checking oil OPEL GT-R 1973 User Guide

[x] Cancel search | Manufacturer: OPEL, Model Year: 1973, Model line: GT-R, Model: OPEL GT-R 1973Pages: 625, PDF Size: 17.22 MB

Page 312 of 625

ENGINE MECHANICAL AND MOUNTS6A- 21

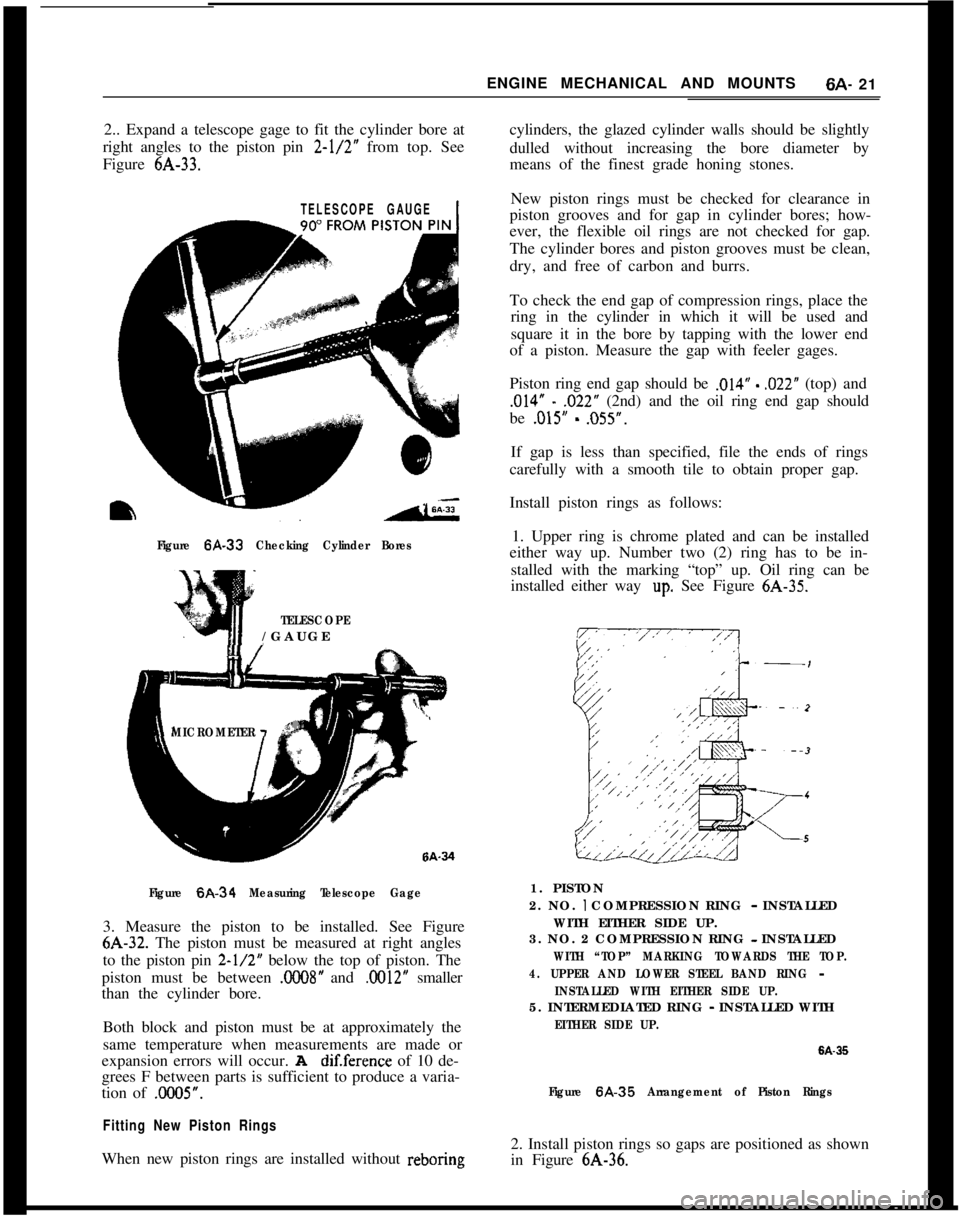

2.. Expand a telescope gage to fit the cylinder bore at

right angles to the piston pin 2-l/2” from top. See

Figure 6A-33.cylinders, the glazed cylinder walls should be slightly

dulled without increasing the bore diameter by

means of the finest grade honing stones.

TELESCOPE GAUGE1

Figure 6A-33 Checking Cylinder Bores

TELESCOPE/GAUGE

MICROMETER

Figure

6A-34 Measuring Telescope Gage3. Measure the piston to be installed. See Figure6A-32. The piston must be measured at right angles

to the piston pin

2-l/2” below the top of piston. The

piston must be between

.C008” and .0012” smaller

than the cylinder bore.

Both block and piston must be at approximately the

same temperature when measurements are made or

expansion errors will occur. A

dif.ference of 10 de-

grees F between parts is sufficient to produce a varia-

tion of .0005”.

Fitting New Piston RingsWhen new piston rings are installed without reboringNew piston rings must be checked for clearance in

piston grooves and for gap in cylinder bores; how-

ever, the flexible oil rings are not checked for gap.

The cylinder bores and piston grooves must be clean,

dry, and free of carbon and burrs.

To check the end gap of compression rings, place the

ring in the cylinder in which it will be used and

square it in the bore by tapping with the lower end

of a piston. Measure the gap with feeler gages.

