checking oil OPEL GT-R 1973 Owner's Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1973, Model line: GT-R, Model: OPEL GT-R 1973Pages: 625, PDF Size: 17.22 MB

Page 529 of 625

98-20 1973 OPEL SERVICE MANUAL

If we were to put a thermometer in the cold drain

water, we would see the temperature gradually creep

upwards. That is to be expected because heat is flow-

ing into the cold water making it warmer. Before

long the water would be as warm as the stored foods.

Then the water could no longer attract heat because

heat will not flow from one warm object to another

equally warm object. Since we no longer can draw

heat out of the foods we no longer are cooling them.

Now, let’s see what happens when we put ice instead

of cold water into the ice-box. This time, we’ll set the

thermometer on top of the ice (Fig. 9B-5). When wefirst look at the thermometer, it reads 32 degrees. A

couple of hours later, we open the ice compartment

door. The ice block is smaller because some of the ice

has already melted away

- but the thermometer still

reads 32 degrees. Again, still later, even more of the

ice has melted, yet the termometer continues to read

32 degrees. So long as any ice remains, no matter

how much of it has melted away, the temperature of

the ice stays right at 32 degrees.

All this time the ice has been soaking up heat, yet it

never gets any warmer no matter how much heat it

draws from the stored food. On the other hand, the

cold drain water got progressively warmer as it

soaked up heat. Why is it the addition of heat will

make water warmer yet won’t raise the temperature

of ice above the 32 degrees mark? If we till one

drinking glass with ice and another with cold water,

and put both glasses in the same room where they

could absorb equal amounts of heat from the room

air, we will find it takes much, much longer for the

ice to melt and reach room temperature than it did

for the water in the other glass to reach the same

temperature. Obviously, most of the heat was being

used to melt the ice. But it was the heat that appar-

ently disappeared or went into hiding because if

couldn’t be located with a thermometer. To best de-

scribe this disappearing heat, scientists turned to

Latin for the right word. They chose the word “la-

tent” which means hidden.

Latent Heat

So latent heat is nothing more nor less than hidden

heat which can’t be found with a thermometer.

What happens to the latent heat? Where does it

disappear to? At first it was thought it was in the

water that melted from the ice. But that wasn’t ex-

actly the right answer because, upon checking water

temperature as it melts from ice, it will be found that

it is only a shade warmer than the ice itself. It is not

nearly warm enough to account for all the heat the

ice had absorbed. The only possible answer is that

the latent heat had been used up to change the ice

from a solid into a liquid.

Many substances can be either a solid, or a liquid, ora gas. It just depends on the temperature whether

water for example was a liquid, or a solid (ice), or gas

(steam) (Fig.

9B-6).Figure 99-6 Temperature Determines State of Water

If we put some water in a tea-kettle, set it over a tire

and watch the thermometer as the water gets hotter

and hotter, the mercury will keep rising until the

water starts to boil. Then the mercury seems to stick

at the 212 degrees mark. If we put more wood on the

fire, despite all the increased heat, the mercury will

not budge above the 212 degree mark (Fig.

9B-7).Figure 98.7 Boiling Water Never Exceeds 2 12

DegreesEven though many housewives won’t believe it, no

matter how large or hot you make the flame, you

can’t make water hotter than 2 12 degrees. As a liquid

changes into a gas, it absorbs abnormally great

amounts of heat without getting any hotter. Here is

another instance where heat disappears.

Now we have two different kinds of latent heat,

which are quite alike. To keep their identities sepa-

rate, the first one is called latent heat of fusion. Since

fusion means the same as melting, it is a good de-

scriptive name. The other kind is called latent heat

of vaporization because‘ that means the same as

evaporation.

