ad blue OPEL FRONTERA 1998 Manual PDF

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 4622 of 6000

ENGINE ELECTRICAL6D1–3

a. VOLTAGE DOES NOT DROP BELOW THE

MINIMUM LISTED IN THE TABLE – The battery is

good and should be returned to service.

b. VOLTAGE IS LESS THAN MINIMUM LISTED –

Replace battery.

ESTIMATED TEMPERATURE

MINIMUM

VOLTAGE

FCV

70219.6

60169.5

50109.4

4049.3

30–19.1

20–78.9

10–128.7

0–188.5

The battery temperature must be estimated by feel

and by the temperature the battery has been

exposed to for the preceding few hours.

Battery Charging

Observe the following safety precautions when charging

the battery:

1. Never attempt to charge the battery when the fluid

level is below the lower level line on the side of the

battery. In this case, the battery must be replaced.

2. Pay close attention to the battery during charging

procedure.

Battery charging should be discontinued or the rate of

charge reduced if the battery feels hot to the touch.

Battery charging should be discontinued or the rate of

charge reduced if the battery begins to gas or spew

electrolyte from the vent holes.

3. In order to more easily view the hydrometer blue dot

or ring, it may be necessary to jiggle or tilt the battery.

4. Battery temperature can have a great effect on

battery charging capacity.

5. The sealed battery used on this vehicle may be either

quick charged or slow charged in the same manner as

other batteries.

Whichever method you decide to use, be sure that

you completely charge the battery. Never partially

charge the battery.

Jump Starting

Jump Starting with an Auxiliary (Booster)

Battery

CAUTION: Never push or tow the vehicle in an

attempt to start it. Serious damage to the emission

system as well as other vehicle parts will result.Treat both the discharged battery and the booster

battery with great care when using jumper cables.

Carefully follow the jump starting procedure, being

careful at all times to avoid sparking.

WARNING: FAILURE TO CAREFULLY FOLLOW THE

JUMP STARTING PROCEDURE COULD RESULT IN

THE FOLLOWING:

1. Serious personal injury, particularly to your eyes.

2. Property damage from a battery explosion, battery

acid, or an electrical fire.

3. Damage to the electronic components of one or both

vehicles particularly.

Never expose the battery to an open flame or electrical

spark. Gas generated by the battery may catch fire or

explode.

Remove any rings, watches, or other jewelry before

working around the battery. Protect your eyes by wearing

an approved set of goggles.

Never allow battery fluid to come in contact with your eyes

or skin.

Never allow battery fluid to come in contact with fabrics or

painted surfaces.

Battery fluid is a highly corrosive acid.

Should battery fluid come in contact with your eyes, skin,

fabric, or a painted surface, immediately and thoroughly

rinse the affected area with clean tap water.

Never allow metal tools or jumper cables to come in

contact with the positive battery terminal, or any other

metal surface of the vehicle. This will protect against a

short circuit.

Always keep batteries out of reach of young children.

Jump Starting Procedure

1. Set the vehicle parking brake.

If the vehicle is equipped with an automatic

transmission, place the selector level in the “PARK”

position.

If the vehicle is equipped with a manual transmission,

place the shift lever in the “NEUTRAL” position.

Turn “OFF” the ignition.

Turn “OFF” all lights and any other accessory

requiring electrical power.

2. Look at the built–in hydrometer.

If the indication area of the built–in hydrometer is

completely clear, do not try to jump start.

3. Attach the end of one jumper cable to the positive

terminal of the booster battery.

Attach the other end of the same cable to the positive

terminal of the discharged battery.

Do not allow the vehicles to touch each other. This will

cause a ground connection, effectively neutralizing

the charging procedure.

Be sure that the booster battery has a 12 volt rating.