Piston ring end gap should be

,014” - ,022” (top) and

,014” - ,022” (2nd) and the oil ring end gap should

be

.015” - ,055”.

If gap is less than specified, file the ends of rings

carefully with a smooth tile to obtain proper gap.

Install piston rings as follows:

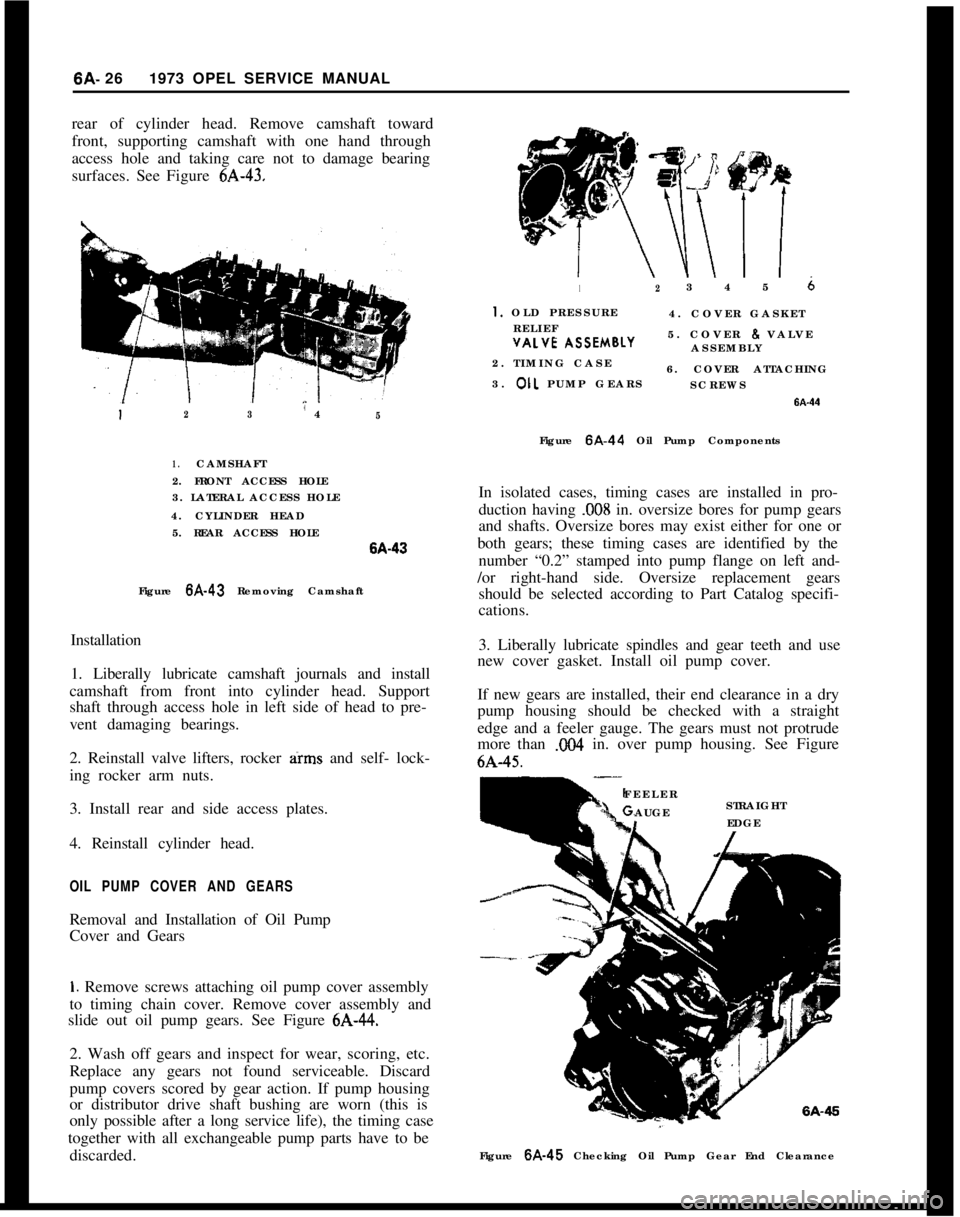

1. Upper ring is chrome plated and can be installed

either way up. Number two (2) ring has to be in-

stalled with the marking “top” up. Oil ring can be

installed either way

up. See Figure 6A-35.

1. PISTON

2. NO.

I COMPRESSION RING - INSTALLED

WITH EITHER SIDE UP.

3. NO. 2 COMPRESSION RING - INSTALLED

WITH “TOP” MARKING TOWARDS THE TOP.

4. UPPER AND LOWER STEEL BAND RING

-

INSTALLED WITH EITHER SIDE UP.5. INTERMEDIATED RING

- INSTALLED WITH

EITHER SIDE UP.

6A-35

Figure 6A.35 Arrangement of Piston Rings2. Install piston rings so gaps are positioned as shown

in Figure 6A-36.

