oil pressure OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 278 of 6000

COMPRESSOR SHAFT SEAL

Service Precaution

When replacing the shaft seal assembly, pressure relief

valve or control switches, it will be necessary to recover

the refrigerant. Other than clutch repair procedures, the

same holds true for any disassembly of the compressor.

A clean workbench covered with a sheet of clean

paper, and a place (clean trays, etc) for all parts being

removed and replaced is important, as is the use of

proper clean service tools.

CAUTION: Any attempt to use makeshift or

inadequate service tools or equipment may result

in damage and/or improper compressor operation.

All parts required for servicing the internal compressor

are protected by a preservative process and packaged

in a manner which will eliminate the necessity of

cleaning, washing or flushing of the parts. The parts

can be used in the internal assembly just as they are

removed from the service package. Seals and

protective packaging should be left intact until just

prior to installation.

If the compressor rear head, front head or cylinder and

shaft assembly is to be serviced or replaced, the oil in

the compressor must be drained, measured, recorded

and replaced.

Legend

(1) Suction Port

(2) Discharge Port

(3) Mounting Boss

(4) Mounting Boss

(5) Pressure Relief Valve

(6) Mounting Boss

Seal Leak Detection

A shaft seal should not be changed because of small

amounts of oil found on an adjacent surface but only

after actual refrigerant leakage is found using an

approved leak detector.

CAUTION: Handling and care of seal protector is

important. If seal protector is nicked or the bottom

flared, the new seal may be damaged during

installation.

Removal

1. Recover the refrigerant using Refrigerant Recovery

System.

2. Loosen and reposition compressor in mounting

brackets, if necessary.

3. Remove clutch plate and hub assembly from

compressor as described previously.

4. Remove the shaft seal retainer ring, using snap ring

pliers.

5. Thoroughly clean inside of compressor neck area

surrounding the shaft, the exposed portion of the

seal, the retainer ring groove and the shaft itself.

Any dirt or foreign material getting into compressor

may cause damage.

6. Fully engage the knurled tangs of Seal Remover-

Installer J-23128-A into the recessed portion of the

Seal (1) by turning the handle clockwise. Remove

the Seal from the compressor with a rotary-pulling

motion.

Discard the seal. The handle must be hand-

tightened securely. Do not use a wrench or pliers.

1

2

3

456

871RW006

J-23128-A1

901RW008

Page 280 of 6000

6. Remove any excess oil resulting from installing the

new seal parts from the shaft and inside the

compressor neck.

7. Install the clutch plate and hub assembly as

described previously.8. Reinstall compressor belt and tighten bracket.

9. Evacuate and charge the refrigerant system.

COMPRESSOR PRESSURE RELIEF VALVE

Removal

1. Recover the refrigerant using Refrigerant Recovery

System.

2. Remove old pressure relief valve.

Installation

1. Clean valve seat area on rear head.2. Lubricate O-ring of new pressure relief valve and

O-ring assembly with new 525 viscosity refrigerant

oil. Install new valve and torque in place, 9.0 Nꞏm

(6.1 ft lbs)

3. Evacuate and recharge the system.

4. Leak test system.

COMPRESSOR OIL

Compressor Oil Check

The oil used to lubricate the compressor is circulating

with the refrigerant.

Whenever replacing any component of the system or a

large amount of gas leakage occurs, add oil to maintain

the original amount of oil.

Checking and Adjusting Oil Quantity for

Used Compressor

1. Perform oil return operation. Refer to Oil Return

Operation in this section.

2. Discharge and recover refrigerant and remove the

compressor.

3. Drain the compressor oil and measure the extracted

oil with a measuring cylinder.

4. If the amount of oil drained is much less than 90 cc

(3.0 fl. oz.), some refrigerant may have leaked out.

Conduct a leak tests on the connections of each

system, and if necessary, repair or replace faulty

parts.

5. Check the compressor oil contamination. (Refer to

Contamination of Compressor Oil in this section.)

6. Adjust the oil level following the next procedure

below.7. Install the compressor, then evacuate, charge and

perform the oil return operation.

8. Check system operation.

When it is impossible to preform oil return

operation, the compressor oil should be checked in

the following order:

1. Discharge and recover refrigerant and remove the

compressor.

2. Drain the compressor oil and measure the extracted

oil with a measuring cylinder.