Page 4658 of 6000

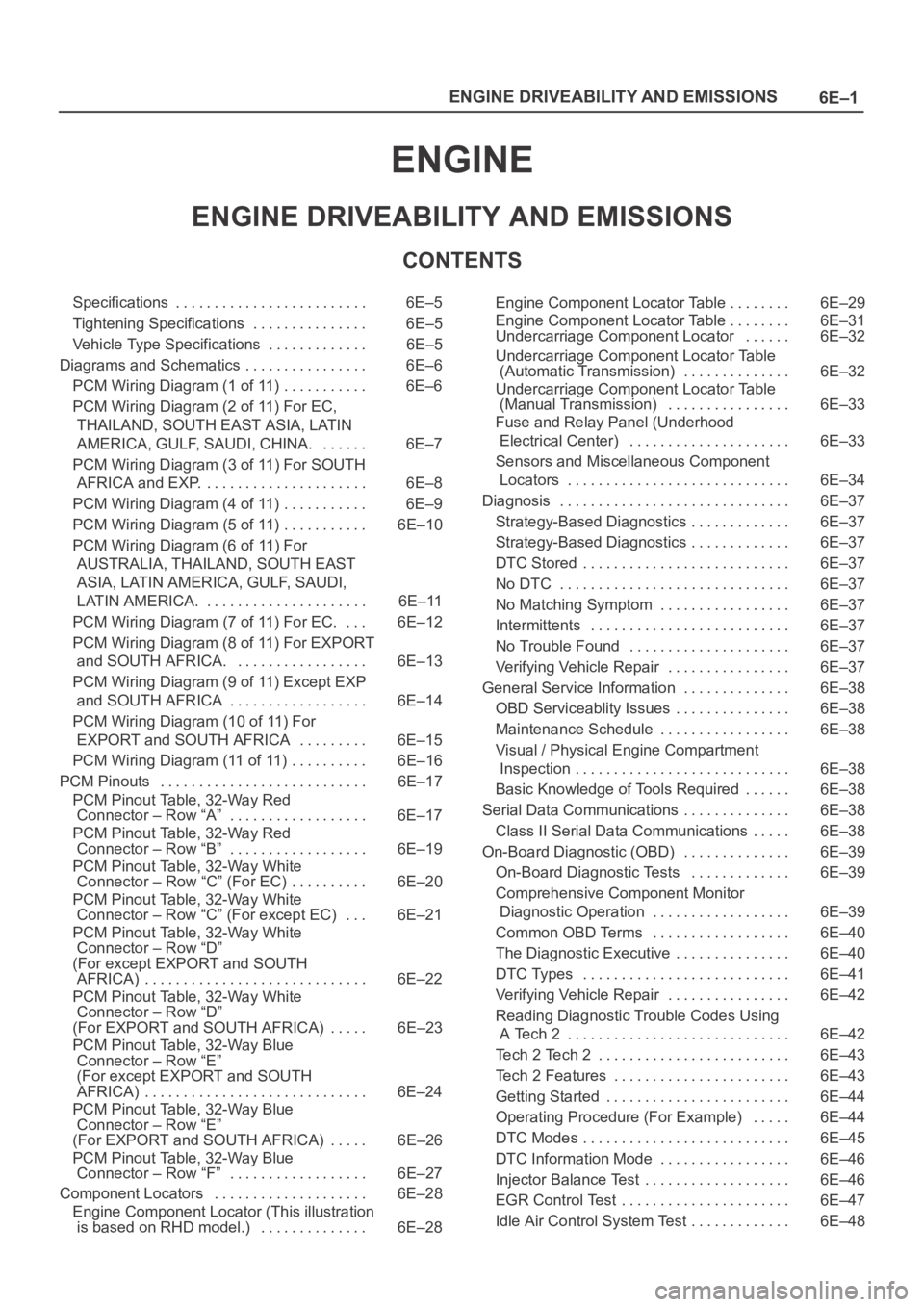

6E–1 ENGINE DRIVEABILITY AND EMISSIONS

ENGINE

ENGINE DRIVEABILITY AND EMISSIONS

CONTENTS

Specifications 6E–5. . . . . . . . . . . . . . . . . . . . . . . . .

Tightening Specifications 6E–5. . . . . . . . . . . . . . .

Vehicle Type Specifications 6E–5. . . . . . . . . . . . .

Diagrams and Schematics 6E–6. . . . . . . . . . . . . . . .

PCM Wiring Diagram (1 of 11) 6E–6. . . . . . . . . . .

PCM Wiring Diagram (2 of 11) For EC,

THAILAND, SOUTH EAST ASIA, LATIN

AMERICA, GULF, SAUDI, CHINA. 6E–7. . . . . .

