check engine OPEL FRONTERA 1998 Manual Online

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 1176 of 6000

6E–59 ENGINE DRIVEABILITY AND EMISSIONS

A/C Clutch Control Circuit Diagnosis

StepNo Ye s Va l u e ( s ) Action

451. Remove the A/C compressor relay.

2. Idle the engine.

Is the compressor clutch still engaged when A/C is not

selected?

—Go to Step 46Go to Step 47

46Repair the short to voltage between the A/C clutch and

A/C compressor relay.

Is the action complete?

—Verify repair—

471. Reinstall the A/C compressor relay.

2. Remove the A/C thermostat relay.

3. Engine idling.

Is the compressor clutch still engaged when A/C is not

selected?

—Go to Step 48Go to Step 50

48Use a DVM to check for a short to ground between the

A/C compressor relay and B-14 of the PCM.

Was a short detected?

—Go to Step 49Go to Step 33

49Repair the short to ground between the PCM and A/C

compressor relay.

Is the action complete?

—Verify repair—

50Repair the short to ground between the A/C thermostat

relay and the electronic thermostat.

Is the action complete?

—Verify repair—

Page 1177 of 6000

6E–60

ENGINE DRIVEABILITY AND EMISSIONS

Electronic Ignition System Diagnosis

If the engine cranks but will not run or immediately stalls,

the Engine Cranks But Will Not Start chart must be used

to determine if the failure is the ignition system or the fuel

system. If DTC P0341, or P0336 is set, the appropriate

diagnostic trouble code chart must be used for diagnosis.

If a misfire is being experienced with no DTC set, refer to

the

Symptoms section for diagnosis.

Fuel Metering System Check

Some failures of the fuel metering system will result in an

“Engine Cranks But Will Not Run” symptom. If this

condition exists, refer to the

Cranks But Will Not Run

chart. This chart will determine if the problem is caused

by the ignition system, the PCM, or the fuel pump

electrical circuit.

Refer to

Fuel System Electrical Test for the fuel system

wiring schematic.

If there is a fuel delivery problem, refer to

Fuel System

Diagnosis

, which diagnoses the fuel injectors, the fuel

pressure regulator, and the fuel pump. If a malfunction

occurs in the fuel metering system, it usually results in

either a rich HO2S signal or a lean HO2S signal. This

condition is indicated by the HO2S voltage, which causes

the PCM to change the fuel calculation (fuel injector pulse

width) based on the HO2S reading. Changes made to the

fuel calculation will be indicated by a change in the long

term fuel trim values which can be monitored with a Tech

2. Ideal long term fuel trim values are around 0%; for a

lean HO2S signal, the PCM will add fuel, resulting in a fuel

trim value above 0%. Some variations in fuel trim values

are normal because all engines are not exactly the same.

If the fuel trim values are greater than +23%, refer to

DTC

P0131, DTC P0151, DTC P0171, and DTC 1171

f o r i t e m s

which can cause a lean HO2S signal.

Idle Air Control (IAC) Valve

The Tech 2 displays the IAC pintle position in counts. A

count of “0” indicates the PCM is commanding the IAC

pintle to be driven all the way into a fully-seated position.

This is usually caused by a large vacuum leak.

The higher the number of counts, the more air is being

commanded to bypass the throttle blade. Refer to IAC

System Check in order to diagnose the IAC system.

Refer to

Rough, Unstable, or Incorrect Idle, Stalling in

Symptoms for other possible causes of idle problems.

Fuel System Pressure Test

A fuel system pressure test is part of several of the

diagnostic charts and symptom checks. To perform this

test, refer to

Fuel Systems Diagnosis.

Fuel Injector Coil Test Procedure and

Fuel Injector Balance Test Procedure

T32003

Test Description

Number(s) below refer to the step number(s) on the

Diagnostic Chart:

2. Relieve the fuel pressure by connecting the

5-8840-0378-0 Fuel Pressure Gauge to the fuel

pressure connection on the fuel rail.

CAUTION: In order to reduce the risk of fire and

personal injury, wrap a shop towel around the fuel

pressure connection. The towel will absorb any fuel

leakage that occurs during the connection of the fuel

pressure gauge. Place the towel in an approved

container when the connection of the fuel pressure

gauge is complete.

Place the fuel pressure gauge bleed hose in an

approved gasoline container.

With the ignition switch “OFF,” open the valve on the

fuel pressure gauge.

3. Record the lowest voltage displayed by the DVM

after the first second of the test. (During the first

second, voltage displayed by the DVM may be

inaccurate due to the initial current surge.)

Injector Specifications:

Resistance Ohms

Voltage Specification at

10

C-35C (50F-95F)

11.8 – 12.65.7 – 6.6

The voltage displayed by the DVM should be within

the specified range.

The voltage displayed by the DVM may increase

throughout the test as the fuel injector windings

warm and the resistance of the fuel injector windings

changes.

Page 1178 of 6000

6E–61 ENGINE DRIVEABILITY AND EMISSIONS

An erratic voltage reading (large fluctuations in

voltage that do not stabilize) indicates an

intermittent connection within the fuel injector.