3. Check the oil for contamination.

4. If more than 90 cc (3.0 fl. oz.) of oil is extracted from

the compressor, supply the same amount of oil to

the compressor to be installed. If the amount of oil

extracted is less than 90 cc (3.0 fl. oz.), recheck the

compressor oil in the following order:

5. Supply 90 cc (3.0 fl. oz.) of oil to the compressor

and install it onto the vehicle.

6. Evacuate and recharge with the proper amount of

refrigerant.

7. Perform the oil return operation.

8. Remove the compressor and recheck the amount of

oil.

9. Adjust the compressor oil, if necessary.

Checking and Adjusting for Compressor

Replacement

The oil is not charged in compressor (service parts). So

it is necessary to charge the proper amount of oil to the

new compressor. (Oil Capacity)

Capacity total in system 150 cc (5.0 fl.oz)

Compressor (Service 150 cc (5.0 fl.oz)

parts) charging amount

(Collected Amount) (Charging Amount)

more than 90 cc same as collected

(3.0 fl.oz) amount

less than 90 cc (3.0 fl.oz) 90 cc (3.0 fl.oz)

(Collected Amount) (Charging Amount)

more than 90 cc same as collected

(3.0 fl.oz) amount

less than 90 cc (3.0 fl.oz) 90 cc (3.0 fl.oz)

Page 281 of 6000

1. Perform oil return operation.

2. Discharge and recover the refrigerant and remove

the compressor.

3. Drain the compressor oil and measure the extracted

oil.

4. Check the compressor oil for contamination.

5. Adjust the oil level as required.

6. Evacuate, charge and perform the oil return

operation.

7. Check the system operation.

Contamination of Compressor Oil

Unlike engine oil, no cleaning agent is added to the

compressor oil. Even if the compressor runs for a long

period of time (approximately one season), the oil never

becomes contaminated as long as there is nothing

wrong with the compressor or its method of use.

Inspect the extracted oil for any of the following

conditions:

The capacity of the oil has increased.

The oil has changed to red.

Foreign substances, metal powder, etc., are present

in the oil.

If any of these conditions exists, the compressor

oil is contaminated. Whenever contaminated

compressor oil is discovered, the receiver/drier

must be replaced.

Oil Return Operation

There is close affinity between the oil and the

refrigerant. During normal operation, part of the oil

recirculates with the refrigerant in the system. When

checking the amount of oil in the system, or replacing

any component of the system, the compressor must be

run in advance for oil return operation. The procedure

is as follows:

1. Open all the doors and the engine hood.

2. Start the engine and air conditioning switch to "ON"

and set the fan control knob at its highest position.

3. Run the compressor for more than 20 minutes

between 800 and 1,000 rpm in order to operate the

system.

4. Stop the engine.

Replacement of Component Parts

When replacing the system component parts, supply

the following amount of oil to the component parts to be

installed.

Compressor Leak Testing (External and

Internal)

Bench-Check Procedure

1. Install test plate J-39893 on rear head of compressor.

2. Using Refrigerant Recovery System, attach center

hose of manifold gage set on charging station to a

refrigerant drum standing in an upright drum.

3. Connect charging station high and low pressure

lines to corresponding fittings on test plate J-39893.

Suction port (low-side) of compressor has large

internal opening. Discharge port (high-side) has

smaller internal opening into compressor and

deeper recess.

4. Open low pressure control, high pressure control

and refrigerant control on charging station to allow

refrigerant vapor to flow into compressor.

5. Using a leak detector, check for leaks at pressure

relief valve, rear head switch location, compressor

front and rear head seals, center cylinder seal,

through bolt head gaskets and compressor shaft

seal. After checking, shut off low pressure control

and high-pressure control on charging station.

6. If an external leak is present, perform the necessary

corrective measures and recheck for leaks to make

certain the leak has been connected.

7. Recover the refrigerant.

8. Disconnect both hoses from the test plate J-39893.

9. Add 90 ml (3 oz.) new PAG lubricant to the

compressor assembly. Rotate the complete

compressor assembly (not the crankshaft or drive

plate hub) slowly several turns to distribute oil to all

cylinder and piston areas.

10. Install a M9

1.25 threaded nut on the compressor

crankshaft if the drive plate and clutch assembly are

not installed.

11. Using a box-end wrench or socket and handle,

rotate the compressor crankshaft or clutch drive

plate on the crankshaft several turns to insure

piston assembly to cylinder wall lubrication.

