wheel torque OPEL GT-R 1973 Owner's Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1973, Model line: GT-R, Model: OPEL GT-R 1973Pages: 625, PDF Size: 17.22 MB

Page 197 of 625

3D- 301973 OPEL SERVICE MANUALFigure 3D-8 - Removing Clamp Bolt3. Remove cotter pin located on left and right tie rod

end and unscrew nut.

4. Using Tool J-21687, press tie rod ends out of

steering arms.

5. Disconnect steering gear housing from front sus-

pension cross member and remove steering gear

together with tie rods.

Installation . GTCAUTION: Fasteners are important attaching parts in

that they could affect the performance of vital com-

ponents and systems, and/or could result in major

repair expense. They must be replaced

with one of

the same part number or with an equivalent part if

replacement becomes necessary. Do not

use a re-

placement part of lesser quality or substitute design.

Torque values must be used as specified during reas-

sembly to assure proper retention of these parts.

1. Position steering gear on front suspension cross

member and torque attaching bolts to 18

lb.ft.2. Position tie rod ball studs in steering arms; install

nuts and torque to 29 lb.ft. Lock in position with new

cotter pins.

3. Fully turn steering wheel so that flat or cutout

surface on lower portion of steering shaft is parallel

to flexible coupling bolt hole.

4. Install the lower end of steering shaft to the flexi-

ble coupling and adjust dimension between steering

wheel hub and direction signal switch housing cover

to

l/8 and 3/32 inch. Maintain adjustment by tight-

ening flexible coupling bolt and nut to 15 lb.ft. Lock

the bolt and nut in position with lock-plate tabs.5. Reinstall stop bolt into steering column.

6. Full turn steering wheel both right and left. If any

resistance is noticeable, it will be necessary to remove

the sleering column and correct the cause.

D. Installation (Opel 1900. Manta)CAUTION: Fasteners are important attachingparts in

that they could affect the performance of vital com-

ponents and systems, and/or could result in

maJbrrepair expense. They must be replaced with one of

the same part number or with an equivalent part if

replacement becomes necessary. Do not use a re-

placement part oflesser

quaky or substitute design.

Torque values must be used as specified during reas-

sembly to assure proper retention of these parts.

1. Prior to installation, set steering gear to high

point. The steering wheel spokes point downwards in

an oblique angle. The elongated cutout of the lower

steering mast must coincide with the clamp bolt hole

of the pinion flange.

2. Position steering gear on front suspension cross

member and torque attaching bolts to 29 lb.ft.

3. Position tie rod studs in steering arms. Install nuts

and torque to 29

Ib.ft. Lock in position with new

cotter pin.

4. Install the lower end of the steering shaft to flexi-

ble coupling and torque clamp bolt to 22

lb.ft.5. Attach guard plate to both side members and

lower deflector panel.

DISASSEMBLY AND ASSEMBLY OF

STEERING GEAR ASSEMBLY WITH TIE RODS

Disassembly - GT1. Carefully clamp gear assembly in soft jaw vise and

slip clamps and rubber bellows off gear housing to

expose area where ball joint screws into rack.

2. Bend up round edges of lockplates from tie rod

ball studs and disconnect tie rod ball studs from rack.

See Figure

3D-9). It is important that rack be held

secure with open end wrench to prevent damage to

rack teeth.

3. Loosen adjusting screw lock nut; remove adjusting

screw from steering gear housing, and take out thrust

spring and sintered bronze shell. See Figure

3D-11.4. Rotate gear assembly in vise so that pinion shaft

portion of assembly is held by vise, and remove pin-

ion nut, flat washer, and special washer.

Page 205 of 625

3E- 38 ,1973 OPEL SERVICE MANUAL

ponents and systems, and/or could result in major

repair expense. They must be replaced with one or

the same part number or with

an equivalent part if

replacement becomes necessary. Do not use a

re-

placement part of lesser quality or substitute design.

Torque

values must be used as specified during reas-

sembly to assure proper retention of these parts.On installation, make sure steering wheel spokes

point downwards and steering gear is in high point.

1. Carefully insert steering mast into universal joint

flange.

2. Loosely attach slide-off base attaching nuts at un-

derside of instrument panel.

