wheel bolts OPEL GT-R 1973 User Guide

[x] Cancel search | Manufacturer: OPEL, Model Year: 1973, Model line: GT-R, Model: OPEL GT-R 1973Pages: 625, PDF Size: 17.22 MB

Page 184 of 625

FRONT SUSPENSION3A- 17Torque values must be used as specified during reas-

sembly to assure proper retention of these parts.1. Attach lower control arm to front spring eye.

Torque bolts to 18

lb.ft.2. Install spring compressor on spring and compress

spring to appropriate length.

3. Raise jack with spring compressor, spring and

control arm assembly into position under the car.

4. Install lower ball joints and torque nuts to 54

Ib.ft.Install new cotter pin.

5. Attach lower control arms to frame cross member

using new lock nuts.

6. Attach both shock absorbers. Torque bolts to 30

lb.ft.7. Remove spring compressor.

8. Install front wheels.

On replacement of the damper bushings on the front

springs, only the one-part damper bushing is in-

stalled for either the two-leaf or three-leaf spring.

For proper location of the marking lugs, see Figure3A-26.

Installation (Opel 1900. Manta)

CAUTION: Fasteners are important attachingparts in

that they

co&d affect the performance of vital com-

ponents and systems, and/or could result in major

repair expense. They must be replaced with one of

the same part number or with an equivalent part, if

replacement becomes necessary. Do not use a re-

placement part of

lesser quality or substitute design.

Torque values must be used as specified

during reas-

sembly to assure proper retention of these parts.1. Properly seat spring between lower control arm

and cross member.

2. Raise jack and place lower control into position.CROSS SECTION

SA-26Fig. 3A-26 Front Spring Damper Bushing.

3. Attach lower control ball joint to steering knuckle

and torque nut to 54

lb.ft.4. Tighten lower control arm to cross member bolt

to 43 lb.ft.

5. Attach stabilizer bar to cross member to body

support.

6. Install shock absorber and torque lower attaching

nut and bolt to 30

lb.ft.7. Install nuts on upper shock absorber attaching

studs. Tighten nuts until a distance from top of nut

to stud is approximately

l/2 inch.

8. Install front wheels and tighten nuts to 65

lb.ft.9. Remove stands and lower car.

SPECIFICATIONSBOLT TORQUE AND FRONT END ALIGNMENT

Page 185 of 625

3A- 161973 OPEL SERVICE MANUAL

SPECIFICATIONS

Torque Specifications

Use a reliable torque wrench to tighten all parts listed to insure proper

tightness without straining or distorting parts. These specifications are for

clean and lightly-lubricated threads only; dry or dirty threads produce in-

creased friction which prevents accurate maasurement of tightness.

LocationFront Suspension Crossmember to Front Frame

Clamp, Steering Mast to Steering Mast Flange

(GT)

........................................................................................

Clamp, Steering Mast to Steering Mast Flange(1900

-Manta)..................................................................

Clamp,UpperUniversalJoint(GT)..................................Clamp, Lower Universal Joint (GT)

..................................

WheelNuts............................................................................Lower Control Arm Shaft to Lower Control Arm

..........Lower Control Arm Ball Joint to Steering Knuckle

......Upper Control Arm Ball Joint to Steering Knuckle

(GT)........................................................................................Upper Control Arm Ball Joint to Steering Knuckle

(1 900 Manta)

..................................................................Upper Control Arm Ball Joint to Upper Control Arm

ShockAbsorbertoLowerControlArm..........................Steering Arm to Steering Knuckle (1900

- Manta)......

Brake Backing Plate or Brake Disc Shield andSteering Arm to Steering Knuckle

(GTJ

Hex Head Bolt M 10......Hex Head Bolt M 8

......

Brake Backing Plate to Steering Knuckle(1900 Manta)

..................................................................

Brake Caliper to Steering Knuckle.................................

Lower Control Arm to Front Spring Eye (GT)................