PCM Wiring Diagram (3 of 11) For SOUTH

AFRICA and EXP. 6E–8. . . . . . . . . . . . . . . . . . . . .

PCM Wiring Diagram (4 of 11) 6E–9. . . . . . . . . . .

PCM Wiring Diagram (5 of 11) 6E–10. . . . . . . . . . .

PCM Wiring Diagram (6 of 11) For

AUSTRALIA, THAILAND, SOUTH EAST

ASIA, LATIN AMERICA, GULF, SAUDI,

LATIN AMERICA. 6E–11. . . . . . . . . . . . . . . . . . . . .

PCM Wiring Diagram (7 of 11) For EC. 6E–12. . .

PCM Wiring Diagram (8 of 11) For EXPORT

and SOUTH AFRICA. 6E–13. . . . . . . . . . . . . . . . .

PCM Wiring Diagram (9 of 11) Except EXP

and SOUTH AFRICA 6E–14. . . . . . . . . . . . . . . . . .

PCM Wiring Diagram (10 of 11) For

EXPORT and SOUTH AFRICA 6E–15. . . . . . . . .

PCM Wiring Diagram (11 of 11) 6E–16. . . . . . . . . .

PCM Pinouts 6E–17. . . . . . . . . . . . . . . . . . . . . . . . . . .

PCM Pinout Table, 32-Way Red

Connector – Row “A” 6E–17. . . . . . . . . . . . . . . . . .

PCM Pinout Table, 32-Way Red

Connector – Row “B” 6E–19. . . . . . . . . . . . . . . . . .

PCM Pinout Table, 32-Way White

Connector – Row “C” (For EC) 6E–20. . . . . . . . . .

PCM Pinout Table, 32-Way White

Connector – Row “C” (For except EC) 6E–21. . .

PCM Pinout Table, 32-Way White

Connector – Row “D”

(For except EXPORT and SOUTH

AFRICA) 6E–22. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PCM Pinout Table, 32-Way White

Connector – Row “D”

(For EXPORT and SOUTH AFRICA) 6E–23. . . . .

PCM Pinout Table, 32-Way Blue

Connector – Row “E”

(For except EXPORT and SOUTH

AFRICA) 6E–24. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PCM Pinout Table, 32-Way Blue

Connector – Row “E”

(For EXPORT and SOUTH AFRICA) 6E–26. . . . .

PCM Pinout Table, 32-Way Blue

Connector – Row “F” 6E–27. . . . . . . . . . . . . . . . . .

Component Locators 6E–28. . . . . . . . . . . . . . . . . . . .

Engine Component Locator (This illustration

is based on RHD model.) 6E–28. . . . . . . . . . . . . . Engine Component Locator Table 6E–29. . . . . . . .

Engine Component Locator Table 6E–31. . . . . . . .

Undercarriage Component Locator 6E–32. . . . . .

Undercarriage Component Locator Table

(Automatic Transmission) 6E–32. . . . . . . . . . . . . .

Undercarriage Component Locator Table

(Manual Transmission) 6E–33. . . . . . . . . . . . . . . .

Fuse and Relay Panel (Underhood

Electrical Center) 6E–33. . . . . . . . . . . . . . . . . . . . .

Sensors and Miscellaneous Component

Locators 6E–34. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagnosis 6E–37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Strategy-Based Diagnostics 6E–37. . . . . . . . . . . . .

Strategy-Based Diagnostics 6E–37. . . . . . . . . . . . .

DTC Stored 6E–37

. . . . . . . . . . . . . . . . . . . . . . . . . . .

No DTC 6E–37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

No Matching Symptom 6E–37. . . . . . . . . . . . . . . . .

Intermittents 6E–37. . . . . . . . . . . . . . . . . . . . . . . . . .

No Trouble Found 6E–37. . . . . . . . . . . . . . . . . . . . .

Verifying Vehicle Repair 6E–37. . . . . . . . . . . . . . . .

General Service Information 6E–38. . . . . . . . . . . . . .

OBD Serviceablity Issues 6E–38. . . . . . . . . . . . . . .

Maintenance Schedule 6E–38. . . . . . . . . . . . . . . . .

Visual / Physical Engine Compartment

Inspection 6E–38. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Basic Knowledge of Tools Required 6E–38. . . . . .

Serial Data Communications 6E–38. . . . . . . . . . . . . .

