ECU OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 12 of 6000

PAGE BACK PAGE NEXT

THIS MALUAL INCLUDES THE FOLLOWING SECTIONS:

SECTION No. CONTRNTS

8A LIGHTING SYSTEM

8B WIPER / WASHER SYSTEM

8C ENTERTAINMENT

8D WIRING SYSTEM

8E METER AND GAUGE

8F BODY STRUCTURE

8G SEATS

8H SECURITY AND LOCKS

8I SUN ROOF/CONVERTIBLE TOP

8J EXTERIOR / INTERIOR TRIM

HOME

8A

8B

8C

8D

8E

8F

8G

8H

8I

8J

Page 278 of 6000

COMPRESSOR SHAFT SEAL

Service Precaution

When replacing the shaft seal assembly, pressure relief

valve or control switches, it will be necessary to recover

the refrigerant. Other than clutch repair procedures, the

same holds true for any disassembly of the compressor.

A clean workbench covered with a sheet of clean

paper, and a place (clean trays, etc) for all parts being

removed and replaced is important, as is the use of

proper clean service tools.

CAUTION: Any attempt to use makeshift or

inadequate service tools or equipment may result

in damage and/or improper compressor operation.

All parts required for servicing the internal compressor

are protected by a preservative process and packaged

in a manner which will eliminate the necessity of

cleaning, washing or flushing of the parts. The parts

can be used in the internal assembly just as they are

removed from the service package. Seals and

protective packaging should be left intact until just

prior to installation.

If the compressor rear head, front head or cylinder and

shaft assembly is to be serviced or replaced, the oil in

the compressor must be drained, measured, recorded

and replaced.

Legend

(1) Suction Port

(2) Discharge Port

(3) Mounting Boss

(4) Mounting Boss

(5) Pressure Relief Valve

(6) Mounting Boss

Seal Leak Detection

A shaft seal should not be changed because of small

amounts of oil found on an adjacent surface but only

after actual refrigerant leakage is found using an

approved leak detector.

CAUTION: Handling and care of seal protector is

important. If seal protector is nicked or the bottom

flared, the new seal may be damaged during

installation.

Removal

1. Recover the refrigerant using Refrigerant Recovery

System.

2. Loosen and reposition compressor in mounting

brackets, if necessary.

3. Remove clutch plate and hub assembly from

compressor as described previously.

4. Remove the shaft seal retainer ring, using snap ring

pliers.

5. Thoroughly clean inside of compressor neck area

surrounding the shaft, the exposed portion of the

seal, the retainer ring groove and the shaft itself.

Any dirt or foreign material getting into compressor

may cause damage.

6. Fully engage the knurled tangs of Seal Remover-

Installer J-23128-A into the recessed portion of the

Seal (1) by turning the handle clockwise. Remove

the Seal from the compressor with a rotary-pulling

motion.

Discard the seal. The handle must be hand-

tightened securely. Do not use a wrench or pliers.

