ECU OPEL GT-R 1973 Manual PDF

[x] Cancel search | Manufacturer: OPEL, Model Year: 1973, Model line: GT-R, Model: OPEL GT-R 1973Pages: 625, PDF Size: 17.22 MB

Page 571 of 625

98-62 1973 OPEL SERVICE MANUAL

Figure 98.99 Refrigerant Hoses Retainer Grommet

-Under Car - GT

8. From under car install four (4) nuts securing

evaporator mounting bracket to floor. See Figures9B- 92 and

9B-93.Figure 98.100 Refrigerant Hoses

- Under Car GT

9. Evacuate system. Refer to EVACUATING SYS-

TEM.

10. While system is being evacuated, connect drain

hoses underneath evaporator housing.

11. Plug in the resistor assembly electrical connector

plug and connect the blower motor connection and

install ground wire and 2 mounting brackets to case

screws using the rearward holes. See Figure

9B-90.12. Install the evaporator cover and all cover screws.

See Figure

9B-88.13. Install luggage tray and attaching screws. See

Figure

9B-87.14. Connect the negative battery cable.

15. Charge system. Refer to CHARGING SYS-

TEM.

REMOVAL AND INSTALLATION OF CONDENSERRECIWER- DEHYDRATOR ASSEMBLY

- GT

Removal

1. Disconnect negative battery cable.

2. Discharge system. Refer to DISCHARGING

SYSTEM.

3. While the system is discharging, remove the

charcoal cannister, washer jar, battery and battery

tray. Battery needs only to be set up out of the way

and not removed from the car.

4. Disconnect inlet and outlet pipes of condenser

receiver-dehydrator and tape closed the open ends of

refrigerant lines, and also the open ends of the inlet

and outlet pipes of the condenser. See Figure 9B-101.

5. Disconnect discharge line from condenser and

tape closed open ends of discharge pipe and con-

denser inlet.

6. Remove 4 condenser attaching screws and lift out

condenser. See Figure 9B-101.

7. Remove 2 screws retaining receiver-dehydrator

to condenser and remove.

Figure

9B-101 Receiver - Dehydrator. Condenser

Attaching Screws and Brackets

- GT

Installation

If refrigerant circuit or condenser has been exposed

to the atmosphere and moisture may be present in

the circuit, the system and/or component must be

flushed prior to installation. Refer to FLUSHING

THE SYSTEM.

1. Install receiver-dehydrator to condenser and fas-

ten with 2 clamps and 2 screws.

Page 572 of 625

REFRIGERANT COMPONENTS ALL MODELSSB-632. Install condenser into car and secure with 4 at-

taching screws. See Figure

9B-101.3. Untape discharge line and pipe and install using

new o-rings lubricated with No. 525 viscosity oil.

Figure

99.102 Condenser - Receiver - Dehydrator

O-Rings. GT

4. Untape and install inlet and outlet pipes into the

receiver-dehydrator using new o-rings lubricated

with No. 525 viscosity oil.

Figure

98-103 Condenser Assembly - GT

5. Evacuate system. Refer to EVACUATING SYS-

TEM.

6. While system is being evacuated, install the char-

coal cannistor, washer jar, battery tray and battery

and connect negative battery cable.

7. Charge system. Refer to CHARGING SYS-

TEM.

DISASSEMBLY AND REASSEMBLY OF CLUTCH

DRIVE PLATE AND SHAFT SEALIt is not necessary to remove the compressor or dis-connect refrigerant lines to remove or install clutch

parts on the GT, however, the compressor must be

removed from the Opel 1900

- Manta.

Disassembly

1. Firmly clamp holding fixture (J-9396) in a vise

and attach compressor assembly to fixture (see Figwe

9B-104).

-_ .s -Figure SE-104 Removing or Installing Shaft Nut

2. Hold hub of clutch drive plate with wrench

(J-9403). Using special thin wall 9/16 inch socket

(J-9399) and 3/g inch drive, remove shaft nut.