5. Injector Specifications:

Highest Acceptable

Voltage Reading

Above/Below 35

C/10C

(95

F/50F)

Acceptable Subtracted

Va l u e

9.5 Volts0.6 Volts

7. The Fuel Injector Balance Test portion of this chart

(Step 7 through Step 11) checks the mechanical

(fuel delivery) portion of the fuel injector. An engine

cool-down period of 10 minutes is necessary in

order to avoid irregular fuel pressure readings due

to “Hot Soak” fuel boiling.

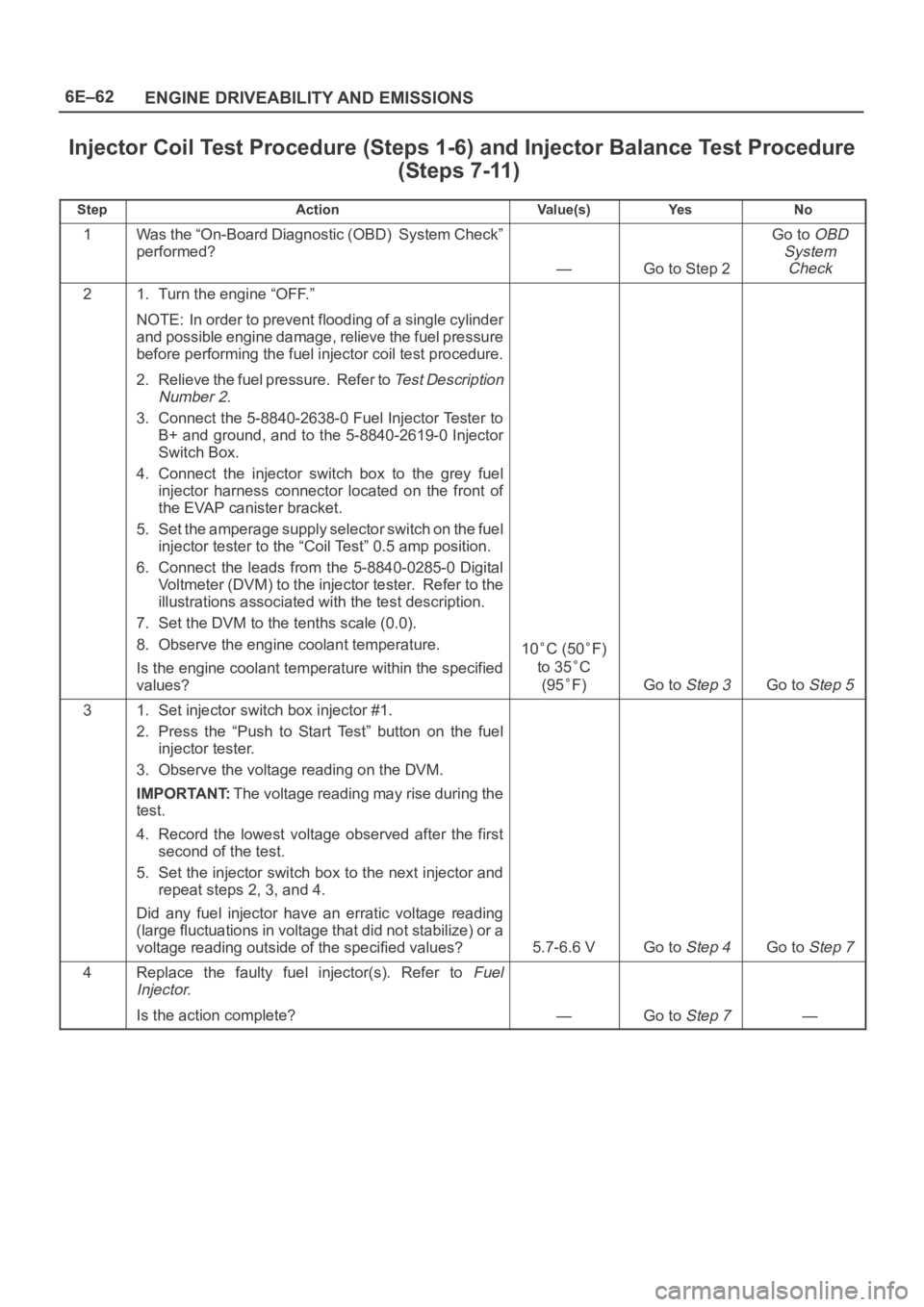

Injector Coil Test Procedure (Steps 1-6) and Injector Balance Test Procedure (Steps 7-11)

R262001

CYLINDER123456

1st Reading (1)296 kPa

(43 psi)296 kPa

(43 psi)296 kPa

(43 psi)296 kPa

(43 psi)296 kPa

(43 psi)296 kPa

(43 psi)

2nd Reading (2)131 kPa

(19 psi)11 7 k P a

(17 psi)124 kPa

(18 psi)145 kPa

(21 psi)131 kPa

(19 psi)130 kPa

(19 psi)

Amount of Drop (1st

Reading–2nd Reading)165 kPa

(24 psi)179 kPa

(26 psi)172 kPa

(25 psi)151 kPa

(22 psi)165 kPa

(24 psi)166 kPa

(24 psi)

Av.drop = 166 kPa/24 psi

10 kPa/1.5 psi

= 156 – 176 kPa or

22.5 – 25.5 psi

OKFaulty, Rich

(Too Much

Fuel Drop)OKFaulty, Lean

(Too Little

Fuel Drop)OKOK

NOTE: These figures are examples only.