Brake Disc to Front Wheel Hub........................................Upper Control Arm to Crossmember (1900

- MantajLower Control Arm to Crossmember (1900

- Manta)

Steering Gear Housing to Front Suspension

Crossmember (GT)

............................................................

Steering Gear Housing to Front SuspensionCrossmember (1900

- Manta)........................................Stabilizer Bar to Lower Control Arm

(Opel 1900

- Manta)........................................................Tie Rod Clamp Bolts

(GTJ....................................................

CastleNut,TieRodtoSteeringArm..............................Upper Control Arm Shaft to Shock Absorber Support

and Upper Control Arm (GT)

..........................................

CrossMember to

BodySupport Attachment................

FrontSuspensionAssemblytoFrame............................Front End Alignment Specifications

Torque

Lb.Ft.36

1522

14

22

6540

5429

ii30

5847

18

58

72

1836

40

43

1830

87

:i33

58

47ModelCaster’

Camber”1900‘3

l/2-6 l/2GT

3+1-:%+*Permissible deviation from left to right wheel

- Max. 1’.

Toe-In”Min.-Max.

l/8-3/ 16

l/32-1/8Outer Wheel

When Inner

Wheel at 20

19

l/418

l/2

Page 189 of 625

3C-22 1973 OPEL SERVICE MANUAL.

FRONT END ALIGNMENT

CONTENTS

SubjectPage No.

DESCRIPTION AND OPERATION:

FrontWheelAlignment

. . . . . . . . . . . . . . . . . . . . . . ..“...........................DIAGNOSIS: (Not Applicable)

MAINTENANCE AND ADJUSTMENTS:

Inspection Before Checking Front Wheel Alignment

AdjustingCaster

. . . . . . . . ...’ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Adjusting Camber

. . . . . . . . . . . . . . . . . . . . . . . . . . * . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Adjusting Toe-In

. . . . . . . . . . . . . . * . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .King Pin Inclination

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .MAJOR REPAIR: (Not Applicable)

SPECIFICATIONS:3C-223C-223C-233C-253C-253C-26

Wheel Alignment Specifications

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3C-26

DESCRIPTION AND OPERATIONFRONT WHEEL ALIGNMENT

Wheel alignment is the mechanics of adjusting the

position of the front wheels in order to attain the

least steering effort with a minimal amount of tire

wear.handling, but require only reasonable accuracy to

provide normal tire life. With the type of front sus-

pension used, the toe-in adjustment is much more

important than caster and camber are as far as tire

wear is concerned.

Correct alignment of the chassis is essential to proper

alignment of front and rear wheels. Briefly, the es-

sentials are that the frame must be square in plain

view within specified limits, that the top and bottom

surfaces of the front cross member must be parallel

fore and aft, and that the upper and lower control

arm must be at correct location in respect to shafts

and the front cross member. All bushings, ball joints

and bolts must be of proper torque and in usable

condition.Caster and camber adjustments need not be consid-

ered unless visual inspection shows these settings to

be out, or unless the car gives poor handling on the

road. In the majority of cases, services consisting of

inflating tires to specified pressure and interchanging

tires at recommended intervals, balancing all wheels

and tires, adjusting steering gear and setting toe-in

correctly will provide more improvement in car han-

dling and tire wear than will other front end align-

ment adjustments.

Wheel and tire balance has an important effect on

steering and tire wear. If wheels and tires are out of

balance, “shimmy” or “tramp” may develop or tires

may wear unevenly and give the erroneous impres-

sion that the wheels are not in proper alignment. For

this reason, the wheel and tire assemblies should be

known to be in proper balance before assuming that

wheels are out of alignment.The correct use of accurate front end alignment

equipment is essential to determine whether front

suspension parts have been damaged by shock or

accident, and to obtain correct alignment settings

after new parts have been installed.