3. Attach steering mast jacket at front of dash, using

a notched hex nut.

4. Torque nuts at slide-off base to II

lb.ft.5. Tighten screw at steering mast clamp to 22

lb.ft.6. Reconnect wires to directional signal switch and

ignition switch.

7. Reconnect battery.

REMOVAL AND INSTALLATION OF

STEERING WHEELThis procedure may be performed with the steering

column assembly either removed or installed in the

car.

Removal

1. Disconnect battery.

2. Pry off horn cap and remove wires from cap. See

Figure

3E-3.3. Bend lockplate tabs down and take off steering

shaft nut and lockplate.

4. Install steering wheel remover J-21686 as shown

in Figure

3E-9 and pull off steering wheel.

Installation1. Before installing steering wheel, lubricate return

pin and sliding area on directional signal switch re-

turn cams and horn contact ring.

2. Make sure that clamp bolt in steering shaft flange

is on top.

3. Make sure notch on steering shaft face is in hori-

zontal position.Figure

3E-9 Removing Steering Wheel

4. With the steering wheel centered, place the steer-

ing wheel onto the steering shaft.

5. Install steering wheel lockplate and nut. Torque to

11

lb.ft.

CAUTION:

This steering wheeI to steering shaft fas-

tener is an important attaching part in that it could

affect the

performance of vital components and sys-

tems, and/or could result in major repair expense. It

must be repked

with one of the same part number

or with an equivalent part if replacement becomes

necessary. Do not use a replacement part of lesser

quality or substitute design. Torque

values must be

used as specified during reassembly to assure proper

retention of this part.6. Bend lockplate tabs up, connect horn cap wires

and replace cable and cap.

7. Reconnect battery.

REMOVAL AND REPLACEMENT OF HORN

CONTACT RING

1. Remove steering wheel.

2. Cut off defective contact ring at wire.

3. Strip wire approximately

l/8”.4. Install new part and solder connection with resin

core solder.

5. Lubricate contact ring with lubriplate, or equiva-

lent.

6. Reinstall steering wheel.

Page 207 of 625

3E- 40 1973 OPEL SERVICE MANUAL

on steering and ignition lock bracket using a new

tear-off bolt (hexagon head tears

ofD.

3. Disconnect slide-off base, install upper half of sig-

nal switch housing cover, and loosely reattach

slide-

off base.

4. Attach steering mast jacket at front of dash panel.

See Figure

3E-7.

5. Torque slide-off base attaching nuts to 11 lb.ft.

6. Install lower half of signal switch housing cover

and connect signal switch, as well as steering ignition

lock wire set.

7. Install steering wheel and torque nut to 11

Ib.ft.

Always use new lock plate.

DISASSEMBLY AND REASSEMBLY OF STEERING

AND IGNITION LOCK CYLINDER AND ELECTRICAL SWITCH FROM MAST JACKET

ASSEMBLY

Disassembly. GT

Disconnect the battery before proceeding.

1. Remove steering wheel.

2. Turn ignition switch to ON position.

3. Insert a suitable rod into stop pin hole on side of

steering and ignition lock (See Figure

3E-13) and

take out steering and ignition lock cylinder. 4. Remove two screws securing electrical switch to

steering and ignition lock housing and take out

switch.

Disassembly (Opel 1900 . Manta)

1. Rezmove steering wheel.

2. Unscrew split signal switch housing cover and

remove lower half. See Figure

3E-10.

3. Remove lock cylinder by pushing in lock spring of

the cylinder using a piece of wire. Cylinder must be

in the

” 1” position. See Figure 3E-14.

Figure 3E-14 Removing Lock Cylinder

Reassembly

1. On the GT reassemble electrical switch into steer-

ing and ignition

lock housing and rotate switch until:

(1) cam in lock housing recess fits into slotted hole

in rear of electrical switch, and (2) projection on

electrical switch fits into recess on lock housing.

2. On the Opel 1900

- Manta, insert lock cylinder in

the

P l* position into housing. Install lower half of

signal switch housing.

