steering OPEL GT-R 1973 User Guide

[x] Cancel search | Manufacturer: OPEL, Model Year: 1973, Model line: GT-R, Model: OPEL GT-R 1973Pages: 625, PDF Size: 17.22 MB

Page 84 of 625

I

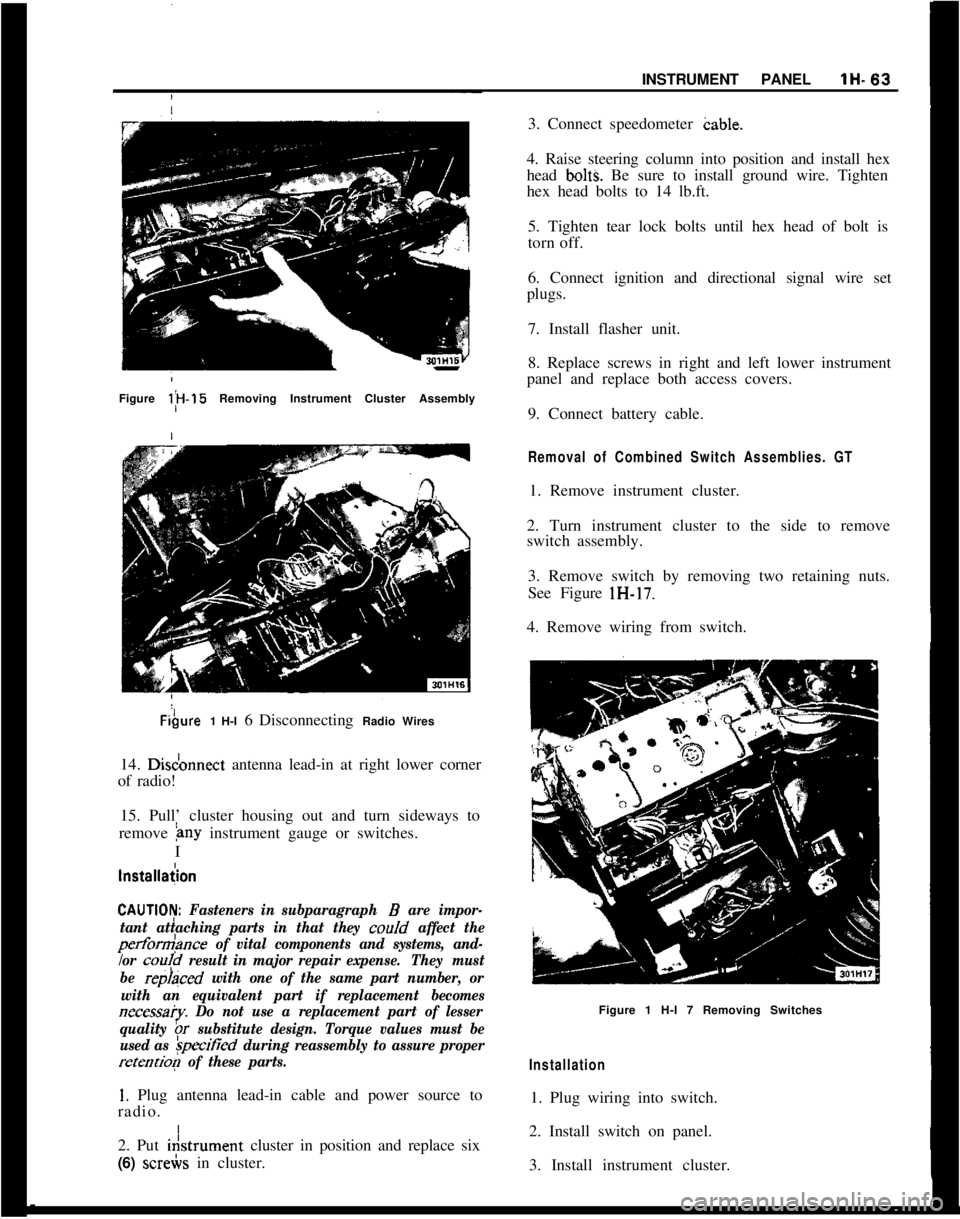

,INSTRUMENT PANELlH-63Figure l;H-15 Removing Instrument Cluster AssemblyFibure1 H-l 6 Disconnecting Radio Wires

14. Disdonnect antenna lead-in at right lower corner

of radio!

