OPEL FRONTERA 1998 Workshop Manual

Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 851 of 6000

5A–41 BRAKE CONTROL SYSTEM

The DLC is located behind the center console

350RV010

Keep #12 terminal connected with #4 terminal or # 5

terminal (GND) during DTC display. (If #12 terminal

is separated from #4 terminal or # 5 terminal (GND)

during display, display will stop.)

2. DTC display:

DTC is displayed by blinking warning light.

Double-digit display.

First, normal DTC 12 is displayed three times and

then any other DTCs are displayed three times. (If

no other DTCs have been stored, the display of DTC

12 will be repeated.)

3. How to erase code:

Conduct brake switch ON/OFF operation 6 or more

times within 3 seconds of self-diagnosis startup.

The code cannot be erased if more than 3 seconds

have passed since self-diagnosis startup, or if

self-diagnosis has started with brake switched on

(brake pedal depressed).

B05RW005

Page 852 of 6000

5A–42

BRAKE CONTROL SYSTEM

4. Notes

If the following should occurs during Diagnostic

Trouble Code (DTC) display the display will be

discontinued. After initial check, the status that is

under the control of ABS will be returned :

– The vehicle starts (The wheels turn) or the brake

pedal is depressed.

Up to 3 different codes can be stored.

If the ABS should turn OFF due to an intermittent

defect, the system will be restored at the next key

cycle, if the initial check finds no abnormality (when

IGN is switched from OFF to ON).

5. An example of DTC display

Display of DTC 23

B05RW006

After displaying DTC 12 three times, one DTC after

another is displayed, starting with the most recent

one. (However, display is discontinued after about 5

minutes.)

B05RS005

The DTC 12 is displayed repeatedly. (display is

discontinued after about 5 minutes)

