radio OPEL GT-R 1973 Service Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1973, Model line: GT-R, Model: OPEL GT-R 1973Pages: 625, PDF Size: 17.22 MB

Page 5 of 625

The 1973 Opel Chassis Service MayI has been completely revised with respect to layout, format and information content

in a” attempt

to provide you “The Technician” with a tiore logical and usable publication. An example of the new grouping

layout 6 exhibited on the preceding

page. Each wow is rubdivided as follows:

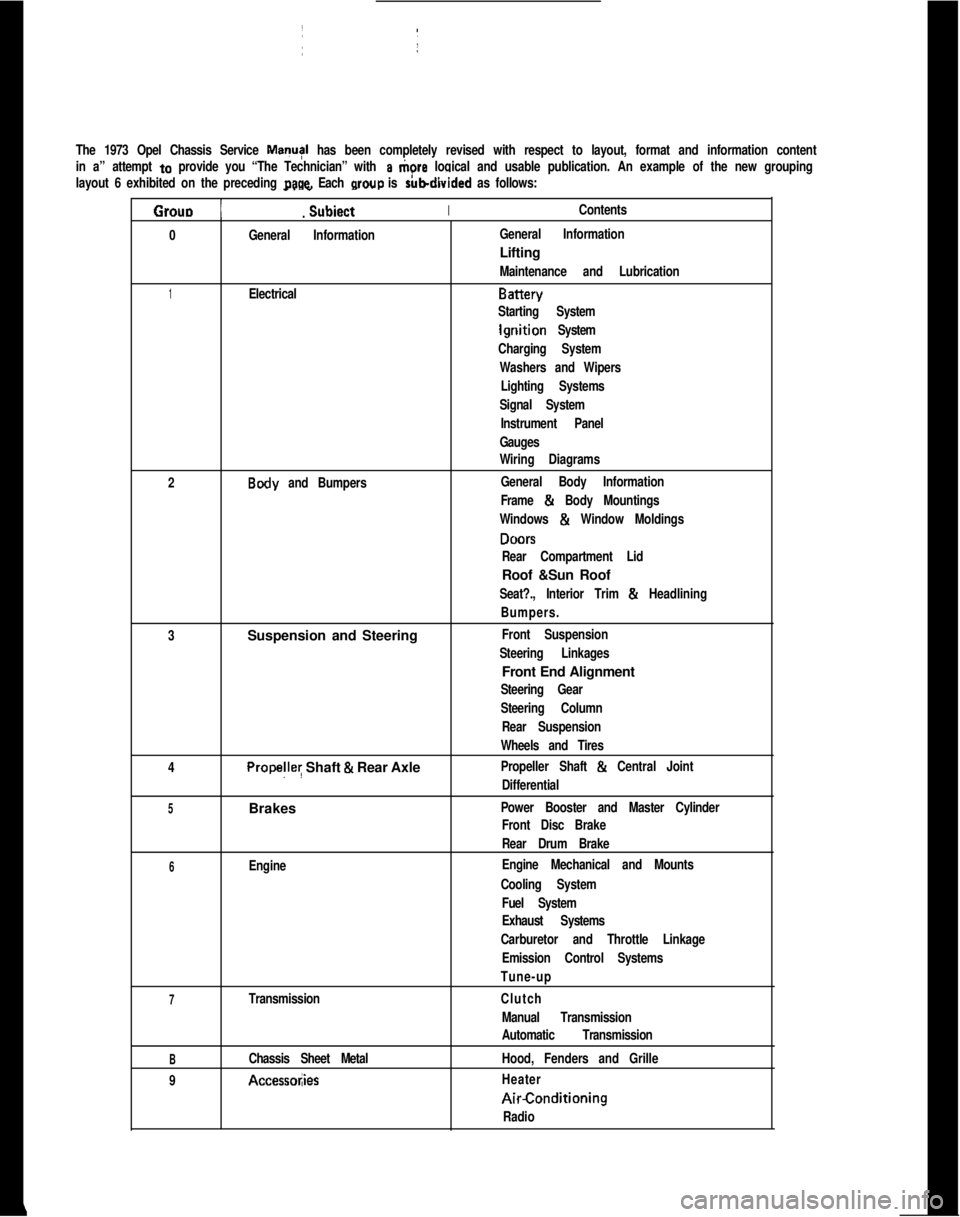

Grouo 1

_. _

Subiect IIContents.