It may seem as though we have drifted into a story

Page 583 of 625

98.74 1973 OPEL SERVICE MANUAL

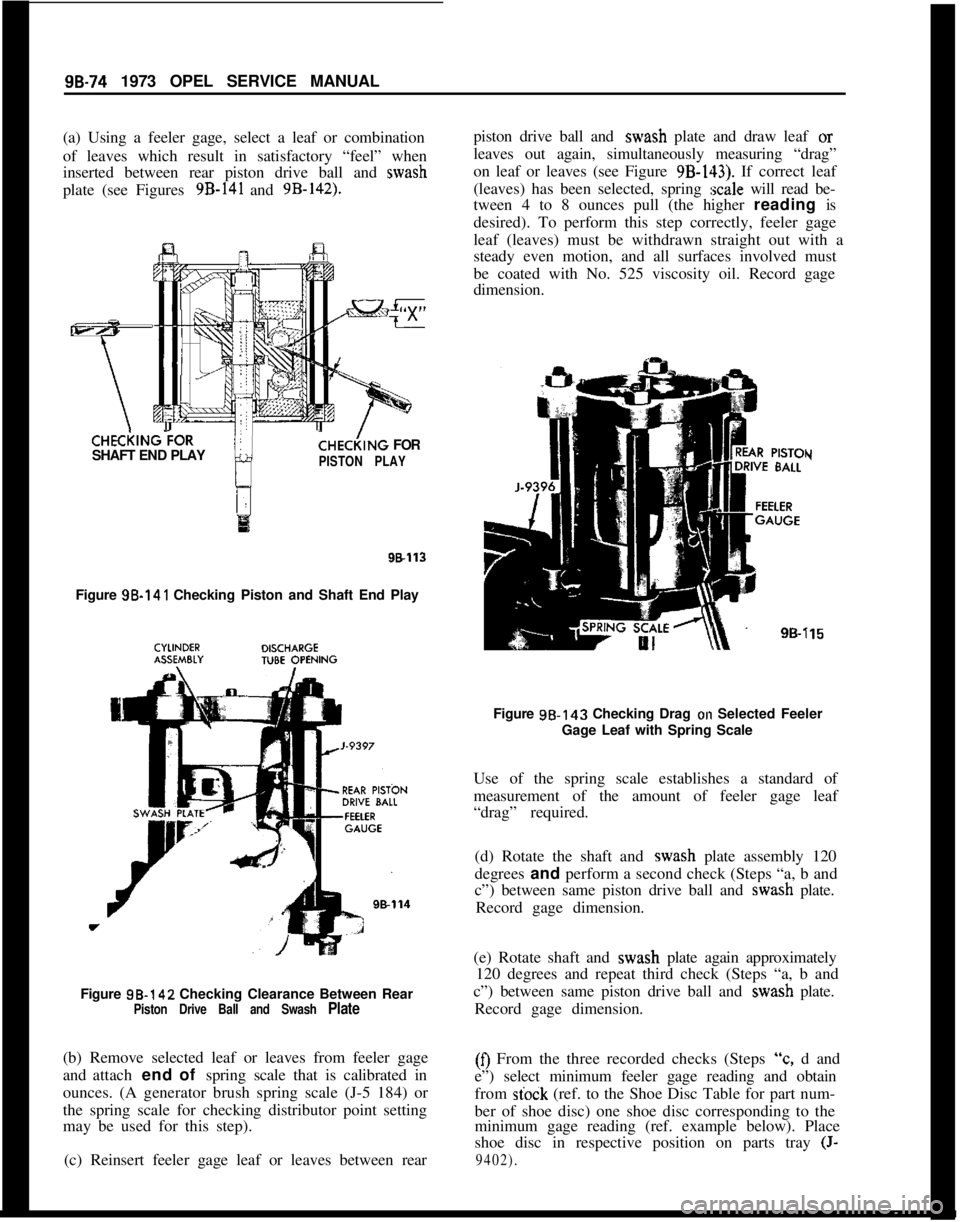

(a) Using a feeler gage, select a leaf or combination

of leaves which result in satisfactory “feel” when

inserted between rear piston drive ball and wash

plate (see Figures 9B-141 and 9B-142).CHECi(lNG?OR

SHAFT END PLAY

CHE&NG FOR

PISTON PLAY

98113Figure 98-141 Checking Piston and Shaft End Play

Figure 98-142 Checking Clearance Between Rear

Piston Drive Ball and Swash Plate(b) Remove selected leaf or leaves from feeler gage

and attach end of spring scale that is calibrated in

ounces. (A generator brush spring scale (J-5 184) or

the spring scale for checking distributor point setting

may be used for this step).

