Transfer box OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 732 of 6000

TRANSFER CASE (STANDARD TYPE)

4D1–11

Transfer Rear Cover Assembly (4WD Switch Model)

Transfer Rear Cover Assembly and Associated Parts

220RW102

Legend

(1) Speedometer Sensor, Speedometer Driven

Gear and Plate

(2) Front Companion Flange

(3) Rear Companion Flange(4) Control Box Assembly

(5) 2WD–4WD Actuator Heat Protector

(6) 2WD–4WD Actuator Assembly

(7) Transfer Rear Cover Assembly

(8) Transfer Case Assembly

Page 733 of 6000

4D1–12

TRANSFER CASE (STANDARD TYPE)

Removal

1. Remove the speedometer sensor.

2. Remove the plate.

3. Remove the speedometer driven gear bushing and

driven gear.

NOTE: Apply a reference mark to the driven gear bushing

before removal.

4. Remove the front companion flange and the rear

companion flange, using the flange companion holder

5–8840–0133–0 (J–8614–11) to remove the end

nuts.

262RW067

NOTE: Use a universal puller to remove the rear

companion flange.

5. Disconnect the actuator breather hose and the

transfer breather hose from the control box.

6. Remove the control box assembly.

7. Disconnect the actuator breather hose and remove

the 2WD–4WD actuator heat protector from the

2WD–4WD actuator assembly.

220RW085

8. Remove the 2WD–4WD actuator assembly bolts.

9. Pull the 2WD–4WD actuator assembly with

2WD–4WD shift rod.

220RW027

Legend

(1) Shift Rod: 2WD–4WD (Position: 2WD)

(2) 2WD–4WD Actuator Assembly

(3) Pull Cover

(4) Rear Cover Assembly

(5) Position: 4WD

(6) Mode: 2WD

Page 735 of 6000

4D1–14

TRANSFER CASE (STANDARD TYPE)

6. Join the rod grooves of 2WD–4WD actuator

assembly (12) and shift rod (11).

220RW030

Legend

(11) Shift Rod: 2WD–4WD (Position: 4WD)

(12) 2WD–4WD Actuator Assembly (Mode: 2WD)

(13) Rear Cover Assembly

7. Push the 2WD–4WD actuator assembly (12) with

2WD–4WD shift rod (11) till the shift rod (11) reaches

the 2WD position.

220RW031

Legend

(14) Position: 2WD

(15) Mode: 2WD

8. Tighten the 2WD–4WD actuator bolts to the specified

torque.

Torque: 19 Nꞏm (1.9kgꞏm/14 lb ft)

9. Install the actuator heat protector.

10. Connect the actuator breather hose to the actuator.11. Install the control box assembly.

Torque: 19 Nꞏm (1.9kgꞏm/14 lb ft)

12. Connect the breather hoses to the control box.

13. Install the rear companion flange and front

companion flange, using the companion flange holder

5–8840–0133–0 (J–8614–11) to tighten the flange

nuts to the transfer case.

262RW067

14. Tighten the new transfer flange nuts to the specified

torque.

To r q u e

Rear companion flange: 167 Nꞏm (17.0kgꞏm/123

lb ft)

Front companion flange: 137 Nꞏm (14.0kgꞏm/101

lb ft)

15. Use the punch 5–8840–2293–0 (J–39209) to stake

the rear companion flange nut at two spots.

266RW027

Page 740 of 6000

TRANSFER CASE (STANDARD TYPE)

4D1–19

Transfer Rear Cover Assembly (Except 4WD Switch Model)

Transfer Rear Cover Assembly and Associated Parts

220RW116

Legend

(1) Speedometer Sensor, Speedometer Driven

Gear and Plate

(2) Front Companion Flange(3) Rear Companion Flange

(4) Control Box Assembly

(5) Transfer Rear Cover Assembly

(6) Transfer Case Assembly

Page 741 of 6000

4D1–20

TRANSFER CASE (STANDARD TYPE)

Removal

1. Remove the speedometer sensor.

2. Remove the plate.

3. Remove the speedometer driven gear bushing and

driven gear.

NOTE: Apply a reference mark to the driven gear bushing

before removal.

4. Remove the front companion flange and the rear

companion flange, using the flange companion holder

5–8840–0133–0 (J–8614–11) to remove the end

nuts.

262RW067

NOTE: Use a universal puller to remove the rear

companion flange.

5. Disconnect the transfer breather hose from the

control box.

6. Remove the control box assembly.

7. Remove the transfer rear cover assembly from the

transfer case assembly.

Installation

1. Apply the recommended liquid gasket (LOCTITE

17430) or its equivalent to the transfer rear cover

fitting faces.

220RS017

2. Install the transfer rear cover assembly to the transfer

case assembly.