Class II Serial Data Communications 6E–38. . . . .

On-Board Diagnostic (OBD) 6E–39. . . . . . . . . . . . . .

On-Board Diagnostic Tests 6E–39. . . . . . . . . . . . .

Comprehensive Component Monitor

Diagnostic Operation 6E–39. . . . . . . . . . . . . . . . . .

Common OBD Terms 6E–40. . . . . . . . . . . . . . . . . .

The Diagnostic Executive 6E–40. . . . . . . . . . . . . . .

DTC Types 6E–41. . . . . . . . . . . . . . . . . . . . . . . . . . .

Verifying Vehicle Repair 6E–42. . . . . . . . . . . . . . . .

Reading Diagnostic Trouble Codes Using

A Tech 2 6E–42. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tech 2 Tech 2 6E–43. . . . . . . . . . . . . . . . . . . . . . . . .

Tech 2 Features 6E–43. . . . . . . . . . . . . . . . . . . . . . .

Getting Started 6E–44. . . . . . . . . . . . . . . . . . . . . . . .

Operating Procedure (For Example) 6E–44. . . . .

DTC Modes 6E–45. . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC Information Mode 6E–46. . . . . . . . . . . . . . . . .

Injector Balance Test 6E–46. . . . . . . . . . . . . . . . . . .

EGR Control Test 6E–47. . . . . . . . . . . . . . . . . . . . . .

Idle Air Control System Test 6E–48. . . . . . . . . . . . .

Page 4679 of 6000

6E–22

ENGINE DRIVEABILITY AND EMISSIONS

PCM Pinout Table, 32-Way White Connector – Row “D”

(For except EXPORT and SOUTH AFRICA)

TS23345

PINPIN FunctionWire ColorIGN ONENG RUNRefer To

D1Injector Cylinder #2GRN/ORNB+B+General Description and

Operation, Fuel Injector

D2Torque Converter Clutch

(TCC)BRN/BLU0.0 V0.0 VOn-Vehicle Service, Torque

Converter Clutch

D3Injector Cylinder #1GRN/WHTB+B+General Description and

Operation, Fuel Injector

D4Serial Data (8192)ORN5.0 V5.0 VChassis Electrical

D5Ignition Control, Cylinder

#5RED/YEL0.0 V0.1 VGeneral Description and

Operation, Ignition Coil

D6Ignition Control, Cylinder

#3RED/BLUE0.0 V0.0 VGeneral Description and

Operation, Ignition Coil

D7VSS Input / IMOB

ResponseWHT/BLK0.0 V0.1 V

(at rest)Chassis Electrical

D8Sensor Ground 5V

Reference A ReturnGRN0.0 V0.0 VAppropriate Sensor

D9Sensor Ground 5 V

Reference B ReturnGRY0.0 V0.0 VAppropriate Sensor

D10Mass Air Flow (MAF)YEL4.9 V4.2 VGeneral Description, Mass

Air Flow Sensor

D11Camshaft Position SensorWHT5.0 V or less

than 1.0 V4.6 VGeneral Description and

Operation, Camshaft

Position Sensor

D12Not Used————

D13Not Used————

D14Bank 1 HO2S 1 LowGRN0.0 V0.1 VGeneral Description and

Operation, Fuel HO2S 1

D15Bank 1 HO2S 1 SignalRED0.4 V0.1-0.9 VGeneral Description and

Operation, Fuel HO2S 1

D16Not Used————

Page 4680 of 6000

6E–23 ENGINE DRIVEABILITY AND EMISSIONS

PCM Pinout Table, 32-Way White Connector – Row “D”

(For EXPORT and SOUTH AFRICA)

