ECU OPEL GT-R 1973 Repair Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1973, Model line: GT-R, Model: OPEL GT-R 1973Pages: 625, PDF Size: 17.22 MB

Page 521 of 625

9A-i2 1973 OPEL SERVICE MANUAL

Check that air doors and water temperature control

valve are operating properly.

Check for plugged heater core-backflush heater core

as necessary.TROUBLEInadequate defrosting action.

CAUSE AND CORRECTIONExamine heater-defroster door for proper operation.

Adjust bowden cable so that door is fully closed in

FULL DEFROST position.

Check that air hoses connecting to defroster outlets

are secure.

Check for air leaks around edges of heater air dis-

tributor housing. Seal leaks, as necessary, with bodysea@. Check for body air leaks and seal, as neces-

sary, with body sealer.

TROUBLEBlower inoperative.

CAUSE AND CORRECTIONCheck blower fuse. Replace, if necessary, fuse posi-

tion 4

- amperage 15.

Check wiring for open circuit. Correct, as required.

Inspect for defective component, (i.e., blower switch

or blower motor)

- replace or repair as necessary.

MAINTENANCE AND ADJUSTMENTS

CONTROL CABLE ADJUSTMENTAdjustment of control cables is accomplished by po-

sitioning of the jacket or sheath of the control cable,

as held by the clamps on the control assembly and

heater case or by loosening screws and slidingbowden wire to obtain desired door or water valve

position.

MAJOR REPAIR

REMOVING AND INSTALLING HEATER HOUSING

Removal1. Unscrew hood lock together with ground wire(ground wire only on vehicles with radio interference

suppression). See Figure 9A-33.

Figure 9A-33 Hood Lock Attachments

2. Unscrew heater housing cover.

3. Pull hose of windshield washer system off jet and

take jet out of housing cover.

4. Unscrew bowden control wire from heater valve.

5. Unscrew heater housing from dash panel and pull

it off carefully. See Figure 9A-34.

Figure 9A-34 Heater Housing Attachments

6. Remove water hoses from heater core and pull

heater core out of heater housing. See Figure

9A-35.

Page 523 of 625

9A-14 1973 OPEL SERVICE MANUAL

upper attaching screw through opening for heater

control housing and lower attaching screw below

instrument panel. See Figure 9A.-38.5. On right side, viewed in driving direction, install

air distributor housing attaching screws. See Figure9A-37.

6. Install radio.

7. Install glove compartment.

8. Install bowden control wires to heater valve and

air distributor housing.

9. Install instrument cover.

10. Install heater switch lever.

Figure 9A-38 Upper Attaching Screw

9. Pull defroster outlets downwards and remove out-

lets through glove compartment opening. See Figure9A-39.

REMOVAL AND INSTALLATION OF HEATER

CONTROL HOUSING

Removal1. Remove instrument panel cover

- refer to operat-

ion,

IRemoving and Installing Instrument Housing.

2. Remove two sheet metal screws for control hous-

ing attachment. See Figure 9A-40.

Figure 9A-39 Removing Defroster Jets

Installation

1. Apply sealing compound between air distributor

housing and dash panel.

2. Install defroster outlets, securing with two (2)

clips at the instrument panel. See Figure 9A-39.

3. Install air distributor housing to dash panel,

4. On left side, viewed in driving direction, installFigure 9A-40 Control Housing Attaching Screws

3. In engine compartment, detach bowden control

wire from heater valve. See Figure 9A-41.

4. Detach bowden control wire from air distribution

flap. See Figure 9A-42.

5. Pull wires off blower switch. See Figure 9A- 43.

Page 536 of 625

REFRIGERANT COMPONENTS ALL MODELS99.27that line, they still hadn’t gotten anywhere. So, they

started from scratch and juggled molecules around

to make an entirely new refrigerant. Eventually they

succeeded by remodeling the molecules in carbon

tetrachloride. This is the same fluid that is used in

fire extinguishers and dry-cleaners’ solvents.

From this fluid, the chemists removed two chlorine

atoms and replaced them with two fluorine atoms.

This newly-formed fluid carried the technical chemi-

cal name of dichlorodifluoromethane. Today, we

know it as Refrigerant-12 or R-12.

Fluorine is an extremely temperamental substance.

Under most conditions it is toxic and highly corro-

sive, and after is is manufactured, it has to be stored

in special containers because it will eat through glass

and will dissolve most metals in short order.

Despite its rambunctious character though, fluorine

is completely tamed when it is combined with the

other substances that go to make up the refrigerant.

Each is non-toxic, non-inflammable, non-explosive,

and non- poisonous; however, breathing large quan-

tities of R-12 should be avoided.