15. Pull’ cluster housing out and turn sideways to

remove

&~y instrument gauge or switches.

I

lnstallaiion

CAUTlOI$ Fasteners in subparagraph B are impor-

tant attaching parts in that they coo/d

affect the

perform>nce of vital components and systems, and-

/or

cou!d result in major repair expense.They must

be

repraced with one of the same part number, or

with an equivalent part if replacement becomes

necessa?y. Do not use a replacement part of lesser

quality

br substitute design. Torque values must be

used as

&ified during reassembly to assure proper

retention of these parts.

1. Plug antenna lead-in cable and power source to

radio. I

2. Put i&trument cluster in position and replace six

(6) screbs in cluster.3. Connect speedometer cable.

4. Raise steering column into position and install hex

head

bolt% Be sure to install ground wire. Tighten

hex head bolts to 14 lb.ft.

5. Tighten tear lock bolts until hex head of bolt is

torn off.

6. Connect ignition and directional signal wire set

plugs.

7. Install flasher unit.

8. Replace screws in right and left lower instrument

panel and replace both access covers.

9. Connect battery cable.

Removal of Combined Switch Assemblies. GT1. Remove instrument cluster.

2. Turn instrument cluster to the side to remove

switch assembly.

3. Remove switch by removing two retaining nuts.

See Figure lH-17.

4. Remove wiring from switch.

Figure 1 H-l 7 Removing Switches

Installation1. Plug wiring into switch.

2. Install switch on panel.

3. Install instrument cluster.

Page 105 of 625

r

2UREDp

IM

BRNIWHI

BUZZER

3 CLOSED POSlTlONl

/-

14 RED - TO STEERING

COLUMN CONN.

20 RED

12 RED FROM BATTERY--18 GRAY--12 RED

-I

J

DOME LIGHT

&SWITCH1

1

.,_ &,,,.~~

STEER I NG

COLUMN

CONNECTORTRUNK LIGHT?&SWITCH

IGNITION

SWITCH‘\BUZZER SWITCH(HELD CLOSED WITH

KEY IN “OFF” & “LOCK”POSITION1

3OlJll

Page 168 of 625

I

GROUP 3

SUSPENSION

AND

STEERING I

SectionTitlePage No

3AFrontSuspension. . . . . . . . . .3A- 2

3BSteering Linkages38-l 9

3C Front End Alignment3C-22

3DSteering Gear.._........3D-27

Steering Column

3E1900 - Manta ,._________...3E-35

GT

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3E-42

3FRear Suspension. . . . . . . . .3F-51

3GWheelsand Tires. . . . . . . . . .36-55

Page 169 of 625

3A- 21973 OPEL SERVICE MANUAL

FRONT SUSPENSION

CONTENTS

Subject

DESCRIPTION AND OPERATION:SuspensionDescription. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .DIAGNOSIS: (Not Applicable)

MAINTENANCE AND ADJUSTMENTS:

FrontWheel

BearingAdjustments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .MAJOR REPAIR:

Removal and Installation of Front Suspension . . . . . . . .Upper Ball Joint Removal and Installation

. . . . . . . . . . . . . .Lower Ball Joint Removal and

Installation

. . . . . . . . . . . . . .Upper Control Arm

Removal andInstallation

. . . . . . . . . .Lower Control Arm Removal and Installation

. . . . . . . .Steering

Knuckle

RemovalandInstallation. . . . . . . . . . . . . .Shock Absorber

RemovalandInstallation. . . . . . . . . . . . . . . .Front Spring Removal and Installation

. . . . . . . . . . . . . . . . . . . . . .SPECIFICATIONS:Page No.

3A- 2

3A- 4

3A- 4

3A- 7

3A- 73A-103A-113A-133A-153A-15

Bolt Torque and Front End Alignment Specifications

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3A-18

DESCRIPTION AND OPERATION

SUSPENSION DESCRIPTION

GTThe GT uses a maintenance-free independent front

wheel suspension and features unequal length con-

trol arms and a transverse three-leaf spring. The en-

tire front suspension is attached to the front cross

member and can be removed as a unit if so desired.

The engines installed in the GT are not supported by

mounting brackets but rest on a separate cross mem-

ber. The front suspension cross member is reinforced

in the area of the attachment to the frame. A one-

part damper plate is installed between cross member

and frame.

