engine oil OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 5687 of 6000

6J – 10 INDUCTION

INTAKE MANIFOLD

REMOVAL

1. Drain engine coolant and remove water hose from

thermostat housing

2. Remove intercooler assembly.

3. Remove bracket fixing bolt of oil level gauge guide

tube.

4. Remove PCV hose.

5. Remove hoses from EGR valve, EGR vacuum

sensor and outlet of heater unit.

6. Disconnect harness connector from MAP sensor,

EGR vacuum sensor, ETC sensor, Water

temperature unit, IAT sensor and EVRV.

7. Remove high pressure oil pipe.

8. Remove two way check valve.

9. Remove fuel pipe.

10. Remove fixing bolts and nuts of intake manifold,

remove intake manifold assembly.

Legend

(1) Intake manifold

(2) Fixing portion of throttle valve

(3) EGR passage

(4) EGR valve

2

3

4

1

Legend

(1) Intake Manifold

(2) Throttle Valve Assembly

(3) EGR Valve

(4) Gasket

025RW022

3124

025RW031

Page 5688 of 6000

INDUCTION 6J – 11

INSPECTION AND RAPAIR

1. Visually check for cracks/clogs inside intake

manifold.

2. If foreign material is observed, it should be taken

out, and if there are some cracks on the intake

manifold, it must be replaced.

INSTALLATION

1. Install the intake manifold assembly, tighten bolts

and to the specified torque.

Torque: 20 Nꞏm (2.0 kgꞏm / 14.5 lb ft) for bolt

Torque: 20 Nꞏm (2.0 kgꞏm / 14.5 lb ft) for nut

2. Install fuel pipe.

Torque: 4 Nꞏm (0.4 kgꞏm / 2.9 lb ft) for M16 nut

(Apply engine oil)

Torque: 13 Nꞏm (1.3 kgꞏm / 9.4 lb ft) for M10 cap nut

Torque: 14 Nꞏm (1.4 kgꞏm / 10 lb ft) for M10

(Apply engine oil)

3. Install two way check valve.

Torque: 20 Nꞏm (2.0 kgꞏm / 14.5 lb ft)

4. Fill with about 300 cc of engine oil from the high

pressure oil pipe installation port of the oil rail using

an oil filler.

If assembled without filling the oil rail with oil, the

time for engine starting will be longer.

5. Install high pressure oil pipe, then tighten sleeve nut

to the specified torque.

Torque: 29 Nꞏm (3.0 kgꞏm / 21.7 lb ft)

6. Reconnect harness connector to MAP sensor, EGR

vacuum sensor, ETC sensor, Water thermo unit,

IAT sensor and EVRV sensor.

7. Install hoses to EGR valve, EGR vacuum sensor

and Water outlet of heater.

8. Connect PCV hose.

9. Install oil level gauge guide and fix it.

10. Install intercooler assembly.

Refer to “Intercooler” in this manual.

11. Install water hose to thermostat housing and fill with

engine coolant.

Model of Turbocharger IHI RHF5

Turbine Maximum Speed 180,000 rpm

Maximum Inlet Gas Temperature 800 °C (1472 °F)

Vibration Peak (G) criteria Maximum 4 (G) at Turbine Rotor Speed 140,000 rpm

Tolerance Limit of Compressor Blade Height Less then 0.5 mm (0.0197 in)

MAIN DATA AND SPECIFICATIONS

Page 5694 of 6000

7A–5 AUTOMATIC TRANSMISSION (4L30–E)

Normal Operation Of 2000 4L30–E

Tr a n s m i s s i o n

Torque Converter Clutch (TCC)

Application Conditions:

The TCC is normally applied in 2nd, 3rd and 4th gears

only when all of the following conditions exist:

— The engine coolant temperature is above 70

C

(158

F).

— The brake pedal is released.

— The shift pattern requests TCC apply.

Moreover, TCC is always applied in 2nd, 3rd and 4th

gears when the transmission oil temperature is above

135

C (275F).

This mode should be canceled at 125

C (257F).

ATF Warning Lamp

The ATF warning lamp will be constantly on (not flashing)

if the transmission oil temperature is above 145

C

(293

F).

The ATF warning lamp goes off again when the

transmission oil temperature is below 125

C (257F).

Special Shift Pattern When The Engine Is

Cold:

A special shift pattern is activated when the engine

coolant temperature is below 70

C (158F). (3–4 shifts,

for example, are delayed for small throttle openings and

will occur a few MPH higher.)

