battery replacement OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 1060 of 6000

ENGINE COOLING6B–7

Water Pump

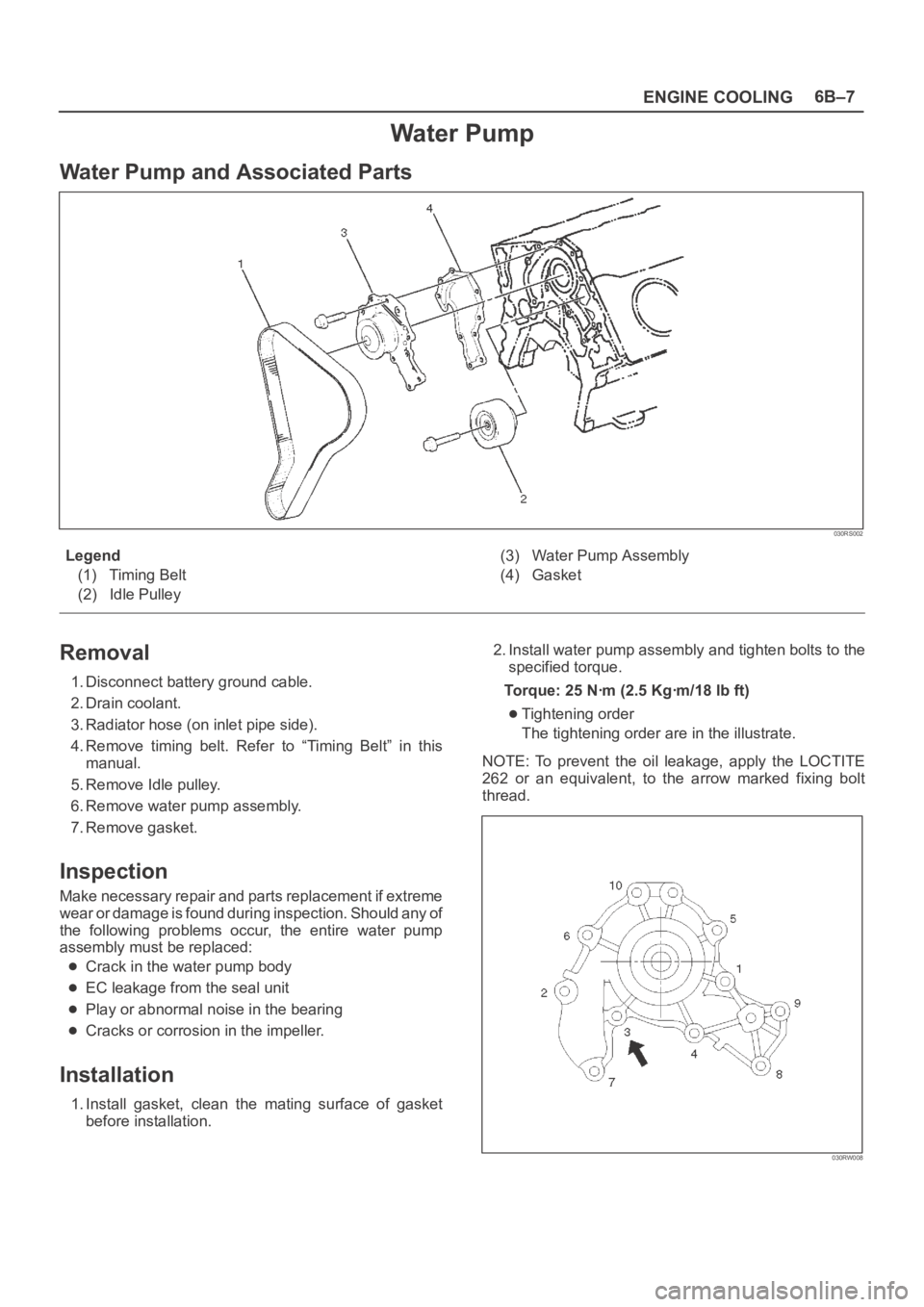

Water Pump and Associated Parts

030RS002

Legend

(1) Timing Belt

(2) Idle Pulley(3) Water Pump Assembly

(4) Gasket

Removal

1. Disconnect battery ground cable.

2. Drain coolant.

3. Radiator hose (on inlet pipe side).

4. Remove timing belt. Refer to “Timing Belt” in this

manual.

5. Remove Idle pulley.

6. Remove water pump assembly.

7. Remove gasket.

Inspection

Make necessary repair and parts replacement if extreme

wear or damage is found during inspection. Should any of

the following problems occur, the entire water pump

assembly must be replaced:

Crack in the water pump body

EC leakage from the seal unit

Play or abnormal noise in the bearing

Cracks or corrosion in the impeller.