3. Reinstall steering wheel.

Figure 3E-13 Removing Ignition Lock Cylinder

Page 209 of 625

3E- 421973 OPEL SERVICE MANUAL

GT STEERING COLUMN ASSEMBLY

CONTENTS

Subject

DESCRIPTION AND OPERATION:

DescriptionofSteeringColumn. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .DIAGNOSIS: (Not Applicable)

MAINTENANCE AND ADJUSTMENTS: (Not

Applicable)

MAJOR REPAIR:

RemovalandInstallationofSteeringWheel. . . . . . . . . . . .Removal and Installation of Ignition Lock

Cylinder

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Removal and Installation of Steering Column

Assembly

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Removal and Installation of Center Steering Shaft

Removal and Installation of Ignition Switch

and/or Steering Lock

.,~ ,........ ~ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Removal and Installation of Upper Steering

Bearing and/or Directional Signal Switch

. . . . . . . . . . . .Removal and Installation of Steering Column

Lower Bearing

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .SPECIFICATIONS:

Steering Column Torques

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page No.

3E-42

3E-44

3E-45

3E-45

3E-46

3E-46

3E-48

3E-49

3E-50

DESCRIPTION AND OPERATION

DESCRIPTION OF STEERING COLUMNThe Energy Abosrbing, Locking Steering .Column

assembly is used on the GT. This cohnnn is designed

to compress under impact. When an automobile is

being driven, the forward movement of the automo-

bile and the forward movement of the driver both

constitute a form of energy or force. When an au-

tomobile is involved in a frontal collision, the pri-

mary force (forward movement of the car) is

suddenly halted, while the secondary force (the

driver) continues its forward direction. A severe col-

lision generally involves these two forces

- the pri-

mary and the secondary forces. The secondaryjmpact occurs when the driver is thrust forward onto

the steering wheel and column.

The Energy Absorbing Column is designed to absorb

these primary and secondary forces to the extent thatthe severity of the secondary impact is reduced. Dur-

ing a collision, the steering column compresses and

thereby reduces its tendency to move rearward into

the driver’s compartment. A split second later when

the driver is thrown forward (the secondary impact)

his energy is also partially abosrbed by the compres-

sion characteristics of the column.

The Energy Absorbing, Locking Column assembly

may be easily disassembled and reassembled. The

serviceman should be aware that it is important that

only the specified screws, bolts and nuts be used as

designated during reassembly, and that they are

tightened to their specified torque. This precaution

will insure the energy absorbing action of the assem-

bly. Particular care should be exercised to avoid us-

ing overlength bolts as they may prevent a portion of

the assembly from compressing under impact.

Equally as important is correct torquing of all bolts

and nuts.

When the Energy Absorbing, Locking Column is

Page 212 of 625

GT STEERING COLUMN ASSEMBLY3E- 45

loose must never be done. The only recommendation

for freeing frozen steering wheels is to use a penetrat-

ing lubricant.Installation1. Before installing steering wheel, lubricate return

pin and slide area on direction signal switch return

cams and horn ring contact.

2. With steering wheel properly aligned to shaft, in-

stall lockplate and nut. Torque nut to 15

Ib.ft.

CAUTION:

This steering wheel to steering shafi fas-

tener is an important attac&ng part in that it could

affect the performance of vital components and sys-

tems, and/or could result in major repair expense. It

must be

rep/aced with one of the same part number

or with an equivalent part, if replacement becomes

necessary. Do not use a replacement part of lesser

quality or substitute design. Torque values must be

used as specified during reassembly to assure proper

retention of this part.3. Bend up lockplate tab and install horn cap.

4. Reconnect battery.

REMOVAL AND INSTALLATION OF IGNITION

LOCK CYLINDER

RemovalThis procedure may be performed with the steering

column assembly either removed or installed in the

car.1. Remove steering wheel, as outlined previously in

this Group.

2. Position lock cylinder to run position.

3. Using suitable piece of wire, push in lock cylinder

retaining pin and remove lock cylinder. See Figure3E- 18.

Installation1. Insert lock cylinder into lock cylinder housing.

2. Install steering wheel, as outlined previously in

this section.

REMOVAL AND INSTALLATION OF STEERING

COLUMN ASSEMBLY

Removal1. Position steering so that front wheels are straight

ahead.Figure

3E-18 Removing Lock Cylinder

2. Loosen steering shaft upper universal joint lower

clamp bolt. See Figure

3E-19.3. Drill off heads of both tear bolts by first drilling

an 3/16 inch pilot hole and then inserting a

l/4 inch

bolt extractor to remove lockbolt.