12. Using Refrigerant Recovery System, connect the

charging station high-pressure line to the test plate

J-39893 high-side connector.

13. Using Refrigerant Recovery System, connect the

charging station low-pressure line to the low

pressure port of the test plate J-39893. Oil will drain

out of the compressor suction port if the compressor

is positioned with the suction port downward. (Component parts to be (Amount of Oil)

installed)

Evaporator 50 cc (1.7 fl. oz.)

Condenser 30 cc (1.0 fl. oz.)

Receiver/dryer 30 cc (1.0 fl. oz.)

Refrigerant line (one 10 cc (0.3 fl. oz.)

piece)

(Amount of oil drained (Charging amount of oil

from used compressor) to new compressor)

more than 90 cc same as drained amount

(3.0 fl.oz)

less than 90 cc (3.0 fl.oz) 90 cc (3.0 fl.oz)

Page 282 of 6000

14. Attach the compressor to the J-34992 holding

fixture and mount the compressor in a vise so that

the compressor will be in a horizontal position and

the shaft can be turned with a wrench.

15. Using a wrench, rotate the compressor crankshaft

or drive plate hub ten complete revolutions at a

speed of approximately one-revolution per second

turning the compressor at less than one-revolution

per second can result in a lower pump-up pressure

and disqualify a good pumping compressor.

16. Observe the reading on high-pressure gauge at the

completion of the tenth revolution of the

compressor. The pressure reading for a good

pumping compressor should be 690 kPa (100 psi)

or above. A pressure reading of less than 620 kPa

(90 psi) would indicate one or more suction and/or

discharge valves leaking an internal leak, or an

inoperative valve, and the refrigerant must be

recovered and the compressor disassembled and

checked for cause of leak. Repair as needed,

reassemble and repeat the pump-up test. Externally

leak test.

17. When the pressure pump-up test is completed,

recover the refrigerant from the high-side and

remove the test plate J-39893.

18. Tilt the compressor so that the compressor suction

and discharge ports are down. Drain the PAG

lubricant from the compressor.

19. Allow the compressor to drain for 10 minutes, then

refill with the proper amount of PAG lubricant, per

oil balance procedure described previously. The

PAG lubricant may be poured into the suction port.

If further assembly or processing is required, a

shipping plate or test plate J-39893 should be

installed to keep out air, dirt and moisture until the

compressor is installed.