(c) Reinsert feeler gage leaf or leaves between rearpiston drive ball and wash plate and draw leaf or

leaves out again, simultaneously measuring “drag”

on leaf or leaves (see Figure

9B-143). If correct leaf

(leaves) has been selected, spring

:scale will read be-

tween 4 to 8 ounces pull (the higher reading is

desired). To perform this step correctly, feeler gage

leaf (leaves) must be withdrawn straight out with a

steady even motion, and all surfaces involved must

be coated with No. 525 viscosity oil. Record gage

dimension.

Y

i15Figure 98.143 Checking Drag

on Selected Feeler

Gage Leaf with Spring Scale

Use of the spring scale establishes a standard of

measurement of the amount of feeler gage leaf

“drag” required.

(d) Rotate the shaft and wash plate assembly 120

degrees and perform a second check (Steps “a, b and

c”) between same piston drive ball and wash plate.

Record gage dimension.

(e) Rotate shaft and wash plate again approximately

120 degrees and repeat third check (Steps “a, b and

c”) between same piston drive ball and wash plate.

Record gage dimension.(0 From the three recorded checks (Steps

“c, d and

e”) select minimum feeler gage reading and obtain

from

stock (ref. to the Shoe Disc Table for part num-

ber of shoe disc) one shoe disc corresponding to the

minimum gage reading (ref. example below). Place

shoe disc in respective position on parts tray

(J-

9402).