Diagnosis

Introduction

The systematic troubleshooting information covered by

this Section offers a practical and systematic approach to

diagnosing 4L30–E transmission, using information that

can be obtained from road tests, electrical diagnosis, oil

pressure checks or noise evaluation.

The key to correcting a complaint is to make use of all of

the available symptoms and logically letting them direct

you to the cause.

When dealing with automatic transmission complaints, it

is best to gather as many symptoms as possible before

making the decision to remove the transmission from the

vehicle.

Frequently, the correction of the complaint does not

require removal of the transmission from the vehicle.

Driver Information

To analyze the problem fill out a complete description of

the owner’s complaint.

Please draw a circle around the right information and

complete the following form. (The next page is an

example of a completed form). You can draw a circle

around many numbers if you are not sure.

Page 5699 of 6000

7A–10

AUTOMATIC TRANSMISSION (4L30–E)

Checking Transmission Fluid Level

and Condition

Checking fluid level and condition (color and odor) at

regular intervals will provide early diagnosis information

about the transmission. This information may be used to

correct a condition that, if not detected early, could result

in major transmission repairs.

IMPORTANT:When new, automatic transmission fluid

is red in color. As the vehicle is driven, the transmission

fluid will begin to look darker in color. The color may

eventually appear light brown.

A dark brown color with burnt odor may indicate

excessive fluid deterioration and signal a need for fluid

change.

Fluid Level

When adding or changing fluid, use only DEXRON –III.

Refer to Maintenance and Lubrication in General

Information section for maintenance information and

servicing interval.

CAUTION: DO NOT OVERFILL.

Overfilling will cause foaming, loss of fluid, abnor-

mal shifting and possible damage to the transmis-

sion.

1. Park the vehicle on level ground and apply the parking

brake firmly.

2. Check fluid level with engine running at idle.

NOTE: Be sure that transmission fluid temperature is

below 30

C (86F).

3. Move the selector lever through all gear ranges.

4. Move the selector lever to “Park”.

5. Let engine idle for 3 minutes and open the overfill

screw (1).

6. Add released transmission fluid until it flows out over

the overfill screw opening.

7. Let engine idle until a fluid temperature between 32

C

(90

F) and 57C (135F) is reached, then close the

overfill screw (1).

Torque: 38 N

m (3.9 kgꞏm/28 lb ft)

NOTE: To prevent fluid leaks, the overfill screw and oil

drain screws gasket must be replaced each time these

screws are removed.NOTE: Check transmission fluid temperature with scan

tool.

Minimum fluid level

57C (135F)

Maximum fluid level

32C (90F)

242RW003

CAUTION: Do not open overfill screw with engine

stopped.

CAUTION: DO NOT CHECK FLUID LEVEL UNDER

THESE CONDITIONS:

Immediately after driving at sustained highway

speeds.

In heavy city traffic during hot weather.

If vehicle is towing a trailer.

If the vehicle has been operated under these conditions,

shut the engine off and allow the vehicle to “cool” for thirty

(30) minutes. After the cool down period, restart the

vehicle and continue from step 2 above.

Page 5707 of 6000

7A–18

AUTOMATIC TRANSMISSION (4L30–E)