Page 453 of 6000

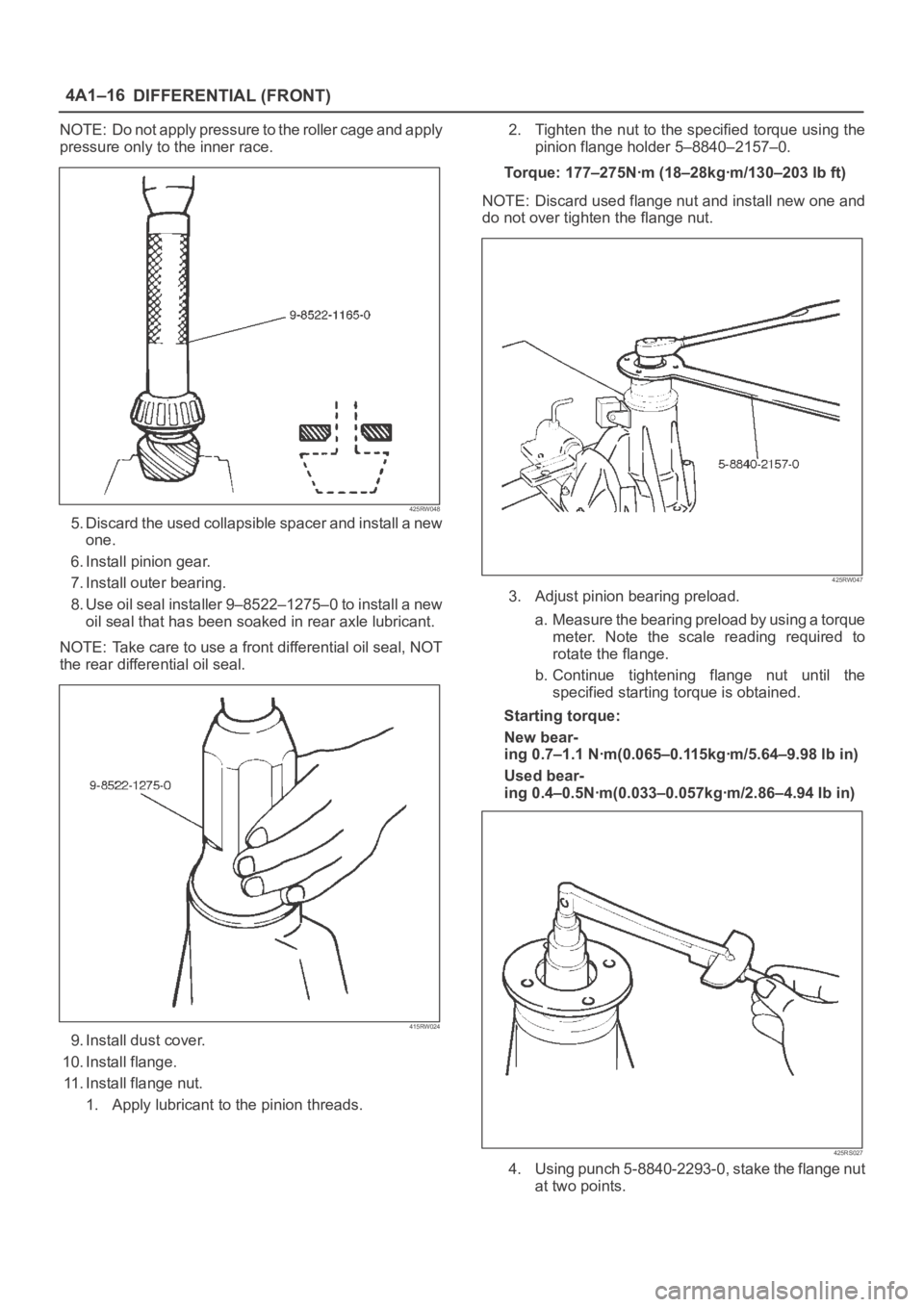

DIFFERENTIAL (FRONT) 4A1–16

NOTE: Do not apply pressure to the roller cage and apply

pressure only to the inner race.

425RW048

5. Discard the used collapsible spacer and install a new

one.

6. Install pinion gear.

7. Install outer bearing.

8. Use oil seal installer 9–8522–1275–0 to install a new

oil seal that has been soaked in rear axle lubricant.

NOTE: Take care to use a front differential oil seal, NOT

the rear differential oil seal.

415RW024

9. Install dust cover.

10. Install flange.

11. Install flange nut.

1. Apply lubricant to the pinion threads.2. Tighten the nut to the specified torque using the

pinion flange holder 5–8840–2157–0.

Torque: 177–275Nꞏm (18–28kgꞏm/130–203 lb ft)

NOTE: Discard used flange nut and install new one and

do not over tighten the flange nut.

425RW047

3. Adjust pinion bearing preload.

a. Measure the bearing preload by using a torque

meter. Note the scale reading required to

rotate the flange.

b. Continue tightening flange nut until the

specified starting torque is obtained.

Starting torque:

New bear-

ing 0.7–1.1 Nꞏm(0.065–0.115kgꞏm/5.64–9.98 lb in)

Used bear-

ing 0.4–0.5Nꞏm(0.033–0.057kgꞏm/2.86–4.94 Ib in)

425RS027

4. Using punch 5-8840-2293-0, stake the flange nut

at two points.