Page 317 of 625

6A- 261973 OPEL SERVICE MANUAL

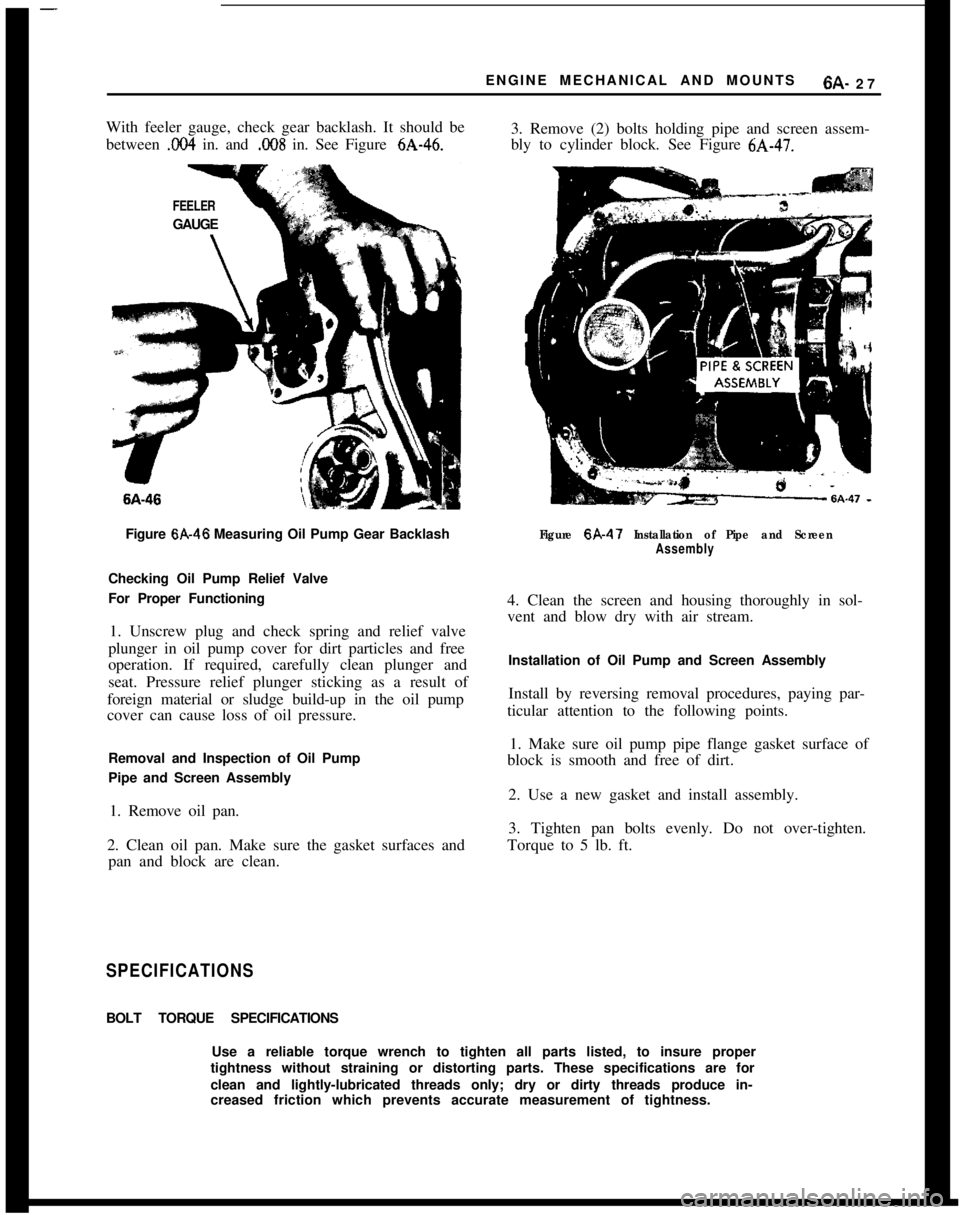

rear of cylinder head. Remove camshaft toward

front, supporting camshaft with one hand through

access hole and taking care not to damage bearing

surfaces. See Figure 6A-43.12345 6

I. OLD PRESSURE

4. COVER GASKET

RELIEF

~~- \SSEMBLY5. COVER 8 VALVE

ASSEMBLYVALVE I

2. TIMING CASE

6. COVER ATTACHING

3. OIL PUMP GEARS

SCREWS

123” 45Figure 6A-44 Oil Pump Components

1.CAMSHAFT

2. FRONT ACCESS HOLE

3. LATERAL ACCESS HOLE

4. CYLINDER HEAD

5. REAR ACCESS HOLEISA-43

Figure 6A-43 Removing Camshaft

Installation

1. Liberally lubricate camshaft journals and install

camshaft from front into cylinder head. Support

shaft through access hole in left side of head to pre-

vent damaging bearings.

2. Reinstall valve lifters, rocker arms and self- lock-

ing rocker arm nuts.

3. Install rear and side access plates.

4. Reinstall cylinder head.

OIL PUMP COVER AND GEARSRemoval and Installation of Oil Pump

Cover and Gears

1. Remove screws attaching oil pump cover assembly

to timing chain cover. Remove cover assembly and

slide out oil pump gears. See Figure 6A-44.

2. Wash off gears and inspect for wear, scoring, etc.

Replace any gears not found serviceable. Discard

pump covers scored by gear action. If pump housing

or distributor drive shaft bushing are worn (this is

only possible after a long service life), the timing case

together with all exchangeable pump parts have to be

discarded.In isolated cases, timing cases are installed in pro-

duction having

.008 in. oversize bores for pump gears

and shafts. Oversize bores may exist either for one or

both gears; these timing cases are identified by the

number “0.2” stamped into pump flange on left and-

/or right-hand side. Oversize replacement gears

should be selected according to Part Catalog specifi-

cations.

3. Liberally lubricate spindles and gear teeth and use

new cover gasket. Install oil pump cover.

If new gears are installed, their end clearance in a dry

pump housing should be checked with a straight

edge and a feeler gauge. The gears must not protrude

more than X04 in. over pump housing. See Figure6A-45.