Page 853 of 6000

5A–43 BRAKE CONTROL SYSTEM

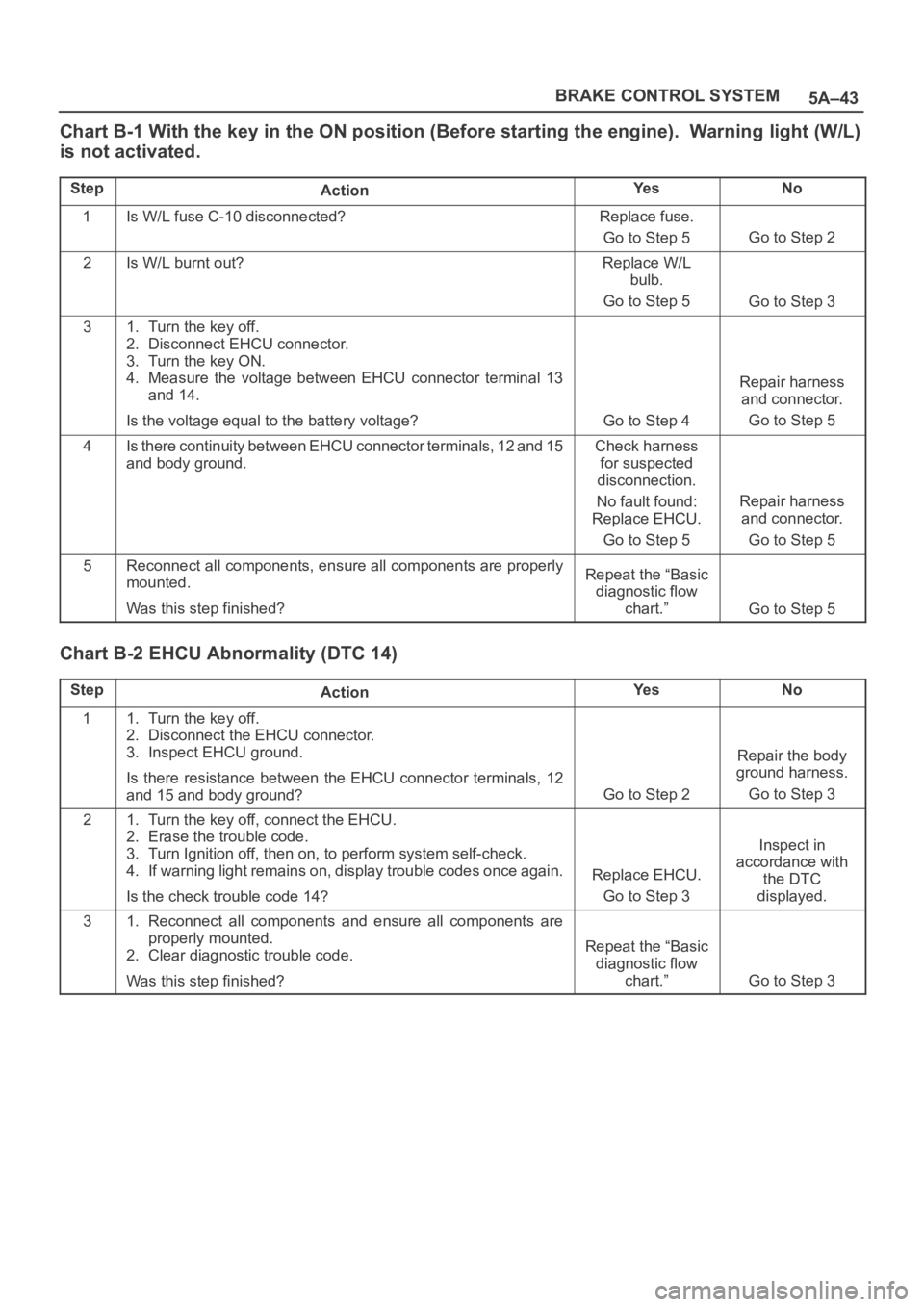

Chart B-1 With the key in the ON position (Before starting the engine). Warning light (W/L)

is not activated.

StepActionYe sNo

1Is W/L fuse C-10 disconnected?Replace fuse.

Go to Step 5

Go to Step 2

2Is W/L burnt out?Replace W/L

bulb.

Go to Step 5

Go to Step 3

31. Turn the key off.

2. Disconnect EHCU connector.

3. Turn the key ON.

4. Measure the voltage between EHCU connector terminal 13

and 14.

Is the voltage equal to the battery voltage?

Go to Step 4

Repair harness

and connector.

Go to Step 5

4Is there continuity between EHCU connector terminals, 12 and 15

and body ground.Check harness

for suspected

disconnection.

No fault found:

Replace EHCU.

Go to Step 5

Repair harness

and connector.

Go to Step 5

5Reconnect all components, ensure all components are properly

mounted.

Was this step finished?Repeat the “Basic

diagnostic flow

chart.”

Go to Step 5

Chart B-2 EHCU Abnormality (DTC 14)

StepActionYe sNo

11. Turn the key off.

2. Disconnect the EHCU connector.

3. Inspect EHCU ground.

Is there resistance between the EHCU connector terminals, 12

and 15 and body ground?

Go to Step 2

Repair the body

ground harness.

Go to Step 3

21. Turn the key off, connect the EHCU.

2. Erase the trouble code.

3. Turn Ignition off, then on, to perform system self-check.

4. If warning light remains on, display trouble codes once again.

Is the check trouble code 14?

Replace EHCU.

Go to Step 3

Inspect in

accordance with

the DTC

displayed.

31. Reconnect all components and ensure all components are

properly mounted.

2. Clear diagnostic trouble code.

Was this step finished?

Repeat the “Basic

diagnostic flow

chart.”

Go to Step 3

Page 854 of 6000

5A–44

BRAKE CONTROL SYSTEM

Chart B-3 Power Voltage Drop (DTC 15)

StepActionYe sNo

1Is the battery voltage normal? (Battery capacity check)

Go to Step 2

Charge or

replace battery.