Page 584 of 625

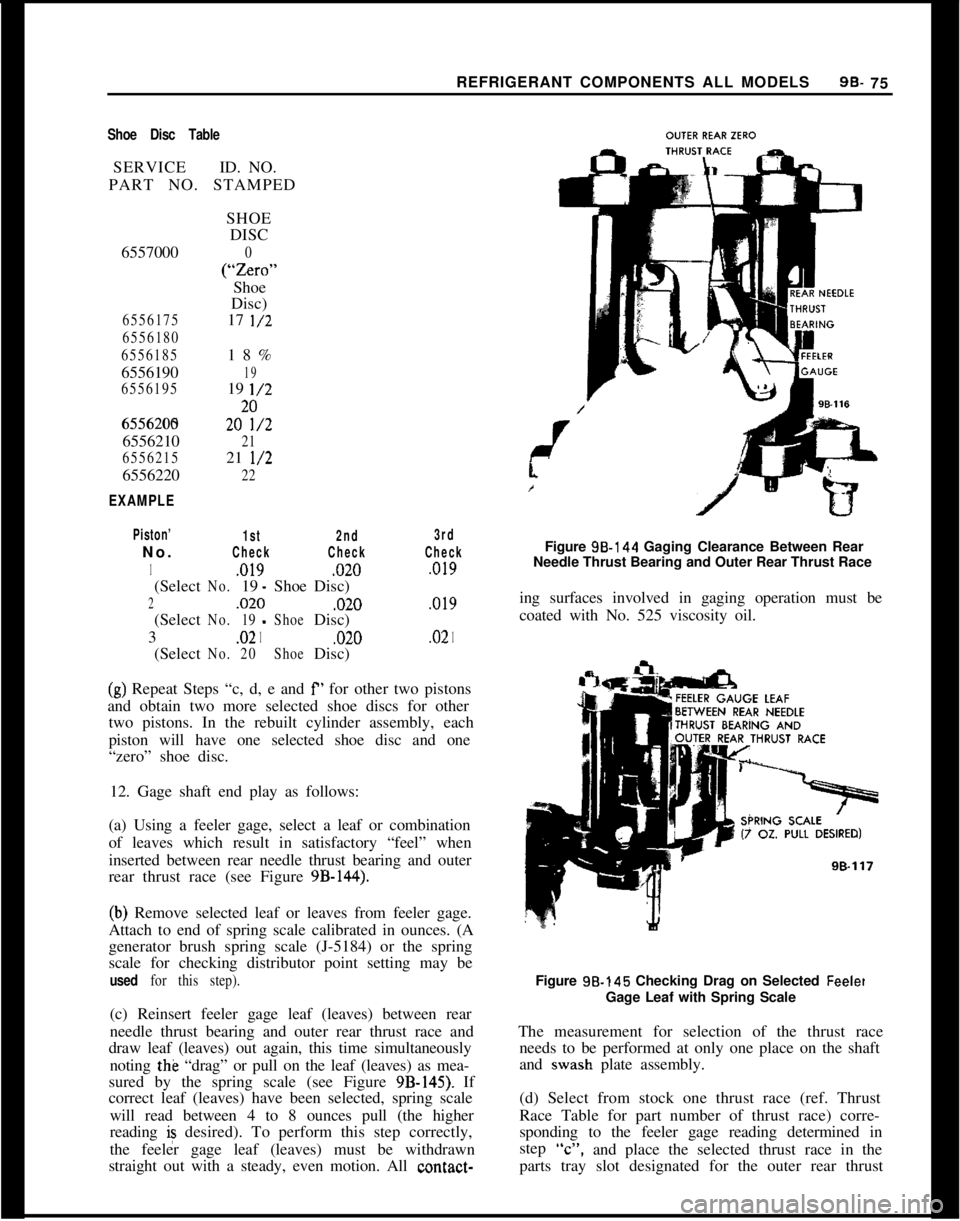

REFRIGERANT COMPONENTS ALL MODELS9B- 75Shoe Disc TableSERVICEID. NO.

PART NO. STAMPED

6557000

6556175

6556180

65561856556190

65561956556200

65562056556210

65562156556220

EXAMPLESHOE

DISC

0

(“ZSXO”Shoe

Disc)

17

l/218%

1919

l/2202&2

2121

l/2

22

Piston’

1st2nd3rdNo.

CheckCheckCheck

1,019,020,019(Select

No.19 -ShoeDisc)

2,020,020,019(Select

No.19-ShoeDisc)

3

.021,020.021(Select

No.20ShoeDisc)

(g) Repeat Steps “c, d, e and f’ for other two pistons

and obtain two more selected shoe discs for other

two pistons. In the rebuilt cylinder assembly, each

piston will have one selected shoe disc and one

“zero” shoe disc.

12. Gage shaft end play as follows:

(a) Using a feeler gage, select a leaf or combination

of leaves which result in satisfactory “feel” when

inserted between rear needle thrust bearing and outer

rear thrust race (see Figure

9B-144).

(b) Remove selected leaf or leaves from feeler gage.

Attach to end of spring scale calibrated in ounces. (A

generator brush spring scale (J-5184) or the spring

scale for checking distributor point setting may be

used for this step).(c) Reinsert feeler gage leaf (leaves) between rear

needle thrust bearing and outer rear thrust race and

draw leaf (leaves) out again, this time simultaneously

noting the “drag” or pull on the leaf (leaves) as mea-

sured by the spring scale (see Figure

9B-145). If

correct leaf (leaves) have been selected, spring scale

will read between 4 to 8 ounces pull (the higher

reading is desired). To perform this step correctly,

the feeler gage leaf (leaves) must be withdrawn

straight out with a steady, even motion. All contact-Figure 98.144 Gaging Clearance Between Rear

Needle Thrust Bearing and Outer Rear Thrust Race

ing surfaces involved in gaging operation must be

coated with No. 525 viscosity oil.