Ball joints are employed in the conventional manner

to provide pivoting joints between the control arms

and steering knuckles. Upward movement of the

control arms is limited by two large rubber bumpers

attached to the cross member.Road shock is dampened by the double direct acting

shock absorbers and a transverse double or triple

steel band spring. In addition, the shock absorber

limits downward travel of the control arms.

All moving parts, including ball joints, have no need

for lubrication as they have been pre-lubricated for

the life of the vehicle.

For distinguishing the individual front suspension

cross members,.a red label with black letters is stuck

onto the front side of the shock absorber support. See

Figure 3A-3.

Opel 1900. Manta

The front wheel suspension has coil springs and con-

trol arms of different length.

The stabilizer is designed to act as a tie strut. The end

is supported in a rubber bushing which is located in

a piece of tubing welded into the longer control arm.

To minimize brake torque, the horizontal shafts of

Page 170 of 625

FRONT SUSPENSION3A- 34RM“PPtR BALL

SHOCK ABSORBER UPPER CONTROL,

UPPER CONTROL

ARM SHAFT

“:,‘,:“,‘,“,“, ,“pd,,‘, T/RUBBER BUMPER

\CROSSMEMBER

ROTOR

/LOWER BALL JOINTFRONT SPRING

Figure 3A-2 GT Front Suspension (Disc Brakes)

the upper and lower control arm are not in parallel

(anti- dive).The lower control arm is connected to the steering

knuckle with a ball joint.3A-4

Figure 3A-3 Cross Member Marking

Figure 3A-4 Front Suspension

- Opel 1900 Manta

Page 171 of 625

3A- 41973 OPEL SERVICE MANUAL

The two cross-members to body supports are at-

tached to the horizontal part of the cross-member

with two bolts. The oufererbolt serves simultaneously

as support for the lower control arm. As the bolt is

inserted from the front, the cross-member to body

support can be removed without the lower control

arm. The inner bolt attaches simultaneously to the

steering.

The stabilizer is U-shaped and supported in rubber

bushings in the two cross-members to body supports.

The complete front suspension is attached to the

underbody in four places.

The engine damper blocks are bolted to the inside of

the inclined parts of the cross-member.

The front wheel bearings are roller bearings.

All front suspension joints are maintenance-free.

MAINTENANCE AND ADJUSTMENTSFRONT WHEEL BEARING ADJUSTMENT

1. If wheel has not previously been removed from the

car, remove grease cap, cotter pin, and spindle nut.

Discard cotter pin.

2. Torque spindle nut to 18

lb.ft. while rotating

wheel. This will allow the bearings to settle.

3. Back offspindle nut

l/4 turn. If slot and cotter pin

hole are staggered, further back off nut

l/l2 turn,

but do not tighten, until next slot in nut is in align-

ment with hole in spindle. Install new cotter pin. A

properly adjusted wheel bearing has a small amount

of end play and a loose nut when adjusted in the

above manner.

MAJOR REPAIRREMOVAL AND INSTALLATION OF FRONT

SUSPENSION

(COMPLETE ASSEMBLY)

Removal GT1. Prior to raising front end of car, apply parking

brake and block rear wheels.

2. Raise front end of car with a jack. It is recom-

mended that a wood block be placed between thejack and the front cross member to prevent damage

to the cross member.

3. Support front end of car by placing floor standsunde:r jacking brackets.

4. Support engine-transmission assembly in upper-

most position with jack stand at rear of engine, or an

alternate method would be to use Engine Holding

Fixture, Tool J-23375. See Figure 3A-5.

Install tool by removing upper kngine mount nut and

installing fixture. Replace nut and tighten. The en-

gine will now be supported by the tool between the

frame rails.

Figure

3A-5 Engine Holding Fixture Installed

5. Loosen steering mast at the lower universal joint

and take out clamp bolt. Loosen clamp at the upper

universal joint and lift steering mast upwards until it

is free at the lower universal joint. See Figure

3A-6.6. Disconnect brake lines at brake hose.

7. Disconnect shock absorber at upper mounting. It

is necessary to remove air cleaner. See Figure

3A-24.8. Disconnect engine mounts at cross member.

9. Remove front suspension cross member attaching

nuts and lower the cross member.

Removal Opel 1900 - Manta1. Prior to raising front end of car, apply parking

brake and block rear wheels.