0

General InformationIGeneral InformationLifting

Maintenance and Lubrication

1ElectricalBattery

Starting System

lgriition System

Charging System

Washers and Wipers

Lighting Systems

Signal SystemI

Instrument Panel

Gauges

Wiring Diagrams

2

Body and Bumpers:General Body InformationI

Frame & Body Mountings

Windows

& Window Moldings

DONS

Rear Compartment LidRoof &Sun Roof

Seat?., Interior Trim & Headlining

Bumpers.

3Suspension and Steering

Front Suspension

Steering Linkages1Front End Alignment

Steering Gear

Steering Column

Rear Suspension

Wheels and Tires

4

Propelley Shaft & Rear AxlePropeller Shaft & Central Joint

Differential

5Brakes ~Power Booster and Master Cylinder

Front Disc BrakeI

Rear Drum Brake

6EngineEngine Mechanical and Mounts

Cooling System

Fuel System

Exhaust Systems

Carburetor and Throttle Linkage

Emission Control Systems

Tune-up

7TransmissionClutch

Manual Transmission

Automatic Transmission

BChassis Sheet MetalHood, Fenders and Grille

9

Accessol;iesHeaterAirConditioning

Radio

Page 42 of 625

IGNITION SYSTEMlC-214. Rota&distributor counterclockwise slightly until

contact pbints just start to open. This must be done

very carefully or engine will not start.

5. Install distributor cap. Make sure spark plug wires

are correctly installed in distributor cap, through clip

and on spark plugs.

Finish TimingIContact boint gap

(.016” at widest gap) or dwell 50

degrees plus or minus 3 degrees should always be

checked before adjusting ignition timing.

1. Connekt timing light to No. 1 spark plug.

2. Disconnect and plug vacuum advance unit and

retard u$it hoses.

3. Connect a tachometer from distributor side of coil

to

groun$l.4. Start dngine. Set idle speed to 900 RPM.