FEELER

AUGESTRAIGHTIEDGE

Figure 6A-45 Checking Oil Pump Gear End Clearance

Page 318 of 625

ENGINE MECHANICAL AND MOUNTS6A- 27

With feeler gauge, check gear backlash. It should be

between

.I?04 in. and .C!OS in. See Figure 6A-46.3. Remove (2) bolts holding pipe and screen assem-

bly to cylinder block. See Figure 6A-47.

FEELERGAUGE6A-46

Figure 6A-46 Measuring Oil Pump Gear Backlash

Checking Oil Pump Relief Valve

For Proper Functioning

1. Unscrew plug and check spring and relief valve

plunger in oil pump cover for dirt particles and free

operation. If required, carefully clean plunger and

seat. Pressure relief plunger sticking as a result of

foreign material or sludge build-up in the oil pump

cover can cause loss of oil pressure.

Removal and Inspection of Oil Pump

Pipe and Screen Assembly

1. Remove oil pan.

2. Clean oil pan. Make sure the gasket surfaces and

pan and block are clean.

Figure 6A-47 Installation of Pipe and Screen

Assembly4. Clean the screen and housing thoroughly in sol-

vent and blow dry with air stream.

Installation of Oil Pump and Screen Assembly

Install by reversing removal procedures, paying par-

ticular attention to the following points.

1. Make sure oil pump pipe flange gasket surface of

block is smooth and free of dirt.

2. Use a new gasket and install assembly.

3. Tighten pan bolts evenly. Do not over-tighten.

Torque to 5 lb. ft.

SPECIFICATIONSBOLT TORQUE SPECIFICATIONS

Use a reliable torque wrench to tighten all parts listed, to insure proper

tightness without straining or distorting parts. These specifications are for

clean and lightly-lubricated threads only; dry or dirty threads produce in-

creased friction which prevents accurate measurement of tightness.

Page 323 of 625

66.321973 OPEL SERVICE MANUAL

COOLING SYSTEM

CONTENTS

Subject

DESCRIPTION AND OPERATION:

Cooling System and Water Pump

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .DIAGNOSIS: (Not Applicable)

MAINTENANCE AND ADJUSTMENTS:

Checking and Filling Cooling System

. . . . . . . . . . . . . . . . . . . . . . . .Draining

andFlushingCoolingSystem. . . . . . . . . . . . . . . . . . . . . .Conditioning the Cooling System

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Using and Testing Anti-Freeze Solutions

. . . . . . . . . . . . . . . . . .Fan Belt Adjustment or Replacement

. . . . . . . . . . . . . . . . . . . . . . . .Radiator Thermostat Inspection and Test

. . . . . . . . . . . . . . . .MAJOR REPAIR:

Water Pump Removal

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Radiator

Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .SPECIFICATIONS:

Cooling System Capacities

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page No.

68-32

6B-32

68-32

68-33

68-33

68-33

68-33

68-34

68-34

6B-35

DESCRIPTION AND OPERATION

COOLING SYSTEM AND WATER PUMPThe coiling system is of the conventional pressurized

type. A centrifugal pump arranged in timing case

serves to circulate the coolant.

When the thermostat is closed, the coolant will re-

turn to the pump via a by-pass for swift and uniform

warming up of the engine the coolant circulates

through the radiator, only when the engine has

reached normal operating temperature.

The heater system branches off the cooling system

ahead of thermostat in flow direction so that the

heater is in operation before engine has reached full

operating temperature.

MAINTENANCE AND ADJUSTMENTS

Checking and Filling Cooling SystemThe coolant level should be checked only when the

engine is cold and only enough coolant should be

added to bring the level halfway between core andtank top. It is unnecessary and undesirable to remove

the radiator cap and check the coolant level each

time the car stops at a filling station for gasoline or

oil, since the engine is usually hot at such times.

WARNING: Never remove the radiator cap quickly

when engine is HOT Sudden release of cooling

sys-

tern pressure may cause the coolant to boil and some

of it may be ejected from the radiator

filler neck,

resulting in

inl’ury to persons or damage to the car

finish.If it is necessary at any time to remove the radiator

cap when engine is hot, rotate the cap counterclock-

wise until first stop is reached. Leave cap in this

position until all pressure in cooling system has been

released, then turn cap past the first stop and remove

it.

Draining and Flushing

Cooling SystemThe cooling system should be completely drained

and the recommended coolant installed every two (2)