Installation

1. Install gasket, clean the mating surface of gasket

before installation.2. Install water pump assembly and tighten bolts to the

specified torque.

Torque: 25 Nꞏm (2.5 Kgꞏm/18 lb ft)

Tightening order

The tightening order are in the illustrate.

NOTE: To prevent the oil leakage, apply the LOCTITE

262 or an equivalent, to the arrow marked fixing bolt

thread.

030RW008

Page 1061 of 6000

6B–8

ENGINE COOLING

3. Idle pulley

Install idle pulley and tighten bolt to the specified

torque.

Torque: 52 Nꞏm (5.3 Kgꞏm/38 lb ft)4. Timing beltInstall timing belt. Refer to timing belt installation

step in “Timing Belt” in this manual.

5. Connect radiator inlet hose and replenish EC.

6. Connect battery ground cable.

Thermostat

Thermostat and Associated Parts

031RW001

Legend

(1) Thermostat Housing

(2) Thermostat

(3) Outlet Pipe

Removal

1. Disconnect battery ground cable.

2. Drain engine coolant from the radiator and engine.

3. Disconnect radiator hose from the inlet pipe.

4. Remove thermostat housing.

5. Remove thermostat(2).

Inspection

Suspend the thermostat in a water–filled container using

thin wire. Place a thermometer next to the thermostat.

Do not directly heat the thermostat.

Gradually increase the water temperature. Stir the water

so that the entire water is same temperature.

031RS003Confirm the temperature when the valve first begins to

open.

Valve opening temperature 74.5C

78.5C

(166.1

F 173.3F)

Confirm the temperature when the valve is fully opened.

Valve full open temperature and lift More than

8.5mm (0.33 in) at 90

C (194F)

Make necessary repair and parts replacement if extreme

wear or damage is found during inspection.

Installation

1. Install thermostat into the outlet pipe(4) making sure

that the air hole is in the up position.

2. Install thermostat housing and tighten bolts to the

specified torque.

Torque: 25 Nꞏm (2.5 Kgꞏm/18 lb ft)

3. Installation rubber hose.

4. Replenish engine coolant (EC).

5. Start engine and check for EC leakage.

Page 1080 of 6000

ENGINE ELECTRICAL6D1–1

ENGINE

ENGINE ELECTRICAL

CONTENTS

Service Precaution 6D1–1. . . . . . . . . . . . . . . . . . . . . .

Battery 6D1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Description 6D1–2. . . . . . . . . . . . . . . . . . . .

Diagnosis 6D1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Battery Charging 6D1–3. . . . . . . . . . . . . . . . . . . . . . Jump Starting 6D1–3. . . . . . . . . . . . . . . . . . . . . . . . .

Battery Removal 6D1–4. . . . . . . . . . . . . . . . . . . . . .

Battery Installation 6D1–4. . . . . . . . . . . . . . . . . . . . .

Main Data and Specifications 6D1–5. . . . . . . . . . .

Service Precaution

WARNING: IF SO EQUIPPED WITH A

SUPPLEMENTAL RESTRAINT SYSTEM (SRS),

REFER TO THE SRS COMPONENT AND WIRING

LOCATION VIEW IN ORDER TO DETERMINE

WHETHER YOU ARE PERFORMING SERVICE ON OR

NEAR THE SRS COMPONENTS OR THE SRS

WIRING. WHEN YOU ARE PERFORMING SERVICE

ON OR NEAR THE SRS COMPONENTS OR THE SRS

WIRING, REFER TO THE SRS SERVICE

INFORMATION. FAILURE TO FOLLOW WARNINGS

COULD RESULT IN POSSIBLE AIR BAG

DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU will call out those fasteners that require a

replacement after removal. ISUZU will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED, do not

use supplemental coatings (Paints, greases, or other

corrosion inhibitors) on threaded fasteners or

fastener joint interfaces. Generally, such coatings

adversely affect the fastener torque and the joint

clamping force, and may damage the fastener. When

you install fasteners, use the correct tightening

sequence and specifications. Following these

instructions can help you avoid damage to parts and

systems.

Page 1193 of 6000

6E–76

ENGINE DRIVEABILITY AND EMISSIONS

No Malfunction Indicator Lamp (MIL)

StepNo Ye s Va l u e ( s ) Action

14Locate and repair the open PCM battery feed circuit.

Is the action complete?

—Verify repair—

15Locate and repair the short to ground in the PCM

ignition feed circuit or PCM battery feed circuit.

Is the action complete?

—Verify repair—

16Locate and repair the short to ground in the ignition

feed circuit to the instrument cluster, and replace the

fuse.

Is the action complete?

—Verify repair—

17Replace the PCM.

IMPORTANT:The replacement PCM must be

programmed. Refer to

PCM in ON-Vehicle Service for

procedures.