MAINTENANCE AND ADJUSTMENTS

Inspection Before Checking Front Wheel AlignmentClose limits on caster, front wheel camber, andBefore making any adjustment affecting caster, cam-

theoretical king pin inclination are beneficial to carber, toe-in, theoretical king pin inclination, or

steer-

Page 192 of 625

FRONT END ALIGNMENT 3C-25

Figure 3C-6 Adjusting Toe-In (GT)ADJUSTING CAMBER

Camber is adjusted by turning the upper ball jointflange 180 degrees. This means that only two possi-

ble camber adjustments can be made. At the factory

camber is set at the smallest possible positive camber

setting for GT and smallest possible negative camber

for Opel

1900 - Manta. Rotating the flange will make

camber more positive on GT and more negative on

Opel

1900 - Manta.

1. Raise front end of car using wood block on jack

to prevent damage to front cross member.

2. Support car below lower control arm and remove

front wheel on side to be adjusted.

3. Remove ball joint from upper control arm and

front steering knuckle.

4. Lift upper control arm and turn the ball joint

flange through 180 degrees.

5. First tighten both ball joint attaching bolts on

upper control arm and then the ball stud castle nut.

Torque to 29 ft. lbs. on GT and 44

ft.lbs. on Opel

1900 - Manta. Install new cotter pin.

6. Install front wheel and torque wheel nuts to 72

lb.ft. on GT and 75 Ib.ft. on Opel 1900 - Manta.

7. Recheck camber.

ADJUSTING TOE-IN

(GT)Toe-in is adjusted by rotating the tie rod sleeves.

Refer to Figure

3C-6.1. Recheck caster and camber before proceeding

with toe-in adjustment. If correct, adjust toe-in.2. Set wormshaft and ball nut to steering gear high

point by turning steering wheel half way from one

stop to the other, noticing the following:

(a) With the steering wheel hub button removed, the

“marking” on the steering shaft end should be in a

horizontal position.

(b) The steering wheel spokes should also be in a

centered position.

3. Remove wire clamps on left and right tie rod and

push back bellows.

4. Loosen clamp bolts and tie rods. See Figure

3C-4.5. The toe-in should be

l/32” - l/8”.When adjusting toe-in, never grip tie rod on inner

ball stud joint. To avoid ball stud resting against

inside of hole in tie rod outer end, center outer end

of each tie rod to the ball stud.

6. Pull bellows over tie rods and attach with wire

clamps. The bellows must not be twisted and wire

ends must show towards steering gear adjusting

screw opening.

7. Torque clamp bolts to 12

Ib.ft.8. After toe-in adjustment, turn steering wheel sev-

eral times completely towards the left and right to

determine whether bellows are properly attached to

the tie rods and steering gear housing.

ADJUSTING TOE-IN (OPEL 1900. MANTA)

The adjustment of the toe-in has always to be carried

out on both tie rods.

Page 196 of 625

STEERING GEAR ASSEMBLY30-292. Loosen clamp securing flexible coupling to steer-

ing shaft.

4. Remove stop bolt (see Figure 3D-4) from under-

side of steering column (secures steering shaft bush-

ing to mast jacket), and pull steering wheel rearward

approximately three inches.

Figure

3D-4 Stop Bolt

4. Remove cotter pin located on left and right tie rod

ends and unscrew nut.

5. Using remover J-21687, press ball studs out of

steering arms (see Figure

3D-5).

IJ-21 68’Figure 3D-5 Removing Ball Stud6. Remove four attaching bolts securing steering gear

to front suspension cross member (see Figure 3D-6)

and lift off steering gear assembly and tie rods.

Figure

3D-6 Steering Gear Assembly Attaching Bolts

Removal (Opel 1900. Manta)1. Remove splash shield from lower deflector pa:

and both side members. See Figure

3D-7.nel

Figure

3D-7 Removing Splash Shield

2. Remove clamp bolt securing flexible coupling to

steering shaft. See Figure

3D-8.

Page 197 of 625

3D- 301973 OPEL SERVICE MANUALFigure 3D-8 - Removing Clamp Bolt3. Remove cotter pin located on left and right tie rod

end and unscrew nut.