years.To drain the cooling system, remove radiator cap,

remove lower radiator hose from the lower tank and

Page 357 of 625

6G- 661973 OPEL SERVICE MANUAL

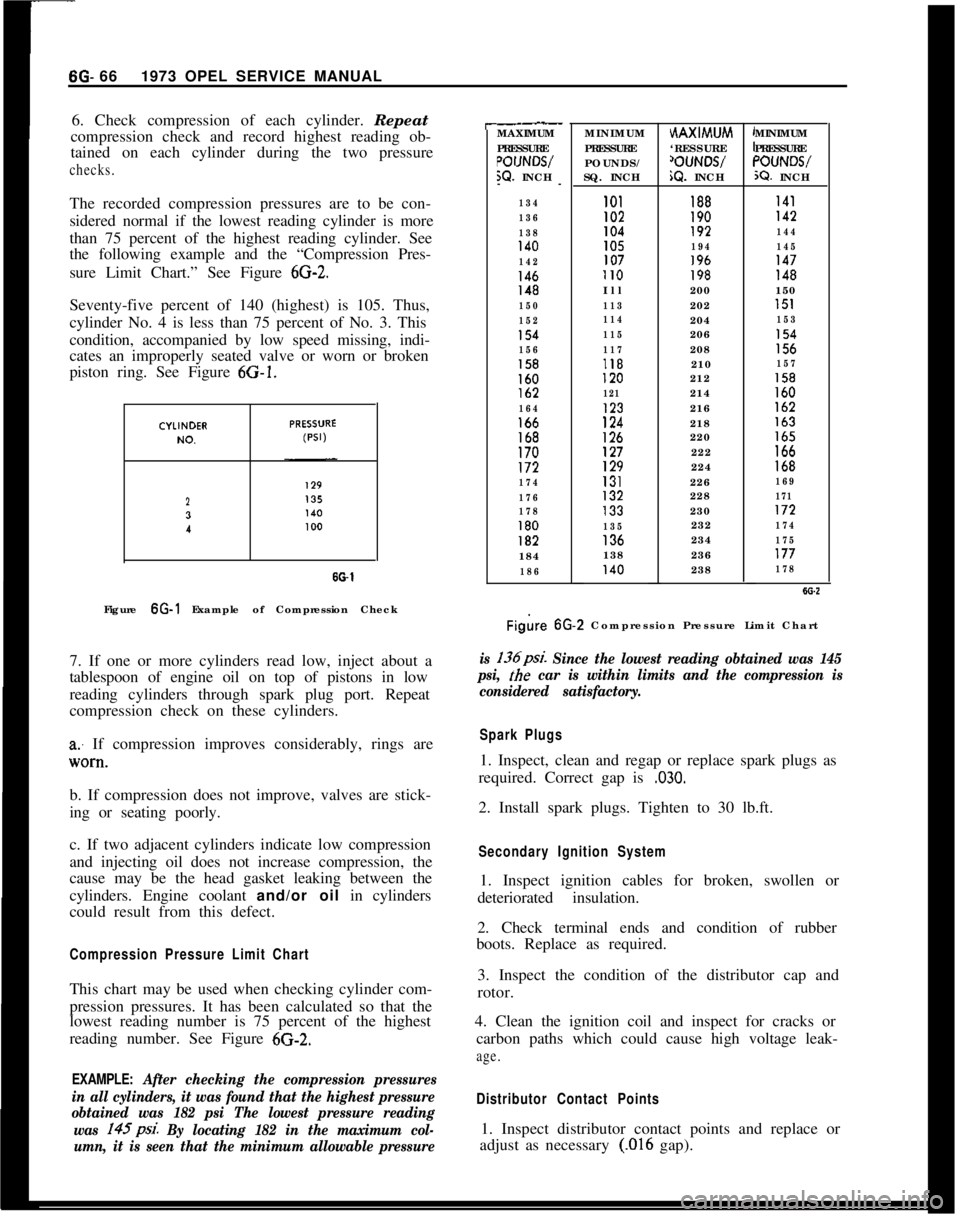

6. Check compression of each cylinder. Repeat

compression check and record highest reading ob-

tained on each cylinder during the two pressurechecks.The recorded compression pressures are to be con-

sidered normal if the lowest reading cylinder is more

than 75 percent of the highest reading cylinder. See

the following example and the “Compression Pres-

sure Limit Chart.” See Figure

6G-2.Seventy-five percent of 140 (highest) is 105. Thus,

cylinder No. 4 is less than 75 percent of No. 3. This

condition, accompanied by low speed missing, indi-

cates an improperly seated valve or worn or broken

piston ring. See Figure 6G-1.

23

I

SO-1Figure 6G-1 Example of Compression Check

7. If one or more cylinders read low, inject about a

tablespoon of engine oil on top of pistons in low

reading cylinders through spark plug port. Repeat

compression check on these cylinders.

a: If compression improves considerably, rings are

lV0*tl.b. If compression does not improve, valves are stick-

ing or seating poorly.

c. If two adjacent cylinders indicate low compression

and injecting oil does not increase compression, the

cause may be the head gasket leaking between the

cylinders. Engine coolant and/or oil in cylinders

could result from this defect.

Compression Pressure Limit ChartThis chart may be used when checking cylinder com-

pression pressures. It has been calculated so that the

lowest reading number is 75 percent of the highest

reading number. See Figure 6G-2.

EXAMPLE: After checking the compression pressures

in all cylinders, it was found that the highest pressure

obtained was 182 psi The lowest pressure reading

was 145psi.

By locating 182 in the maximum col-

umn, it is seen that the minimum allowable pressure

r-.__MAXIMUM

PRESSURE

POIJNWW. INCH

--

134

136

138

140

142

146148

150

152

154

156

158160lb2

164166168170172

174

176

178

180182184

186MINIMUM

PRESSURE

POUNDS/

SQ. INCHHAXIMUM

‘RESSURE

‘OUNWiQ. INCHMINIMUM

PRESSURE“OUNWX?. INCH

101188I41I02190142104192144105194145107196147II0198148Ill200150

113202151

114204153

115206154

117208156118210157120212158

121214160123216162

124218163

126220165127222166129224168131226169132228171133230172

135232174136234175138236177140238178

Figire 6G.2 Compression Pressure Limit Chart

is 136psi. Since the lowest reading obtained was 145

psi,

the car is within limits and the compression is

considered satisfactory.

Spark Plugs1. Inspect, clean and regap or replace spark plugs as

required. Correct gap is

,030.2. Install spark plugs. Tighten to 30 lb.ft.

Secondary Ignition System1. Inspect ignition cables for broken, swollen or

deteriorated insulation.

2. Check terminal ends and condition of rubber

boots. Replace as required.

3. Inspect the condition of the distributor cap and

rotor.