Page 172 of 625

FRONT SUSPENSION3A- 5

Figure 3A-6 GT Steering Mast Joint

2. Install Hooks J-23697 before jacking up car to

assure proper loading of suspension bushings and

mounts. See Figure

3A-7.3. Raise front of vehicle and support with stands.

4. Remove front wheels.

5. Remove guard plate. See Figure

3A-8,6. Remove brake line retainers on both sides. The

brake system remains closed. Unscrew brake calipersand suspend them in wheel house.Figure

3A-9 Removing Guard Plate

7. Suspend engine with a suitable engine lifter, simi-

lar to the one shown in Figure

3A-9.8. Unscrew lower steering mast clamp bolt out of

pinion flange. See Figure

3A- 10.

9. Unscrew front left and right engine mount from

damper block.

10. On top and in the rear, unscrew front suspensionFigure

3A-7 Installing Hooks J-23697Figure 3A-9 Suitable Engine Liftel

Page 173 of 625

3A- 6 1973 OPEL SERVICE MANUAL

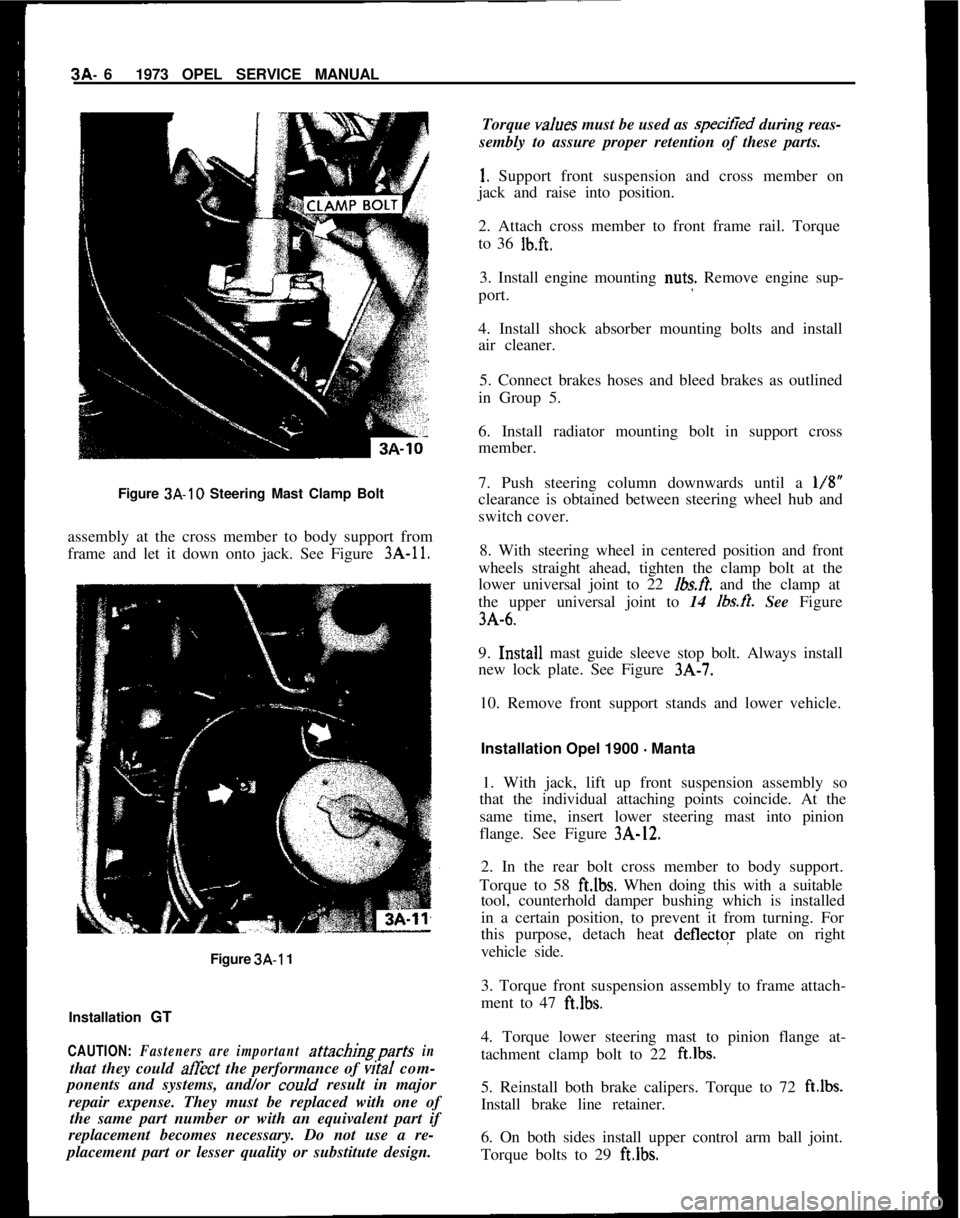

Figure 3A-10 Steering Mast Clamp Bolt

assembly at the cross member to body support from

frame and let it down onto jack. See Figure

3A-11.

Figure 3A-1 1

Installation

GT

CAUTION: Fasteners are important attachingparts in

that they could affect the performance of vitaI com-

ponents and systems, and/or

coo/d result in major

repair expense. They must be replaced with one of the same part number or with an equivalent part if

replacement becomes necessary. Do not use a re-

placement part or lesser quality or substitute design. Torque

values

must be used as speciiied during reas-

sembly to assure proper retention of these parts.

I. Support front suspension and cross member on