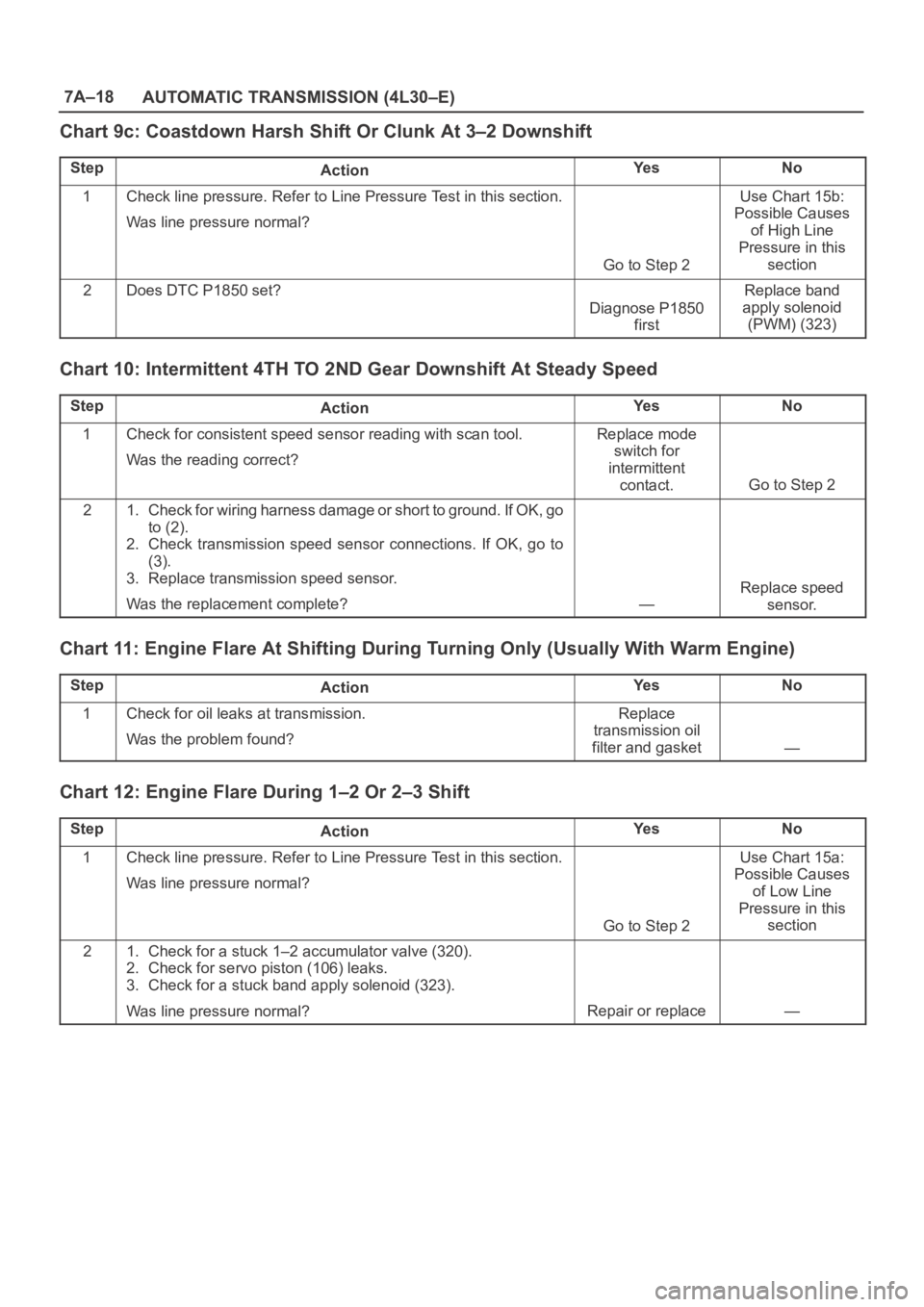

Chart 9c: Coastdown Harsh Shift Or Clunk At 3–2 Downshift

StepActionYe sNo

1Check line pressure. Refer to Line Pressure Test in this section.

Was line pressure normal?

Go to Step 2

Use Chart 15b:

Possible Causes

of High Line

Pressure in this

section

2Does DTC P1850 set?

Diagnose P1850

first

Replace band

apply solenoid

(PWM) (323)

Chart 10: Intermittent 4TH TO 2ND Gear Downshift At Steady Speed

StepActionYe sNo

1Check for consistent speed sensor reading with scan tool.

Was the reading correct?Replace mode

switch for

intermittent

contact.

Go to Step 2

21. Check for wiring harness damage or short to ground. If OK, go

to (2).

2. Check transmission speed sensor connections. If OK, go to

(3).

3. Replace transmission speed sensor.

Was the replacement complete?

—

Replace speed

sensor.

Chart 11: Engine Flare At Shifting During Turning Only (Usually With Warm Engine)

StepActionYe sNo

1Check for oil leaks at transmission.

Was the problem found?Replace

transmission oil

filter and gasket

—

Chart 12: Engine Flare During 1–2 Or 2–3 Shift

StepActionYe sNo

1Check line pressure. Refer to Line Pressure Test in this section.

Was line pressure normal?

Go to Step 2

Use Chart 15a:

Possible Causes

of Low Line

Pressure in this

section

21. Check for a stuck 1–2 accumulator valve (320).

2. Check for servo piston (106) leaks.

3. Check for a stuck band apply solenoid (323).

Was line pressure normal?

Repair or replace—

Page 5711 of 6000

7A–22

AUTOMATIC TRANSMISSION (4L30–E)

Chart 16: Possible Causes Of

Transmission Fluid Leaks

Before attempting to correct an oil leak, the actual source

of the leak must be determined. In many cases, the

source of the leak may be difficult to determine due to

“wind flow” around the engine and transmission.

The suspected area should be wiped clean before in-

specting for the source of the leak.Oil leaks around the engine and transmission are gener-

ally carried toward the rear of the vehicle by the air

stream. In determining the source of an leak, the following

two checks should be made:

1. With the engine running, check for external line

pressure leaks.