4. Clean the ignition coil and inspect for cracks or

carbon paths which could cause high voltage leak-

age.

Distributor Contact Points1. Inspect distributor contact points and replace or

adjust as necessary

(.016 gap).

Page 358 of 625

2. If inspection of contact points indicates excessive

burning, pitting or wear, check condenser and re-

place if necessary.

3. Inspect all connections and wires in the primary

ignition circuit. Correct any abnormal conditions

found.Carburetor1. Clean fuel strainer in fuel pump. To prevent fuel

leakage in pump, disconnect “IN” line from pump

and raise end above fuel level. The in-line fuel filter

should be replaced every 12,000 miles or every 12

months.

2. Check for freedom of choke valve operation and

clean shaft if necessary, with suitable solvent.

3. Inspect throttle cable or linkage bracket and re-

turn spring for wear. With helper depressing acceler-

ator pedal to floor, check for wide open throttle.

Adjust accelerator pedal height so wide open throttle

is obtained when pedal is within

l/2 inch from floor.

Lubricate linkage pivot points with engine oil.

Air CleanerCheck paper element every 6,000 miles and replace

every

24,ooO miles. If a vehicle is operated in dusty

territory, check condition of air cleaner element

more frequently and replace if necessary.

Fan Belt1. Inspect belt for wear, cracks or frayed points.

Replace and/or adjust as necessary. Specified ten-

sion for belt using Gauge J-23600 is 45 lbs.

Cooling System1. Inspect the radiator, water pump, cylinder head

areas and all radiator and heater hose connections

for evidence of engine coolant leaks.

2. Inspect all hoses for deterioration from gas and oil

contact. Correct as required.

Inspection should be made with engine operating at

normal temperature, cooling system completely

filled, temperature control lever fully open and nor-

mal pressure in the system. Normal pressure should

be 13.2 to 15.2 psi.

Engine Lubrication SystemInspect engine for evidence of oil leakage. Correctany abnormal condition with sealastic or new seals

and gaskets.

Battery

1. Inspect battery, battery mount and cables and

check electrolyte level. Proper level should be just

above the cell plates.

CAUTION:Do not over fill.

2. Determine the serviceability of the battery by ap-

plying the 421 Battery Test.

Positive Crankcase VentilationClean crankcase ventilator metered orifice in the in-

take manifold fitting every 6,000 miles. Also all hoses

and fittings should be inspected, cleaned and re-

placed, if necessary.

To clean, remove rubber hose from metered orifice

and apply air pressure to orifice to remove any for-

eign particles that may be trapped.

Valve Lifter AdjustmentRefer to Engine Mechanical and Mounts section for

valve lifter adjustment procedure.

Engine Tune-Up Instrument ChecksThe following instrument checks and adjustments

serve as a final check on engine condition. These

checks may discover some new problems that may

not have been obvious before. The engine is also

given its final adjustments that will assure maximum

performance, reliability, and proper emission con-

trol.

Refer to Electrical Group for checking procedures of

the following:

Cranking Voltage Check

Ignition Timing

Distributor Advance

Ignition Output

Secondary Resistance

Current Output and Voltage Setting

Idle Speed and Mixture AdjustmentsRefer to carburetor section.

Page 397 of 625

7C- 361973 OPEL SERVICE MANUAL

CONTENTS

Subject

DESCRIPTION AND OPERATION:

Description of the Opel Three-Speed Automatic,Transmission....................................................................

Principles of Operation....................................................

ComponentOperation

andLocation............................

Mechanical Operation......................................................

Hydraulic Control Units and Valves............................H,y&aulic Operation..........................................................

DIAGNOSIS:

Sequence for Trouble Diagnosis..................................

Checking

Procedures........................................................

ExternalOil

Leaks..............................................................

Trouble

DiagnosisChart..................................................

Hydraulic Pressure

Checks............................................

MAINTENANCE AND ADJUSTMENTS:

Detent Cable Adjustment..............................................

ServicingSelector

Lever..................................................

MAJOR REPAIR:

Transmission Removal and Installation

AllModels........................................................................

Removalof

OilPan............................................................

RemovalofValveBody....................................................

Removalof

ServoPiston................................................

Removalof

Selector

LeverandShaft........................

RemovalofModulatorAssembly..................................

RemovalofDetentValveAssembly............................

RemovalofExtensionHousing......................................

Removal of Speedometer Drive Gear, Governor

Body and Governor Hub..............................................

Removal of Converter Housing, Oil Pump, Reverse

and Second Clutch Assembly..................................

Removal of Third Clutch Assembly, Planetary

Carrier Assembly, Reaction Sun Gear and Drum

Assembly and Low Bank............................................

Disassembly, Inspection and Reassembly of

Converter Housing, Oil Pump and Reverse Clutch

Disassembly, Inspection and Reassembly of

SecondClutch

................................................................

Disassembly, Inspection and Reassembly of

ThirdClutch....................................................................

Disassembly, Inspection and Reassembly of

Planetary Carrier

............................................................Page No.7c- 377c- 387c- 447c- 487c- 487c- 64

7C- 81

7C- 81IC- 817c- 827c- 877c- 917c- 937c- 947c- 99.7c- 99

7c-1007c-loo

7&l 01

7c-102

7c-102

7c-103

7c-103

7c-104

7c-105

7c-111

7c-114

7c-118

Page 442 of 625

DIAGNOSIS

SEQUENCE

1. Check and correct oil level. Refer to Specifications

for checking and refill procedures.