Page 1179 of 6000

6E–62

ENGINE DRIVEABILITY AND EMISSIONS

Injector Coil Test Procedure (Steps 1-6) and Injector Balance Test Procedure

(Steps 7-11)

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

21. Turn the engine “OFF.”

NOTE: In order to prevent flooding of a single cylinder

and possible engine damage, relieve the fuel pressure

before performing the fuel injector coil test procedure.

2. Relieve the fuel pressure. Refer to

Test Description

Number 2.

3. Connect the 5-8840-2638-0 Fuel Injector Tester to

B+ and ground, and to the 5-8840-2619-0 Injector

Switch Box.

4. Connect the injector switch box to the grey fuel

injector harness connector located on the front of

the EVAP canister bracket.

5. Set the amperage supply selector switch on the fuel

injector tester to the “Coil Test” 0.5 amp position.

6. Connect the leads from the 5-8840-0285-0 Digital

Voltmeter (DVM) to the injector tester. Refer to the

illustrations associated with the test description.

7. Set the DVM to the tenths scale (0.0).

8. Observe the engine coolant temperature.

Is the engine coolant temperature within the specified

values?

10C (50F)

to 35

C

(95

F)Go to Step 3Go to Step 5

31. Set injector switch box injector #1.

2. Press the “Push to Start Test” button on the fuel

injector tester.

3. Observe the voltage reading on the DVM.

IMPORTANT:The voltage reading may rise during the

test.

4. Record the lowest voltage observed after the first

second of the test.

5. Set the injector switch box to the next injector and

repeat steps 2, 3, and 4.

Did any fuel injector have an erratic voltage reading

(large fluctuations in voltage that did not stabilize) or a

voltage reading outside of the specified values?

5.7-6.6 VGo to Step 4Go to Step 7

4Replace the faulty fuel injector(s). Refer to Fuel

Injector.

Is the action complete?—Go to Step 7—

Page 1181 of 6000

6E–64

ENGINE DRIVEABILITY AND EMISSIONS

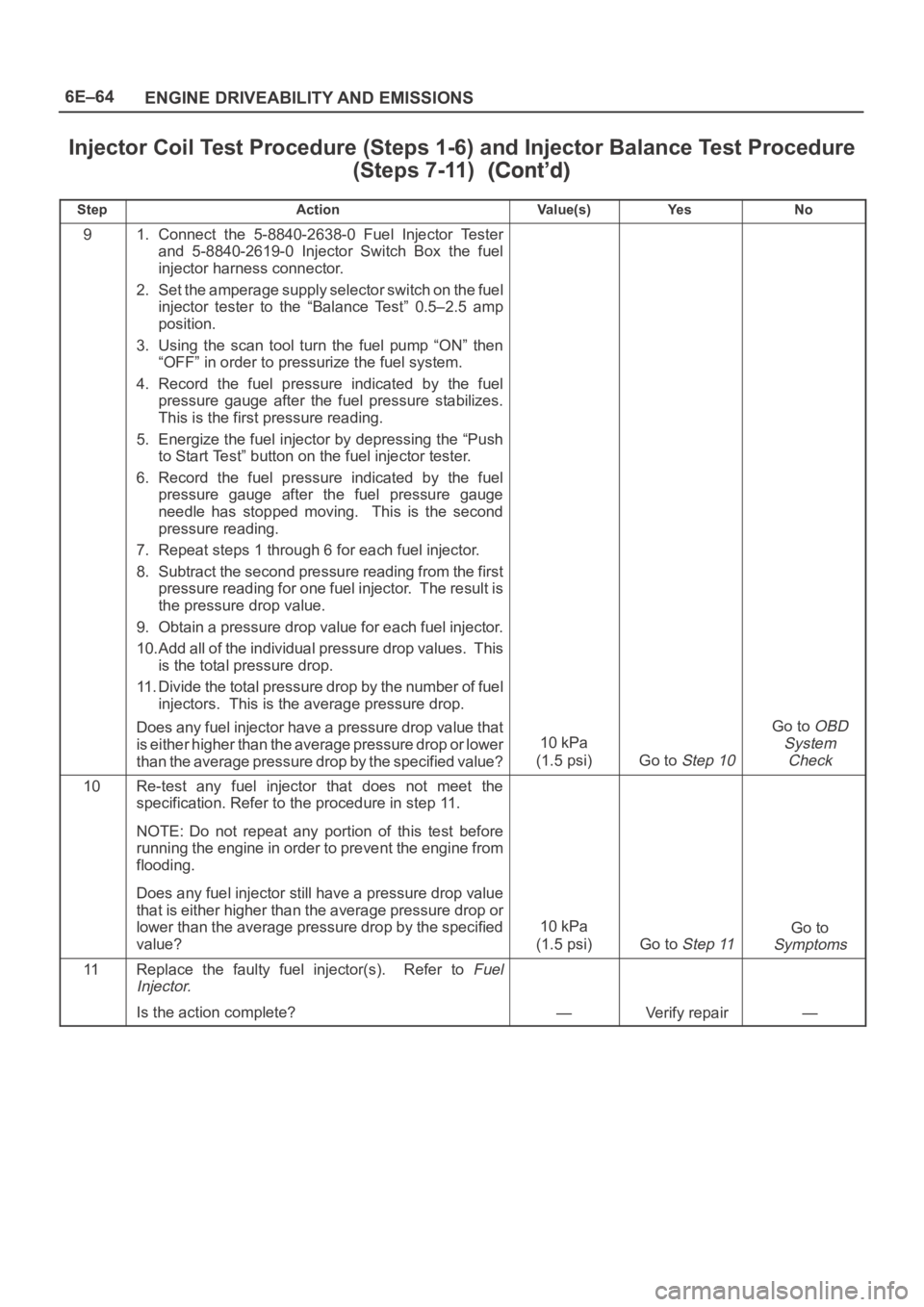

Injector Coil Test Procedure (Steps 1-6) and Injector Balance Test Procedure

(Steps 7-11)