2. With the engine off, check for oil leaks due to the

raised oil level caused by drainback of converter oil

into the transmission.

Possible Causes Of Fluid Leaks Due To Sealing Malfunction

240RX008

Legend

(1) Electrical Connector (Main Case) Seal

(2) Transmission Vent (Breather)

(3) Speed Sensor O–Ring

(4) Extension (Adapter) Lip Seal

(5) Extension (Adapter) to Main Case Gasket

(6) Overfill and Oil Drain Screws Gasket

(7) Oil Pan Gasket (Main Case)

(8) Selector Shaft Seal(9) Oil Cooler Connectors (2)

(10) Oil Pan Gasket (Adapter Case)

(11) Converter housing attaching bolts not correctly

torqued

(12) Converter Housing Lip Seal

(13) Line Pressure Tap Plug

(14) Electrical Connector (Adapter Case) Seal

(15) Adapter Case Seal Rings (2)

Page 5712 of 6000

7A–23 AUTOMATIC TRANSMISSION (4L30–E)

Stall Test

The stall test allows you to check the transmission for

internal abrasion and the one way clutch for slippage.

Torque converter performance can also be evaluated.

The stall test results together with the road test results will

identify transmission components requiring servicing or

adjustment.

Stall Test Procedure:

1. Check the level of the engine coolant, the engine oil,

and the automatic transmission fluid. Replenish if

necessary.

2. Block the wheels and set the parking brake.

3. Connect a tachometer to the engine.

4. Start the engine and allow it to idle until the engine

coolant temperature reaches 70 – 80

C (158 –

176

F).

5. Hold the brake pedal down as far as it will go.

6. Place the selector in the “D” range.

7. Gradually push the accelerator pedal to the floor.

The throttle valve will be fully open.

Note the engine speed at which the tachometer

needle stabilizes.

Stall Speed : 2,100

150 rpm

NOTE: Do not continuously run this test longer than 5

seconds.

8. Release the accelerator pedal.

9. Place the selector in the “N” range.

10. Run the engine at 1,200 rpm for one minute.

This will cool the transmission fluid.

11. Repeat Steps 7 – 10 for the “3”, “2”, “L” and “R”

ranges.

Line Pressure Test

The line pressure test checks oil pump and control valve

pressure regulator valve function. It will also detect oil

leakage.

Line Pressure Test Procedure:

1. Check the level of the engine coolant, the engine oil,

and the automatic transmission fluid.

Replenish if required.

2. Block the wheels and set the parking brake.

3. Remove the pressure detection plug at the left side of

the transmission case.

Set 5–8840–0004–0 pressure gauge and adapter to

the pressure detection plug hole.

241RS001

4. Start the engine and allow it to idle until the engine

coolant temperature reaches 70 – 80

C (158 –

176

F).

5. Hold the brake pedal down as far as it will go.

6. Place the selector in the “D” range.

7. Note the pressure gauge reading with the engine

idling.

8. Gradually push the accelerator pedal to the floor. The

throttle valve will be fully open.

Note the pressure gauge reading with the accelerator

pedal fully depressed.

NOTE: Do not continuously run this test longer than 5

seconds.

9. Release the accelerator pedal.

10. Place the selector in the “N” range.

11. Run the engine at 1,200 rpm for one minute.

This will cool the transmission fluid.

12. Repeat Steps 7 – 11 for the “3”, “2”, “L”, and “R”

ranges.

13. Install a pressure detection plug to the transmission

case, applying recommended thread locking agent

(LOCTITE 242) or its equivalent to thread of plug.

Make sure that thread is cleaned before applying

locking agents.

14. Tighten the pressure detection plug to the specified

torque.

Torque:9–14Nꞏm(0.9–1.4kgꞏm/7–10lbft)

Page 5718 of 6000

7A–29 AUTOMATIC TRANSMISSION (4L30–E)

Changing Transmission Fluid

There is no need to change the transmission fluid unless

the transmission is used under one or more of the

following heavy duty conditions.

A. Repeated short trips

B. Driving on rough roads

C. Driving on dusty roads

D. Towing a trailer

If the vehicle is used under these conditions, change the

fluid every 20,000 miles (32,000 km).

More over, the remaining life percentage of ATF can be

estimated by using Tech 2 as an auxiliary tool to judge the

right time for ATF replacement.

The remaining life percentage is calculated from ATF’S

heat history. When it is close to 0%, ATF replacement is

recommended.