2. Check and correct vacuum line and fittings.

3. Check and correct manual linkage.

4. Road test car using all selective ranges, noting

when discrepancies in operation occur.

5. If engine performances indicates an engine tuneup

is required, this should be performed before road

testing is completed or transmission correction at-

tempted. Poor engine performance can result in

rough shifting or other malfunctions.

CHECKING PROCEDURESBefore diagnosis of any transmission complaint is

attempted, there must be an understanding of oil

checking procedure and what appearance the oil

should have. Many times a transmission malfunction

can be traced to low oil level, improper reading of

dipstick, or oil appearances; therefore, a careful anal-

ysis of the condition of oil and the level may elimi-

nate needless repairs.

When checking oil level in the Opel Three Speed

Automatic Transmission, the procedure outlined in

Specifications should be followed to obtain the most

accurate reading.

Also when the dipstick is removed, it should be noted

whether the oil is devoid of air bubbles or not. Oil

with air bubbles gives an indication of an air leak in

the suction lines, which can cause erractic operation

and slippage. Water in the oil imparts a milky, pink

cast to the oil and can cause spewing.

EXTERNAL OIL LEAKS

Determining source of oil leakBefore attempting to correct an oil leak, the actual

source of the leak must be determined. In many

cases, the source of the leak can be deceiving due to

“wind flow” around the engine and transmission.

The suspected area should be wiped clear of all oil

before inspecting for the source of the leak. Red dyeAUTOMATIC TRANSMISSION 7C- 81

is used in the transmission oil at the assembly plant

and will indicate if the oil leak is from the transmis-

sion.The use of a “Black Light” to locate the point at

which the oil is leaking is helpful. Comparing the oil

from the leak to that on the engine or transmission

dipstick, when viewed by Black Light, will determine

the source of the leak-engine or transmission.

Oil leaks around the engine and transmission are

generally carried toward the rear of the car by air

stream. For example, a transmission oil filler tube to

case leak will sometimes appear as a leak at the rear

of the transmission. In determining the source of a

leak, proceed as follows:

1. Degrease underside of transmission.

2. Road test to get unit at operating temperature.

3. Inspect for leak with engine running.

4. With engine off, check for oil leaks due to the

raised oil level caused by drain back.

Case Porosity RepairOpel Three-Speed Automatic Transmission external

oil leaks caused by case porosity can be successfully

repaired with the transmission in the car by using the

following recommended procedures:

1. Road test and bring the transmission to operating

temperature, approximately 180 degrees F.

2. Raise car on a hoist or jack stand, engine running,

and locate source of oil leak. Check for oil leaks in

low, drive, and reverse.

3. Shut engine off and thoroughly clean area to be

repaired with a suitable cleaning solvent and a

brush- air dry. A clean, dry soldering acid brush can

be used to clean the area and also to apply the epoxy

cement.

4. Using instructions of the manufacturer, mix a suf-

ficient amount of epoxy, BUICK Group 0.423, Part

No. 1360016, or equivalent, to make the repair. Ob-

serve cautions of manufacturer in handling.

5. While the transmission case is still HOT, apply the

epoxy to the area to be repaired. Make certain the

area to be repaired is fully covered.

6. Allow cement to cure for 3 hours before starting

engine.

7. Road test and check for leaks.

Page 486 of 625

AUTOMATIC TRANSMISSION 7C-1251. CASE VENT4.3RD CLUTCH7.SUCTION

2. CONVERTER OUT5MODULATOR8.LINE/3.2ND CLUTCH

6. BOOST9.REVERSEFigure 7C-202 Case Front View Oil Passage

Identification

7.

!nspect reaction sun gear drum bushing sleeve

inside case at rear for scoring. If necessary, replace

sleeve before installing rear case bushing.

8. Remove sleeve by grinding. Care must be used in

order that aluminum case is not damaged when

grinding sleeve.

9. Install new sleeve using installer tool J-23130-7

and driver handle J-8092.

10. Install new case bushing using remover and in-

staller tool J-23130-3 and driver handle J-8092.

Bushing should be installed flush with case at rear.

See Figure

7C-203.Figure 7C-2031. Drain Converter. If clutch disc material or

foreign matter has been found while draining con-

verter,

replace entire converter assembly as it can not be

cleaned properly.

2. Air check converter for leaks using converter

checking tool J-21369. Install tool and tighten. Ap-

ply 80 psi air pressure to tool. See Figure

7C-204.Figure 7C-204

3. Submerge in water and check for leaks.

4. Check converter hub surfaces for scoring or wear.

Installation of Selector Lever and Shaft1. Install new selector lever shaft oil seal in case.

Insert selector lever shaft through case from outside.

Care should be exercised so that oil seal is not da-

maged. See Figure

7C-206.2. Insert spring pin in case to secure selector lever

shaft.3. Guide selector lever over shaft and secure with

lock nut.

4. Insert parking

paw1 actuator rod from front of the

case and through hole in case at rear. See Figure 7C-

207.5. Install parking

paw1 actuator rod retaining ring.

Installation of Low Band1. Turn transmission case so that front of case is

upward.