4. Disconnect ignition (white) and direction signal

(black) wire set plugs.

5. Support steering column assembly and remove

both hex. head bolts.

6. Pull steering column assembly off center steering

shaft. Do not apply any force as plastic injections in

center steering shaft may be loosened and shaft

would then require replacement.

Installation

CAUTION:

Fasteners are important attachingparts in

that they

cooId affect the performance of vital com-

ponents and systems, and/or could result in major

repair expense. They must be replaced with one of

the same part number or with an equivalent part if

replacement becomes necessary. Do not use a re-

placement part of lesser quality or

substitute design.

Torque values must be used as specified during

reas-

sembIy to assure proper retention of these parts.1. Install steering column assembly onto steering

shaft and torque steering shaft upper universal joint

lower clamp bolt to 14

lb.ft.2. Install hex head bolts and torque to 14

lb.ft.

NOTE:

Be sure to install ground wire.

Page 213 of 625

I3E. 461973 OPEL SERVICE MANUAL

Figure 3E-19 Steering Column Attachments

3. Install new tear bolts and tighten until hex

head of bolt is tom off.

4. Reconnect ignition and direction signal wire sets.

REMOVAL AND INSTALLATION OF CENTER

STEERING SHAFT

RemovalSteering shaft must be handled carefully so as not to

loosen plastic injections as shaft would then require

replacement.

CAUTION:Fasteners are important attaching parts

in that they could affect the performance of vital

components and systems, and/or could result in

major repair expense. They must be replaced with

one of the same part number or with an

equivalent part if replacement becomes necessary.

Do not use a replacement part or lesser quality or

substitute design. Torque values must be used as

specitied during reassembIy to assure proper

retention of these parts.1. Install steering shaft through bottom and position

into upper universal joint.

1. Position steering so that front wheels are straight

ahead.2. Insert shaft into lower universal joint and torque

bolt to 22 lb.ft.

2. Loosen steering shaft upper universal joint lower

clamp bolt.3. Torque upper universal joint bolt to 14

lb.ft.3. Remove steering shaft lower universal joint upper

clamp screw.

4. Carefully push center steering shaft up into steel

washer joint until lower end is free.REMOVAL AND INSTALLATION OF IGNITION

SWITCH AND/OR STEERING LOCK

Removal5. Remove steering shaft through bottom.

1, Remove ignition lock cylinder, see previous para-

graph in this section.

Page 216 of 625

GT STEERING COLUMN ASSEMBLY3E- 49

4. Install ignition switch and steering lock

REMOVAL AND INSTALLATION OF STEERING

COLUMN LOWER BEARING

The following is with steering column assembly

removed.

1. Remove steering wheel.

2. Remove screws securing lower bearing housing to

mast jacket.

3. Remove steering shaft together with universal

joint and bearing and housing.

4. Remove universal joint from shaft. See Figure 3E-28.Figure 3627 Removing Upper Bearing

SERRATED SOCKET

“‘*E.Z<~lh I’

I//

11 uBEARING HOUSINGy

SE-28Figure 3E.28 Removing Lower Bearing

5. Remove bearing retainer snap ring and remove

bearing.

Installation3. Install steering shaft, together with universal joint

bearing and housing to mast jacket. Serrated socket

head screw must be installed on

tm side of steering

column assembly. See Figure 3E-2\.

1. Install bearing and bearing retainer snap ring.

2. Install universal joint and torque to 22

Ib.ft.4. Install steering wheel. On installation of steering

wheel, make sure that with flats of lower portion of

universal joint horizontal, the center steering wheel

spoke must be vertical.

Page 217 of 625

13E. 50 1973 OPEL SERVICE MANUALPART

Bolt

BoltLOCATION

Steering WheelUpper Universal Joint

- Lower Clamp

Upper Universal Joint

- Hex Head

Lower Universal Joint

TORQUE

LB.FT.

15

14

Page 219 of 625

3F. 521973 OPEL SERVICE MANUAL

3. Install rubber grommet, retainer and self-locking

nut at top of shock absorber. Torque to 10 lb. ft.

Always use new self-locking nuts.