StepNo Ye s Va l u e ( s ) Action

91. Connect the 5-8840-2638-0 Fuel Injector Tester

and 5-8840-2619-0 Injector Switch Box the fuel

injector harness connector.

2. Set the amperage supply selector switch on the fuel

injector tester to the “Balance Test” 0.5–2.5 amp

position.

3. Using the scan tool turn the fuel pump “ON” then

“OFF” in order to pressurize the fuel system.

4. Record the fuel pressure indicated by the fuel

pressure gauge after the fuel pressure stabilizes.

This is the first pressure reading.

5. Energize the fuel injector by depressing the “Push

to Start Test” button on the fuel injector tester.

6. Record the fuel pressure indicated by the fuel

pressure gauge after the fuel pressure gauge

needle has stopped moving. This is the second

pressure reading.

7. Repeat steps 1 through 6 for each fuel injector.

8. Subtract the second pressure reading from the first

pressure reading for one fuel injector. The result is

the pressure drop value.

9. Obtain a pressure drop value for each fuel injector.

10.Add all of the individual pressure drop values. This

is the total pressure drop.

11. Divide the total pressure drop by the number of fuel

injectors. This is the average pressure drop.

Does any fuel injector have a pressure drop value that

is either higher than the average pressure drop or lower

than the average pressure drop by the specified value?

10 kPa

(1.5 psi)

Go to Step 10

Go to OBD

System

Check

10Re-test any fuel injector that does not meet the

specification. Refer to the procedure in step 11.

NOTE: Do not repeat any portion of this test before

running the engine in order to prevent the engine from

flooding.

Does any fuel injector still have a pressure drop value

that is either higher than the average pressure drop or

lower than the average pressure drop by the specified

value?

10 kPa

(1.5 psi)

Go to Step 11

Go to

Symptoms

11Replace the faulty fuel injector(s). Refer to Fuel

Injector.