Page 495 of 625

7C-1341973 OPEL SERVICE MANUAL

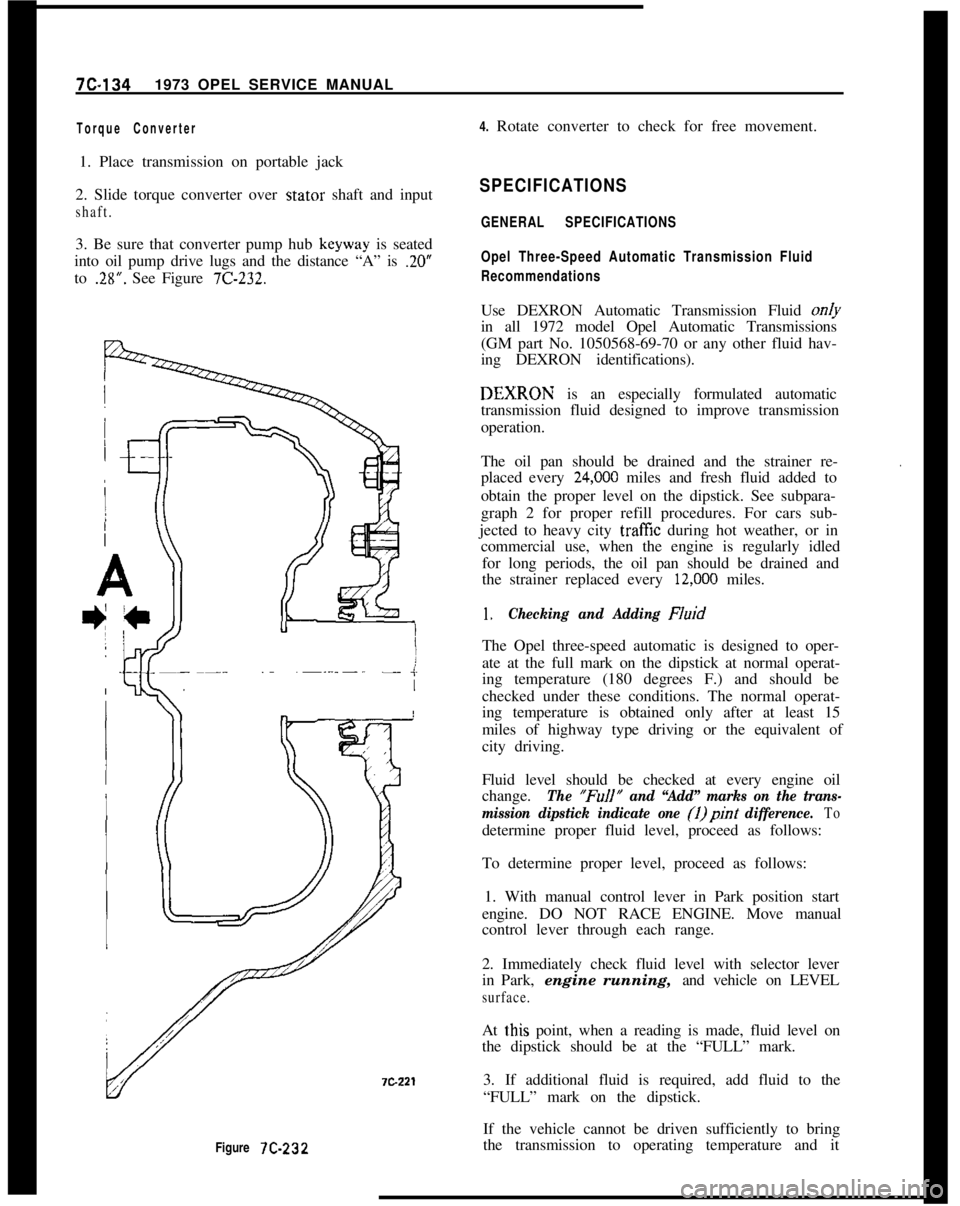

Figure 7C-232

Torque Converter4. Rotate converter to check for free movement.

1. Place transmission on portable jack

2. Slide torque converter over stator shaft and input

shaft.3. Be sure that converter pump hub keyway is seated

into oil pump drive lugs and the distance “A” is

.20”to

.28”. See Figure 7C-232.

SPECIFICATIONS

GENERAL SPECIFICATIONS

Opel Three-Speed Automatic Transmission Fluid

RecommendationsUse DEXRON Automatic Transmission Fluid on/y

in all 1972 model Opel Automatic Transmissions

(GM part No. 1050568-69-70 or any other fluid hav-

ing DEXRON identifications).DEXIRON is an especially formulated automatic

transmission fluid designed to improve transmission

operation.

The oil pan should be drained and the strainer re-

placed every

24,ooO miles and fresh fluid added to

obtain the proper level on the dipstick. See subpara-

graph 2 for proper refill procedures. For cars sub-

jected to heavy city

traff%z during hot weather, or in

commercial use, when the engine is regularly idled

for long periods, the oil pan should be drained and

the strainer replaced every

12,ooO miles.

.

1.Checking and Adding FluidThe Opel three-speed automatic is designed to oper-

ate at the full mark on the dipstick at normal operat-

ing temperature (180 degrees F.) and should be

checked under these conditions. The normal operat-

ing temperature is obtained only after at least 15

miles of highway type driving or the equivalent of

city driving.

Fluid level should be checked at every engine oil

change.

The “FuIl” and “Add” marks on the trans-

mission dipstick indicate one (1)pint

difference. Todetermine proper fluid level, proceed as follows:

To determine proper level, proceed as follows:

1. With manual control lever in Park position start

engine. DO NOT RACE ENGINE. Move manual

control lever through each range.

2. Immediately check fluid level with selector lever

in Park, engine running, and vehicle on LEVEL

surface.At

t,his point, when a reading is made, fluid level on

the dipstick should be at the “FULL” mark.

3. If additional fluid is required, add fluid to the

“FULL” mark on the dipstick.

If the vehicle cannot be driven sufficiently to bring

the transmission to operating temperature and it