TS23345

PINPIN FunctionWire ColorIGN ONENG RUNRefer To

D1Injector Cylinder #2GRN/ORNB+B+General Description and

Operation, Fuel Injector

D2Torque Converter Clutch

(TCC)BRN/BLU0.0 V0.0 VOn-Vehicle Service, Torque

Converter Clutch

D3Injector Cylinder #1GRN/WHTB+B+General Description and

Operation, Fuel Injector

D4Serial Data (8192)ORN5.0 V5.0 VChassis Electrical

D5Ignition Control, Cylinder

#5RED/YEL0.0 V0.1 VGeneral Description and

Operation, Ignition Coil

D6Ignition Control, Cylinder

#3RED/BLUE0.0 V0.0 VGeneral Description and

Operation, Ignition Coil

D7VSS Input / IMOB

ResponseLIGHT

GRN/WHT0.0 V0.1 V

(at rest)Chassis Electrical

D8Sensor Ground 5V

Reference A ReturnGRN0.0 V0.0 VAppropriate Sensor

D9Sensor Ground 5 V

Reference B ReturnGRY0.0 V0.0 VAppropriate Sensor

D10Mass Air Flow (MAF)YEL4.9 V4.2 VGeneral Description, Mass

Air Flow Sensor

D11Camshaft Position SensorWHT5.0 V or less

than 1.0 V4.6 VGeneral Description and

Operation, Camshaft

Position Sensor

D12Not Used————

D13Not Used————

D14Not Used————

D15Not Used————

D16Not Used————

Page 4681 of 6000

6E–24

ENGINE DRIVEABILITY AND EMISSIONS

PCM Pinout Table, 32-Way Blue Connector – Row “E”

(For except EXPORT and SOUTH AFRICA)

TS23346

PINPIN FunctionWire ColorIGN ONENG RUNRefer To

E1Transmission Output Shaft

Sensor (TOSS) HighRED0.0 V0.1 VAutomatic Transmission

(4L30E)

E2Transmission Output Shaft

Sensor (TOSS) LowWHT0.0 V0.0 VAutomatic Transmission

(4L30E)

E3Pressure Control Solenoid

LowPPL/RED0.0 V1.1 VAutomatic Transmission

(4L30E)

E4Pressure Control Solenoid

HighPPL/WHT0.0 V4.9 VAutomatic Transmission

(4L30E)

E5Exhaust Gas Recirculation

(EGR) Control HighBLK/YELB+B+General Description and

Operation, EGR Control

E6Exhaust Gas Recirculation

(EGR) Control LowYELB+B+General Description and

Operation, EGR Control

E7Transmission Range

Signal “B”BLU/YEL0.0 V0.0 VAutomatic Transmission

(4L30E)

E8Throttle Position (TP)

SensorBLU0.5-0.8 V0.5-0.8 V

(at idle)General Description and

Operation, Throttle Position

Sensor

E9Engine Coolant

Temperature (ECT)

SensorBLU/RED0.5-4.9 V

(depends on

temperature)0.5-4.9 V

(depends on

temperature)General Description and

Operation, Engine Coolant

Temperature (ECT) Sensor

E10Not Used————

E11Crankshaft Position (CKP)

Sensor +5 Volt ReferenceYEL/RED5.0 V or less

than 1.0 V5.0 VGeneral Description and

Operation, Crankshaft

Position Sensor

E12Transmission Range

Signal “A”BLU/WHTB+B+Automatic Transmission

(4L30E)

E13Fuel Pump (FP) RelayRED/WHT0.0 VB+On-Vehicle Service, Fuel

Pump Relay

E14Shift High (BAND APPLY)BRN/WHTB+B+Automatic Transmission

(4L30E)

Page 4683 of 6000

6E–26

ENGINE DRIVEABILITY AND EMISSIONS

PCM Pinout Table, 32-Way Blue Connector – Row “E”

(For EXPORT and SOUTH AFRICA)

TS23346

PINPIN FunctionWire ColorIGN ONENG RUNRefer To

E1Transmission Output Shaft

Sensor (TOSS) HighRED0.0 V0.1 VAutomatic Transmission

(4L30E)

E2Transmission Output Shaft

Sensor (TOSS) LowWHT0.0 V0.0 VAutomatic Transmission

(4L30E)

E3Pressure Control Solenoid

LowPPL/RED0.0 V1.1 VAutomatic Transmission

(4L30E)

E4Pressure Control Solenoid

HighPPL/WHT0.0 V4.9 VAutomatic Transmission

(4L30E)

E5Not Used————

E6Not Used————

E7Transmission Range

Signal “B”BLU/YEL0.0 V0.0 VAutomatic Transmission

(4L30E)

E8Throttle Position (TP)

SensorBLU0.5-0.8 V0.5-0.8 V

(at idle)General Description and

Operation, Throttle Position

Sensor

E9Engine Coolant

Temperature (ECT)

