If your work area is poorly lit, additional light may be

necessary to read the hydrometer.

a. BLUE RING OR DOT VISIBLE(5) – Go to Step 4.

b . B L U E R I N G O R D O T N O T V I S I B L E ( 4 ) – G o t o S t e p

3.

061RW001

3. Fluid Level Check

The fluid level should be between the upper level line(2)

and lower level line(3) on side of battery.

a. CORRECT FLUID LEVEL – Charge the battery.

b. BELOW LOWER LEVEL – Replace battery.

061RW001

4. Voltage Check

1. Put voltmeter test leads to battery terminals.

a. VOLTAGE IS 12.4V OR ABOVE – Go to Step 5.

b. VOLTAGE IS UNDER 12.4V – Go to procedure (2)

below.

2. Determine fast charge amperage from specification.

(See Main Data and Specifications in this section).

Fast charge battery for 30 minutes at amperage rate

no higher than specified value.

Take voltage and amperage readings after charge.

a. VOLTAGE IS ABOVE 16V AT BELOW 1/3 OF

AMPERAGE RATE – Replace battery.

b. VOLTAGE IS ABOVE 16V AT ABOVE 1/3 OF

AMPERAGE RATE – Drop charging voltage to

15V and charge for 10 – 15 hours. Then go to Step

5.

c. VOLTAGE IS BETWEEN 12V AND 16V –

Continue charging at the same rate for an

additional 3–1/2 hours. Then go to Step 5.

d. VOLTAGE BELOW 12V – Replace Battery.

5. Load Test

1. Connect a voltmeter and a battery load tester across

the battery terminals.

2. Apply 300 ampere load for 15 seconds to remove

surface charge from the battery. Remove load.

3. Wait 15 seconds to let battery recover. Then apply

specified load from specifications (See Main Data

and Specifications in this section).

Read voltage after 15 seconds, then remove load.

Page 1089 of 6000

6D2–4

IGNITION SYSTEM

Spark Plug

Removal

1. Remove spark plugs.

Inspection and Repair

The spark plug affects entire engine performance and

therefore its inspection is very important.

Check electrode and insulator for presence of cracks,

and replace if any.

Check electrode for wear, and replace if necessary.

Check gasket for damage, and replace if necessary.

Measure insulation resistance with an ohmmeter, and

replace if faulty.

Adjust spark plug gap to 1.0 mm (0.04 in) 1.1 mm

(0.043 in).

Check fuel and electrical systems if spark plug is

extremely dirty.

Use spark plugs having low heat value (hot type plug)

if fuel and electrical systems are normal.

Use spark plugs having high heat value (cold type

plug) if insulator and electrode are extremely burned.

Sooty Spark Plugs

Much deposit of carbon or oil on the electrode and

insulator of spark plug reduces the engine performance.

Possible causes:

Too rich mixture

Presence of oil in combustion chamber

Incorrectly adjusted spark plug gap

Burning Electrodes

This fault is characterized by scorched or heavily oxidized

electrode or blistered insulator nose.

Possible causes:

Too lean mixture

Improper heat value

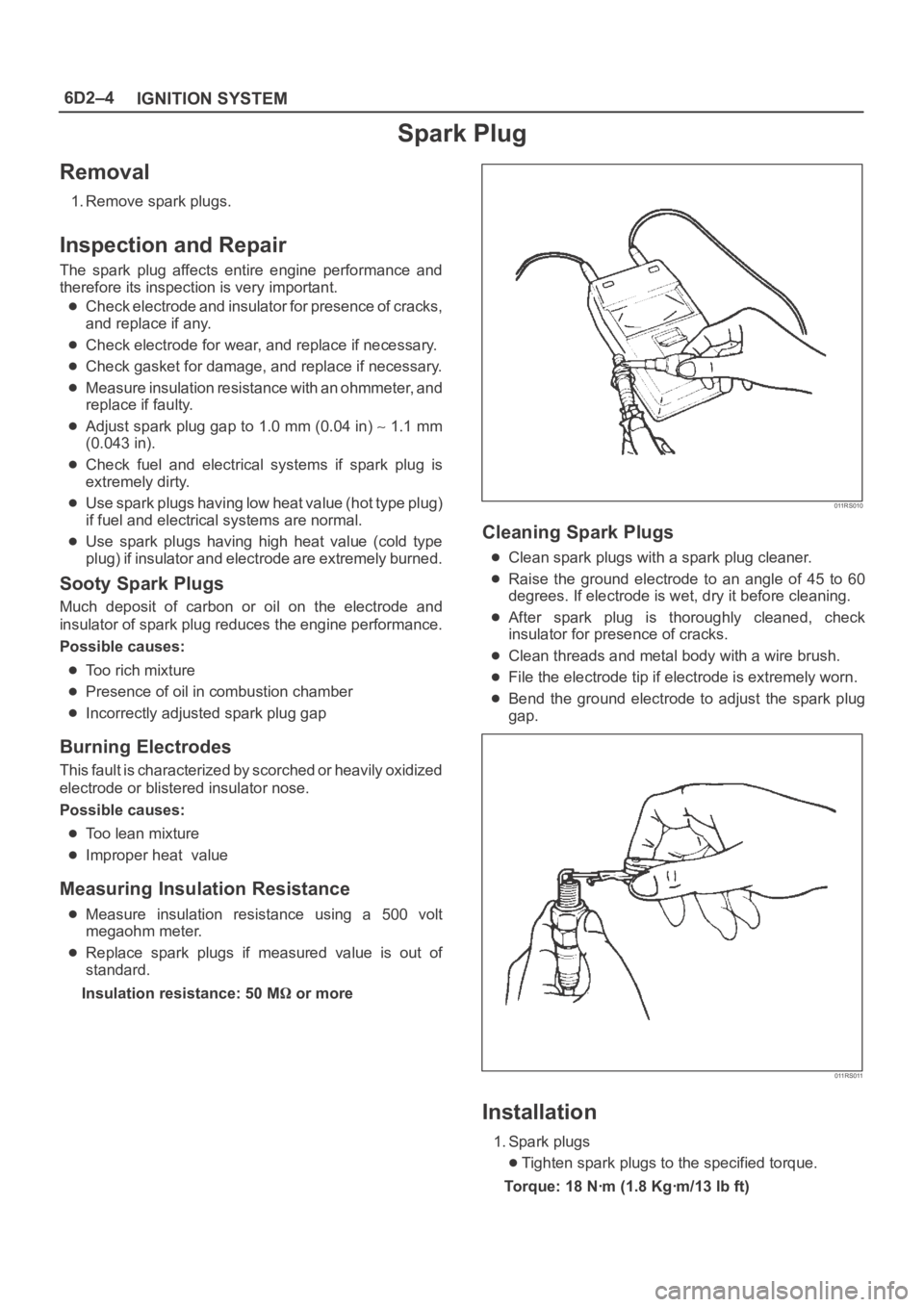

Measuring Insulation Resistance

Measure insulation resistance using a 500 volt

megaohm meter.

Replace spark plugs if measured value is out of

standard.

Insulation resistance: 50 M

or more

011RS010

Cleaning Spark Plugs

Clean spark plugs with a spark plug cleaner.

Raise the ground electrode to an angle of 45 to 60

degrees. If electrode is wet, dry it before cleaning.

After spark plug is thoroughly cleaned, check

insulator for presence of cracks.

Clean threads and metal body with a wire brush.

File the electrode tip if electrode is extremely worn.

Bend the ground electrode to adjust the spark plug

gap.

011RS011

Installation

1. Spark plugs

Tighten spark plugs to the specified torque.

Torque: 18 Nꞏm (1.8 Kgꞏm/13 lb ft)

Page 1868 of 6000

ENGINE ELECTRICAL 6D – 1

ENGINE ELECTRICAL

CONTENTS

Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6D–1

General Description . . . . . . . . . . . . . . . . 6D–1

Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . 6D–1

On Vehicle Service . . . . . . . . . . . . . . . . . 6D–3

Main Data and Specification . . . . . . . . . . 6D–4

Starting System . . . . . . . . . . . . . . . . . . . . . 6D–5

General Description . . . . . . . . . . . . . . . . 6D–5

On Vehicle Service . . . . . . . . . . . . . . . . . 6D–7

Starter . . . . . . . . . . . . . . . . . . . . . . . . . . 6D–7

Unit Repair . . . . . . . . . . . . . . . . . . . . . . . 6D–8Charging System . . . . . . . . . . . . . . . . . . . . 6D–15