Is the action complete?—Verify repair—

Page 1182 of 6000

6E–65 ENGINE DRIVEABILITY AND EMISSIONS

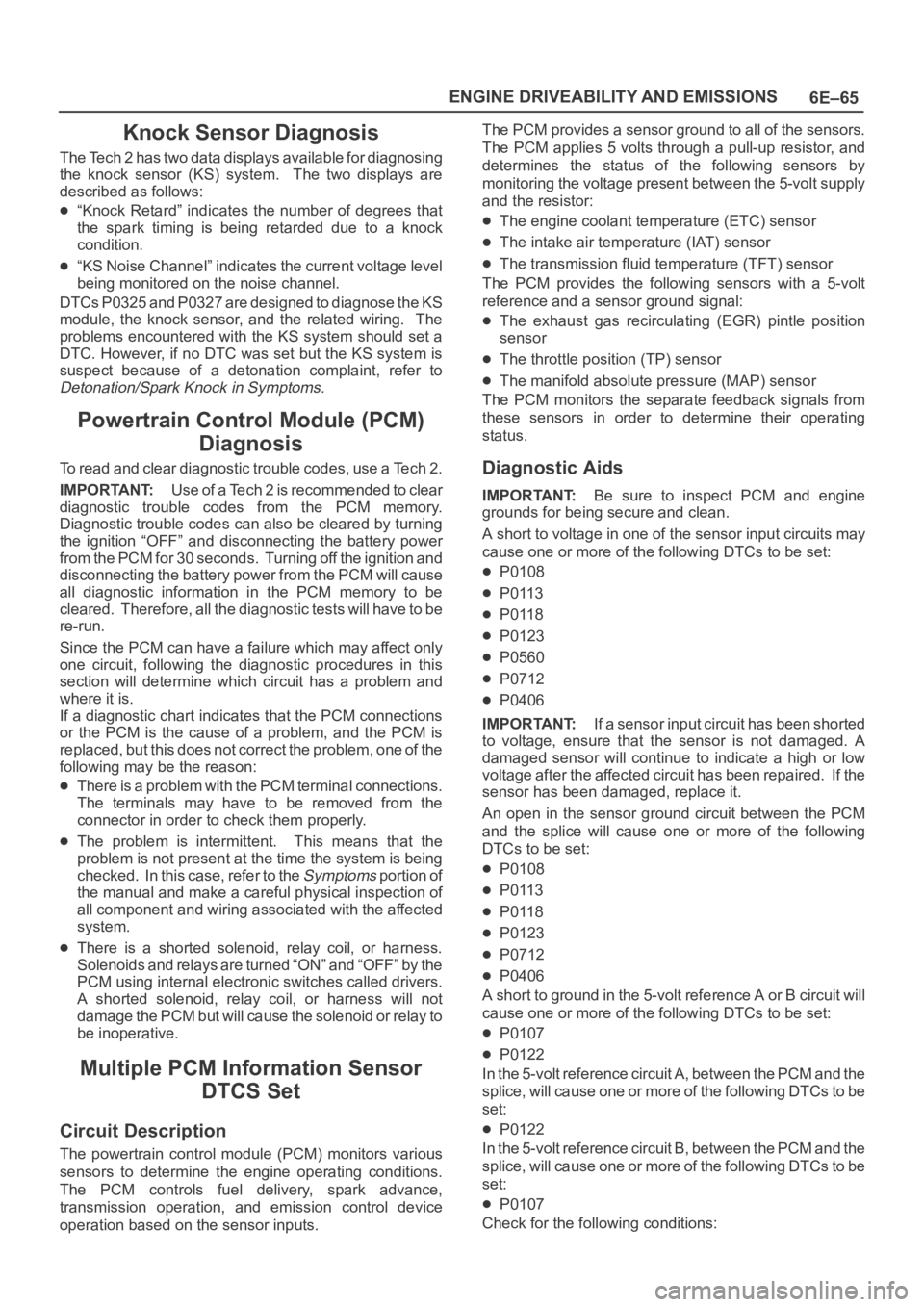

Knock Sensor Diagnosis

The Tech 2 has two data displays available for diagnosing

the knock sensor (KS) system. The two displays are

described as follows:

“Knock Retard” indicates the number of degrees that

the spark timing is being retarded due to a knock

condition.

“KS Noise Channel” indicates the current voltage level

being monitored on the noise channel.

DTCs P0325 and P0327 are designed to diagnose the KS

module, the knock sensor, and the related wiring. The

problems encountered with the KS system should set a

DTC. However, if no DTC was set but the KS system is

suspect because of a detonation complaint, refer to

Detonation/Spark Knock in Symptoms.

Powertrain Control Module (PCM)

Diagnosis

To read and clear diagnostic trouble codes, use a Tech 2.

IMPORTANT:Use of a Tech 2 is recommended to clear

diagnostic trouble codes from the PCM memory.

Diagnostic trouble codes can also be cleared by turning

the ignition “OFF” and disconnecting the battery power

from the PCM for 30 seconds. Turning off the ignition and

disconnecting the battery power from the PCM will cause

all diagnostic information in the PCM memory to be

cleared. Therefore, all the diagnostic tests will have to be

re-run.

Since the PCM can have a failure which may affect only

one circuit, following the diagnostic procedures in this

section will determine which circuit has a problem and

where it is.

If a diagnostic chart indicates that the PCM connections

or the PCM is the cause of a problem, and the PCM is

replaced, but this does not correct the problem, one of the

following may be the reason:

There is a problem with the PCM terminal connections.

The terminals may have to be removed from the

connector in order to check them properly.

The problem is intermittent. This means that the

problem is not present at the time the system is being

checked. In this case, refer to the

Symptoms p o r t i o n o f

the manual and make a careful physical inspection of

all component and wiring associated with the affected

system.

There is a shorted solenoid, relay coil, or harness.

S o l e n o i d s a n d r e l a y s a r e t u r n e d “ O N ” a n d “ O F F ” b y t h e

PCM using internal electronic switches called drivers.

A shorted solenoid, relay coil, or harness will not

damage the PCM but will cause the solenoid or relay to

be inoperative.

Multiple PCM Information Sensor

DTCS Set

Circuit Description

The powertrain control module (PCM) monitors various

sensors to determine the engine operating conditions.

The PCM controls fuel delivery, spark advance,

transmission operation, and emission control device

operation based on the sensor inputs.The PCM provides a sensor ground to all of the sensors.

The PCM applies 5 volts through a pull-up resistor, and

determines the status of the following sensors by

monitoring the voltage present between the 5-volt supply

and the resistor:

The engine coolant temperature (ETC) sensor

The intake air temperature (IAT) sensor

The transmission fluid temperature (TFT) sensor

The PCM provides the following sensors with a 5-volt

reference and a sensor ground signal:

The exhaust gas recirculating (EGR) pintle position

sensor

The throttle position (TP) sensor

The manifold absolute pressure (MAP) sensor

The PCM monitors the separate feedback signals from

these sensors in order to determine their operating

status.

Diagnostic Aids

IMPORTANT:Be sure to inspect PCM and engine

grounds for being secure and clean.

A short to voltage in one of the sensor input circuits may

cause one or more of the following DTCs to be set:

P0108

P0113

P0118

P0123

P0560

P0712

P0406

IMPORTANT:If a sensor input circuit has been shorted

to voltage, ensure that the sensor is not damaged. A

damaged sensor will continue to indicate a high or low

voltage after the affected circuit has been repaired. If the

sensor has been damaged, replace it.

An open in the sensor ground circuit between the PCM

and the splice will cause one or more of the following

DTCs to be set:

P0108

P0113

P0118

P0123

P0712

P0406

A short to ground in the 5-volt reference A or B circuit will

cause one or more of the following DTCs to be set:

P0107

P0122

In the 5-volt reference circuit A, between the PCM and the

splice, will cause one or more of the following DTCs to be

set:

P0122

In the 5-volt reference circuit B, between the PCM and the

splice, will cause one or more of the following DTCs to be

set:

P0107

Check for the following conditions:

Page 1183 of 6000

6E–66

ENGINE DRIVEABILITY AND EMISSIONS

Poor connection at PCM. Inspect the harness

connectors for backed-out terminals, improper mating,

broken locks, improperly formed or damage terminals,

and a poor terminal-to-wire connection.