4. Using Tool J-21687, press tie rod ends out of

steering arms.

5. Disconnect steering gear housing from front sus-

pension cross member and remove steering gear

together with tie rods.

Installation . GTCAUTION: Fasteners are important attaching parts in

that they could affect the performance of vital com-

ponents and systems, and/or could result in major

repair expense. They must be replaced

with one of

the same part number or with an equivalent part if

replacement becomes necessary. Do not

use a re-

placement part of lesser quality or substitute design.

Torque values must be used as specified during reas-

sembly to assure proper retention of these parts.

1. Position steering gear on front suspension cross

member and torque attaching bolts to 18

lb.ft.2. Position tie rod ball studs in steering arms; install

nuts and torque to 29 lb.ft. Lock in position with new

cotter pins.

3. Fully turn steering wheel so that flat or cutout

surface on lower portion of steering shaft is parallel

to flexible coupling bolt hole.

4. Install the lower end of steering shaft to the flexi-

ble coupling and adjust dimension between steering

wheel hub and direction signal switch housing cover

to

l/8 and 3/32 inch. Maintain adjustment by tight-

ening flexible coupling bolt and nut to 15 lb.ft. Lock

the bolt and nut in position with lock-plate tabs.5. Reinstall stop bolt into steering column.

6. Full turn steering wheel both right and left. If any

resistance is noticeable, it will be necessary to remove

the sleering column and correct the cause.

D. Installation (Opel 1900. Manta)CAUTION: Fasteners are important attachingparts in

that they could affect the performance of vital com-

ponents and systems, and/or could result in

maJbrrepair expense. They must be replaced with one of

the same part number or with an equivalent part if

replacement becomes necessary. Do not use a re-

placement part oflesser

quaky or substitute design.

Torque values must be used as specified during reas-

sembly to assure proper retention of these parts.

1. Prior to installation, set steering gear to high

point. The steering wheel spokes point downwards in

an oblique angle. The elongated cutout of the lower

steering mast must coincide with the clamp bolt hole

of the pinion flange.

2. Position steering gear on front suspension cross

member and torque attaching bolts to 29 lb.ft.

3. Position tie rod studs in steering arms. Install nuts

and torque to 29

Ib.ft. Lock in position with new

cotter pin.

4. Install the lower end of the steering shaft to flexi-

ble coupling and torque clamp bolt to 22

lb.ft.5. Attach guard plate to both side members and

lower deflector panel.

DISASSEMBLY AND ASSEMBLY OF

STEERING GEAR ASSEMBLY WITH TIE RODS

Disassembly - GT1. Carefully clamp gear assembly in soft jaw vise and

slip clamps and rubber bellows off gear housing to

expose area where ball joint screws into rack.

2. Bend up round edges of lockplates from tie rod

ball studs and disconnect tie rod ball studs from rack.

See Figure

3D-9). It is important that rack be held

secure with open end wrench to prevent damage to

rack teeth.

3. Loosen adjusting screw lock nut; remove adjusting

screw from steering gear housing, and take out thrust

spring and sintered bronze shell. See Figure

3D-11.4. Rotate gear assembly in vise so that pinion shaft

portion of assembly is held by vise, and remove pin-

ion nut, flat washer, and special washer.

Page 203 of 625

3E- 361973 OPEL SERVICE MANUAL

and ignition switch in RUN position, the fog lights

are automatically switched off. Direction signals

work in the normal manner; pushing the lever up for

right turn signal and pulling the lever down for left

turn signal.