Page 483 of 6000

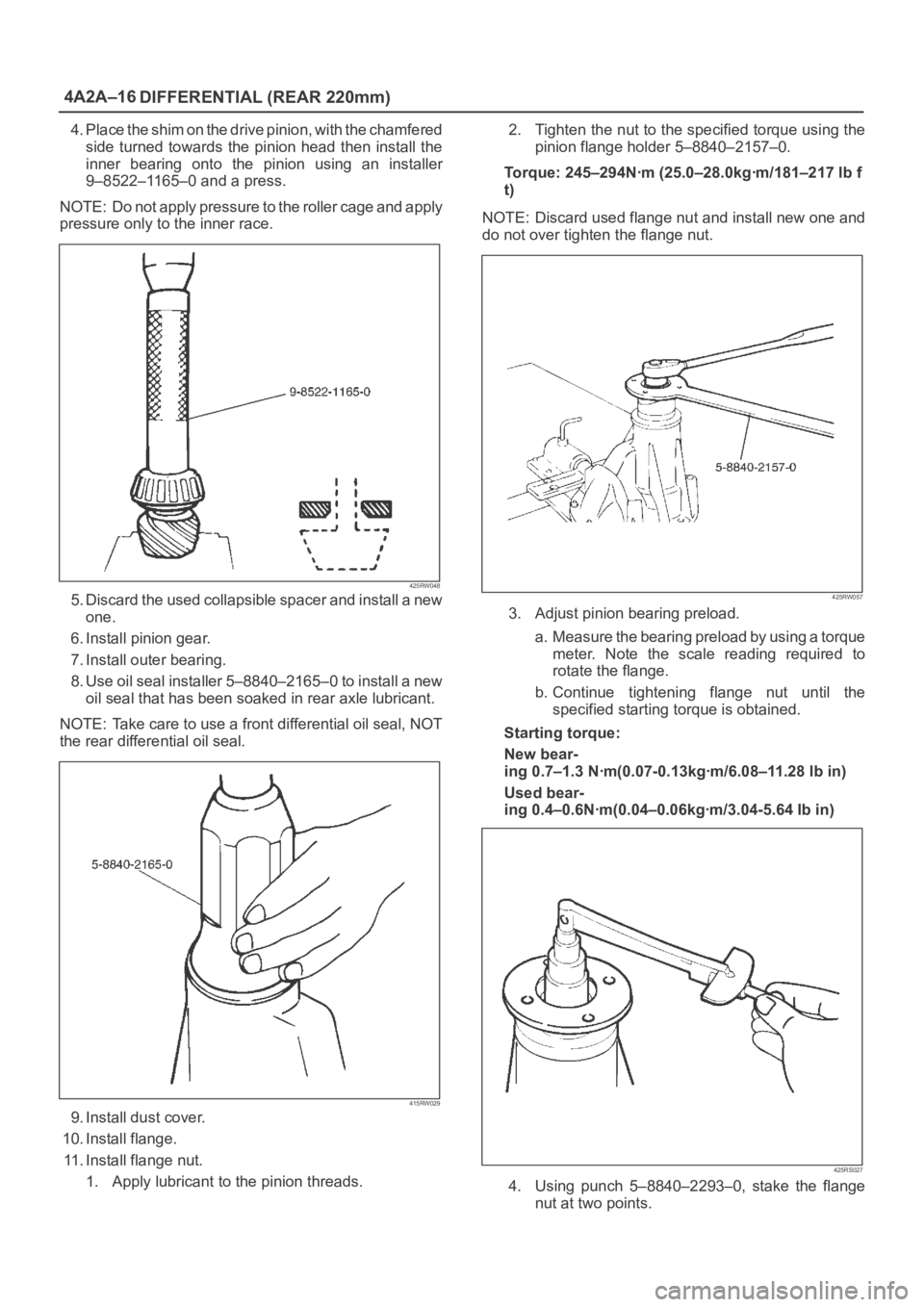

4A2A–16

DIFFERENTIAL (REAR 220mm)

4. Place the shim on the drive pinion, with the chamfered

side turned towards the pinion head then install the

inner bearing onto the pinion using an installer

9–8522–1165–0 and a press.

NOTE: Do not apply pressure to the roller cage and apply

pressure only to the inner race.

425RW048

5. Discard the used collapsible spacer and install a new

one.

6. Install pinion gear.

7. Install outer bearing.

8. Use oil seal installer 5–8840–2165–0 to install a new

oil seal that has been soaked in rear axle lubricant.

NOTE: Take care to use a front differential oil seal, NOT

the rear differential oil seal.

415RW029

9. Install dust cover.

10. Install flange.

11. Install flange nut.

1. Apply lubricant to the pinion threads.2. Tighten the nut to the specified torque using the

pinion flange holder 5–8840–2157–0.

Torque: 245–294Nꞏm (25.0–28.0kgꞏm/181–217 lb f

t)

NOTE: Discard used flange nut and install new one and

do not over tighten the flange nut.

425RW057

3. Adjust pinion bearing preload.

a. Measure the bearing preload by using a torque

meter. Note the scale reading required to

rotate the flange.

b. Continue tightening flange nut until the

specified starting torque is obtained.

Starting torque:

New bear-

ing 0.7–1.3 Nꞏm(0.07-0.13kgꞏm/6.08–11.28 lb in)

Used bear-

ing 0.4–0.6Nꞏm(0.04–0.06kgꞏm/3.04-5.64 Ib in)

425RS027

4. Using punch 5–8840–2293–0, stake the flange

nut at two points.