1. Place a large drain pan under the oil pan.

2. Remove the transmission oil drain screw (2) and drain

fluid.

3. Tighten drain screw (2).

Torque: 38 N

m (3.9 kgꞏm/28 lb ft)

4. Remove the transmission overfill screw (1) and fill

transmission through overfill screw opening, using

DEXRON

–III ATF.

NOTE: Add transmission fluid until it flows out over the

overfill screw opening.

5. Let engine idle until a fluid temperature between 32

C

(90

F) and 57C (135F) is reached.

6. Add transmission fluid until it flows out over the overfill

screw opening, then close the overfill screw (1).

Torque: 38 N

m (3.9 kgꞏm/28 lb ft)NOTE: To prevent fluid leaks, the overfill screw and oil

drain screws gasket must be replaced each time these

screws are removed.

NOTE: Check transmission fluid temperature with

service scan tool.

7. Reset “Oil Life Monitor” data by using Tech 2.

Refer to Tech 2 OBD II Connector in Transmission

Control System (4L30-E) Section.

242RW003

Selector Lever

Inspection

1. Make sure that when the selector lever is shifted from

“P” to “L”, a “clicking” can be felt at each shift position.

Make sure that the gear corresponds to that of the

position plate indicator.

2. Check to see if the selector lever can be shifted as

shown in illustration.

C07RW009

Page 5719 of 6000

7A–30

AUTOMATIC TRANSMISSION (4L30–E)

Removal

1. Disconnect battery ground cable.

2. Remove transfer control lever knob.

3. Remove front console.

Disconnect wiring harness connectors from front

console.

4. Disconnect shift lock cable (1) from the selector lever

assembly side.

256RW012

5. Disconnect shift control rod (2) from the selector lever

assembly side.

256RW013

6. Disconnect wiring harness connectors from the

selector lever assembly.

7. Remove selector lever assembly.

Installation

To install, follow the removal steps in the reverse order,

noting the following points:

Adjustment of select lever and control rod

1. Place the vehicle on a level surface.

NOTE: If the vehicle is not on level surface, the shift

select cable set positions will vary with the movement of

engine. To prevent possible misadjustment of the cable,

the vehicle must be placed on a level surface.

2. Install the shift control rod (1) to the transmission

select lever (2), and then place the lever in the “N”

position.

3. Set select lever in the “N” position.

4. Push select lever forward (“R” position side) and

s e c u r e i t ( u s i n g a r u b b e r b a n d ( 3 ) , e t c . ) s o t h a t t h e p i n

comes into contact with the wall of the detent plate.

5. Install the shift control rod (1) to the selector lever arm

(4).

To r q u e : 3 2 N

m (3.3 kgꞏm/24 lb ft)

NOTE: Do not apply oil to the threaded portions.

256RW014

6. After adjustment, make sure that the selector lever

operates normally, and that each selector position is

properly indicated. (The red mark shows through the

window.)

Adjustment of shift lock cable

1. Set ignition key in “LOCK” position and selector lever

in “P” position.

2. Adjust cable screw cap on selector lever side to

provide a gap (slack for cable) of 1 – 2 mm between

rod on steering lock side and stopper.

Adjust cap as follows:

a. Pull screw cap (1) in arrow direction to remove

inner cable slack.

b. With cable kept as (a), adjust gap between nut (2)

and bracket to 5 mm (0.2 in).

c. Lock inner cable by turning nut (3) while holding nut

(2) in place.

Torque : 3.7 N

m (38 kgꞏcm/33 lb in)

Page 5722 of 6000

7A–33 AUTOMATIC TRANSMISSION (4L30–E)

Transmission (With Transfer Case)

Transmission And Associated Parts

240RW027

Legend

(1) Transfer Control Lever Knob

(2) Front Console

(3) Selector Lever Assembly

(4) Transfer Control Lever

(5) Transfer and Exhaust Protector

(6) Rear Propeller Shaft

(7) Front Propeller Shaft

(8) Harness Protector

(9) Rear Mount Nut(10) Third Crossmember

(11) Exhaust Pipe

(12) Transmission Oil Cooler Pipe

(13) Starter

(14) Transmission Harness Connector

(15) Under Cover

(16) Torque Converter Bolt

(17) Engine Transmission Bolt

(18) Transmission Assembly

Removal

NOTE: Before remove transmission and transfer

assembly from vehicle, change the tansfer mode to 2WD

using push button on dash panel.1. Remove engine hood.

2. Disconnect battery ground cable.

3. Remove transfer control lever knob (1) and

disconnect wiring harness connectors, then remove

front console (2).