5. Rotate distributor as necessary to align timing

marks. T;ming mark is a steel ball embedded in the

flywheel and a pointer in a window in the right fly-

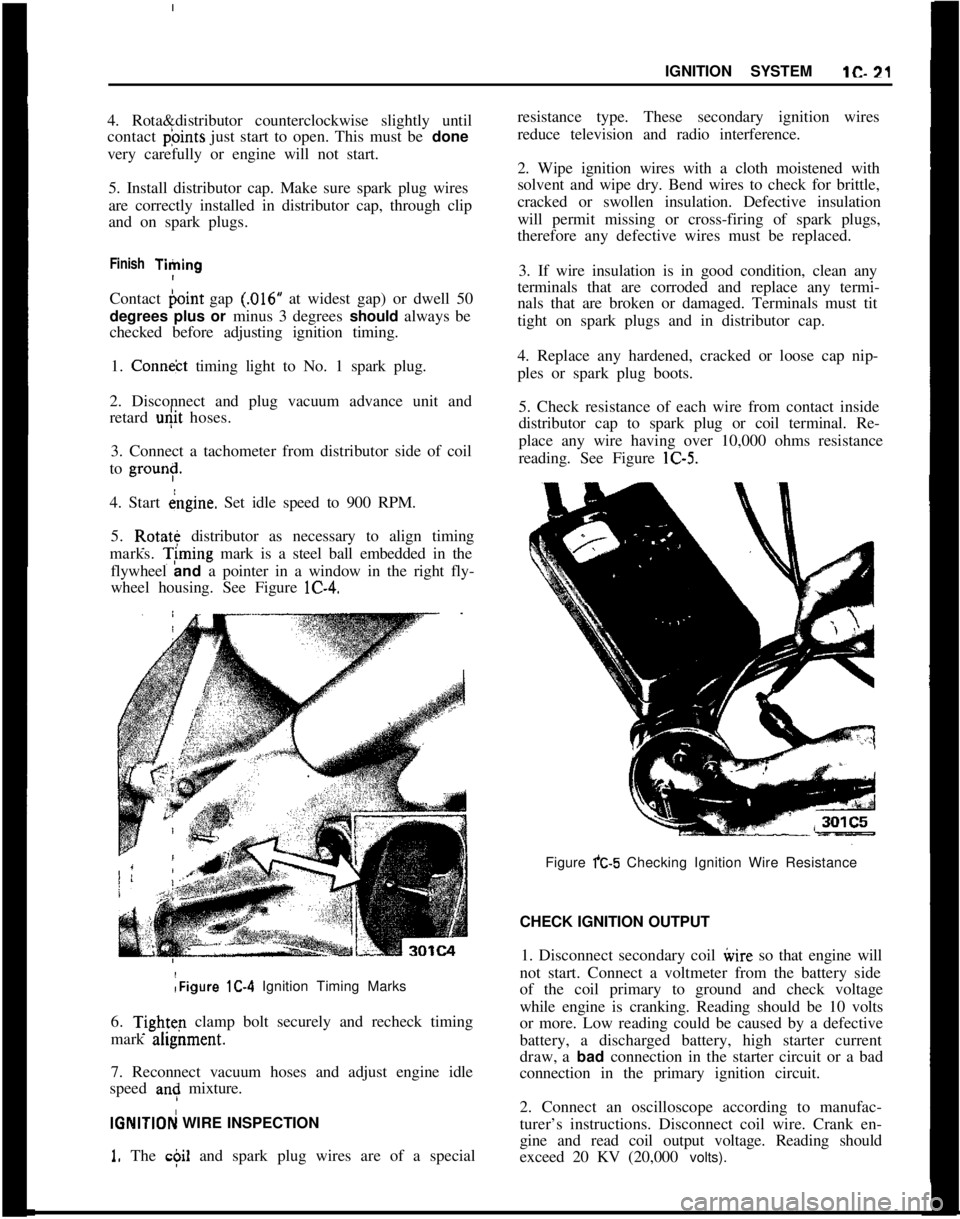

wheel housing. See Figure lC-4.:Figure lC-4 Ignition Timing Marks

6.

Tightq clamp bolt securely and recheck timing

mark ahgnment.

7. Reconnect vacuum hoses and adjust engine idle

speed

an: mixture.

IGNlTlOFj WIRE INSPECTION

1. The c$il and spark plug wires are of a specialresistance type. These secondary ignition wires

reduce television and radio interference.

2. Wipe ignition wires with a cloth moistened with

solvent and wipe dry. Bend wires to check for brittle,

cracked or swollen insulation. Defective insulation

will permit missing or cross-firing of spark plugs,

therefore any defective wires must be replaced.

3. If wire insulation is in good condition, clean any

terminals that are corroded and replace any termi-

nals that are broken or damaged. Terminals must tit

tight on spark plugs and in distributor cap.

4. Replace any hardened, cracked or loose cap nip-

ples or spark plug boots.

5. Check resistance of each wire from contact inside

distributor cap to spark plug or coil terminal. Re-

place any wire having over 10,000 ohms resistance

reading. See Figure lC-5.

Figure fC-5 Checking Ignition Wire Resistance

CHECK IGNITION OUTPUT

1. Disconnect secondary coil ivire so that engine will

not start. Connect a voltmeter from the battery side

of the coil primary to ground and check voltage

while engine is cranking. Reading should be 10 volts

or more. Low reading could be caused by a defective

battery, a discharged battery, high starter current

draw, a bad connection in the starter circuit or a bad

connection in the primary ignition circuit.

2. Connect an oscilloscope according to manufac-

turer’s instructions. Disconnect coil wire. Crank en-

gine and read coil output voltage. Reading should

exceed 20 KV (20,000 volts).