DESCRIPTION AND OPERATION OF HORN

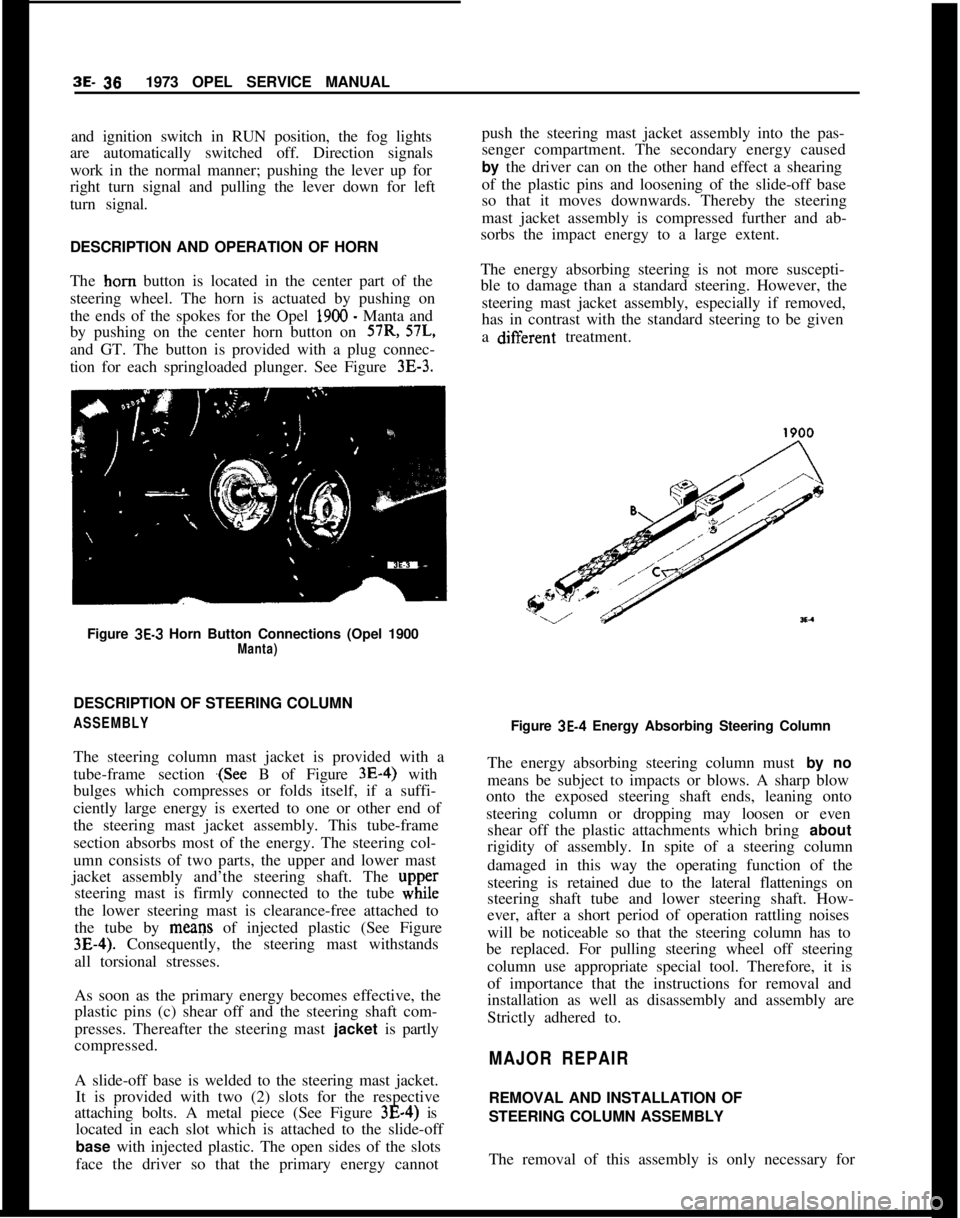

The horn button is located in the center part of the

steering wheel. The horn is actuated by pushing on

the ends of the spokes for the Opel 1900 - Manta and

by pushing on the center horn button on 57R, 57L,

and GT. The button is provided with a plug connec-

tion for each springloaded plunger. See Figure

3E-3.Figure

3E-3 Horn Button Connections (Opel 1900Manta)DESCRIPTION OF STEERING COLUMN

ASSEMBLYThe steering column mast jacket is provided with a

tube-frame section

.(See B of Figure 3E-4) with

bulges which compresses or folds itself, if a suffi-

ciently large energy is exerted to one or other end of

the steering mast jacket assembly. This tube-frame

section absorbs most of the energy. The steering col-

umn consists of two parts, the upper and lower mast

jacket assembly and’the steering shaft. The

upp,ersteering mast is firmly connected to the tube while

the lower steering mast is clearance-free attached to

the tube by means of injected plastic (See Figure

3E-4). Consequently, the steering mast withstands

all torsional stresses.