SensorBLU/RED0.5-4.9 V

(depends on

temperature)0.5-4.9 V

(depends on

temperature)General Description and

Operation, Engine Coolant

Temperature (ECT) Sensor

E10Not Used————

E11Crankshaft Position (CKP)

Sensor +5 Volt ReferenceYEL/RED5.0 V or less

than 1.0 V5.0 VGeneral Description and

Operation, Crankshaft

Position Sensor

E12Transmission Range

Signal “A”BLU/WHTB+B+Automatic Transmission

(4L30E)

E13Fuel Pump (FP) RelayRED/WHT0.0 VB+On-Vehicle Service, Fuel

Pump Relay

E14Shift High (BAND APPLY)BRN/WHTB+B+Automatic Transmission

(4L30E)

E15A/C RequestGRN/ORN0.0 V0.0 VElectric Cooling Fans

E16Ignition Feed (1 of 2 F16)RED/BLUB+B+—

Page 4684 of 6000

6E–27 ENGINE DRIVEABILITY AND EMISSIONS

PCM Pinout Table, 32-Way Blue Connector – Row “F”

TS23346

PINPIN FunctionWire ColorIGN ONENG RUNRefer To

F1Not Used————

F2Transmission Range

Signal “C”BLU/BLK0.0 V0.0 VAutomatic Transmission

(4L30E)

F3Transmission Range

Signal “P”YEL/GRNB+0.0 VAutomatic transmission

(4L30E)

F4Brake SwitchGRN/YEL0.0 V0.0 VAutomatic transmission

(4L30E)

F5Power SwitchPPL/REDB+B+Automatic Transmission

(4L30E)

F6Winter SwitchPPL/GRNB+B+Automatic Transmission

(4L30E)

F7Transmission Fluid

TemperatureRED/BLK0.5-4.9 V

(depends on

temperature)0.5-4.9 V

(depends on

temperature)Automatic Transmission

(4L30E)

F8Manifold Absolute

Pressure (MAP)GRY/BLK3.5-4.9 V

(depends on

altitude and

barometric

pressure)0.6-1.3 VGeneral Description and

Operation, Manifold Absolute

Pressure

F9Not Used————

F10Cruise ControlGRY/BLUB+B+Automatic transmission

(4L30E)

F11Kickdown SwitchLT B L UB+B+Automatic Transmission

(4L30E)

F12DIAGORN/BLUB+B+—

F13Injector “C” Cylinder #3GRNB+B+General Description and

Operation, Fuel Injector

F14Shift “A” SolenoidBRN/REDB+B+Automatic Transmission

(4L30E)

F15Injector Cylinder #5GRN/BLKB+B+General Description and

Operation, Fuel Injector

F16Ignition Feed (1 of 2 E16)RED/BLUB+B+—

Page 4739 of 6000

6E–82

ENGINE DRIVEABILITY AND EMISSIONS

Engine Cranks But Will Not Run

StepNo Ye s Va l u e ( s ) Action

131. Remove any ignition coil and install a spark tester at

the spark plug end of the coil.

2. Observe the tester while the engine is cranking.

Was a crisp, blue spark observed? Only one or two

sparks followed by no result is considered the same as

“No Spark.”

—Go to Step 15Go to Step 14

14Replace the ignition coil, and return to Step 13 to test

the remaining coils.

Is the action complete?

—Verify repair—

15Repeat Step 13 for each coil. Remove only one coil at a

time, and reinstall each coil on its spark plug after

testing, but do not refasten coils with screws at this

time.

After all coils have passed the spark test, does the

engine start?

—

Refasten all

coils with

their screws

Go to Step 16

161. Remove the spark plugs from all cylinders.

2. Visually inspect the spark plug electrodes.

3. Replace any spark plugs with loose or missing

electrodes or cracked insulators.

Did your inspection reveal any spark plugs exhibiting

excessive fouling?

—

Correct the

fouling

condition

Go to Step 17

17Refer to Engine Mechanical Diagnosis to diagnose the

following conditions:

Faulty or incorrect camshaft drive belts

Leaking or sticky valves or rings

Excessive valve deposits

Loose or worn rocker arms

Weak valve springs

Incorrect valve timing

Leaking head gasket

Is the action complete?