Is the action complete?

—Verify repair—

18Check the MIL driver circuit for a poor connection at the

instrument panel connector.

Was a problem found?

—Verify repair

Go to

Instrument

Panel

in

Electrical

Diagnosis

Page 1355 of 6000

6E–238

ENGINE DRIVEABILITY AND EMISSIONS

DTC P0562 – System Voltage Low

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

2Using a Tech 2, measure the battery voltage at the

battery.

Is the battery voltage greater than the specified value?

11.5 VGo to Step 3

Charge

battery, then

go to

Step 3

31. Using a Tech 2.

2. Select “Ignition Volts” on the Tech 2.

3. Start the engine and raise the engine speed to the

specified value.

4. Load the electrical system by turning on the

headlights, high blower, etc.

Is the ignition voltage approximately equal to the

specified value?

2000 RPM

12.8-14.1 V

Go to Step 4

Go to

Starting/Char

ging

41. Ignition “OFF.”

2. Disconnect the PCM connector at the PCM.

3. Using a DVM, measure the battery voltage at the

PCM connector A-4.

Is it approximately equal to battery voltage?

—

Check for

excessive

current draw

with ignition

“OFF,” engine

“OFF.”

Go to Step 5

51. Check for faulty connections at the PCM harness

terminals.

2. Repair as necessary.

Was a repair necessary?

—Verify repairGo to Step 6

6Check for an open battery feed circuit to the PCM.

Is the action complete?

—Verify repairGo to Step 7

7Replace the PCM.

IMPORTANT:The replacement PCM must be

programmed. Refer to

UBS 98model year Immobilizer

Workshop Manual.

Is the action complete?—Verify repair—

Page 1356 of 6000

6E–239 ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0563 System Voltage High

Circuit Description

The powertrain control module (PCM) monitors the

system voltage on the ignition feed terminals to the PCM.

A system voltage DTC will set whenever the voltage is

above a calibrated value.

Conditions for Setting the DTC

Ignition “ON.”

System voltage is above 16 volts for 15 minutes.

Action Taken When the DTC Sets

The PCM will not illuminate the malfunction indicator

lamp (MIL).

The PCM will store as Failure Records only conditions

which were present when the DTC was set. This

information will not be stored as Freeze Frame data.

Conditions for Clearing the MIL/DTC

A history DTC P0563 will clear after 40 consecutive

warm-up cycles have occurred without a fault.

DTC P0563 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the PCM battery

feed.

Diagnostic Aids

If the DTC sets when an accessory is operated, check for

a poor connection or excessive current draw.

DTC P0563 – System Voltage High

StepActionVa l u e ( s )Ye sNo

1Was the “ON-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

2Using a Tech 2, measure the battery voltage at the

battery.

Is the battery voltage less than the specified value?

11 . 5 VGo to Step 3Go to Step 4

31. Charge the battery and clean the battery terminals.

2. Clean the battery ground cable connection if

corrosion is indicated.

Is the battery voltage less than the specified value?

11 . 5 V

Replace

battery

Go to Step 4

41. Turn “OFF” all the accessories.

2. Install a Tech 2.

3. Select the ignition voltage parameter on the Tech 2.

4. Start the engine and raise the engine RPM to the

specified value.

Is the voltage more than 2.5 volts greater than the

measurement taken in step 2 or 3?

2000 RPM

Go to

Starting/Char

ging

Go to Step 5

5Replace the PCM.

IMPORTANT:The replacement PCM must be

programmed. Refer to

UBS 98 model year Immobilizer

Workshop Manual.

Is the action complete?—Verify repair—

Page 1357 of 6000

6E–240

ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0601 PCM Memory

Circuit Description

The powertrain control module (PCM) used in this vehicle

utilizes an electrically erasable programmable read-only

memory (EEPROM). The EEPROM contains program

information and the calibrations required for engine,

transmission, and powertrain diagnostics operation.

Unlike the PROM used in past applications, the EEPROM

is not replaceable.

Conditions for Setting the DTC

The PCM detects an internal program fault (check sum

error).

Action Taken When the DTC Sets

The PCM will not illuminate the malfunction indicator

lamp (MIL).

The PCM will store conditions which were present

when the DTC was set in the Failure Records data only.

Conditions for Clearing the MIL/DTC

DTC P0601 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the PCM battery

feed.

Diagnostic Aids

DTC P0601 indicates that the contents of the

EEPROM have changed since the PCM was

programmed. The only possible repair is PCM

replacement.

DTC P0601 – PCM Memory

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

2Replace the PCM.

IMPORTANT:The replacement PCM must be

programmed. Refer to

UBS 98model year Immobilizer

Workshop Manual.