1

2

3

456

871RW006

J-23128-A1

901RW008

Page 461 of 6000

DIFFERENTIAL (FRONT) 4A1–24

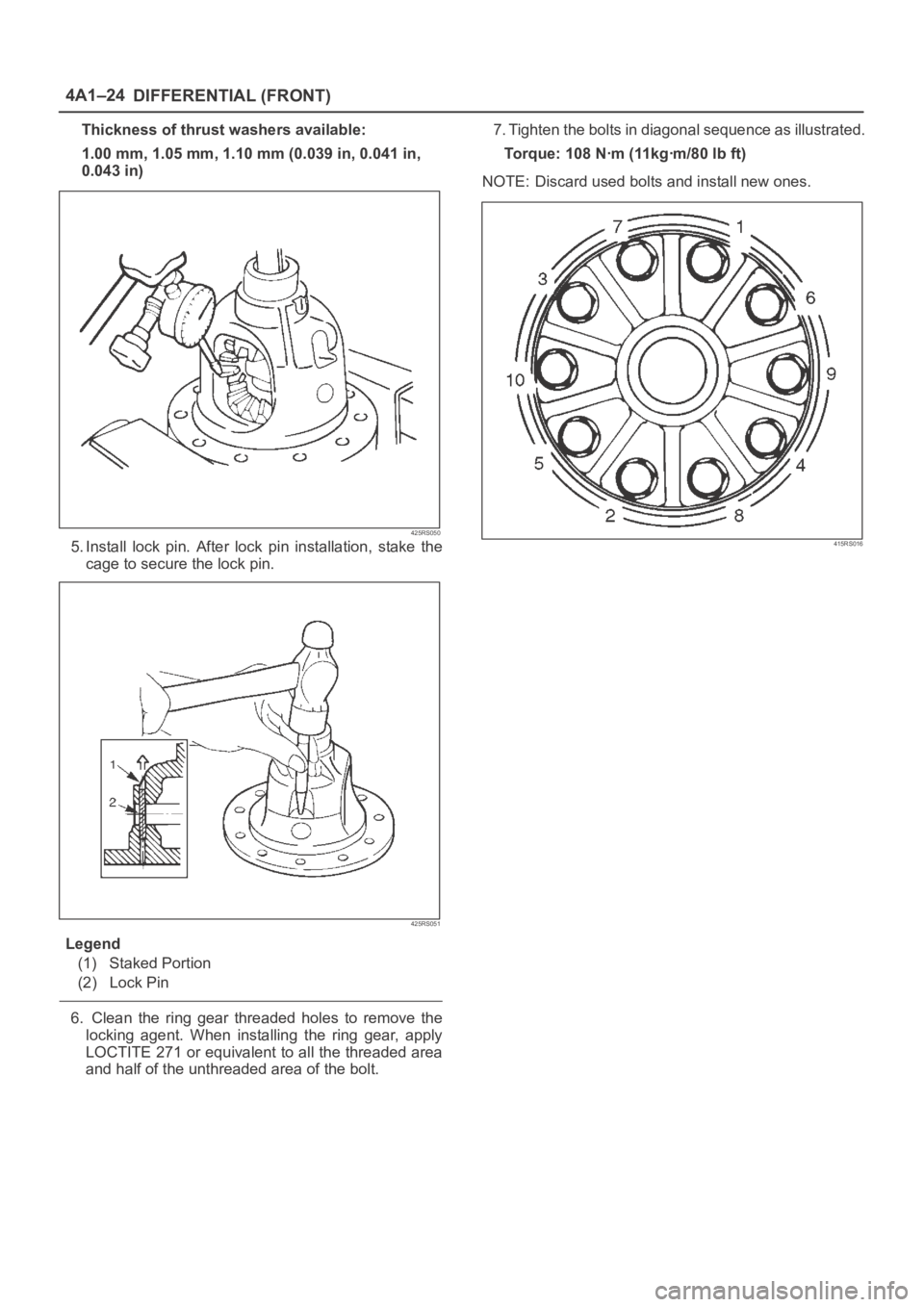

Thickness of thrust washers available:

1.00 mm, 1.05 mm, 1.10 mm (0.039 in, 0.041 in,

0.043 in)

425RS050

5. Install lock pin. After lock pin installation, stake the

cage to secure the lock pin.

425RS051

Legend

(1) Staked Portion

(2) Lock Pin

6. Clean the ring gear threaded holes to remove the

locking agent. When installing the ring gear, apply

LOCTITE 271 or equivalent to all the threaded area

and half of the unthreaded area of the bolt.7. Tighten the bolts in diagonal sequence as illustrated.

Torque: 108 Nꞏm (11kgꞏm/80 lb ft)

NOTE: Discard used bolts and install new ones.

415RS016

Page 491 of 6000

4A2A–24

DIFFERENTIAL (REAR 220mm)

Thickness of thrust washers available:

0.80 mm, 0.90 mm, 1.00 mm 1.10 mm, 1.20 mm,

1.30 mm (0.031 in, 0.035 in, 0.039 in,0.043 in,

0.047 in, 0.051 in)

425RS050

5. Install lock pin. After lock pin installation, stake the

cage to secure the lock pin.