As soon as the primary energy becomes effective, the

plastic pins (c) shear off and the steering shaft com-

presses. Thereafter the steering mast jacket is partly

compressed.

A slide-off base is welded to the steering mast jacket.

It is provided with two (2) slots for the respective

attaching bolts. A metal piece (See Figure 3E-4) is

located in each slot which is attached to the slide-off

base with injected plastic. The open sides of the slots

face the driver so that the primary energy cannotpush the steering mast jacket assembly into the pas-

senger compartment. The secondary energy caused

by the driver can on the other hand effect a shearing

of the plastic pins and loosening of the slide-off base

so that it moves downwards. Thereby the steering

mast jacket assembly is compressed further and ab-

sorbs the impact energy to a large extent.

The energy absorbing steering is not more suscepti-

ble to damage than a standard steering. However, the

steering mast jacket assembly, especially if removed,

has in contrast with the standard steering to be given

a difierent treatment.

Figure

3E-4 Energy Absorbing Steering Column

The energy absorbing steering column must by no

means be subject to impacts or blows. A sharp blow

onto the exposed steering shaft ends, leaning onto

steering column or dropping may loosen or even

shear off the plastic attachments which bring about

rigidity of assembly. In spite of a steering column

damaged in this way the operating function of the

steering is retained due to the lateral flattenings on

steering shaft tube and lower steering shaft. How-

ever, after a short period of operation rattling noises

will be noticeable so that the steering column has to

be replaced. For pulling steering wheel off steering

column use appropriate special tool. Therefore, it is

of importance that the instructions for removal and

installation as well as disassembly and assembly are

Strictly adhered to.

MAJOR REPAIRREMOVAL AND INSTALLATION OF

STEERING COLUMN ASSEMBLY

The removal of this assembly is only necessary for

Page 208 of 625

OPEL 1900 AND MANTA STEERING COLUMN ASSEMBLY3E- 41

SPECIFICATIONS

Steering Column Tightening Specifications

PartLocationToraue

1b.k.Nut

Steering Wheel Retaining (1900

- Manta) .._......._...,,....BoltSteering Column Flexible Coupling (1900 - Manta) ._.,

NutSlide Off Base Attaching (1 900 - Manta) ._..,,,,,,...._,,,,,..

NutMass Jacket (1 900

- Manta) .,............,,,............,,,,,.......,,,,,

screw

Steering Mast Clamp (1900

- Manta) .,.........,.._...............1122

10::

Page 209 of 625

3E- 421973 OPEL SERVICE MANUAL

GT STEERING COLUMN ASSEMBLY

CONTENTS

Subject

DESCRIPTION AND OPERATION:

DescriptionofSteeringColumn. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .DIAGNOSIS: (Not Applicable)

MAINTENANCE AND ADJUSTMENTS: (Not

Applicable)

MAJOR REPAIR:

RemovalandInstallationofSteeringWheel. . . . . . . . . . . .Removal and Installation of Ignition Lock

Cylinder

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Removal and Installation of Steering Column

Assembly

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Removal and Installation of Center Steering Shaft

Removal and Installation of Ignition Switch

and/or Steering Lock

.,~ ,........ ~ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Removal and Installation of Upper Steering

Bearing and/or Directional Signal Switch

. . . . . . . . . . . .Removal and Installation of Steering Column

Lower Bearing

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .SPECIFICATIONS:

Steering Column Torques

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page No.