Page 494 of 6000

DIFFERENTIAL (REAR 220mm)

4A2A–27

Pressure ring

425RS057

Legend

(3) Sliding surface with the friction disc. When

nicks or scratches are found, polish with an oil

stone and repair on a level block using a

compound.

(4) Sliding spherical surface with the pinion gear.

(5) Sliding surface with the side gear.

(6) V–shaped groove of the pressure ring and V

–shaped section of the pinion shaft.

(7) Fitting section with the case.

(8) Face contacting the inner surface of the

differential case. Repair burrs and nicks using

an oil stone.

Thrust washer

425RS058

Legend

(9) Sliding surface with the side gear or case.

(10) Peripheral groove of the side gear.

Repair light nicks and burrs using an oil stone.

Case

425RS059

Legend

(11) Contact surface with the spring disc.

(12) Inner groove of the differential cage B.

Repair light nicks and burrs using an oil stone.

425RS060

Page 495 of 6000

4A2A–28

DIFFERENTIAL (REAR 220mm)

Legend

(7) Fitting section with the case.

(8) Face contacting the inner surface of the

differential case.

Repair burrs and nicks using an oil stone.

(9) Sliding surface with the side gear or case.

(11) Contact surface with spring disc.

Measure the Deformation of the friction disc & plate.

Limit: 0.08 mm (0.003 in)

425RS061

Measure the wear of the friction plate & disc

Limit(A–B): 0.1 mm (0.004 in)

Remarks:

A=Inner or outer projections

B=Sliding surface subjected to abrasion

425RS062

Measure the wear of the thrust washer

Limit: 1.3 mm (0.05 in)

425RS063

Reassembly

Adjust the clearance between the friction disc and plate.

1. Measuring the depth of the differential cage.

Standard (A–B): 80.58 mm (3.17 in)

(C): 10.58 mm (0.41 in)

425RS064

2. Measuring the overall length of the pressurering,

friction disc and friction plate.

Mount the pinion shaft in the pressurering and then

install the friction disc & plate.

Page 497 of 6000

4A2A–30

DIFFERENTIAL (REAR 220mm)

3. After measuring dimensions of each of the above

sections, proceed with the adjustment in the following

manner:

Adjust the clearance to satisfy the equation below.

{(F – B) + G – H}=0.05 – 0.20 mm

Also, select the thrust washers so that the

dimensional difference between the back surfaces of

the left and right pressure rings to the thrust washers

is 0.05mm or less.

Thickness : 1.5mm (0.059 in)

1.6 mm(0.063 in)

1.7 mm(0.067 in)

NOTE: When assembling the parts, apply recommended

gear oil sufficiently to each of the parts, especially, to the

contact surfaces and sliding surfaces.