425RS051

Legend

(1) Staked Portion

(2) Lock Pin

6. Clean the ring gear threaded holes to remove the

locking agent. When installing the ring gear, apply

LOCTITE 271 or equivalent to all the threaded area

and half of the unthreaded area of the bolt.7. Tighten the bolts in diagonal sequence as illustrated.

Torque: 108 Nꞏm (11.0kgꞏm/80 lb ft)

NOTE: Discard used bolts and install new ones.

415RW036

Page 525 of 6000

4A2B–22DIFFERENTIAL (REAR 244mm)

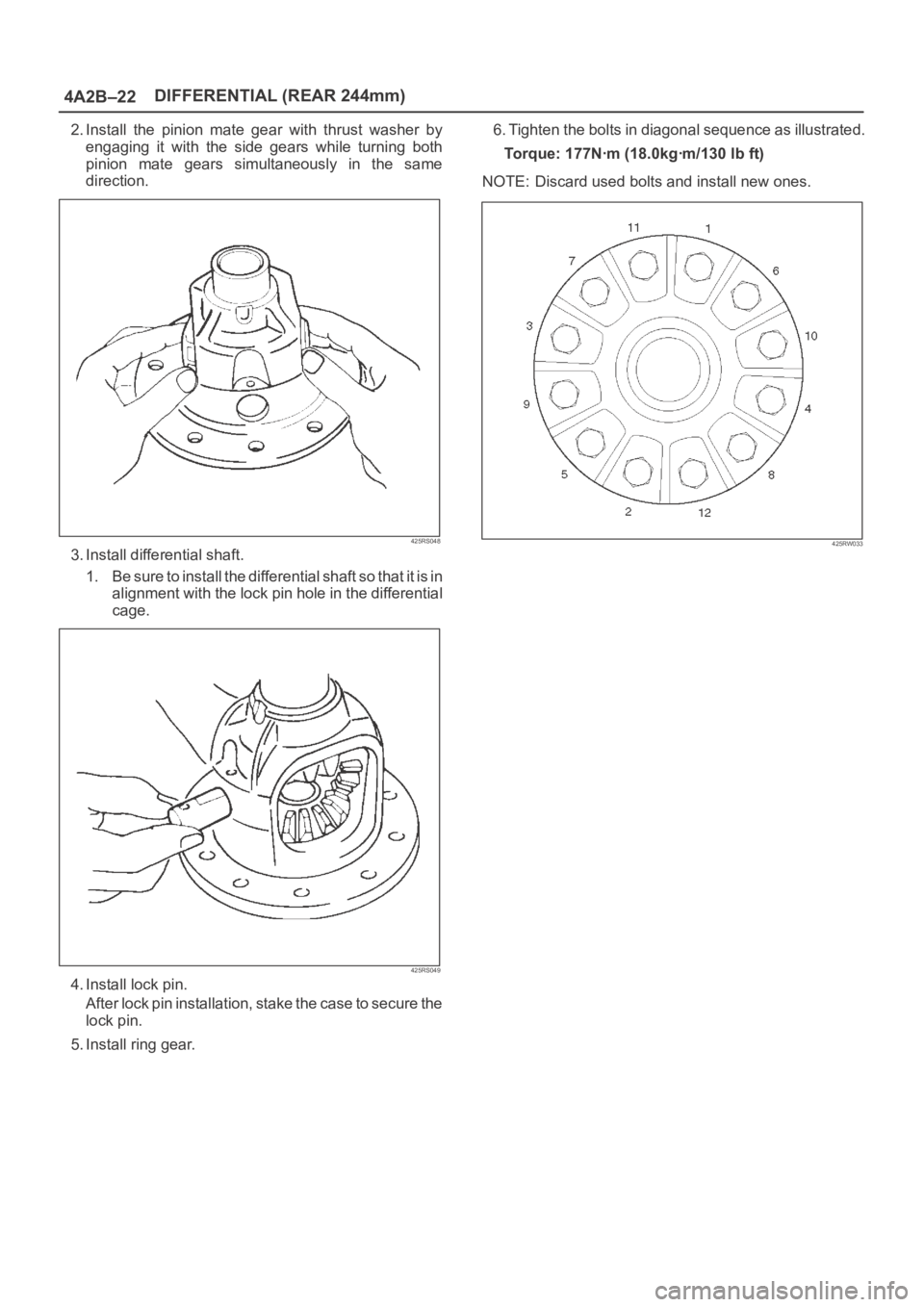

2. Install the pinion mate gear with thrust washer by

engaging it with the side gears while turning both

pinion mate gears simultaneously in the same

direction.