Page 77 of 625

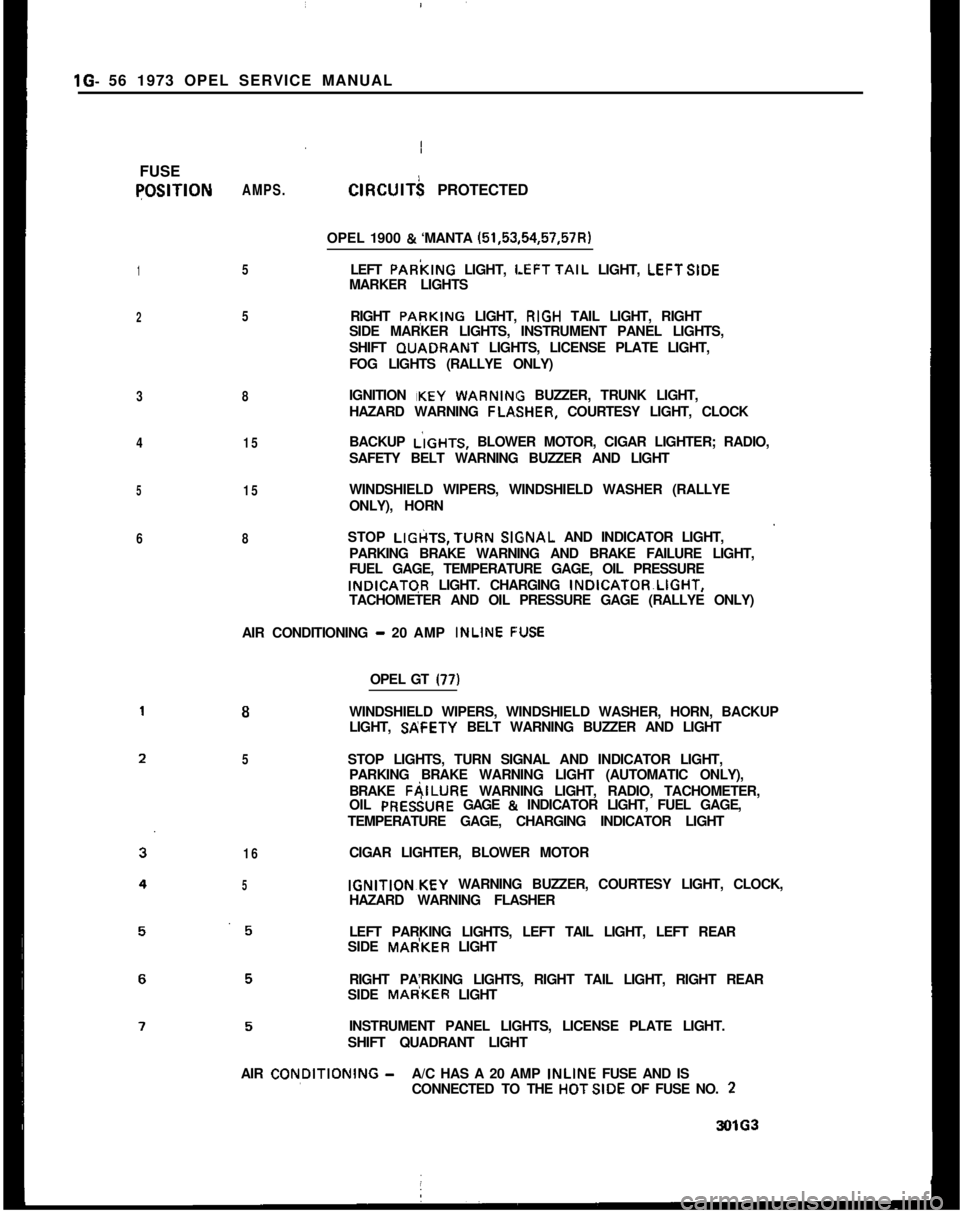

:lG- 56 1973 OPEL SERVICE MANUAL

I

FUSEqOSlTlON

1

2

3

4

5

6AMPS.

5

5

8

15

15

8ClRClJlT$ PROTECTED

OPEL 1900

& ‘MANTA (51,53,54,57,57R)

LEFT PARkING LIGHT,

LEFTTAIL LIGHT, LEFTSIDE

MARKER LIGHTS

RIGHT PApKING LIGHT, RIGH TAIL LIGHT, RIGHT

SIDE MARKER LIGHTS, INSTRUMENT PANEL LIGHTS,

SHIFT GUADRANT LIGHTS, LICENSE PLATE LIGHT,

FOG LIGHTS (RALLYE ONLY)

IGNITION IKEY

WARNIN BUZZER, TRUNK LIGHT,

HAZARD WARNING FLA,SHER, COURTESY LIGHT, CLOCK

BACKUP L’IGHTS, BLOWER MOTOR, CIGAR LIGHTER; RADIO,

SAFETY BELT WARNING BUZZER AND LIGHT

WINDSHIELD WIPERS, WINDSHIELD WASHER (RALLYE

ONLY), HORN

STOP LIGtiTS,TURN

SlGsNAL AND INDICATOR LIGHT,

PARKING BRAKE WARNING AND BRAKE FAILURE LIGHT,

FUEL GAGE, TEMPERATURE GAGE, OIL PRESSUREINDICATGR LIGHT. CHARGING INDICATOR~LIGHT,

TACHOMETER AND OIL PRESSURE GAGE (RALLYE ONLY)

AIR CONDITIONING

- 20 AMP INLINE F:USE

8

5

16

5OPEL GT

(77)WINDSHIELD WIPERS, WINDSHIELD WASHER, HORN, BACKUP

LIGHT, SP;FETY BELT WARNING BUZZER AND LIGHT

STOP LIGHTS, TURN SIGNAL AND INDICATOR LIGHT,

PARKING BRAKE WARNING LIGHT (AUTOMATIC ONLY),

BRAKE FAILURE WARNING LIGHT, RADIO, TACHOMETER,

OIL PRESiURE GAGE

& INDICATOR LIGHT, FUEL GAGE,

TEMPERATURE GAGE, CHARGING INDICATOR LIGHT

CIGAR LIGHTER, BLOWER MOTORIGNITION~KEY WARNING BUZZER, COURTESY LIGHT, CLOCK,

HAZARD WARNING FLASHER

LEFT PARKING LIGHTS, LEFT TAIL LIGHT, LEFT REAR

SIDE MAdKER LIGHT

RIGHT PA’RKING LIGHTS, RIGHT TAIL LIGHT, RIGHT REAR

SIDE MAdKER LIGHT

INSTRUMENT PANEL LIGHTS, LICENSE PLATE LIGHT.