Go to Step 2

21. Turn the key off.

2. Disconnect EHCU connector.

3. Turn the key on.

Is the voltage between EHCU connector terminals 8 and 15,

higher than 10V?Check harness

connector for

suspected

disconnection.

Fault found:

Repair, and

perform system

self-check.

No fault found:

replace EHCU.

Go to Step 3

Repair harness or

connector.

Go to Step 3

31. Reconnect all components, ensure all components are

properly mounted.

2. Clear diagnostic trouble code.

Was this step finished?

Repeat the “Basic

diagnostic flow

chart.”

Go to Step 3

Chart B-4 CLASS-2 Communication Line Abnormality (DTC 16)

StepActionYe sNo

11. Turn the key off.

2. Disconnect EHCU and PCM connector.

Is there continuity between EHCU connector terminals 25 and

ground?

Go to Step 2

Repair harness or

connector.

Go to Step 3

21. Connect EHCU connector.

2. Clear diagnostic trouble code.

3. Turn the key on.

Is the diagnostic trouble code 16 shown on the displayed?Check the PCM

harness. Refer to

6E section.

Go to Step 3

Replace EHCU.

Go to Step 3

31. Reconnect all components, ensure all components are

properly mounted.

2. Clear diagnostic trouble code.

Was this step finished?

Repeat the “Basic

diagnostic flow

chart.”