425RS048

3. Install differential shaft.

1 . B e s u r e t o i n s t a l l t h e d i f f e r e n t i a l s h a f t s o t h a t i t i s i n

alignment with the lock pin hole in the differential

cage.

425RS049

4. Install lock pin.

After lock pin installation, stake the case to secure the

lock pin.

5. Install ring gear.6. Tighten the bolts in diagonal sequence as illustrated.

Torque: 177Nꞏm (18.0kgꞏm/130 lb ft)

NOTE: Discard used bolts and install new ones.

425RW033

Page 573 of 6000

DRIVE LINE CONTROL SYSTEM (TOD) 4B2–2

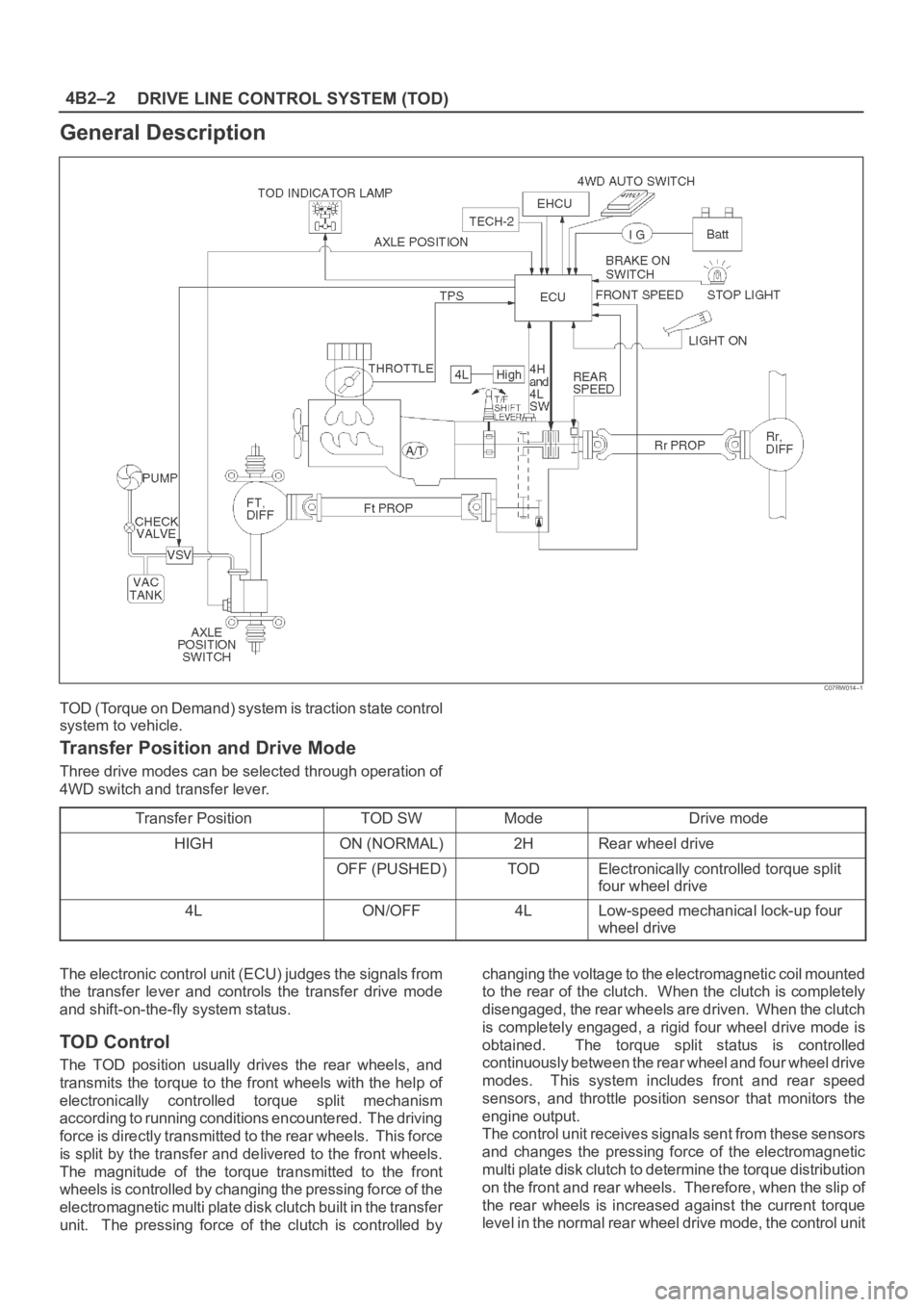

General Description

C07RW014–1

TOD (Torque on Demand) system is traction state control

system to vehicle.

Transfer Position and Drive Mode

Three drive modes can be selected through operation of

4WD switch and transfer lever.

Transfer Position

TOD SWModeDrive mode

HIGHON (NORMAL)2HRear wheel drive

OFF (PUSHED)TODElectronically controlled torque split

four wheel drive

4LON/OFF4LLow-speed mechanical lock-up four

wheel drive

The electronic control unit (ECU) judges the signals from

the transfer lever and controls the transfer drive mode

and shift-on-the-fly system status.

TOD Control

The TOD position usually drives the rear wheels, and

transmits the torque to the front wheels with the help of

electronically controlled torque split mechanism

according to running conditions encountered. The driving

force is directly transmitted to the rear wheels. This force