SHIFT QUADRANT LIGHT

AIR CON,DlTlONlNG

-A/C HAS A 20 AMP INLINE FUSE AND IS

CONNECTED TO THE HOTSIDE OF FUSE NO. 23OlG3

Page 83 of 625

1 H- 62 1973 OPEL SERVICE, MANUAL

4. Remove flasher unit. See Figure IH-12.

5. Position steering so that wheels are straight ahead.

6. Pull off heads of both tear bolts by first drilling a3/16 inch pilot hole and then using a stud extractor

to remove tear bolts. See Figure lH-13.

Figure 1 H-10 Removing Right Aicess Cover andSWW3. Remove left access cover and f”rnove screw. See

Figure lH-11.

Figure 1 H-l 3 Steering Column Attaching Bolts

7. Disconnect ignition (white) and directional signal

(black) wire set plugs.

8. Support steering column assembly and remove

both hex head bolts. See Figure lH-13.

9. Drop steering column assembly to floor.

10. Disconnect speedometer cable.

11. Remove six (6) screws on instrument cluster. See

Figure

lH- 14.

Figure lli-1 1 Removing Left Access Cover and

SC&Figure lH-14 Instrument Cluster Screws

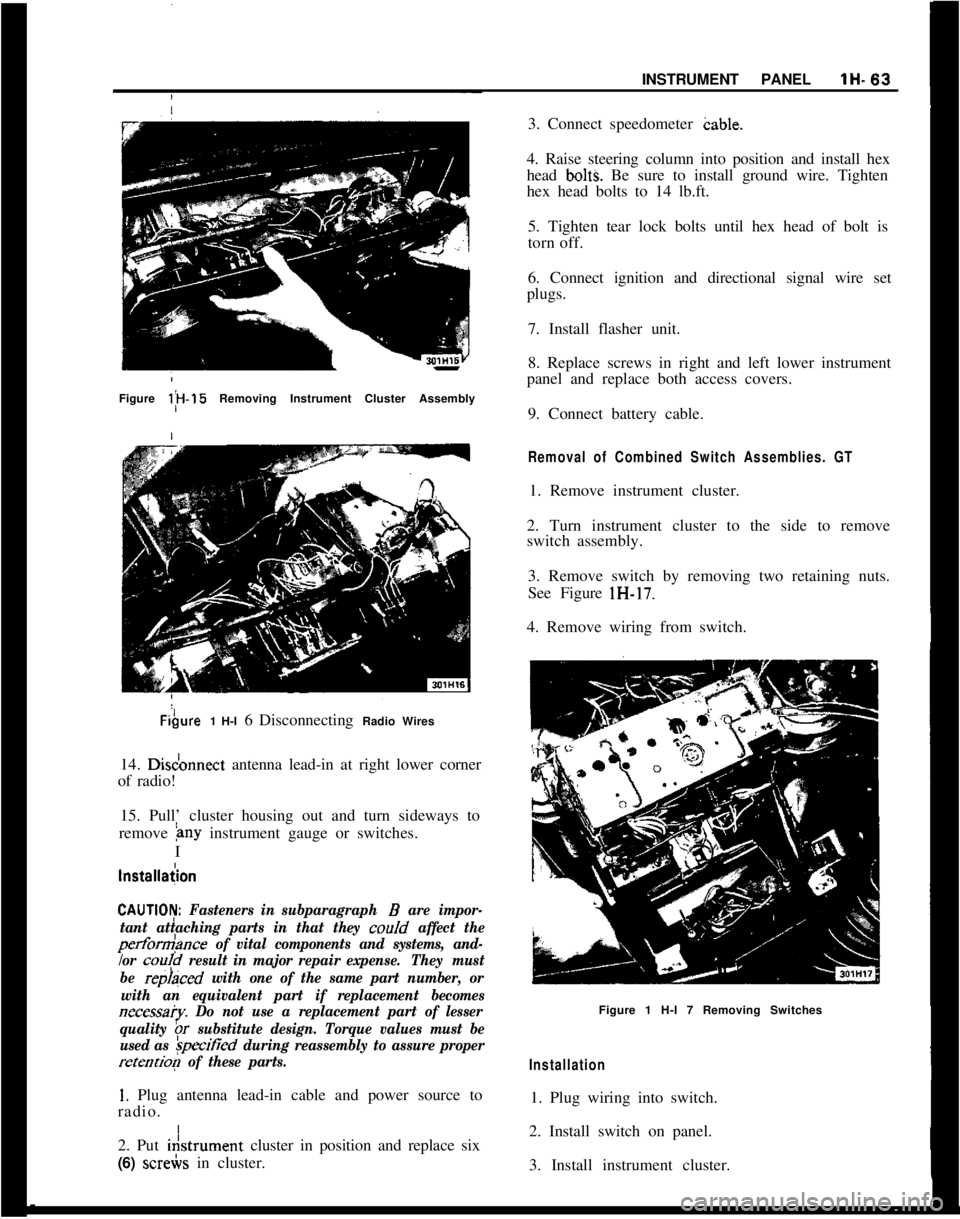

12. Pull back on instrument cluster from top to

remove. See Figure lH-15.

Figure l H-12 Flasher Unit Installed13. Disconnect wires on back of radio. See FigurelH-16.

Page 84 of 625

I

,INSTRUMENT PANELlH-63Figure l;H-15 Removing Instrument Cluster AssemblyFibure1 H-l 6 Disconnecting Radio Wires

14. Disdonnect antenna lead-in at right lower corner

of radio!

15. Pull’ cluster housing out and turn sideways to

remove

&~y instrument gauge or switches.

I

lnstallaiion

CAUTlOI$ Fasteners in subparagraph B are impor-

tant attaching parts in that they coo/d

affect the

perform>nce of vital components and systems, and-

/or

cou!d result in major repair expense.They must

be

repraced with one of the same part number, or

with an equivalent part if replacement becomes

necessa?y. Do not use a replacement part of lesser

quality

br substitute design. Torque values must be

used as

&ified during reassembly to assure proper

retention of these parts.

1. Plug antenna lead-in cable and power source to

radio. I

2. Put i&trument cluster in position and replace six

(6) screbs in cluster.3. Connect speedometer cable.

4. Raise steering column into position and install hex

head

bolt% Be sure to install ground wire. Tighten