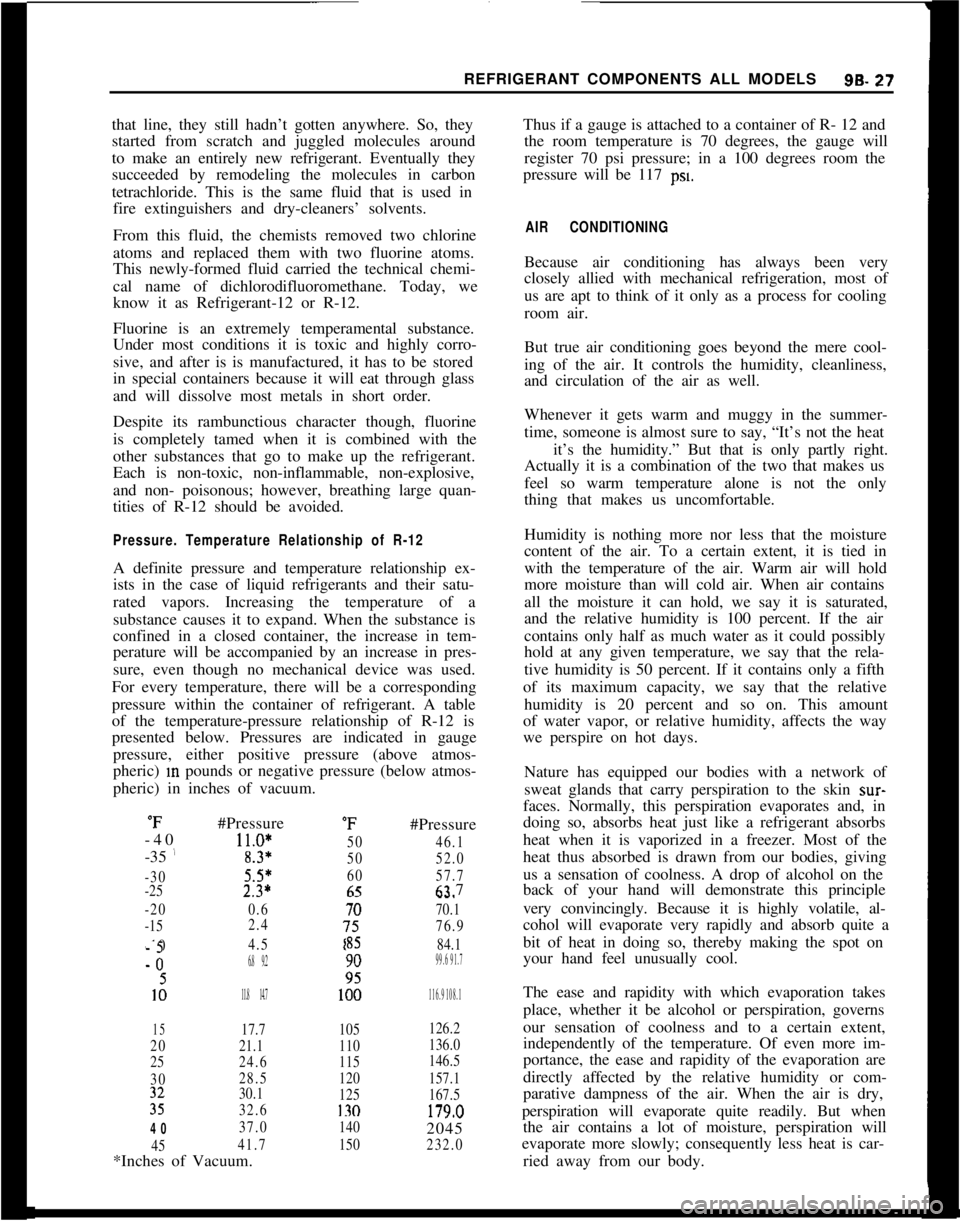

Pressure. Temperature Relationship of R-12A definite pressure and temperature relationship ex-

ists in the case of liquid refrigerants and their satu-

rated vapors. Increasing the temperature of a

substance causes it to expand. When the substance is

confined in a closed container, the increase in tem-

perature will be accompanied by an increase in pres-

sure, even though no mechanical device was used.

For every temperature, there will be a corresponding

pressure within the container of refrigerant. A table

of the temperature-pressure relationship of R-12 is

presented below. Pressures are indicated in gauge

pressure, either positive pressure (above atmos-

pheric) m pounds or negative pressure (below atmos-

pheric) in inches of vacuum.

“F-40

-35

i#Pressure

11.0*

8.3*

“F

50

50#Pressure

46.1

52.0

-30~

5.5*6057.7

-252.3*6s67 7__.