—Verify repairGo to Step 19

18Observe the “Engine Speed” data display on the scan

tool while cranking the engine.

Is the engine RPM indicated? (If the scan tool is

normally powered from the cigarette lighter socket, and

if the scan tool display goes blank while cranking the

engine, it will be necessary to power the scan tool

directly from the vehicle battery.)

—Go to Step 19Go to Step 28

191. Disconnect the 7-pin gray connector at the rear of

the air filter beneath the point where the air duct

attaches to the MAF sensor.

2. Ignition “ON.”

3. Using a test light connected to ground, probe the

ignition terminal at the PCM (female) side of the

7-pin connector.

Is the test light “ON?”

—Go to Step 20Go to Step 26

Page 4827 of 6000

6E–170

ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0201 Injector 1 Control Circuit

D06RW034

Circuit Description

The powertrain control module (PCM) has six individual

injector driver circuits. Each controls an injector. When a

driver circuit is grounded by the PCM, the injector is

activated. The PCM monitors the current in each driver

circuit. The voltage on each driver is monitored to detect

a fault. If the voltage is not what the PCM expects to

m o n i t o r o n t h e c i r c u i t , a D T C i s s e t . T h i s D T C i s a l s o s e t i f

an injector driver is shorted to voltage or if there is an open

circuit.

Conditions for Setting the DTC

The battery voltage is more than 9 volts.

The engine is turning, determined by 58X crankshaft

position input signal.

The injector voltage does not equal the ignition voltage

when the injector is commanded “OFF” or the injector

voltage does not equal 0 volts when the injector is

commanded “ON.”

The above conditions are met for 15 seconds.

Action Taken When the DTC Sets

The PCM will illuminate the malfunction indicator lamp

(MIL) the first time the fault is detected.

The PCM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

DTC P0201 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the PCM battery

feed.

Diagnostic Aids

An injector driver circuit that is open or shorted to voltage

will cause a DTC P0201 to set. It will also cause a misfire

due to an inoperative injector. A misfire DTC will also be

set indicating which cylinder is inoperative.

Long term and short term fuel trims that are excessively

high or low are a good indication that an injector is faulty.

Use Fuel Injector Coil Test Procedure to check for faulty

injectors.

Test Description

The number(s) below refer to the step number(s) on the

Diagnostic Chart.

3. This step determines if DTC P0201 is the result of a

hard failure or an intermittent condition.

5. A special injector test connector is provided so that

the injectors can be electrically tested without

removal of the manifold. On the Trooper, the

special 7-way gray connector is located at the front

of the charcoal canister. The test connector can be

identified by the blue connector lock which is

tethered to the wiring harness. If the light for

cylinder 1 is “ON” steady before cranking the engine

as well as while cranking the engine, then the

injector driver circuit is shorted to ground.

Page 4829 of 6000

6E–172

ENGINE DRIVEABILITY AND EMISSIONS

DTC P0201 – Injector 1 Control Circuit

StepNo Ye s Va l u e ( s ) Action

71. Disconnect the PCM connector for the affected

injectors.

2. With a test light connected to B+, probe the affected

injector driver circuit.

Does the test light illuminate?

—Go to Step 8Go to Step 15

8Repair short to ground in the injector driver circuit.

Is the action complete?

—

Go to OBD

System

Check

—

91. Disconnect the injector test connector.

2. At the injector side of the harness, connect an

ohmmeter between the positive wire (red with blue

tracer) and the wire for cylinder 1 (green with white

tracer).

Does the ohmmeter indicate continuity?

—Go to Step 11Go to Step 10

10Repair the open injector harness wire or open injector.

Is the action complete?

—Verify repair—

11At the PCM side of the injector test connector, check

the green/white wire for a short to voltage.

Was there a short to voltage?

—Go to Step 12Go to Step 13

12Repair the short to voltage.

Is the action complete?

—Verify repair—

13Check for an open circuit between the injector test

connector and the PCM.

Was there an open circuit?

—Go to Step 14Go to Step 15

14Repair the open circuit.

Is the action complete?

—Verify repair—

15Replace the PCM.

IMPORTANT:The replacement PCM must be

programmed. Refer to

UBS 98model year Immobilizer

Workshop Manual.

Is the action complete?—Verify repair—