hex head bolts to 14 lb.ft.

5. Tighten tear lock bolts until hex head of bolt is

torn off.

6. Connect ignition and directional signal wire set

plugs.

7. Install flasher unit.

8. Replace screws in right and left lower instrument

panel and replace both access covers.

9. Connect battery cable.

Removal of Combined Switch Assemblies. GT1. Remove instrument cluster.

2. Turn instrument cluster to the side to remove

switch assembly.

3. Remove switch by removing two retaining nuts.

See Figure lH-17.

4. Remove wiring from switch.

Figure 1 H-l 7 Removing Switches

Installation1. Plug wiring into switch.

2. Install switch on panel.

3. Install instrument cluster.

Page 90 of 625

I

IGAUGES1 I- 69

I

I

3. Replace instrument housing.InstallationFiemoving~Temperature Indicator or Fuel Gauge

1. Remov+ instrument cluster housing.

2. Remov; six screws and remove both instrument

cluster

le+ See Figure 11-2.3. Pull v&age stabilizer off printed circuit and

remove fohr instrument attaching screws, as shown

in Figure

111-5.Figure

11-5 Removing Four Instrument Attaching\SCWWS

4. Take temperature or fuel gauge out of clusterlnstallatidn

1. Install itemperature or fuel gauge in cluster.

2. Replack voltage stabilizer on back of printed cir-

cuit. I

3. Replack both instrument cluster lens.

I

4. Install /instrument cluster housing.

I

IRemwind Rallye Gauges

1. Removt glove compartment.

2. Remo?e radio, if equipped.

3.

Remoje screws holding instrument carrier frominstrumejf

pane!.4. Disconpect wres from instrument gauge.

5.

Removal attaching nuts from gauge and remove.I1. Replace gauge with attaching nuts on panel.

2. Hook up wires to gauges.

3. With holding screws, attach gauge cluster to in-

strument panel.

4. Replace radio.

5. Replace glove compartment.

Removal of Temperature Sending Unit

1. Drain and collect coolant.

To drain radiator, remove end of lower radiator hose

that is connected to radiator.

2. Remove wire from temperature sending unit.

3. Unscrew temperature sending unit from thermo-

stat housing. See Figure

11-6.Figure

11-S -Temperature Sending Unitlnstalletian

1. Screw temperature sending unit into thermostat

housing after sealing unit with non-hardening per-matex.