is split by the transfer and delivered to the front wheels.

The magnitude of the torque transmitted to the front

wheels is controlled by changing the pressing force of the

electromagnetic multi plate disk clutch built in the transfer

unit. The pressing force of the clutch is controlled bychanging the voltage to the electromagnetic coil mounted

to the rear of the clutch. When the clutch is completely

disengaged, the rear wheels are driven. When the clutch

is completely engaged, a rigid four wheel drive mode is

obtained. The torque split status is controlled

continuously between the rear wheel and four wheel drive

modes. This system includes front and rear speed

sensors, and throttle position sensor that monitors the

engine output.

The control unit receives signals sent from these sensors

and changes the pressing force of the electromagnetic

multi plate disk clutch to determine the torque distribution

on the front and rear wheels. Therefore, when the slip of

the rear wheels is increased against the current torque

level in the normal rear wheel drive mode, the control unit

Page 578 of 6000

4B2–7 DRIVE LINE CONTROL SYSTEM (TOD)

Check Lamp

Inform the following items.

Bulb check

Fail (fail alarm)

Trouble code

Diesel/gasoline MAP

821RW078

TOD ECU

This control unit is mounted to the front right hand seat via

a special bracket.

F07RW029

Page 582 of 6000

4B2–11 DRIVE LINE CONTROL SYSTEM (TOD)