Go to Step 3

Page 855 of 6000

5A–45 BRAKE CONTROL SYSTEM

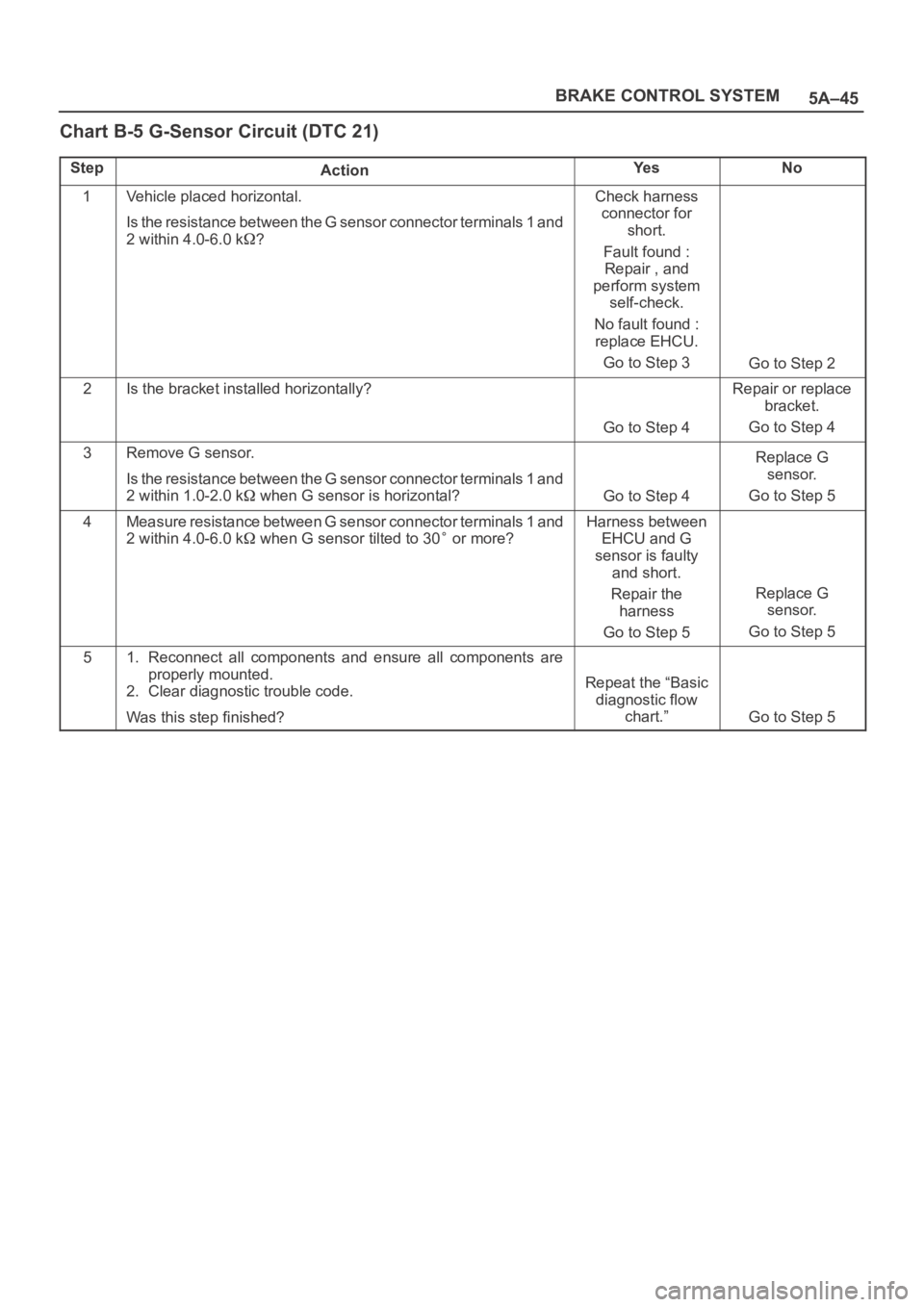

Chart B-5 G-Sensor Circuit (DTC 21)

StepActionYe sNo

1Vehicle placed horizontal.

Is the resistance between the G sensor connector terminals 1 and

2 within 4.0-6.0 k

?

Check harness

connector for

short.

Fault found :

Repair , and

perform system

self-check.

No fault found :

replace EHCU.

Go to Step 3

Go to Step 2

2Is the bracket installed horizontally?

Go to Step 4

Repair or replace

bracket.

Go to Step 4

3Remove G sensor.

Is the resistance between the G sensor connector terminals 1 and

2 within 1.0-2.0 k

when G sensor is horizontal?Go to Step 4

Replace G

sensor.

Go to Step 5

4Measure resistance between G sensor connector terminals 1 and

2 within 4.0-6.0 k

when G sensor tilted to 30 or more?

Harness between

EHCU and G

sensor is faulty

and short.

Repair the

harness

Go to Step 5

Replace G

sensor.

Go to Step 5

51. Reconnect all components and ensure all components are

properly mounted.

2. Clear diagnostic trouble code.

Was this step finished?

Repeat the “Basic

diagnostic flow

chart.”

Go to Step 5

Page 856 of 6000

5A–46

BRAKE CONTROL SYSTEM

Chart B-6 Abnormal Transmission Input (DTC 23)

StepActionYe sNo

11. Turn the key off.

2. Disconnect EHCU connector.

Is there continuity between EHCU connector terminal 6 to 15

(Gear position-P(A/T), N(M/T))?Shorted switch

harness.

Repair switch or

harness.

Go to Step 6

Go to Step 2

2Is the vehicle an A/T model?Go to Step 3Go to Step 4

3Turn the key on and measure the voltage between EHCU

connector terminal 6 and 15.

Is the 6V under when the gear position is L, and R(Battery voltage

12V)?

Go to Step 5

Transmission SW

trouble.

Disconnected

harness.

Repair SW and

harness.

Go to Step 6

4Turn the key on and measure the voltage between EHCU

connector terminal 6 and 15.

Is the 9.6V over when the gear position is 1, 2, R(Battery voltage

12V)?

Go to Step 5

Transmission SW

trouble.

Disconnected

harness.

Repair SW and

harness.

Go to Step 6

5Is there 6.6 to 9.0V when the gear position is 3, 4, 5 and N(M/T) or

2,3,D,N and P(A/T)(Battery voltage 12V)?Suspected

harness/

connector short

power

source/GND.

Suspected

shorted

transmission SW.

Fault found:

repair, and

perform system

self-check.

No fault found:

replace EHCU.

Go to Step 6

Transmission SW

trouble.

Disconnected

harness.

Repair SW and

harness.