jack and raise into position.

2. Attach cross member to front frame rail. Torque

to 36

lb.ft.

3. Install engine mounting nut? Remove engine sup-

port.

4. Install shock absorber mounting bolts and install

air cleaner.

5. Connect brakes hoses and bleed brakes as outlined

in Group 5.

6. Install radiator mounting bolt in support cross

member.

7. Push steering column downwards until a

l/8”

clearance is obtained between steering wheel hub and

switch cover.

8. With steering wheel in centered position and front

wheels straight ahead, tighten the clamp bolt at the

lower universal joint to 22

fbs.fi. and the clamp at

the upper universal joint to 14

lbs.ft. See Figure

3A-6.

9. Inr;tall mast guide sleeve stop bolt. Always install

new lock plate. See Figure

3A-7.

10. Remove front support stands and lower vehicle.

Installation Opel 1900 - Manta

1. With jack, lift up front suspension assembly so

that the individual attaching points coincide. At the

same time, insert lower steering mast into pinion

flange. See Figure

3A-12.

2. In the rear bolt cross member to body support.

Torque to 58

ft.lbs. When doing this with a suitable

tool, counterhold damper bushing which is installed

in a certain position, to prevent it from turning. For

this purpose, detach heat

deflectqr plate on right

vehicle side.

3. Torque front suspension assembly to frame attach-

ment to 47

ft.lbs.

4. Torque lower steering mast to pinion flange at-

tachment clamp bolt to 22

ft.lbs.

5. Reinstall both brake calipers. Torque to 72 ft.lbs.

Install brake line retainer.

6. On both sides install upper control arm ball joint.

Torque bolts to 29

ft.lbs.