Damaged harness. Inspect the wiring harness for

damage. If the harness is not damaged, observe an

affected sensor’s displayed value on the Tech 2 with

the ignition “ON” and the engine “OFF” while you move

the connectors and the wiring harnesses related to the

following sensors:

IAT

ECT

TP

MAP

EGR

TFT

Multiple PCM Information Sensor DTCs Set

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

21. Turn the ignition “OFF,” disconnect the PCM.

2. Turn the ignition “ON,” check the 5 volt reference A

circuit for the following conditions:

A poor connection at the PCM.

An open between the PCM connector and the

splice.

A short to ground.

A short to voltage.

Is there an open or short?

—Go to Step 3Go to Step 4

3Repair the open or short.

Is the action complete?

—Verify repair—

4Check the sensor ground circuit for the following

conditions:

A poor connection at the PCM or the affected

sensors.

An open between the PCM connector and the

affected sensors.

Is there an open or a poor connection?

—Go to Step 5Go to Step 6

5Repair the open or the poor connection.

Is the action complete?

—Verify repair—

6Measure the voltage between the EGR pintle position

sensor signal circuit at the PCM harness connector and

ground.

Does the voltage measure near the specified value?

0 VGo to Step 7Go to Step 12

7Measure the voltage between the MAP sensor signal

circuit at the PCM harness connector and ground.

Does the voltage measure near the specified value?

0 VGo to Step 8Go to Step 15

8Measure the voltage between the TP sensor signal

circuit at the PCM harness connector and ground.

Does the voltage measure near the specified value?

0 VGo to Step 9Go to Step 16

9Measure the voltage between the IAT sensor signal

circuit at the PCM harness connector and ground.

Does the voltage measure near the specified value?

0 VGo to Step 10Go to Step 17

10Measure the voltage between the ECT sensor signal

circuit at the PCM harness connector and ground.

Does the voltage measure near the specified value?

0 VGo to Step 11Go to Step 18

Page 1184 of 6000

6E–67 ENGINE DRIVEABILITY AND EMISSIONS

Multiple PCM Information Sensor DTCs Set

StepNo Ye s Va l u e ( s ) Action

111. Disconnect the EGR valve.

2. Measure the voltage between the EGR pintle

position sensor signal circuit at the PCM harness

connector and ground.

Does the voltage measure near the specified value?

0 VGo to Step 13Go to Step 18

12Measure the voltage between the TFT sensor signal

circuit at the PCM harness connector and ground.

Does the voltage measure near the specified value?

0 VGo to Step 20Go to Step 19

13Replace the EGR valve.

Is the action complete?

—Verify repair—

14Locate and repair the short to voltage in the MAP

sensor signal circuit.

Is the action complete?

—Verify repair—

15Locate and repair the short to voltage in the TP sensor

signal circuit.

Is the action complete?

—Verify repair—

16Locate and repair the short to voltage in the IAT sensor

signal circuit.

Is the action complete?

—Verify repair—

17Locate and repair the short to voltage in the ECT

sensor signal circuit.

Is the action complete?

—Verify repair—

18Locate and repair the short to voltage in the EGR pintle

position sensor signal circuit.

Is the action complete?

—Verify repair—

19Locate and repair the short to voltage in the TFT sensor

signal circuit.

Is the action complete?

—Verify repair—

20Replace the PCM.

IMPORTANT:The replacement PCM must be

programmed. Refer to

UBS 98model year Immobilizer

Workshop Manual.

Is the action complete?—

Go to OBD

System

Check

—

Page 1185 of 6000

6E–68

ENGINE DRIVEABILITY AND EMISSIONS

Exhaust Gas Recirculation (EGR)

Diagnosis (For except EXPORT and

SOUTH AFRICA)

Pintle position error diagnosis is covered by DTC P0402,

P0404, P1404, P0405, P0406. If EGR diagnostic trouble

codes P0402, P0404, P1404, P0405, P0406 are

encountered, refer to the DTC charts.

Engine Tech 2 Data Definitions and

Ranges

A/C CLUTCH – Tech 2 Displays ON or OFF –

Indicates whether the PCM has commanded the A/C

clutch ON. Used in A/C system diagnostic.

A/C REQUEST — Tech 2 Displays YES or NO —

Indicates the state of the A/C request input circuit from the

HVAC controls. The PCM uses the A/C request signal to

determine whether A/C compressor operation is being

requested.

AIR/FUEL RATIO — Tech 2 Range 0.0-25.5 —

Air/fuel ratio indicates the PCM commanded value. In

closed loop, the air/fuel ratio should normally be

displayed around “14.2-14.7.” A lower air/fuel ratio

indicates a richer commanded mixture, which may be

seen during power enrichment or TWC protection modes.

A higher air/fuel ratio indicates a leaner commanded

mixture. This can be seen during deceleration fuel mode.