REAR SPRING REMOVAL AND INSTALLATION

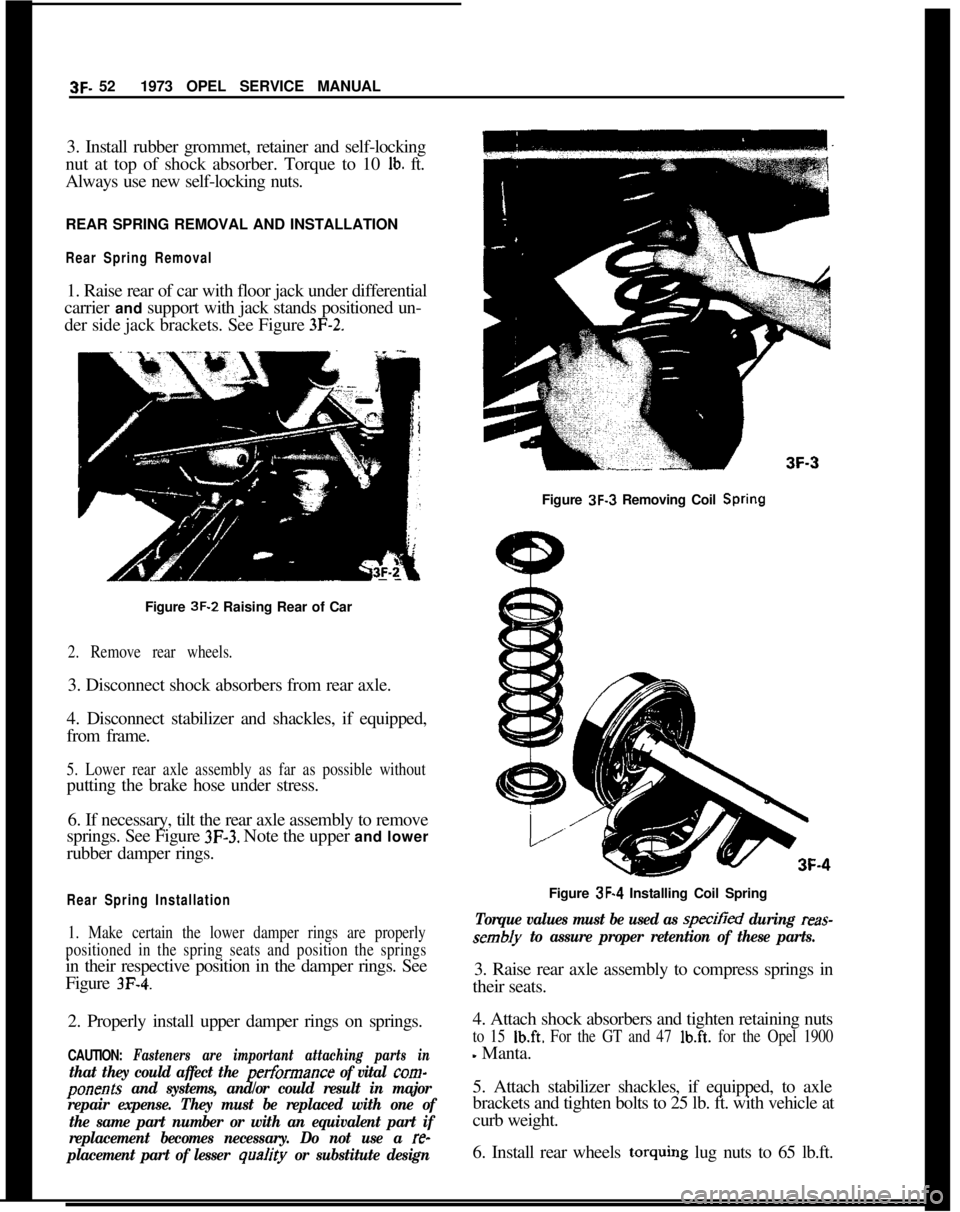

Rear Spring Removal1. Raise rear of car with floor jack under differential

carrier and support with jack stands positioned un-

der side jack brackets. See Figure

3F-2.Figure 3F-3 Removing Coil

SpringFigure 3F-2 Raising Rear of Car

2. Remove rear wheels.3. Disconnect shock absorbers from rear axle.

4. Disconnect stabilizer and shackles, if equipped,

from frame.