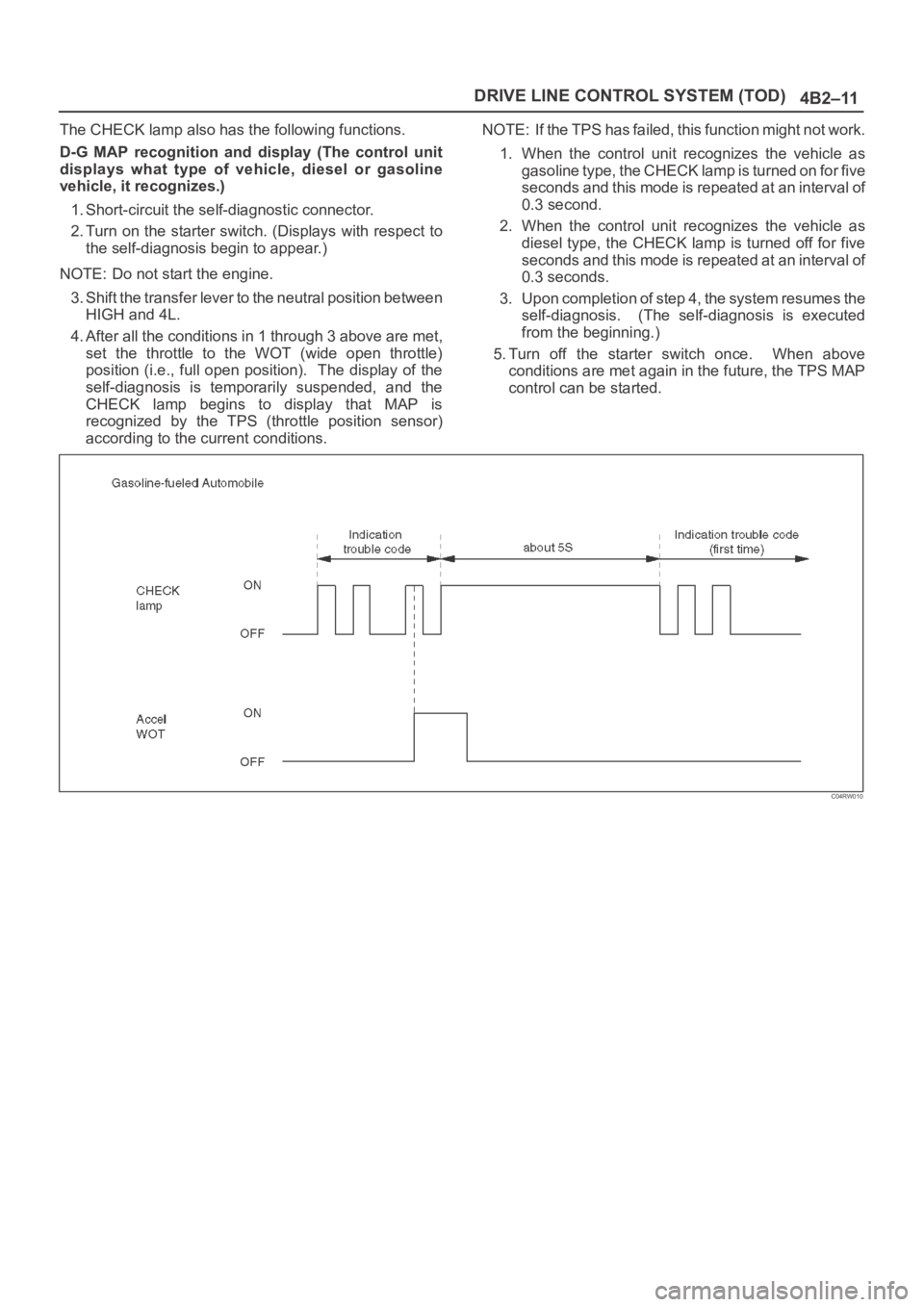

The CHECK lamp also has the following functions.

D-G MAP recognition and display (The control unit

displays what type of vehicle, diesel or gasoline

vehicle, it recognizes.)

1. Short-circuit the self-diagnostic connector.

2. Turn on the starter switch. (Displays with respect to

the self-diagnosis begin to appear.)

NOTE: Do not start the engine.

3. Shift the transfer lever to the neutral position between

HIGH and 4L.

4. After all the conditions in 1 through 3 above are met,

set the throttle to the WOT (wide open throttle)

position (i.e., full open position). The display of the

self-diagnosis is temporarily suspended, and the

CHECK lamp begins to display that MAP is

recognized by the TPS (throttle position sensor)

according to the current conditions.NOTE: If the TPS has failed, this function might not work.

1. When the control unit recognizes the vehicle as

gasoline type, the CHECK lamp is turned on for five

seconds and this mode is repeated at an interval of

0.3 second.

2. When the control unit recognizes the vehicle as

diesel type, the CHECK lamp is turned off for five

seconds and this mode is repeated at an interval of

0.3 seconds.

3. Upon completion of step 4, the system resumes the

self-diagnosis. (The self-diagnosis is executed

from the beginning.)