Figure 98.145 Checking Drag on Selected

FeeletGage Leaf with Spring Scale

The measurement for selection of the thrust race

needs to be performed at only one place on the shaft

and wash plate assembly.

(d) Select from stock one thrust race (ref. Thrust

Race Table for part number of thrust race) corre-

sponding to the feeler gage reading determined in

step

“C”,and place the selected thrust race in the

parts tray slot designated for the outer rear thrust

Page 622 of 625

Subject

Page NumbelSubjectPage Number4.Speed Manual I..

Clutch

Detent Cable Adjustment

:Differential

Directional Signal Switch

Repair Opel 1900 & Manta

Repair GT

:Disassembly of

4.Speed Manual Transmission

DistributorFunction of Valves and Hydraulic Control Units

Opel

3.Speed Automatic.................

74-21

Fuse Chart..............................lG-56

Fusible Link.............................

lA-8Specifications.

Point Replacement..

..,78-127A-

17c-9148-73E-393E-4878.23

1C-26

1 c-20

GEGas Tank See Fuel Tank

General Specifications

Engine...............................6A-28

Opel 3.Speed Automatic

.................7C-134

Transmission, Manual.,

..................78-33

Clutch...............................7A-7

Body................................ZA-4

Governor Drive Gear

Opel

3.Speed Automatic.................7C-103

Grille

Opel 1900 & Manta.....................8A-7

GT..................................8A-6 Electrically Heated Rear Window

Engine

General Description

Cooling System

Lubrication System

Trouble Diagnosis

Exhaust Manifold

Exhaust System

Removal and Installation

External Oil Leaks,

Opel 3 Speed Automatic

FFast Idle Adjustment

..................

Filter-Engine Oil

......................

Fluid Checking Procedure Transmission

Opel 3Speed Automatic.............

Frame-Opel 1900 & Manta.............

Frame

GT-Opel......................

SWVOOpel Xipeed Automatic...........

Front Suspension

Opel1900&Manta.................

GT..............................

Front Wheel Alignment................

Front Wheel Bearing Adjustment

All Series.........................

Fuel Gauge

Trouble Diagnosis

Opell$OO&Manta...............

GT............................

Fuel Pump Operation..................

Fuel System

Fuel Tank (Opel 1900 & Manta)

.......

Fuel Lines (Opel 1900 & Manta)

.......

Fuel Tank

(GT)....................

Fuel Gauge Tank Unit

(GT)...........

Fuel Lines

(GT)....................

Fuel Tank Removal and Installation....

Cleaning Tank.....................

lH-576A-268-326A-46A-66A-126D-427C-816E-51

oc-77C~Bl2B-826-77c-1003A-23A-23C-223A-4

HHazard Warning Flasher

....................lG-55

Headlamp Aiming

.........................1 F-46

Headlamp Switch

Opel 190.0 & Manta

.....................1 F-46

Headlamp Mechanism GT

..................8A-2

Heater System Opel 1900 &Manta

Trouble Diagnosis

......................9A-11

Description and Operation

................9A-10

Adjustments and Minor Service............9A-12

Removal and Installation

.................9A-12

Specifications..........................$A-16

Heater System GT

Trouble Diagnosis

......................9A-4

Description and Operation

................9A-2

Adjustments and Minor Service

............9A-4

Removal and Installation.................9A-5

Specifications..........................$A-9Horn

Operation.............................lG-54

Hydraulic Operation

Opel

3.Speed Automatic.................7C-64

IIdentification Number Vehicle...............

OA-1ldle.Adjustment

..........................6E-51

Inflation Pressures, Tires.

...................36-62

Ignition Coil

Specifications.

.........................

lC-26Identification, Engine

......................

OA-1Ignition System

Timing...............................

lC-20Instrument Panel Parts Removal