General Description . . . . . . . . . . . . . . . . 6D–15

Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . 6D–16

Unit Repair . . . . . . . . . . . . . . . . . . . . . . . 6D–17

Main Data and Specification . . . . . . . . . . 6D–22

QOS4 Preheating System . . . . . . . . . . . . . . 6D–23

General Description . . . . . . . . . . . . . . . . 6D–23

System Diagram . . . . . . . . . . . . . . . . . . . 6D–23

Inspection of QOS4 System Operation . . 6D–24

BATTERY

GENERAL DESCRIPTION

DIAGNOSIS

There are six battery fluid caps at the top of the battery.

These are covered by a paper label.

The battery is completely sealed except for the six

small vent holes at the side. These vent holes permit

the escape of small amounts of gas generated by the

battery.

This type of battery has the following advantages over

conventional batteries:1. There is no need to add water during the entire

service life of the battery.

2. The battery protects itself against overcharging.

The battery will refuse to accept an excessive

charge.

(A conventional battery will accept an excessive

charge, resulting in gassing and loss of battery

fluid.)

3. The battery is much less vulnerable to self-

discharge than a conventional type battery.

1. VISUAL INSPECTION (Step 1)

Inspect the battery for obvious physical damage, such

as a cracked or broken case, which would permit

electrolyte loss.

Replace the battery if obvious physical damage is

discovered during inspection.

Check for any other physical damage and correct it as

necessary. If not, proceed to Step 2.

2. HYDROMETER CHECK (Step 2)

There is a built-in hydrometer (Charge test indicator) at

the top of the battery. It is designed to be used during

diagnostic procedures.

Before trying to read the hydrometer, carefully clean the

upper battery surface.

If your work area is poorly lit, additional light may be

necessary to read the hydrometer.

a. BLUE RING OR DOT VISIBLE – Go to Step 4.

b. BLUE RING OR DOT NOT VISIBLE – Go to

Step 3.3. FLUID LEVEL CHECK (Step 3)

The fluid level should be between the upper level line

and lower level line on side of the battery.

a. CORRECT FLUID LEVEL – Charge the battery.

b. BELOW LOWER LEVEL – Replace battery.

4. VOLTAGE CHECK (Step 4)

(1) Put voltmeter test leads to battery terminals.

a. VOLTAGE IS 12.4V OR ABOVE – Go to Step 5.

b. VOLTAGE IS UNDER 12.4V – Go to procedure

(2) below.

(2) Determine fast charge amperage from

specification. (See Main Data and Specifications in

this section.)

Fast charge battery for 30 minutes at amperage

rate no higher than specified value.

Take voltage and amperage readings after charge.

a. VOLTAGE IS ABOVE 16V AT BELOW 1/3 OF

AMPERAGE RATE – Replace battery.

Page 3449 of 6000

SUPPLEMENTAL RESTRAINT SYSTEM 9J–12

Deployed Air Bag Assembly (Driver Side)

“You should wear gloves and glasses. After the air bag

assembly has been deployed, the surface of the air bag

may contain solid particulate. This solid particulate

c o n s i s t s p r i m a r i l y o f b y p r oducts of the chemical reaction,

Potassium Chloride and copper metal dust. Compounds

of Potassium Borate, Strontium Chloride, Copper

Chloride, and Ammonium Chloride may be found in

amounts of about 1% (each) of the total particulate.”

Deployed Pretensioner Seat Belt.

You should wear gloves and safety glasses. After the

pretensioner seat belt has been deployed, the surface of

the pretensioner seat belt cylinder may heating up.

Air Bag Assembly and/or Pretensioner

Seat Belt Scrapping Procedure.

During the cause of vehicle’s useful life, certain situations

may arise which will necessitate the disposal of a live air

bag and/or pretensioner seat belt. (This information

covers proper procedures for disposing of a live air bag

assembly and/or pretensioner seat belt.)

Before a live air bag assembly can be dispose off, it must

be deployed.

A live air bag assembly and/or pretensioner seat belt

must not be disposed of though normal refuse channels.