2. Install wire on sending unit.

3. Replace coolant.

Page 510 of 625

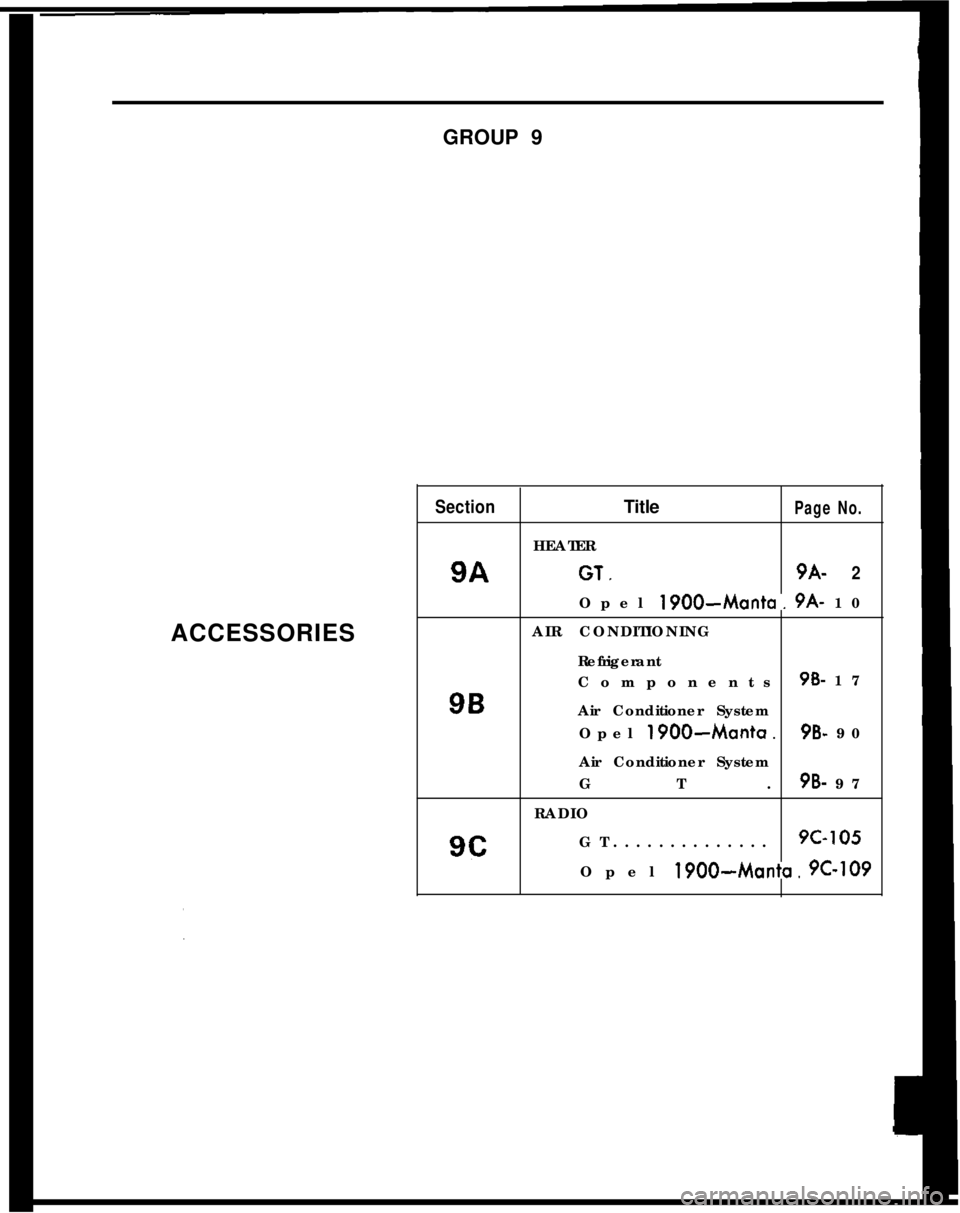

GROUP 9

ACCESSORIESSectionTitlePage No.HEATER

9AGT,9A-2Opel

1900-Manta. 9A- 10

AIR CONDITIONING

Refrigerant

Components9B- 179B

Air Conditioner System

Opel

1900~Manta.9B- 90

Air Conditioner System

GT.

OB- 97

RADIO

9cGT..............9c-105Opel

1900~Manta. PC-109

Page 521 of 625

9A-i2 1973 OPEL SERVICE MANUAL

Check that air doors and water temperature control

valve are operating properly.

Check for plugged heater core-backflush heater core

as necessary.TROUBLEInadequate defrosting action.