3. Install threaded hub puller (J-9401) onto hub of

clutch drive plate (see Figure

9B-105). Hold body of

hub puller with wrench, tighten center screw of hub

puller, and lift off clutch drive plate and woodruff

key.Figure SE-105 Removing Clutch Drive Plate

Page 575 of 625

9B-66 1973 OPEL SERVICE MANUAL

LEAK TEST

FIXTURE

\ Js - s ---Y623

\COMPRESSOR

ADAPTERS

J-5420

USE LINE ONLY

DURING

-

COMPRESSOR

SEAL TEST

-4

-

It-’rDISCHARGE LINE

-

LOW PRESSUREHIGt

GAGE

4

PRESSURE

GAGE

(TOP VIEW)

GAGE

*-LINE (3)

J-54 18

GAGE SET

REFRIGERANT

J-5725-01

-CYLINDER

LMANIFOLD AND

9&86

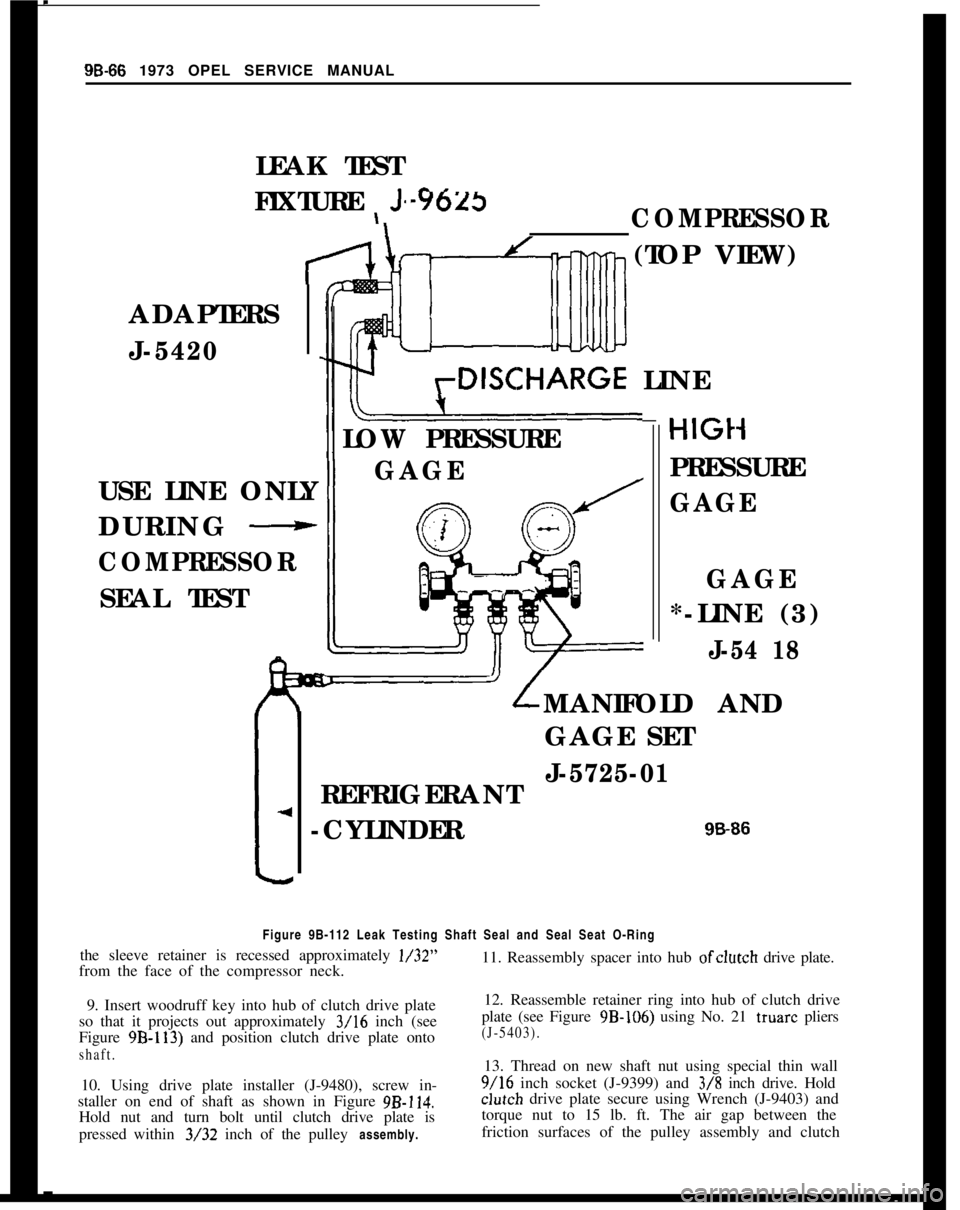

Figure 9B-112 Leak Testing Shaft Seal and Seal Seat O-Ring

the sleeve retainer is recessed approximately l/32”

from the face of the compressor neck. 11. Reassembly spacer into hub ofclutch

drive plate.