WARNING: FAILURE TO FOLLOW PROPER

SUPPLEMENTAL RESTRAINT SYSTEM (SRS) AIR

BAG ASSEMBLY DISPOSAL PROCEDURES CAN

RESULT IN AIR BAG DEPLOYMENT WHICH MAY

CAUSE PERSONAL INJURY. AN UNDPLOYED AIR

BAG ASSEMBLY MUST NOT BE DISPOSED OF

THROUGH NORMAL REFUSE CHANNELS. THE

UNDEPLOYED AIR BAG ASSEMBLY CONTAINS

SUBSTANCES THAT CAN CAUSE SEVERE ILLNESS

OR PERSONAL INJURY IF THE SEALED CONTAINER

IS DAMAGED DURING DISPOSAL. DISPOSAL IN

ANY MANNER INCONSISTENT WITH PROPER

PROCEDURES MAY BE A VIOLATION OF LOCAL

LAW.

In situations which require deployment of a live air bag

assembly, deployment may be accomplished inside or

outside the vehicle. The method employed depends

upon the final disposition of the particular vehicle, as

noted in “Deployment Outside Vehicle” and “Deployment

Inside Vehicle” in this section.

Cautions About Air Bag Deployment And

Disposal

Failure to follow proper procedures could result in

erroneous air bag deployment which may cause personal

injury be sure to follow proper procedures.

1. Turn off (Lock) the ignition switch and disconnect the

minus terminal of the battery, then start the work 15 or

more sec later. (Air bag is designed to work by the

back-up power source even if the battery power

source is cut off at vehicle collision).

2. Be sure not to disassemble the air bag.

3. Do not give an impact to the air bag and bring the air

bag close to magnet. (The air bag could deploy

unexpectedly).4. Place the air bag with its trim cover up.

5. Do not let the air bag deploy directly on the floor. (The

air bag may be blown off 2

3 m (6.5 or 10 feet)).

6. Be sure to install the air bag firmly to a deployment

tool (fixing tool).

7. Set a battery 10 m (33 feet) or more away from the air

bag.

8. Before disconnecting air bag harness, ground the

worker by touching the vehicle outer panel with bare

hand.

9. When connecting or disconnecting the harness, do

not work just in front of the air bag.

10. As deployment gives rise to big sound, warn the

people around against it. Further, try to reduce the

sound by covering the steering wheel or tires, and

shut the vehicle windows in case of deployment

inside the vehicle.

11. As deployment generates smoke, select a well

ventilated place. (In case of deployment indoors,

avoid deployment just under a fire alarm, smoke

sensor, and fluorescent lamps).

12. Be careful not to inhale the smoke after deployment.

13. If part of the vehicle glass is damaged, cover the

vehicle with a car cover to prevent the glass from

braking at the time of deployment.

14. Do not touch the air bag immediately after

deployment, since it remains hot for 30 minutes.

15. Do not water the air bag immediately after

deployment.

16. Wear safety glasses and gloves throughout the work

and wash the glasses and gloves after the work.

17. Do not reuse the removed air bag for another vehicle.

(Deployment characteristic is different with vehicle

types).

Deployment Outside Vehicle (Driver Air

Bag Assembly)

Deployment outside the vehicle is proper when the

vehicle is to be returned to service. This includes, for

example, situations in which the vehicle will be returned to

useful service after a functionally or cosmetically deficient

air bag assembly is replaced. Deployment and disposal

of a malfunctioning air bag assembly is, of course, subject

to any required retention period.

For deployment of a live (undeployed) air bag assembly

outside the vehicle, the deployment procedure must be

followed exactly. Always wear safety glasses during this

deployment procedure until a deployed air bag assembly

is scrapped or until an undeployed air bag assembly is

shipped. Before performing the procedures you should

be familiar with servicing the SRS and with proper

handling of the air bag assembly. Procedures should be

read fully before they are performed.

The following procedure requires use of 5–8840–2468–0

SRS deployment harness with appropriate pigtail

adapter. Do not attempt procedure without

5–8840–2468–0 adapter.

WARNING: FAILURE TO FOLLOW PROCEDURES IN

THE ORDER LISTED MAY RESULT IN PERSONAL

INJURY. NEVER CONNECT DEPLOYMENT