Is the action complete?—Verify repair—

Page 1365 of 6000

6E–248

ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P1380 ABS Rough Road ABS System Fault

Circuit Description

The powertrain control module (PCM) monitors ABS fault

signal. When PCM receives fault signal, PCM will set

DTC P1380.

Conditions for Setting the DTC

Vehicle speed is more than 5 mph.

Load is less than 99%.

Engine revolution is less than 6250 rpm.

PCM receives ABS fault signals from ABS unit.

Ignition on.

Misfire DTCs exist.

100 test failures within 120 test samples.

Action Taken When the DTC Sets

The PCM will store DTC 1380 only, no MIL turn on.

Conditions for Clearing the MIL/DTC

A history DTC P1380 will clear after 40 consecutive

warm-up cycles have occurred without a fault.

DTC 1380 can be cleared by using Tech-2 or

disconnecting the PCM battery feed.

Diagnostic Aids

Check for the following conditions:

PCM and ABS communication line short circuit to other

line may cause faulty signal. Inspect communication

line.

Follow ABS ECU diagnosis procedure, refer to ABS

procedure page.

DTC P1380 – ABS Rough Road ABS System Fault

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

21. Ignition “ON,” engine “OFF”, review and record

Tech 2 Failure Records Data.

2. Operate the vehicle within Failure Records

conditions as noted.

3. Using a Tech 2, monitor “Specific DTC” info for DTC

P1380 and Misfire DTCs until the DTC P1380 and

Misfire DTCs test runs. Note the result.

Does the Tech 2 indicates DTC P1380 and Misfire

DTCs failed this ignition?

—

Refer to ABS

diagnosis

After inspect

ABS, unit re-

peat

Step 2

Still problem

exists, go to

Step 3

Clear DTC by

Te c h 2

3Check short circuit among communication line of

PCM/ABS and others.

Was short circuit?

—

Repair wiring

Verify repair

Go to Step 4

4Replace the PCM.

IMPORTANT:The replacement PCM must be

programmed. Refer to

UBS 98model year Immobilizer

Workshop Manual.

Is the action complete?—Verify repair—

Page 1374 of 6000

6E–257 ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P1618 Serial Peripheral Interface (SPI) PCM

Interprocessor Communication Error

Circuit Description

The serial peripheral interface (SPI) communication is

used internally by the PCM to send messages between

the engine processor and the automatic transmission

processor. Included in each message sent between the

two-processors is a checksum of the message. Both the

engine processor and automatic transmission processor

will compare this check sum value with the calculated

value. If the checksums don’t match, the processor will

view the new data as being corrupted and ignore the

values. The processor will then use the previous

message. The receiving processor will then send a

message to the sending processor informing it that it’s

last message was corrupted.

Conditions for Setting the DTC

Battery voltage is above 9.0 V for 2 seconds.

The PCM detects an internal program fault (check sum

of data communications error).

Check sum fault present for 3 out 6 seconds.

No TCM resets for 2 seconds.

Action Taken When the DTC Sets

The PCM will flash the “Check Trans” lamp the first

time the fault is detected.

The PCM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

The automatic transmission will operate in the “safety

mode” to protect the mechanical parts of the

transmission. Shift quality and/or gear changes may

not be normal.

Conditions for Clearing the MIL/DTC

DTC P1618 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the PCM battery

feed.

DTC P1618 – Serial Peripheral Interface (SPI) PCM Interprocessor

Communication Error

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

2Is the EEPROM calibration the latest version

available?

—Go to Step 4Go to Step 3

3Reprogram the PCM with the latest available

calibrations.

Does DTC 1618 re-appear when the

OBD System

Check

is repeated?—Go to Step 4

Repair

completed

4Replace the PCM.

IMPORTANT:The replacement PCM must be

programmed. Refer to

UBS 98model year Immobilizer

Workshop Manual.

Is the action complete?—Verify repair—

Page 1378 of 6000

6E–261 ENGINE DRIVEABILITY AND EMISSIONS

DTC P1640 – Driver-1-Input High Voltage

StepNo Ye s Va l u e ( s ) Action

13Repair the open circuit between the fuse and the PCM

driver terminal for the affected circuit.

Is the action complete?

—Verify repair—

141. Connect the PCM.

2. Start the engine and let it idle.

3. Backprobe the affected terminal at the PCM with a

DVM.

Was the voltage equal to the specified value?

+BGo to Step 16Go to Step 15

151. Run the engine at idle.

2. Check for battery voltage at the fuse for the affected

circuit.

Was battery voltage available at the fuse?

—Go to Step 11Go to Step 10

16Replace the PCM.

IMPORTANT:The replacement PCM must be

programmed. Refer to

UBS 98model year Immobilizer

Workshop Manual.

Is the action complete?—Verify repair—