3E-42

3E-44

3E-45

3E-45

3E-46

3E-46

3E-48

3E-49

3E-50

DESCRIPTION AND OPERATION

DESCRIPTION OF STEERING COLUMNThe Energy Abosrbing, Locking Steering .Column

assembly is used on the GT. This cohnnn is designed

to compress under impact. When an automobile is

being driven, the forward movement of the automo-

bile and the forward movement of the driver both

constitute a form of energy or force. When an au-

tomobile is involved in a frontal collision, the pri-

mary force (forward movement of the car) is

suddenly halted, while the secondary force (the

driver) continues its forward direction. A severe col-

lision generally involves these two forces

- the pri-

mary and the secondary forces. The secondaryjmpact occurs when the driver is thrust forward onto

the steering wheel and column.

The Energy Absorbing Column is designed to absorb

these primary and secondary forces to the extent thatthe severity of the secondary impact is reduced. Dur-

ing a collision, the steering column compresses and

thereby reduces its tendency to move rearward into

the driver’s compartment. A split second later when

the driver is thrown forward (the secondary impact)

his energy is also partially abosrbed by the compres-

sion characteristics of the column.

The Energy Absorbing, Locking Column assembly

may be easily disassembled and reassembled. The

serviceman should be aware that it is important that

only the specified screws, bolts and nuts be used as

designated during reassembly, and that they are

tightened to their specified torque. This precaution

will insure the energy absorbing action of the assem-

bly. Particular care should be exercised to avoid us-

ing overlength bolts as they may prevent a portion of

the assembly from compressing under impact.

Equally as important is correct torquing of all bolts

and nuts.