Page 174 of 625

FRONT SUSPENSION3A- 7

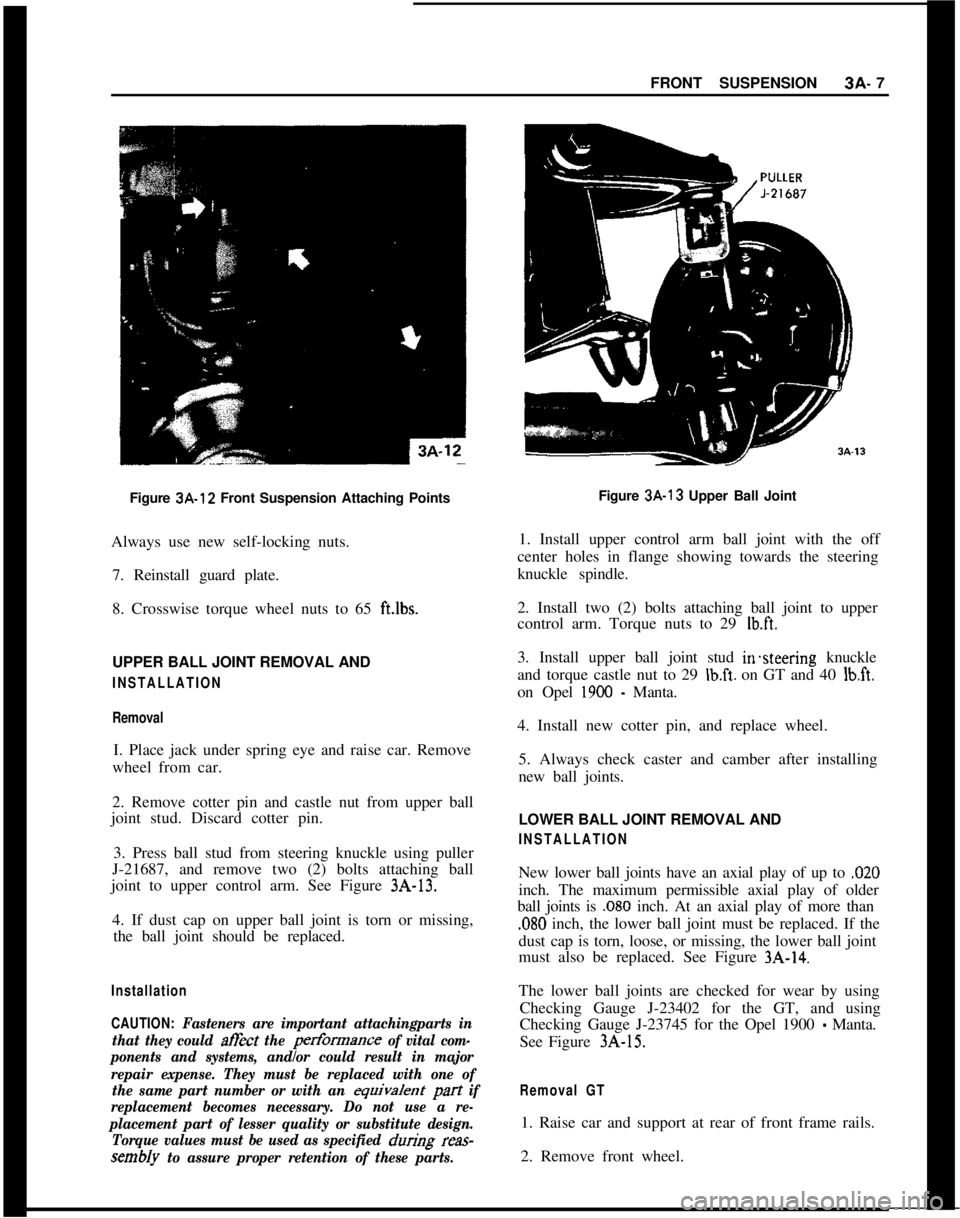

Figure 3A-12 Front Suspension Attaching Points

Always use new self-locking nuts.

7. Reinstall guard plate.

8. Crosswise torque wheel nuts to 65 ft.lbs.UPPER BALL JOINT REMOVAL AND

INSTALLATION

RemovalI. Place jack under spring eye and raise car. Remove

wheel from car.

2. Remove cotter pin and castle nut from upper ball

joint stud. Discard cotter pin.

3. Press ball stud from steering knuckle using puller

J-21687, and remove two (2) bolts attaching ball

joint to upper control arm. See Figure 3A-13.

4. If dust cap on upper ball joint is torn or missing,

the ball joint should be replaced.

Installation

CAUTION:

Fasteners are important attachingparts in

that they could

afEct the pertkmance of vital com-

ponents and systems, and/or could result in major

repair expense. They must be replaced with one of

the same part number or with an

equivaknt pa-t if

replacement becomes necessary. Do not use a re-

placement part of lesser quality or substitute design.

Torque values must be used as specified

durikg reas-

sembly to assure proper retention of these parts.Figure 3A-13 Upper Ball Joint

1. Install upper control arm ball joint with the off

center holes in flange showing towards the steering

knuckle spindle.

2. Install two (2) bolts attaching ball joint to upper

control arm. Torque nuts to 29 Ibft.

3. Install upper ball joint stud in%eering knuckle

and torque castle nut to 29

Ib.ft. on GT and 40 lb&.

on Opel

1900 - Manta.

4. Install new cotter pin, and replace wheel.

5. Always check caster and camber after installing

new ball joints.

LOWER BALL JOINT REMOVAL AND

INSTALLATIONNew lower ball joints have an axial play of up to

,020inch. The maximum permissible axial play of older

ball joints is

,080 inch. At an axial play of more than

,080 inch, the lower ball joint must be replaced. If the

dust cap is torn, loose, or missing, the lower ball joint

must also be replaced. See Figure

3A-14.The lower ball joints are checked for wear by using

Checking Gauge J-23402 for the GT, and using

Checking Gauge J-23745 for the Opel 1900

- Manta.