9. Insert woodruff key into hub of clutch drive plate

so that it projects out approximately

3/16 inch (see

Figure

9B-113) and position clutch drive plate onto

shaft.

10. Using drive plate installer (J-9480), screw in-

staller on end of shaft as shown in Figure

9B-114.

Hold nut and turn bolt until clutch drive plate is

pressed within

3/32 inch of the pulley assembly.

12. Reassemble retainer ring into hub of clutch drive

plate (see Figure

9B-106) using No. 21 truarc pliers

(J-5403).

13. Thread on new shaft nut using special thin wall

9/16 inch socket (J-9399) and 3/8 inch drive. Hold

clut~ch drive plate secure using Wrench (J-9403) and

torque nut to 15 lb. ft. The air gap between the

friction surfaces of the pulley assembly and clutch

Page 600 of 625

98-92 1973 OPEL SERVICE MANUAL

MAJOR REPAIR

REMOVAL AND INSTALLATION OF BLOWER

SWITCH

Removal

I. Remove the face plate retaining screws and

remove the face plate assembly. See Figure 9B-172.

Figure SE-172 Face Plate Retaining Screws andcontrots

2. Remove the blower switch retaining screws and

remove switch.

Installation

1. Install the blower switch and retainer screws.

2. Install the face plate and secure with the retainer

screws. See Figure

9B-372.

REMOVAL AND INSTALLATION OF

TEMPERATURE CONTROL SWITCH

Removal

1. Remove the face plate retaining screws and

remove the face plate assembly noting the position of

the air sensing capillary so that it can be reinstalled

in the same location as when removed. See Figure

9B- 173.

2. Remove the temperature control switch retaining

screws and remove switch.

AIR SENSING CAPILLARY,yT,,ERMOSTATIC SWITCH

!IBUMPERBLOWER SWITCH98-136

Figure SB-173 Location of Air Sensing Capillary

Installation

1. Install the temperature control switch and secure

with the retaining screws.

2. Position the air sensing capillary in the exact

location as was noted when removing.

3. Install the face plate and secure with the retain-

ing screws. See Figure

9B-172.

REMOVAL AND INSTALLATION OF RESISTOR

ASSEMBLY

Removal

1. Disconnect the negative battery cable.

2. Remove the glove box assembly. 3. Disconnect the electrical plug from the resistor

assembly. See Figure

9B-176.

4. Remove two (2) screws and remove resistor as-

sembly.

Installation

1. Install the resistor assembly and secure with two

(2) screws.

2. Install the electrical plug onto the resistor assem-

bly. See Figure

9B-176.

3. Install the glove box assembly.

4. Connect the negative battery cable.

REMOVAL AND INSTALLATION OF BLOWER

MOTOR ASSEMBLY

REMOVAL

1. Remove the negative battery cable from the bat-

tery.

Page 607 of 625

5. If the low side pressure was less than the pre-

scribed pressure at the end of each cooling cycle, turnthe adjusting screw a partial turn clockwise. See Fig-ure 9B-192.AIR CONDITIONER SYSTEM

- GT9B- 99

CONNECTOR

Figure 98.192 Adjusting Thermostatic Switch6. If the pressure was more than the prescribed

value, tuin the adjusting screw counter-clockwise.7. Reinstall switch end plate and install switch in

face plate. Install face plate on evaporator assembly

assuring

,that the air sensing capillary has been re-

placed properly.

Figure 98-l 93 Vacuum Switch8. Check system performance. Iffurther adjustment

is needed, repeat steps 3 thru 7 until the correct

pressure is reached.

REMOVAL AND INSTALLATION OF BLOWER

SWITCHDo not attempt to run a performance test with the

duct assembly and switch removed from the

evaporator assembly

- inaccurate readings will re-

sult. Always replace the switch and duct assemblies

before c+ecking the system performance.

Removal

MAJOFi REPAIR

1. Remove the negative cable from the battery2. Remove the retaining screws from the duct as-

sembly. See Figure

9B-190.3. Remove 2 blower switch rejaining screws and

remove blower switch.