5. Lower rear axle assembly as far as possible withoutputting the brake hose under stress.

6. If necessary, tilt the rear axle assembly to remove

springs. See Figure

3F-3. Note the upper and lower

rubber damper rings.

Rear Spring Installation

1. Make certain the lower damper rings are properly

positioned in the spring seats and position the springsin their respective position in the damper rings. See

Figure

3F-4.2. Properly install upper damper rings on springs.

CAUTION: Fasteners are important attaching parts in

that they could affect the performance of vital corn-

ponents and systems, and/or could result in major

repair expense. They must be replaced with one of

the same part number or with an equivalent part if

replacement becomes necessary. Do not use a

re-

placement part of lesser

qua/ity or substitute designFigure 3F-4 Installing Coil Spring

Torque values must be used as specitied during reas-

sembly to assure proper retention of these parts.3. Raise rear axle assembly to compress springs in

their seats.

4. Attach shock absorbers and tighten retaining nuts

to 15 Ib.ft. For the GT and 47 lb.ft. for the Opel 1900

- Manta.

5. Attach stabilizer shackles, if equipped, to axle

brackets and tighten bolts to 25 lb. ft. with vehicle at

curb weight.

6. Install rear wheels torquing lug nuts to 65 lb.ft.

Page 220 of 625

REAR SUSPENSION3F- 53

7. Remove jack stands.

LOWER CONTROL ARM REPLACEMENTRemovalThis operation can be performed with the vehicle

standing at curb height or elevated.

1. Disconnect parking brake cable from support

bracket on control arm.

2. Loosen and remove front and rear control arm

attaching bolts and remove control arm.

installation1. On

1900’s and Manta’s place a load of approxi-

mately 350 lbs. in luggage compartment or on the

GT, place a load of approximately 150

Ibs. on dri-

ver’s seat. Torque control arm attaching nut and

bolts to 18 lb.ft on

GT’s and 23 Ib.ft. on the 1900 -Manta.

2. Connect parking brake cable to support bracket on

control

ranI.

STABILIZER ROD REPLACEMENT

Removal1. Raise and support rear of vehicle.

2. Disconnect stabilizer rod to shackle bolts.

3. Disconnect stabilizer rod to underbody retainers

and work stabilizer rod out from under vehicle.

SPECIFICATIONS

REAR SUSPENSION SPECIFICATIONS

Tightening SpecificationsInstallation1. Work stabilizer rod into position and loosely at-

tach stabilizer to underbody retainers.

2. Connect stabilizer rod to shackles.

3. With the vehicle standing on its wheels or the rear

axle assembly lifted, tighten stabilizer rod to under-

body bracket bolts to 15 lb. ft.

4. Remove jack stands and lower vehicle.

TRACK ROD REPLACEMENT

Removal1. Lift rear of car and suitably support.

2. Disconnect track rod from rear axle and frame

side member.

Installation

1. Loosely connect track rod first to side member and

then to the rear axle.

2. On the

1900 - Manta, load luggage compartment

of vehicle with approximately 350 lbs. or on the GT,

place a load of approximately 150 lbs. on driver’s

seat and tighten track rod attaching bolts to specified

torque.

3. Remove supports (jack stands) and lower vehicle.

Use a reliable torque wrench. Specifications are for clean and lightly-oiled

threads.

Part

Nut

Nut

Nut

Bolt

Nut

Nut

Nut

BoltName

WheelNuts.

.._.._......._........................................................

Control Arm Attaching (GT) .._.._.,,,........,,.,,.......,,......,,,,......

Control Arm Attaching (1 900 - Manta) .,,...._...,,,,_.....,,.,...

Stabilizer Rod to Underbody Retainers ,....._.,.,,.,.....,,,....

Shock Absorber Lower Attachment (GT) . .._.....,._.._.,,,...

Shock Absorber Lower Attachment (1900 Manta) ,,.,

Shock Absorber Upper Attachment. .._.....................

Stabilizer Shackle to Axle Bracket .._._.._,...._..,,.,,.......,,,...

Torque

Lb.Ft.

65

16

23

15

1,5

47

1025