See Figure

3A-15.

Removal GT1. Raise car and support at rear of front frame rails.

2. Remove front wheel.

Page 176 of 625

FRONT SUSPENSION3A- 9

8. Press ball stud out of lower control arm.Removal Opel 1900 - MantaBefore raising vehicle, install Hooks J-23697 on re-

spective vehicle side to cross member and upper con-

trol arm. See Figure 3A-7.

1. Raise car and support at rear of front frame rails.

2. Remove front wheel.

3. At the lower control arm ball joint, remove castle

nut cotter pin and slacken back nut so that the thread

can no longer be damaged.

4. With a suitable drift, detach ball joint from steer-

ing knuckle. With jack, lift up lower control arm,

unscrew castle nut and remove Hooks J-23697.

5. Unscrew upper control arm ball joint and suspend

front wheel hub and brake caliper in wheel house. Do

not turn upper control arm ball joint flange, as this

would result in a change of camber.

6. Remove defective lower control arm ball joint

using Tools J-9519 and Receiver J-23754.

Installation GT

CAUTION:

Fasteners are important attachingparts in

that they could affect the performance of

vitaI com-

ponents and systems, and/or could result in

ma&r

repair expense. They must be replaced with one of

the same part

numer or with an equivalent part if

replacement becomes necessary. Do not use a

re-

placement part of lesser quality or substitute design.

Torque values must be used as specified during reas-

sembly to assure proper retention of these parts.1. When pressing the ball joint in place, make certain

the locating notch in the lower rim of the ball joint

matches the alignment reference mark placed on the

lower control arm prior to removal. The notch in the

ball joint bottom plate, identifying the direction of

the elongated slot, must point towards the brake

drum backing plate. See Figure

3A-17. Alignment

must be within 2 degrees of lower control arm center-

line. If proper positioning of the ball joint is not

accomplished, the result is a limitation of the neces-

sary ball stud movement. If ball stud movement is

limited, an interference between the ball stud and

housing is created, and binding or even fracture may

occur. Replacement ball joints may or may not have

marking notch as shown in Figure

3A-20. If it does

not have a marking notch, the joint is completelysymetrical and may be installed in any position.

When pressing in ball joint do not press on bottom

plate, but on ball joint housing only.2. Install dust cap on lower ball joint and fill with

chassis lubricant. Attach dust cap retainer.

3. Press ball joint into steering knuckle. Use

J-9519-3 as installer and J-21690 as a supporting

sleeve.4. Install castle nut on ball joint stud and torque to

40

Ib.ft. Install new cotter pin.

5. Reconnect shock absorber to lower control arm

and torque to 30 lb.ft.

6. Remove spring compressor.

7. Install front wheel, and lower the car.

8. Always check caster and camber after ball joint

replacement.

Installation Opel 1900 - Manta

CAUTION:

Fasteners are important attachingparts in

that they could

aff’ect the performance of vital com-

ponents and systems, and/or could result in

ma&r

repair expense. They must be

rep/aced with one of

the same part number or with equivalent parts, if

rep/acement becomes necessary. Do not use a re-

p/acement part of lesser quality or substitute design.

Torque valves must be used as

specitied during reas-

sembIy to assure proper retention of these parts.1. Drive new ball joint into lower control arm using

Tools J-9519 as installer and J-23755 as a supporting

sleeve. Do not strike onto ball joint bottom.

The ball joint is maintenance-free. It is supplied as an

assembly only and cannot be disassembled further.

2. On new lower control arm ball joint, make sure

that the marking groove in the housing bottom in

alignment with the axis of the lower control arm.

Permissible deviation: minus 2 degrees to plus 2 de-

grees.This is required, to obtain the maximum freedom of

movement of the ball stud in the housing. See Figure

3A-18.3. Attach steering knuckle together with front wheel

hub and brake caliper to lower control arm ball joint.

Torque castle nut to 54

ft.lbs.4. Attach ball joint to upper control arm and torque

to 29

ft.lbs. Always use new self-locking nuts.

5. Install wheel and tighten nuts to a torque of 65

ft.lbs.6. Lower car and check caster and camber.