Go to Step 6

61. Reconnect all components, ensure all components are

properly mounted.

2. Clear diagnostic trouble code.

Was this step finished?

Repeat the “Basic

diagnostic flow

chart.”

Go to Step 6

Page 857 of 6000

5A–47 BRAKE CONTROL SYSTEM

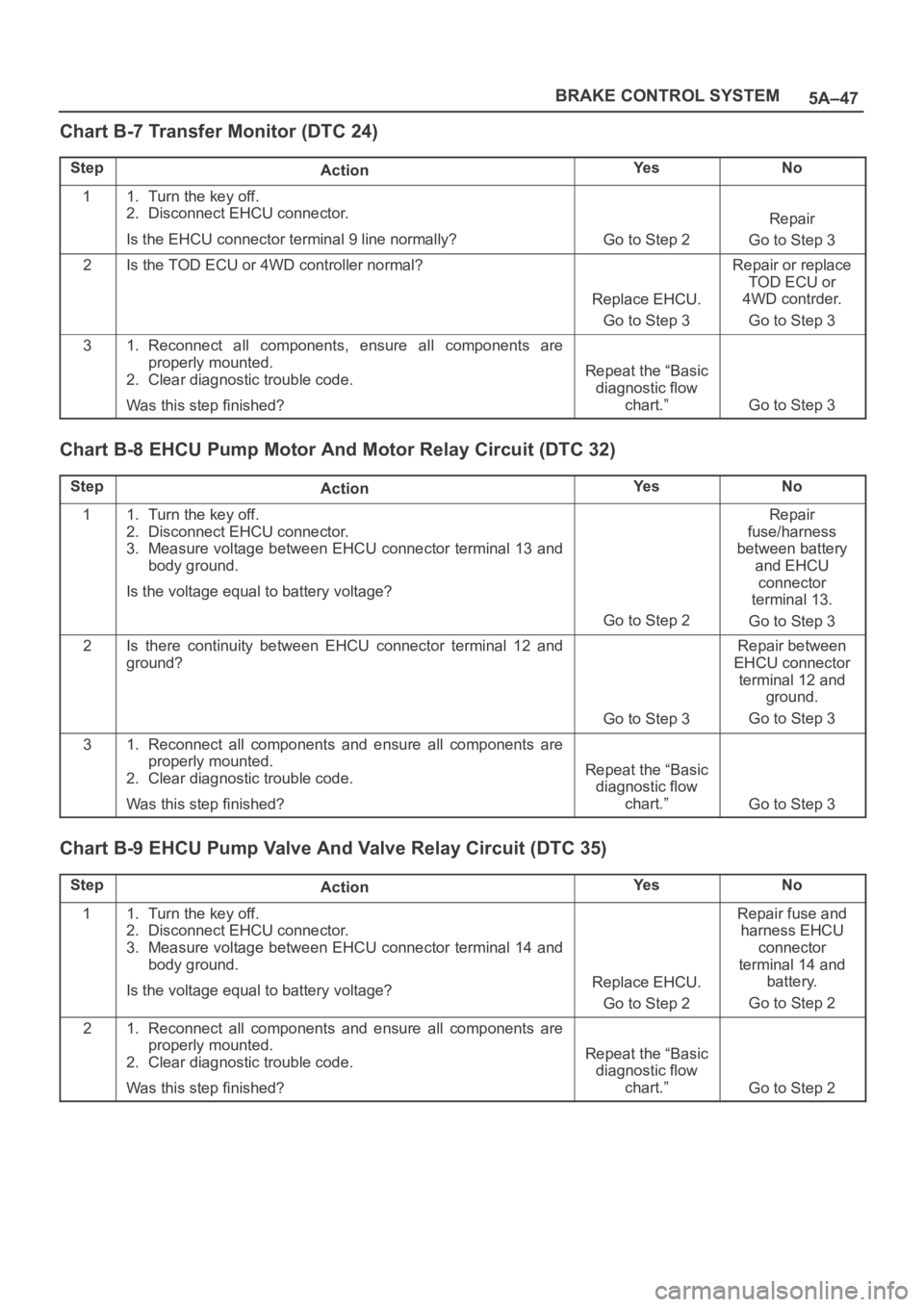

Chart B-7 Transfer Monitor (DTC 24)

StepActionYe sNo

11. Turn the key off.

2. Disconnect EHCU connector.

Is the EHCU connector terminal 9 line normally?