REMOVAL AND INSTALLATION OF VACUUM

SWITCH,

Installation

Ramoval~1. Remove right trim pad below instrument panel.

2. Rembve two (2) screws and unplug the vacuum

hose and electrical connector. See Figure

9B-193.1. Install the blower switch and

secure with two (2)

retaining screws.

2. Install the duct assembly retaining screws.

3. Install the negative battery cable.

Installation1. Install two (2) screws and plug in electrical con-

nector and connect the delay restrictor and checkvalve

hose assembly.

I

REMOVAL AND INSTALLATIDN:OF

TEMPERATURE CONTROL SWITCH

Removal2. Install right trim pad.I. Remove the negative battery cable.

Page 608 of 625

gB-100 1973 OPEL SERVICE MANUAL

2. Remove the retaining screws from the duct as-

sembly. See Figure 9B-190.3. Lift up duct assembly and note the position of the

air sensing capillary so that it can be reinstalled in

the same location as when removed.

4. Remove the temperature control switch retaining

screws and remove switch.

Installation

1. Install the temperature control switch and secure

with the retainer screws.

2. Position the air sensing capillary in the exact

location as was noted when removing.

3. Install the duct assembly retaining screws.

4. Install the negative battery cable.

REMOVAL AND INSTALLATION OF RESISTOR

ASSEMBLY

Removal1. Remove the negative battery cable from the bat-

tery.2. Remove the luggage tray attaching screws and

lift out tray. See Figure 9B-194.

Figure 98-194 Luggage Tray3. Remove all evaporator cover attaching screws

and remove cover. See Figure

9B’-195.Figure 98.195 Evaporator Cover Assembly and

Attaching Screws

4. Remove the electrical plug connector from the

resistor assembly.

5. Remove 2 resistor attaching screws and remove

resistor assembly. See Figure 9B-197.

/98-147Figure 9B-196 Resistor and Blower Motor

Connections

Page 610 of 625

98-102 1973 OPEL SERVICE MANUAL

2. Discharge system. Refer to DISCHARGING

SYSTEM in Refrigerant Components Section.

3. While system is discharging remove the luggage

tray attaching screws and lift out tray. See Figure9B-200.

4. Remove all evaporator cover screws and remove

cover. See Figure

9B-201.Figure

98.202 Evaporator Cover and Luggage Tray5. Remove the electrical plug connector from the

resistor assembly, and unplug blower motor connec-

tion and remove ground wire. See Figure

9B-203.6. From underneath evaporator housing, discon-

nect 2 drain hoses. See Figure 9B-204.

EVAPORATORFigure

98.204 Drain Hose

7. From under car remove 4 nuts securing evapora-

tor mounting bracket to floor. See Figure 9B- 205

and 9B-206.

Figure

98.203 Electrical Connections and Ground

WireFigure 98-205 Evaporator Mounting Bracket Bolts -Driver Side

Page 612 of 625

98-104 1973 OPEL SERVICE MANUAL

the el&trical connector side of the motor to the right

side of the bracket.

2. Assemble the fan housing case halves and attach

the cover plate.

3. Install the resistor assembly.

4. Install the evaporator assembly into the car and

install mounting bracket. See Figure

9B-209.5. Untape the refrigerant lines and the inlet and

outlet pipes from the evaporator and install using

new o-rings on line fittings.

6. From under the car, install 4 nuts securing

evaporator mounting bracket to floor. See Figures9B- 205 and

9B-206.7. Evacuate system. Refer to EVACUATING SYS-

TEM in REFRIGERANT COMPONENTS Sec-

tion.

SPECIFICATIONS8. While system is being evacuated:

9. Connect 2 drain hoses underneath the evaporator

housing.

10. Plug in the resistor assembly electrical connector

plug and connect the blower motor connection and

install ground wire and 2 mounting bracket to case

screws using the rearward holes.

S’ee Figure 9B-209.11. Install the evaporator cover and all cover screws.

See Figure 9B-202.

12. Install luggage tray and attaching screws. See

Figure

9B-202.13. Connect the negative battery cable.

14. Charge system. Refer to CHARGING SYSTEM

in Refrigerant Components Section.