1. Install Differential cage B.

2. Install Thrust washer.

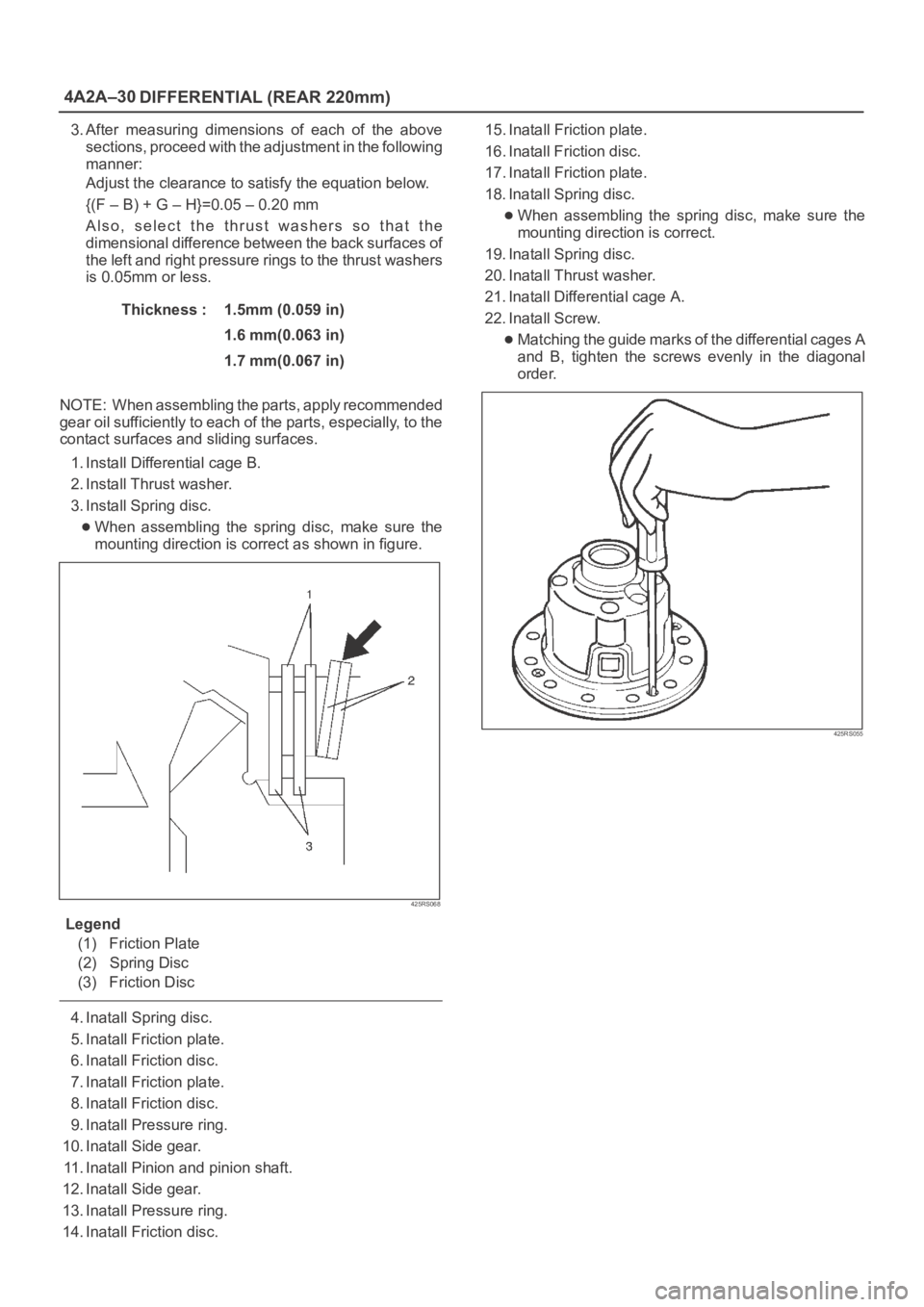

3. Install Spring disc.

When assembling the spring disc, make sure the

mounting direction is correct as shown in figure.

425RS068

Legend

(1) Friction Plate

(2) Spring Disc

(3) Friction Disc

4. Inatall Spring disc.

5. Inatall Friction plate.

6. Inatall Friction disc.

7. Inatall Friction plate.

8. Inatall Friction disc.

9. Inatall Pressure ring.

10. Inatall Side gear.

11. Inatall Pinion and pinion shaft.

12. Inatall Side gear.

13. Inatall Pressure ring.

14. Inatall Friction disc.15. Inatall Friction plate.

16. Inatall Friction disc.

17. Inatall Friction plate.

18. Inatall Spring disc.

When assembling the spring disc, make sure the

mounting direction is correct.

19. Inatall Spring disc.

20. Inatall Thrust washer.

21. Inatall Differential cage A.

22. Inatall Screw.

Matching the guide marks of the differential cages A

and B, tighten the screws evenly in the diagonal

order.

425RS055

Page 519 of 6000

4A2B–16DIFFERENTIAL (REAR 244mm)