Go to Step 2

Repair

Go to Step 3

2Is the TOD ECU or 4WD controller normal?

Replace EHCU.

Go to Step 3

Repair or replace

TOD ECU or

4WD contrder.

Go to Step 3

31. Reconnect all components, ensure all components are

properly mounted.

2. Clear diagnostic trouble code.

Was this step finished?

Repeat the “Basic

diagnostic flow

chart.”

Go to Step 3

Chart B-8 EHCU Pump Motor And Motor Relay Circuit (DTC 32)

StepActionYe sNo

11. Turn the key off.

2. Disconnect EHCU connector.

3. Measure voltage between EHCU connector terminal 13 and

body ground.

Is the voltage equal to battery voltage?

Go to Step 2

Repair

fuse/harness

between battery

and EHCU

connector

terminal 13.

Go to Step 3

2Is there continuity between EHCU connector terminal 12 and

ground?

Go to Step 3

Repair between

EHCU connector

terminal 12 and

ground.

Go to Step 3

31. Reconnect all components and ensure all components are

properly mounted.

2. Clear diagnostic trouble code.

Was this step finished?

Repeat the “Basic

diagnostic flow

chart.”

Go to Step 3

Chart B-9 EHCU Pump Valve And Valve Relay Circuit (DTC 35)

StepActionYe sNo

11. Turn the key off.

2. Disconnect EHCU connector.

3. Measure voltage between EHCU connector terminal 14 and

body ground.

Is the voltage equal to battery voltage?

Replace EHCU.

Go to Step 2

Repair fuse and

harness EHCU

connector

terminal 14 and

battery.

Go to Step 2

21. Reconnect all components and ensure all components are

properly mounted.

2. Clear diagnostic trouble code.

Was this step finished?

Repeat the “Basic

diagnostic flow

chart.”

Go to Step 2

Page 858 of 6000

5A–48

BRAKE CONTROL SYSTEM

Chart B-10 FL Isolation Solenoid Valve Abnormality (DTC 41)

StepActionYe sNo

1Was the “EHCU Connector Pin-out Checks” performed?

Go to Step 2

Go to “EHCU

Connector

Pin-out Checks”.

2Is the EHCU connector free from damage or corrosion?

Go to Step 3

Repair the

connector.

Repeat the “Basic

Diagnostic Flow

Chart”.

31. Replace the EHCU.

2. Reconnect all component, ensure all component are properly

mounted.

Was this step finished?

Repeat the “Basic

Diagnostic Flow

Chart”.

Go to Step 3

Chart B-11 FL Dump Solenoid Valve Abnormality (DTC 42)

StepActionYe sNo

1Was the “EHCU Connector Pin-out Checks” performed?

Go to Step 2

Go to “EHCU

Connector

Pin-out Checks”.

2Is the EHCU connector free from damage or corrosion?

Go to Step 3

Repair the

connector.

Repeat the “Basic

Diagnostic Flow

Chart”.

31. Replace the EHCU.

2. Reconnect all component, ensure all component are properly

mounted.

Was this step finished?

Repeat the “Basic

Diagnostic Flow

Chart”.

Go to Step 3

Chart B-12 FR Isolation Solenoid Valve Abnormality (DTC 43)

StepActionYe sNo

1Was the “EHCU Connector Pin-out Checks” performed?

Go to Step 2

Go to “EHCU

Connector

Pin-out Checks”.

2Is the EHCU connector free from damage or corrosion?

Go to Step 3

Repair the

connector.

Repeat the “Basic

Diagnostic Flow

Chart”.