BAROMETRIC PRESSURE — Tech 2 Range 10-105

kPa/0.00-5.00 Volts —

The barometric pressure reading is determined from the

MAP sensor signal monitored during key up and wide

open throttle (WOT) conditions. The barometric pressure

is used to compensate for altitude differences and is

normally displayed around “61-104” depending on

altitude and barometric pressure.

CHECK TRANS LAMP — AUTO TRANSMISSION —

Indicates the need to check for a DTC with the Tech 2

when the lamp is flashing 0.2 seconds ON and 0.2

seconds OFF.

CMP ACT. COUNTER – Cam Position Activity

DECEL FUEL MODE — Tech 2 Display ACTIVE or

INACTIVE —

“ACTIVE” displayed indicates that the PCM has detected

conditions appropriate to operate in deceleration fuel

mode. The PCM will command the deceleration fuel

mode when it detects a closed throttle position while the

vehicle is traveling over 20 mph. While in the deceleration

fuel delivered by entering open loop and decreasing the

injector pulse width.

DESIRED EGR POS. — Tech 2 Range 0%-100% —

Represents the EGR pintle position that the PCM is

commanding.

DESIRED IDLE — Tech 2 Range 0-3187 RPM —

The idle speed that the PCM is commanding. The PCM

will compensate for various engine loads based on engine

coolant temperature, to keep the engine at the desired

speed.ECT — (Engine Coolant Temperature) Tech 2

Range –40

C to 151C (–40F to 304F) —

The engine coolant temperature (ECT) is mounted in the

coolant stream and sends engine temperature

information to the PCM. The PCM applies 5 volts to the

ECT sensor circuit. The sensor is a thermistor which

changes internal resistance as temperature changes.

When the sensor is cold (high resistance), the PCM

monitors a high signal voltage and interprets that as a cold

engine. As the sensor warms (decreasing resistance),

the voltage signal will decrease and the PCM will interpret

the lower voltage as a warm engine.

EGR DUTY CYCLE — Tech 2 Range 0%-100% —

Represents the EGR valve driver PWM signal from the

PCM. A duty cycle of 0% indicates that no EGR flow is

being commanded; a 100% duty cycle indicates

maximum EGR flow commanded.

EGR FEEDBACK — Tech 2 Range 0.00-5.00 Volts —

Indicates the EGR pintle position sensor signal voltage

being monitored by the PCM. A low voltage indicates a

fully extended pintle (closed valve); a voltage near 5 volts

indicates a retracted pintle (open valve).

ENGINE LOAD — Tech 2 Range 0%-100% —

Engine load is calculated by the PCM from engine speed

and MAF sensor readings. Engine load should increase

with an increase in RPM or air flow.

ENGINE RUN TIME — Tech 2 Range

00:00:00-99:99:99 Hrs:Min:Sec —

Indicates the time elapsed since the engine was started.

If the engine is stopped, engine run time will be reset to

00:00:00.

ENGINE SPEED — Range 0-9999 RPM —

Engine speed is computed by the PCM from the 58X

reference input. It should remain close to desired idle

under various engine loads with engine idling.

FUEL PUMP — Tech 2 Displays ON or OFF —

Indicates the PCM commanded state of the fuel pump

relay driver circuit.

FUEL TRIM CELL — Tech 2 Range 0-21 —

The fuel trim cell is dependent upon engine speed and

MAF sensor readings. A plot of RPM vs. MAF is divided

into 22 cells. Fuel trim cell indicates which cell is currently

active.

FUEL TRIM LEARN — Tech 2 Displays NO or YES

—

When conditions are appropriate for enabling long term

fuel trim corrections, fuel trim learn will display “YES.”

This indicates that the long term fuel trim is responding to

the short term fuel trim. If the fuel trim learn displays

“NO,” then long term fuel trim will not respond to changes

in short term fuel trim.

HO2S BANK 1, SEN. 1 — Tech 2 Range 0-1132 mV

—

Represents the fuel control exhaust oxygen sensor

output voltage. Should fluctuate constantly within a range

between 10 mV (lean exhaust) and 1000 mV (rich

exhaust) while operating in closed loop.