5. Turn off the starter switch once. When above

conditions are met again in the future, the TPS MAP

control can be started.

C04RW010

Page 585 of 6000

DRIVE LINE CONTROL SYSTEM (TOD) 4B2–14

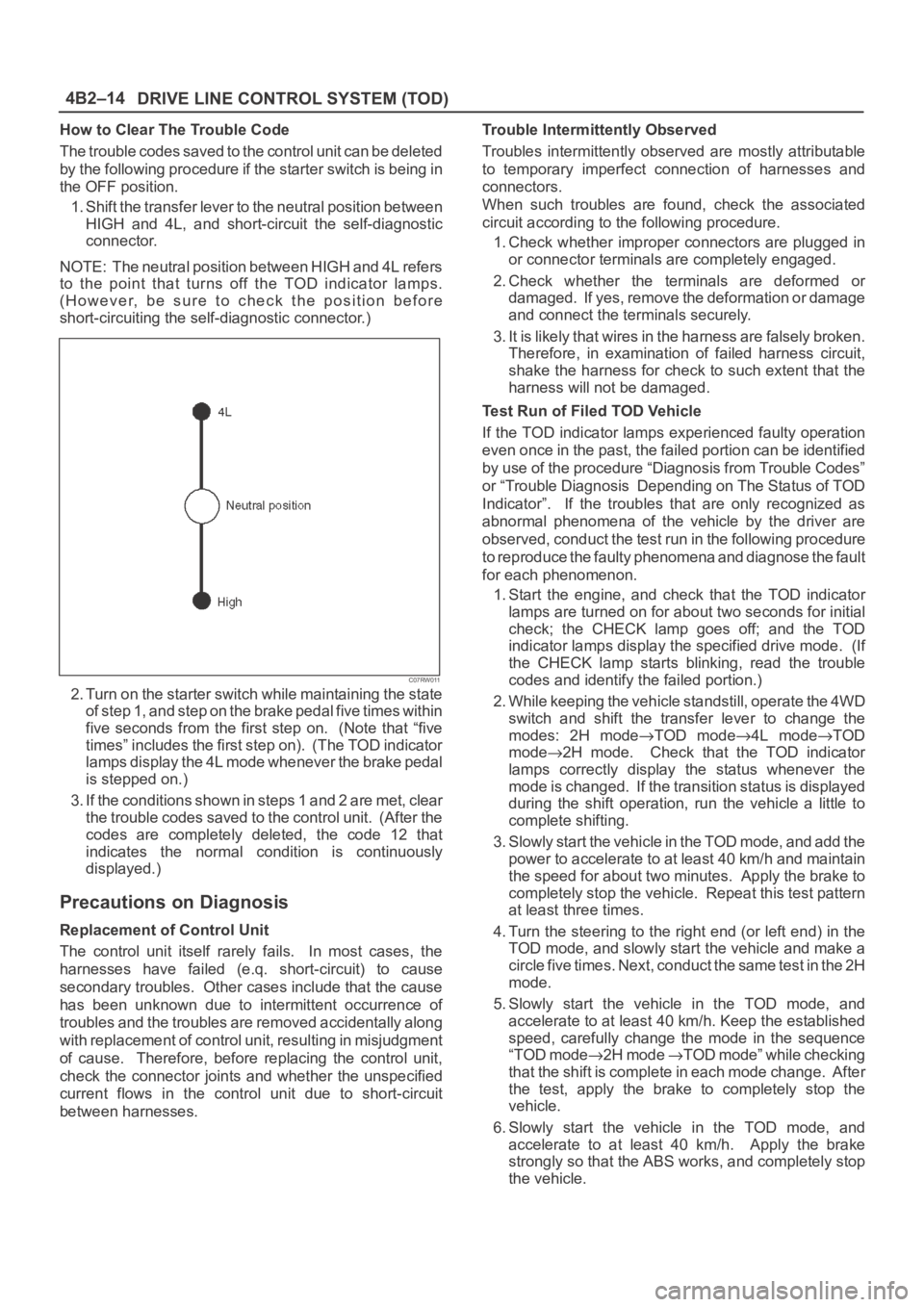

How to Clear The Trouble Code

The trouble codes saved to the control unit can be deleted

by the following procedure if the starter switch is being in

the OFF position.