3. Perform the following steps before fitting the transfer

rear case:

1. Shift the high–low shift rod to the 4H side.

2. Turn the select rod counterclockwise so that the

select block projection may enter into the

2WD–4WD shift block.

3. The cut–away portion of the select rod head (9)

should align with that of the rear case hole’s

stopper (10).

230RW004

4. Tighten the transfer rear case bolts to the specified

torque.

Torque: 37 Nꞏm (3.8kgꞏm/27 lb ft)

Page 742 of 6000

TRANSFER CASE (STANDARD TYPE)

4D1–21

5. Install the control box assembly.

Torque: 19 Nꞏm (1.9kgꞏm/14 lb ft)

6. Connect the breather hoses to the control box.

7. Install the rear companion flange and front

companion flange, using the companion flange holder

5–8840–0133–0 (J–8614–11) to tighten the flange

nuts to the transfer case.

262RW067

8. Tighten the new transfer flange nuts to the specified

torque.

Torque

Rear companion flange: 167 Nꞏm (17.0kgꞏm/123

lb ft)

Front companion flange: 137 Nꞏm (14.0kgꞏm/101

lb ft)

9. Use the punch 5–8840–2293–0 (J–39209) to stake

the rear companion flange nut at two spots.

266RW027

266RW002

10. Stake the front companion flange nut at one spot.

NOTE: Be sure to confirm that there is no crack at the

staked portion of the flange nut after staking.

11. Install the O–ring (8) to the speedometer driven gear

bushing (7).

12. Install the driven gear to the speedometer driven gear

bushing (7).

13. Install the speedometer driven gear assembly to the

transfer rear cover.

14. Install the plate (6) to the transfer rear case and

tighten to the specified torque.

Torque: 15 Nꞏm (1.5kgꞏm/11 lb ft)

Page 2322 of 6000

7B–4MANUAL TRANSMISSION

Diagnosis

ConditionPossible causeCorrection

Abnormal noiseFlywheel pilot bearing wornReplace

Bearings worn or broken (Mainshaft,

counter shaft, and transfer shaft)Replace

Gear tooth contact surfaces worn or

scuffed (Mainshaft, counter shaft,

reverse idler gear and transfer gears)Replace

Splines worn (Mainshaft,

synchronizer clutch hub)Replace

Gear or bearing thrust face seizedReplace

Lack of backlash between meshing

gearsReplace

Hard ShiftingImproper clutch pedal free playReadjust

Change lever sliding portions wornRepair or replace

Regrease

Shift block, shift rod and/or control

box sliding faces wornReplace

Shift arm and synchronizer sleeve

groove wornReplace worn parts

Thrust washer, collar, and/or gear

thrust faces worn (Mainshaft and

counter shaft thrust play)Replace worn parts

Synchronizer parts wornReplace

Walking or Jumping out of gearDetent ball wornReplace

Detent spring weakened or brokenReplace

Shift rod and/or control box sliding

faces wornReplace

Shift arm and synchronizer sleeve

groove wornReplace worn parts

Thrust washer, collar, and/or gear

thrust faces worn (Mainshaft and

counter shaft thrust play)Replace worn parts

Bearings worn or brokenReplace

Splines worn (Mainshaft,

synchronizer hub)Replace

Synchronizer spring weakened or

brokenReplace

Oil leakageLoose drain plug(s) and/or filler

plug(s)Tighten

Replenish oil

Defective or improperly installed

gasket(s)Replace

Oil seal worn or scratchedReplace

Page 2338 of 6000

7B–20MANUAL TRANSMISSION

220RW095

Legend

(1) Release Bearing and Shift Fork

(2) Clutch Housing

(3) Front Cover

(4) Snap Ring

(5) Snap Ring

(6) 1st and 2nd Switch

(7) Drain Plug

(8) Backup Light Switch

(9) Transmission Case(10) Filler Plug

(11) Gear Control Rod

(12) Reverse Restrict Pin

(13) Oil Receiver Pipe

(14) Transfer Adapter

(15) Plug (6VE1) or Neutral Switch (4JX1)