Page 1187 of 6000

6E–70

ENGINE DRIVEABILITY AND EMISSIONS

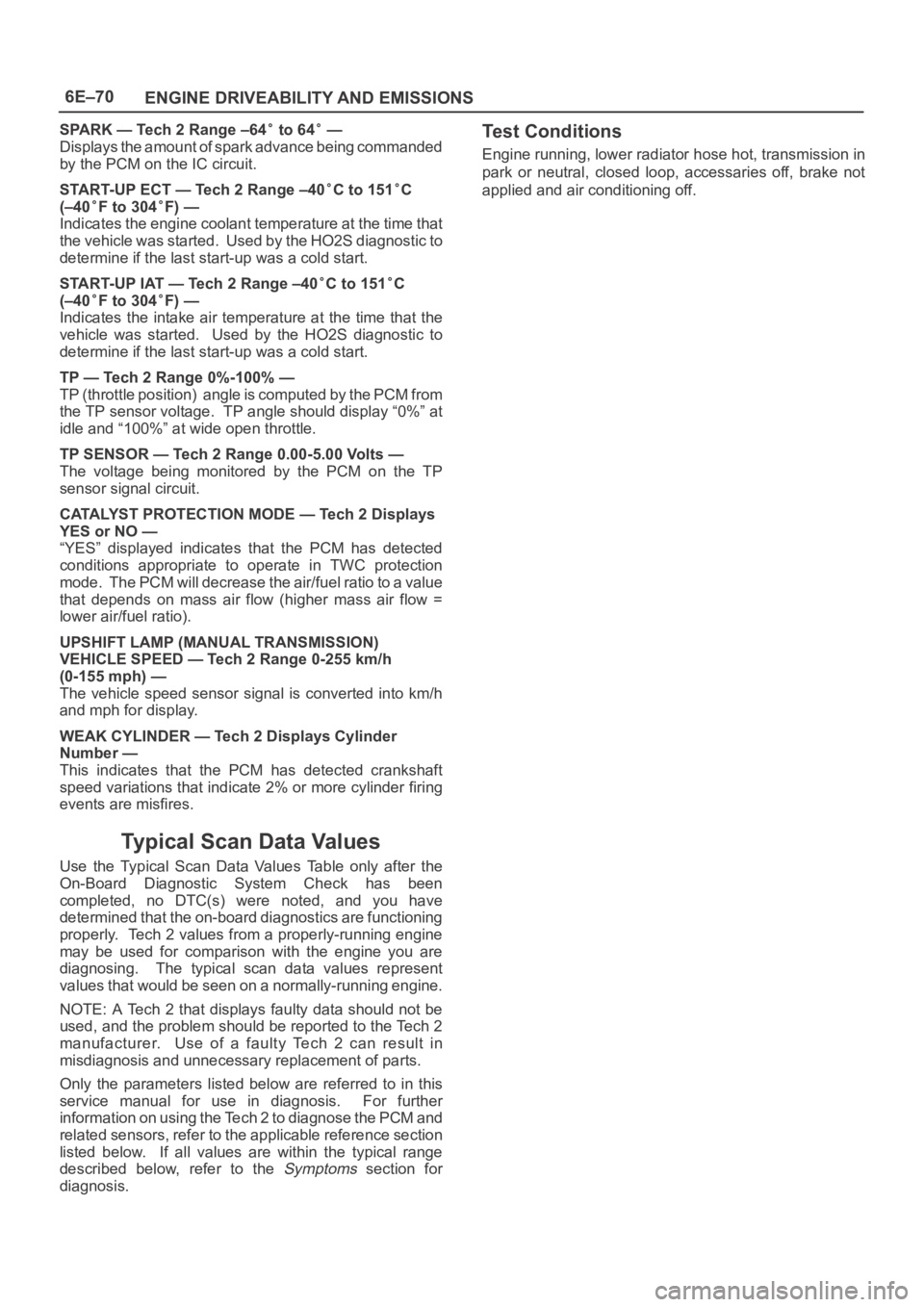

SPARK — Tech 2 Range –64 to 64 —

Displays the amount of spark advance being commanded

by the PCM on the IC circuit.

START-UP ECT — Tech 2 Range –40

C to 151C

(–40

F to 304F) —

Indicates the engine coolant temperature at the time that

the vehicle was started. Used by the HO2S diagnostic to

determine if the last start-up was a cold start.

START-UP IAT — Tech 2 Range –40

C to 151C

(–40

F to 304F) —

Indicates the intake air temperature at the time that the

vehicle was started. Used by the HO2S diagnostic to

determine if the last start-up was a cold start.

TP — Tech 2 Range 0%-100% —

TP (throttle position) angle is computed by the PCM from

the TP sensor voltage. TP angle should display “0%” at

idle and “100%” at wide open throttle.

TP SENSOR — Tech 2 Range 0.00-5.00 Volts —

The voltage being monitored by the PCM on the TP

sensor signal circuit.

CATALYST PROTECTION MODE — Tech 2 Displays

YES or NO —

“YES” displayed indicates that the PCM has detected

conditions appropriate to operate in TWC protection

mode. The PCM will decrease the air/fuel ratio to a value

that depends on mass air flow (higher mass air flow =

lower air/fuel ratio).

UPSHIFT LAMP (MANUAL TRANSMISSION)

VEHICLE SPEED — Tech 2 Range 0-255 km/h

(0-155 mph) —

The vehicle speed sensor signal is converted into km/h

and mph for display.

WEAK CYLINDER — Tech 2 Displays Cylinder

Number —

This indicates that the PCM has detected crankshaft

speed variations that indicate 2% or more cylinder firing

events are misfires.

Typical Scan Data Values

Use the Typical Scan Data Values Table only after the

On-Board Diagnostic System Check has been

completed, no DTC(s) were noted, and you have

determined that the on-board diagnostics are functioning

properly. Tech 2 values from a properly-running engine

may be used for comparison with the engine you are

diagnosing. The typical scan data values represent

values that would be seen on a normally-running engine.

NOTE: A Tech 2 that displays faulty data should not be

used, and the problem should be reported to the Tech 2

manufacturer. Use of a faulty Tech 2 can result in

misdiagnosis and unnecessary replacement of parts.

Only the parameters listed below are referred to in this

service manual for use in diagnosis. For further

information on using the Tech 2 to diagnose the PCM and

related sensors, refer to the applicable reference section

listed below. If all values are within the typical range

described below, refer to the

Symptoms section for

diagnosis.

Test Conditions

Engine running, lower radiator hose hot, transmission in

park or neutral, closed loop, accessaries off, brake not

applied and air conditioning off.