CAUSE AND CORRECTIONExamine heater-defroster door for proper operation.

Adjust bowden cable so that door is fully closed in

FULL DEFROST position.

Check that air hoses connecting to defroster outlets

are secure.

Check for air leaks around edges of heater air dis-

tributor housing. Seal leaks, as necessary, with bodysea@. Check for body air leaks and seal, as neces-

sary, with body sealer.

TROUBLEBlower inoperative.

CAUSE AND CORRECTIONCheck blower fuse. Replace, if necessary, fuse posi-

tion 4

- amperage 15.

Check wiring for open circuit. Correct, as required.

Inspect for defective component, (i.e., blower switch

or blower motor)

- replace or repair as necessary.

MAINTENANCE AND ADJUSTMENTS

CONTROL CABLE ADJUSTMENTAdjustment of control cables is accomplished by po-

sitioning of the jacket or sheath of the control cable,

as held by the clamps on the control assembly and

heater case or by loosening screws and slidingbowden wire to obtain desired door or water valve

position.

MAJOR REPAIR

REMOVING AND INSTALLING HEATER HOUSING

Removal1. Unscrew hood lock together with ground wire(ground wire only on vehicles with radio interference

suppression). See Figure 9A-33.

Figure 9A-33 Hood Lock Attachments

2. Unscrew heater housing cover.

3. Pull hose of windshield washer system off jet and

take jet out of housing cover.

4. Unscrew bowden control wire from heater valve.

5. Unscrew heater housing from dash panel and pull

it off carefully. See Figure 9A-34.

Figure 9A-34 Heater Housing Attachments

6. Remove water hoses from heater core and pull

heater core out of heater housing. See Figure

9A-35.

Page 522 of 625

Figure SA-35 Heater Core

Installation

1. Apply sealing compound between heater housing

and dash panel.

2. Install heater core into heater housing and attach

water hoses. See Figure 9A-35.

3. Instaii heater housing to dash panel. S,ee Figure9A-44.

4. Install bowden control wire to heater valve.

5. Install windshield washer jet into housing cover

and attach hose.

6. Install heater housing cover, and seal with a seal-

ing compound.

7. Install hood lock, together with

grc’und wire

(ground wire only on vehicles with radio interference

suppression).

REMOVING AND INSTALLING

DEFROSTE+lOUTLETS

Removal

1. Pull out heater switch lever. See Figure 9A- 36.

2. Remove instrument cover.

3. Unscrew bowden control wires from heater valve

and air distributor housing and pull out heater con-

trols.

4. Remove glove compartment.

HEiATER SYSTEM - OPEL 1900 - MANTA9A. 13Figure SA-36 Removing Heater Switch Lever

5. Remove radio.

6. On right side, viewed in driving direction, remove

air distributor housing attaching screws. See Figure9A-37

Figure SA-37 Air Distributor Housing Attaching

SCWWS7. On left side, viewed in driving direction, remove

upper attaching screw through opening for heater

control housing and lower attaching screw below

instrument panel. See Figure 9A-38.

8. Pull air distributor housing off dash panel

Page 523 of 625

9A-14 1973 OPEL SERVICE MANUAL

upper attaching screw through opening for heater

control housing and lower attaching screw below

instrument panel. See Figure 9A.-38.5. On right side, viewed in driving direction, install

air distributor housing attaching screws. See Figure9A-37.

6. Install radio.

7. Install glove compartment.

8. Install bowden control wires to heater valve and

air distributor housing.

9. Install instrument cover.

10. Install heater switch lever.

Figure 9A-38 Upper Attaching Screw

9. Pull defroster outlets downwards and remove out-

lets through glove compartment opening. See Figure9A-39.

REMOVAL AND INSTALLATION OF HEATER

CONTROL HOUSING

Removal1. Remove instrument panel cover

- refer to operat-

ion,

IRemoving and Installing Instrument Housing.

2. Remove two sheet metal screws for control hous-

ing attachment. See Figure 9A-40.

Figure 9A-39 Removing Defroster Jets

Installation

1. Apply sealing compound between air distributor

housing and dash panel.

2. Install defroster outlets, securing with two (2)

clips at the instrument panel. See Figure 9A-39.

3. Install air distributor housing to dash panel,

4. On left side, viewed in driving direction, installFigure 9A-40 Control Housing Attaching Screws

3. In engine compartment, detach bowden control

wire from heater valve. See Figure 9A-41.

4. Detach bowden control wire from air distribution

flap. See Figure 9A-42.

5. Pull wires off blower switch. See Figure 9A- 43.