31. Replace the EHCU.

2. Reconnect all component, ensure all component are properly

mounted.

Was this step finished?

Repeat the “Basic

Diagnostic Flow

Chart”.

Go to Step 3

Page 859 of 6000

5A–49 BRAKE CONTROL SYSTEM

Chart B-13 FR Dump Solenoid Valve Abnormality (DTC 44)

StepActionYe sNo

1Was the “EHCU Connector Pin-out Checks” performed?

Go to Step 2

Go to “EHCU

Connector

Pin-out Checks”.

2Is the EHCU connector free from damage or corrosion?

Go to Step 3

Repair the

connector.

Repeat the “Basic

Diagnostic Flow

Chart”.

31. Replace the EHCU.

2. Reconnect all component, ensure all component are properly

mounted.

Was this step finished?

Repeat the “Basic

Diagnostic Flow

Chart”.

Go to Step 3

Chart B-14 Rear Isolation Solenoid Valve Abnormality (DTC 45)

StepActionYe sNo

1Was the “EHCU Connector Pin-out Checks” performed?

Go to Step 2

Go to “EHCU

Connector

Pin-out Checks”.

2Is the EHCU connector free from damage or corrosion?

Go to Step 3

Repair the

connector.

Repeat the “Basic

Diagnostic Flow

Chart”.

31. Replace the EHCU.

2. Reconnect all component, ensure all component are properly

mounted.

Was this step finished?

Repeat the “Basic

Diagnostic Flow

Chart”.

Go to Step 3

Chart B-15 Rear Dump Solenoid Valve Abnormality (DTC 46)

StepActionYe sNo

1Was the “EHCU Connector Pin-out Checks” performed?

Go to Step 2

Go to “EHCU

Connector

Pin-out Checks”.

2Is the EHCU connector free from damage or corrosion?

Go to Step 3

Repair the

connector.

Repeat the “Basic

Diagnostic Flow

Chart”.

31. Replace the EHCU.

2. Reconnect all component, ensure all component are properly

mounted.

Was this step finished?

Repeat the “Basic

Diagnostic Flow

Chart”.