1. Shift the transfer lever to the neutral position between

HIGH and 4L, and short-circuit the self-diagnostic

connector.

NOTE: The neutral position between HIGH and 4L refers

to the point that turns off the TOD indicator lamps.

(However, be sure to check the position before

short-circuiting the self-diagnostic connector.)

C07RW011

2. Turn on the starter switch while maintaining the state

of step 1, and step on the brake pedal five times within

five seconds from the first step on. (Note that “five

times” includes the first step on). (The TOD indicator

lamps display the 4L mode whenever the brake pedal

is stepped on.)

3. If the conditions shown in steps 1 and 2 are met, clear

the trouble codes saved to the control unit. (After the

codes are completely deleted, the code 12 that

indicates the normal condition is continuously

displayed.)

Precautions on Diagnosis

Replacement of Control Unit

The control unit itself rarely fails. In most cases, the

harnesses have failed (e.q. short-circuit) to cause

secondary troubles. Other cases include that the cause

has been unknown due to intermittent occurrence of

troubles and the troubles are removed accidentally along

with replacement of control unit, resulting in misjudgment

of cause. Therefore, before replacing the control unit,

check the connector joints and whether the unspecified

current flows in the control unit due to short-circuit

between harnesses.Trouble Intermittently Observed

Troubles intermittently observed are mostly attributable

to temporary imperfect connection of harnesses and

connectors.

When such troubles are found, check the associated

circuit according to the following procedure.

1. Check whether improper connectors are plugged in

or connector terminals are completely engaged.

2. Check whether the terminals are deformed or

damaged. If yes, remove the deformation or damage

and connect the terminals securely.

3. It is likely that wires in the harness are falsely broken.

Therefore, in examination of failed harness circuit,

shake the harness for check to such extent that the

harness will not be damaged.

Test Run of Filed TOD Vehicle

If the TOD indicator lamps experienced faulty operation

even once in the past, the failed portion can be identified

by use of the procedure “Diagnosis from Trouble Codes”

or “Trouble Diagnosis Depending on The Status of TOD

Indicator”. If the troubles that are only recognized as

abnormal phenomena of the vehicle by the driver are

observed, conduct the test run in the following procedure

to reproduce the faulty phenomena and diagnose the fault

for each phenomenon.

1. Start the engine, and check that the TOD indicator

lamps are turned on for about two seconds for initial

check; the CHECK lamp goes off; and the TOD

indicator lamps display the specified drive mode. (If

the CHECK lamp starts blinking, read the trouble

codes and identify the failed portion.)

2. While keeping the vehicle standstill, operate the 4WD

switch and shift the transfer lever to change the

modes: 2H mode

TOD mode4L modeTOD

mode

2H mode. Check that the TOD indicator

lamps correctly display the status whenever the

mode is changed. If the transition status is displayed

during the shift operation, run the vehicle a little to

complete shifting.

3. Slowly start the vehicle in the TOD mode, and add the

power to accelerate to at least 40 km/h and maintain

the speed for about two minutes. Apply the brake to

completely stop the vehicle. Repeat this test pattern

at least three times.

4. Turn the steering to the right end (or left end) in the

TOD mode, and slowly start the vehicle and make a

c i r c l e f i v e t i m e s . N e x t , c o n d u c t t h e s a m e t e s t i n t h e 2 H

mode.

5. Slowly start the vehicle in the TOD mode, and

accelerate to at least 40 km/h. Keep the established

speed, carefully change the mode in the sequence

“TOD mode

2H mode TOD mode” while checking

that the shift is complete in each mode change. After

the test, apply the brake to completely stop the

vehicle.

6. Slowly start the vehicle in the TOD mode, and

accelerate to at least 40 km/h. Apply the brake

strongly so that the ABS works, and completely stop

the vehicle.

Page 594 of 6000

4B2–23 DRIVE LINE CONTROL SYSTEM (TOD)

Checking Failed Pin

Connector Pin Assignment

ECU pin assignment

D04RW032