When the Energy Absorbing, Locking Column is

Page 211 of 625

3E. 441973 OPEL SERVICE’MANUAL

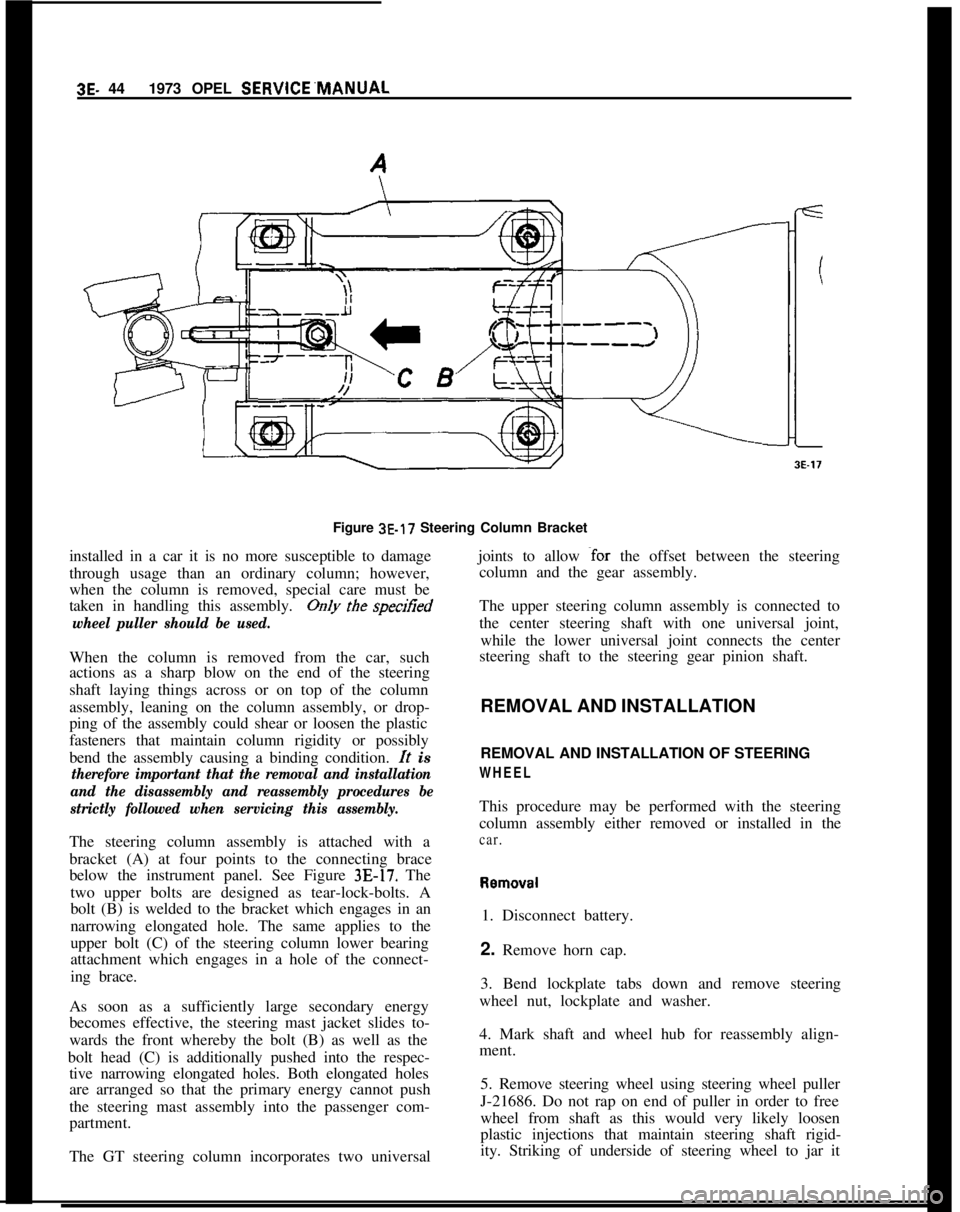

Figure 3E-17 Steering Column Bracket

installed in a car it is no more susceptible to damage

through usage than an ordinary column; however,

when the column is removed, special care must be

taken in handling this assembly.Only the speufied

wheel puller should be used.When the column is removed from the car, such

actions as a sharp blow on the end of the steering

shaft laying things across or on top of the column

assembly, leaning on the column assembly, or drop-

ping of the assembly could shear or loosen the plastic

fasteners that maintain column rigidity or possibly

bend the assembly causing a binding condition.

It is

therefore important that the removal and installation

and the disassembly and reassembly procedures be

strictly followed when servicing this assembly.The steering column assembly is attached with a

bracket (A) at four points to the connecting brace

below the instrument panel. See Figure

3E-17. The

two upper bolts are designed as tear-lock-bolts. A

bolt (B) is welded to the bracket which engages in an

narrowing elongated hole. The same applies to the

upper bolt (C) of the steering column lower bearing

attachment which engages in a hole of the connect-

ing brace.

As soon as a sufficiently large secondary energy

becomes effective, the steering mast jacket slides to-

wards the front whereby the bolt (B) as well as the

bolt head (C) is additionally pushed into the respec-

tive narrowing elongated holes. Both elongated holes

are arranged so that the primary energy cannot push

the steering mast assembly into the passenger com-

partment.

The GT steering column incorporates two universaljoints to allow

~for the offset between the steering

column and the gear assembly.

The upper steering column assembly is connected to

the center steering shaft with one universal joint,

while the lower universal joint connects the center

steering shaft to the steering gear pinion shaft.

REMOVAL AND INSTALLATION

REMOVAL AND INSTALLATION OF STEERING

WHEELThis procedure may be performed with the steering

column assembly either removed or installed in the

car.Removal

1. Disconnect battery.

2. Remove horn cap.

3. Bend lockplate tabs down and remove steering

wheel nut, lockplate and washer.

4. Mark shaft and wheel hub for reassembly align-

ment.

5. Remove steering wheel using steering wheel puller

J-21686. Do not rap on end of puller in order to free

wheel from shaft as this would very likely loosen

plastic injections that maintain steering shaft rigid-

ity. Striking of underside of steering wheel to jar it