Go to Step 3

Page 860 of 6000

5A–50

BRAKE CONTROL SYSTEM

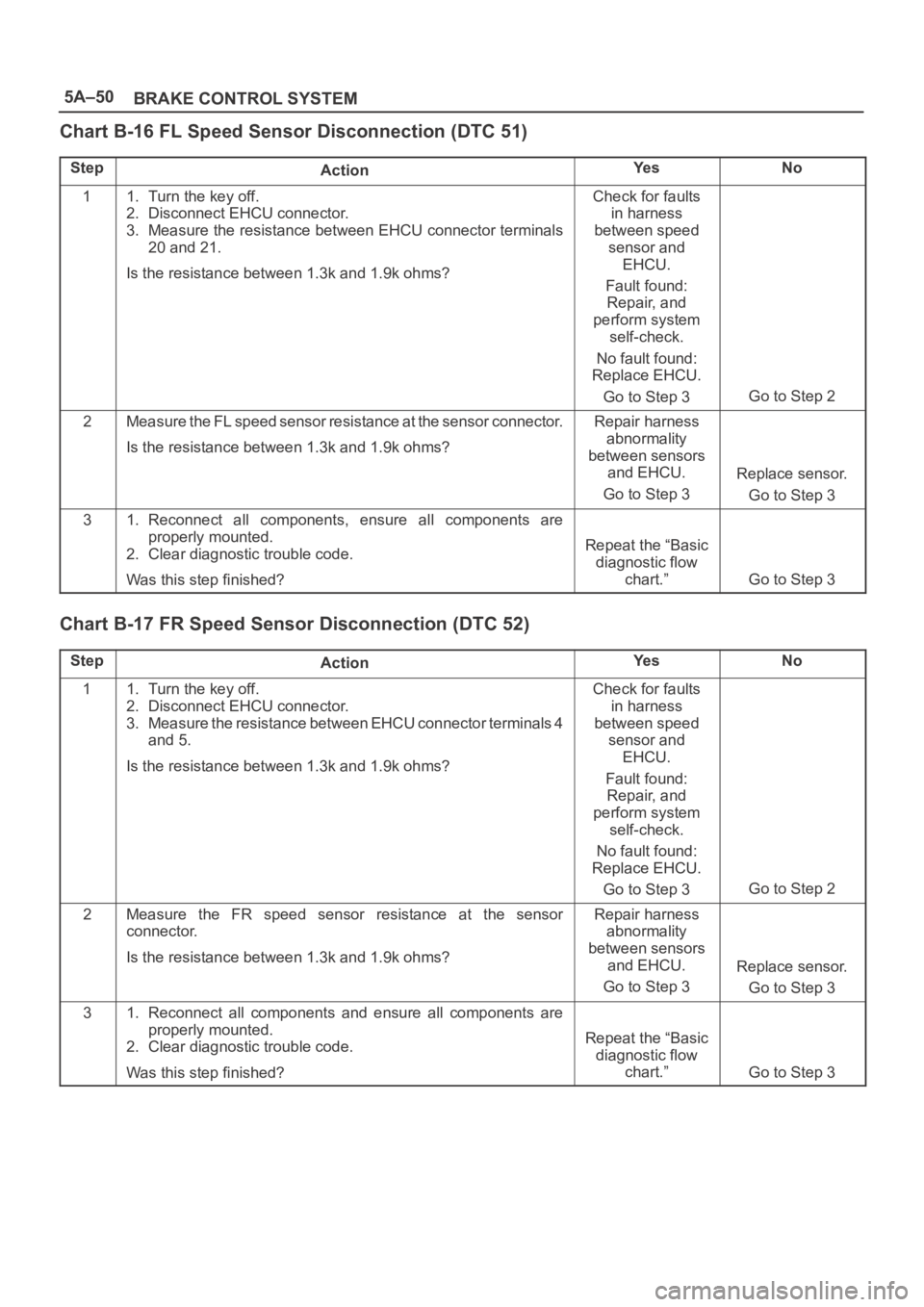

Chart B-16 FL Speed Sensor Disconnection (DTC 51)

StepActionYe sNo

11. Turn the key off.

2. Disconnect EHCU connector.

3. Measure the resistance between EHCU connector terminals

20 and 21.

Is the resistance between 1.3k and 1.9k ohms?Check for faults

in harness

between speed

sensor and

EHCU.

Fault found:

Repair, and

perform system

self-check.

No fault found:

Replace EHCU.

Go to Step 3

Go to Step 2

2Measure the FL speed sensor resistance at the sensor connector.

Is the resistance between 1.3k and 1.9k ohms?Repair harness

abnormality

between sensors

and EHCU.

Go to Step 3

Replace sensor.

Go to Step 3

31. Reconnect all components, ensure all components are

properly mounted.

2. Clear diagnostic trouble code.

Was this step finished?

Repeat the “Basic

diagnostic flow

chart.”

Go to Step 3

Chart B-17 FR Speed Sensor Disconnection (DTC 52)

StepActionYe sNo

11. Turn the key off.

2. Disconnect EHCU connector.

3. Measure the resistance between EHCU connector terminals 4

and 5.

Is the resistance between 1.3k and 1.9k ohms?Check for faults

in harness

between speed

sensor and

EHCU.

Fault found:

Repair, and

perform system

self-check.

No fault found:

Replace EHCU.

Go to Step 3

Go to Step 2

2Measure the FR speed sensor resistance at the sensor

connector.

Is the resistance between 1.3k and 1.9k ohms?Repair harness

abnormality

between sensors

and EHCU.

Go to Step 3

Replace sensor.

Go to Step 3

31. Reconnect all components and ensure all components are

properly mounted.

2. Clear diagnostic trouble code.

Was this step finished?

Repeat the “Basic

diagnostic flow

chart.”

Go to Step 3