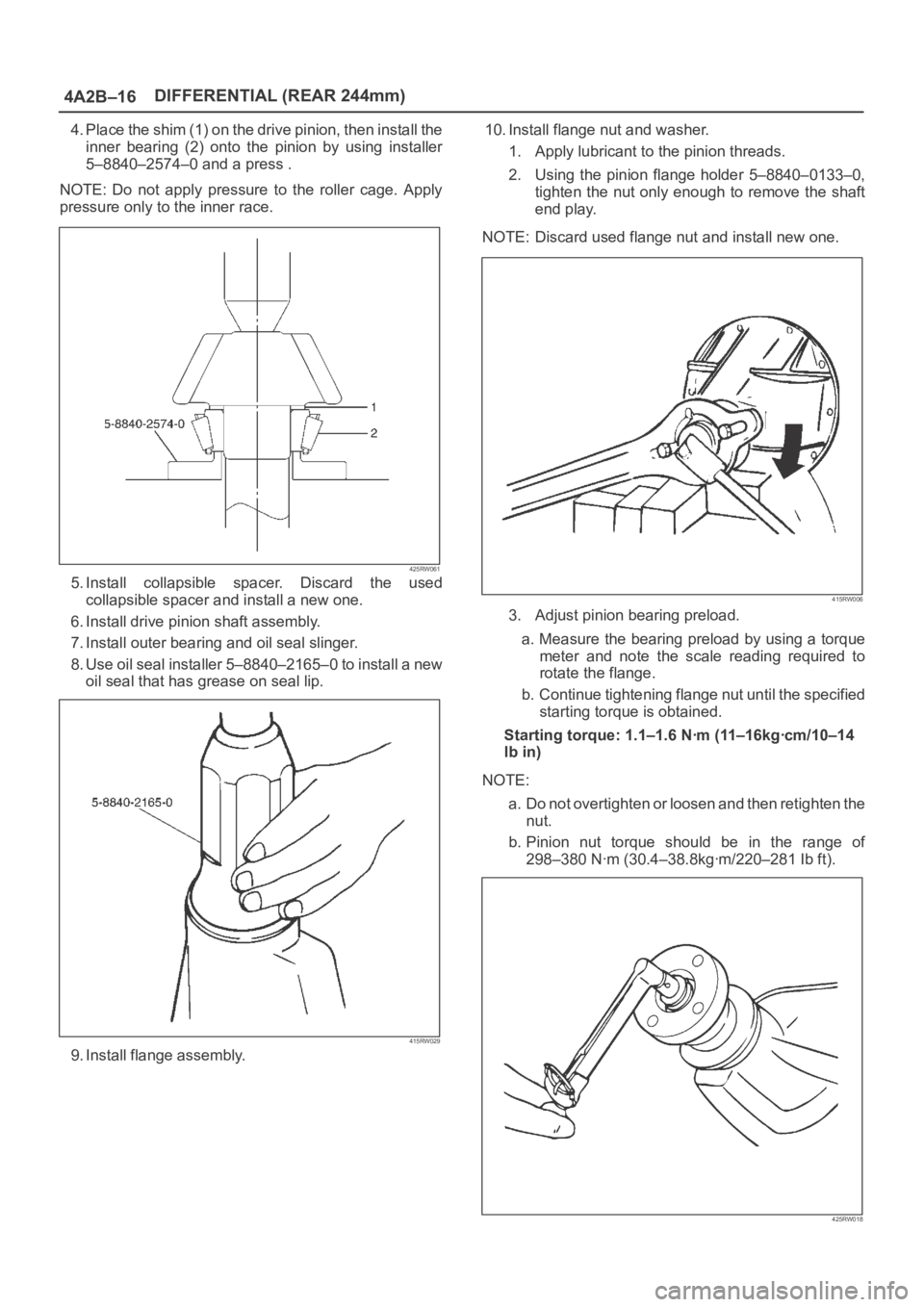

4. Place the shim (1) on the drive pinion, then install the

inner bearing (2) onto the pinion by using installer

5–8840–2574–0 and a press .

NOTE: Do not apply pressure to the roller cage. Apply

pressure only to the inner race.

425RW061

5. Install collapsible spacer. Discard the used

collapsible spacer and install a new one.

6. Install drive pinion shaft assembly.

7. Install outer bearing and oil seal slinger.

8. Use oil seal installer 5–8840–2165–0 to install a new

oil seal that has grease on seal lip.

415RW029

9. Install flange assembly.10. Install flange nut and washer.

1. Apply lubricant to the pinion threads.

2. Using the pinion flange holder 5–8840–0133–0,

tighten the nut only enough to remove the shaft

end play.

NOTE: Discard used flange nut and install new one.

415RW006

3. Adjust pinion bearing preload.

a. Measure the bearing preload by using a torque

meter and note the scale reading required to

rotate the flange.

b. Continue tightening flange nut until the specified

starting torque is obtained.

Starting torque: 1.1–1.6 Nꞏm (11–16kgꞏcm/10–14

lb in)

NOTE:

a. Do not overtighten or loosen and then retighten the

nut.

b. Pinion nut torque should be in the range of

298–380 Nꞏm (30.4–38.8kgꞏm/220–281 Ib ft).

425RW018