Page 613 of 625

RADIO. GT9c- 105

RADIO

GTCONTENTS

Subject

DESCRIPTION AND OPERATION: (Not Applicable)

DIAGNOSIS:

RadioTroubleDiagnosis. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .MAINTENANCE AND ADJUSTMENTS:

Antenna Trimmer Adjustment

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .MAJOR REPAIR:

RemovingandInstallingRadio. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .SPECIFICATIONS: (Not Applicable)

Page No.

9c-105

9C-106

9c-107

DIAGNOSIS

RADIO TROUBLE DIAGNOSISBecause radio problems are most often repaired at

United Delco authorized warranty repair stations,

the tendency for many dealer servicemen is to

remove the set when a problem is reported, without

any preliminary diagnosis. This results in a large

number of radios showing up as “NO TROUBLE

FOUND” units when received by the warranty re-

pair stations. This indicates that the trouble can

often be corrected without removal of the radio.

The inconvenience to an owner of driving without a

radio while his set is being serviced at a warranty

station can frequently be avoided if the following

quick checks are used to eliminate external radio

system :problems before removing the radio for re-

pair.

Always determine from the owner the exact nature

of the radio problem as an aid to diagnosis. Knowing

whether the condition is intermittent or constant,

whether it occurs with engine off or running, with

car stationary or moving, will help to pinpoint the

problem. Never turn on radio with speaker discon-

nected.

Radio Ii

Inoperative.1. Turn on the radio. The dial should light and a

thump should be heard from the speaker.a. If a thump is heard, go to Step No. 2 for antenna

check.b. If no thump is heard,

check the fuse.

(1) If fuse is bad, replace and try radio again. Race

engine and, if fuse blows again,‘remove the radio and

speaker assembly for repair by

4 trained radio techni-

cian.

(2) If fuse is good, check to

s&e that the speaker-to-

receiver interconnecting cable is connected securely.

If there is still no thump when the radio is turned on,

remove the receiver and speaker for repair.

2. Check the antenna by substituting with one held

out the car window.

a. If radio is still dead with substitute antenna,

remove the receiver and spea!er for repair.

b. If radio operates near normal with substitute an-

tenna, some part of the car antenna or lead-in is at

fault.

Radio Reception Is Weak1. Check to see if antenna trimmer is peaked.

a. Position antenna at a height of 31 inches.

b. Tune radio to weak station at or near 1400 KHz

on the dial, and turn volume control to maximum.

Page 614 of 625

9C-106 1973 OPEL SERVICE MANUAL

c. Adjust trimmer screw for maximum volume.

d. If antenna trimmer does not have a definite peak, check for defective antenna by substitution.

2. Check that the speaker connection is plugged in

SXUdY.

3. If the radio is still weak, remove the receiver and

speaker assembly for repair.

Radio Is Noisy

1. Radio is noisy all the time:

a. Check for defective antenna by striking antenna

with hand. If static is heard while tapping, replace

antenna.

b. If antenna is not defective, remove receiver and

speaker for repair.

2. Radio is noisy only when jarred:

a. Check antenna as in Step No. 1 above.

b. Check speaker connection. If speaker connection is not at fault, remove receiver and speaker for re-

pair.

3. Radio is noisy when engine is running:

a. Check noise suppressor by substituting on genera-

tor with known good one.

b. Check to see that antenna is mounted securely,

grounding the antenna base to the fender. The an-

tenna lead-in wire is shielded and the shield should

have good ground connection at the receiver and the

antenna base.

c. Check for other car wiring, passing too close to

radio receiver case.

d. If engine noise is still present, remove receiver and

speaker for repair.

4. Radio is noisy when car equipment is operated,

such as directional lights or brake lights:

Check for defective antenna lead-in wire or, loose

antenna mounting, as in Step No. 3b above.

MAINTENANCE AND ADJUSTMENTS

ANTENNA TRIMMER ADJUSTMENT

An antenna trimmer adjusment screw is provided for

matching of the antenna coil in the receiver to the car antenna. This adjustment must always be made after

installation of a receiver or an antenna, or after re-

pair to these units. This adjustment should also be

performed whenever radio reception is unsatisfac-

tory.

1. Position antenna to a height of 31 inches.

2. Tune receiver

tb a weak station at or near 1400

KHz that can barely be heard

with volume turned

fully up.

3. Insert a small-bladed screwdriver in antenna trim-

Figure 9C-1 Location of Access Trim Plug

Figure

9C-2 Removing Hex Head Screw