(16) Gear Control Box

(17) Shift Lever Housing

(18) Oil Seal

(19) Plug

Page 2340 of 6000

7B–22MANUAL TRANSMISSION

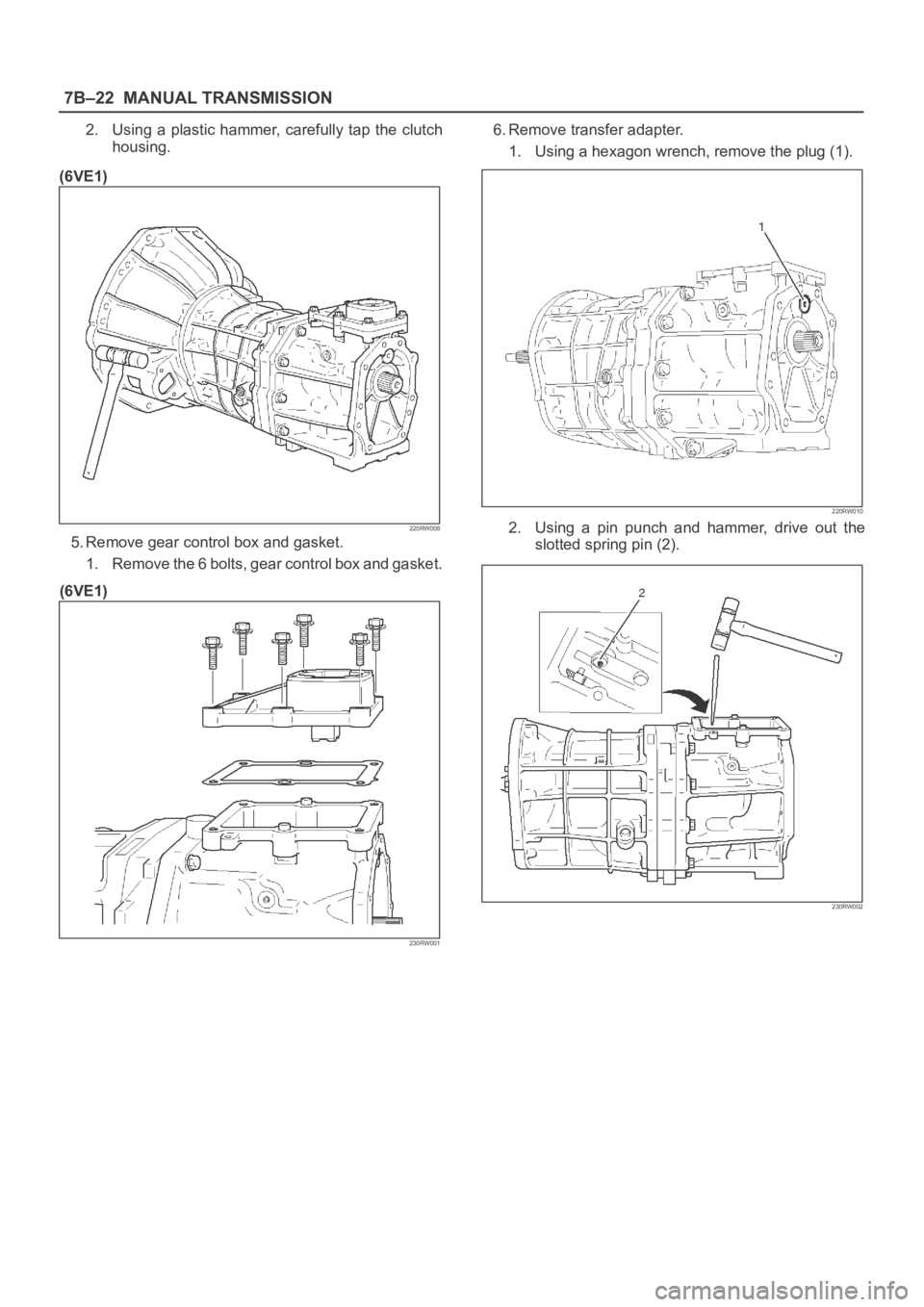

2. Using a plastic hammer, carefully tap the clutch

housing.

(6VE1)

220RW008

5. Remove gear control box and gasket.

1. Remove the 6 bolts, gear control box and gasket.

(6VE1)

230RW001

6. Remove transfer adapter.

1. Using a hexagon wrench, remove the plug (1).

220RW010

2. Using a pin punch and hammer, drive out the

slotted spring pin (2).

230RW002

Page 2382 of 6000

7B–64MANUAL TRANSMISSION

6. Check that the top gear shaft and mainshaft

rotate.

36. Install the transfer adapter.

1. Clean up the fitting surface.

2. Apply recommended liquid gasket (THREE

BOND 1281 or equivalent), as shown.

NOTE:

Don’t dry the liquid gasket.

220RW026

3. Using a plastic hammer, tap the transfer adapter

and attach it to the intermediate plate.

220RW034

4. Using 10 bolts, install the transfer adapter.

Torque: 37 Nꞏm (3.8 kgꞏm/27 lb ft)

NOTE:

Tighten the all bolts evenly.

Don’t damage the lip of the oil seal.

Install the wire clamp (9) to the transfer adapter.

220RW083

37. Install the gear control box.

1. Align the projection of the shift lever housing to

the shaft rod groove, and install the gear control

rod.

230RW003