-200.6

io70.1

-152.4

76.9

-104.584.1

1;6.8 9.2tz99.6 91.71;

11.8 14.712116.9 108.1

1517.7105126.2

2021.1110136.0

2524.6115146.5

3028.5120157.1

;:

30.1

125167.5

32.6

131)179n

4037.0

4541.7*Inches of Vacuum.-. _.-

1402045

150232.0Thus if a gauge is attached to a container of R- 12 and

the room temperature is 70 degrees, the gauge will

register 70 psi pressure; in a 100 degrees room the

pressure will be 117

ps~

AIR CONDITIONINGBecause air conditioning has always been very

closely allied with mechanical refrigeration, most of

us are apt to think of it only as a process for cooling

room air.

But true air conditioning goes beyond the mere cool-

ing of the air. It controls the humidity, cleanliness,

and circulation of the air as well.

Whenever it gets warm and muggy in the summer-

time, someone is almost sure to say, “It’s not the heat

it’s the humidity.” But that is only partly right.

Actually it is a combination of the two that makes us

feel so warm temperature alone is not the only

thing that makes us uncomfortable.

Humidity is nothing more nor less that the moisture

content of the air. To a certain extent, it is tied in

with the temperature of the air. Warm air will hold

more moisture than will cold air. When air contains

all the moisture it can hold, we say it is saturated,

and the relative humidity is 100 percent. If the air

contains only half as much water as it could possibly

hold at any given temperature, we say that the rela-

tive humidity is 50 percent. If it contains only a fifth

of its maximum capacity, we say that the relative

humidity is 20 percent and so on. This amount

of water vapor, or relative humidity, affects the way

we perspire on hot days.

Nature has equipped our bodies with a network of

sweat glands that carry perspiration to the skin

sur-faces. Normally, this perspiration evaporates and, in

doing so, absorbs heat just like a refrigerant absorbs

heat when it is vaporized in a freezer. Most of the

heat thus absorbed is drawn from our bodies, giving

us a sensation of coolness. A drop of alcohol on the

back of your hand will demonstrate this principle

very convincingly. Because it is highly volatile, al-

cohol will evaporate very rapidly and absorb quite a

bit of heat in doing so, thereby making the spot on

your hand feel unusually cool.

The ease and rapidity with which evaporation takes

place, whether it be alcohol or perspiration, governs

our sensation of coolness and to a certain extent,

independently of the temperature. Of even more im-

portance, the ease and rapidity of the evaporation are

directly affected by the relative humidity or com-

parative dampness of the air. When the air is dry,

perspiration will evaporate quite readily. But when

the air contains a lot of moisture, perspiration will

evaporate more slowly; consequently less heat is car-

ried away from our body.

Page 541 of 625

98-32 1973 OPEL SERVICE MANUAL

inserting it in the connection. Another precaution -inspect the fitting for burrs which can cut the

“0”ring.

Restrictions

Restrictions may be due to powdered desiccant or

dirt and foreign matter. This may result in starved

evaporator and loss of cooling, or a seized compres-

SOT.When the amount of moisture in a system sufti-

ciently exceeds the capacity of the desiccant, it can

break down the desiccant and cause it to powder.

The powder passes through the dehydrator screen

with the refrigerant liquid and is carried to the ex-

pansion valve screen. While some of it may pass

through the valve screen into the evaporator, it may

quickly build up to cause a restriction.

Due to the fact that sufftcient oil can not be returned

to the compressor, it may seize.

Dirt

Dirt, which is any foreign material, may come from

cleaner residues, cutting, machining, or preserving

oils, metal dust or chips, lint or dust, loose rust,

soldering or brazing fluxes, paint or loose oxide

scale. These can also cause seized bearings by abra-

sion or wedging, discharge and expansion valve fail-

ure, decomposition of refrigerant and oil, or

corrosion of metal parts.

CorrosionCorrosion and its by-products can restrict valve and

drier screens, rough bearing surfaces or rapid fatigu-

ing of discharge reeds. This can result in high tem-

perature and pressure, decomposition or leaks. In

any event, this means a wrecked compressor.

From this, we can see the vicious circle that can be

produced in a refrigerating system to cause its fail-

ure. Corrosion can be the indirect cause of leaks, and

leaks can be the direct cause of corrosion. We can

also see the important role we as servicemen play in

maintaining chemical stability.

The major cause of corrosion is moisture.

Moisture

Moisture is the greatest enemy of refrigerating sys-

tems. Combined with metal, it produces oxide, Iron

Hydroxide and Aluminum Hydroxide. Combined

with R-12 it produces Carbonic acid, Hydrochloric

acid, and Hydrofluoric acid. Moisture can also cause

freeze-up of expansion valve and powdered desic-

cant.Although high temperature and dirt are responsible

for many difficulties in refrigerating systems, in most

instances it is the presence of moisture in the system

that accelerates these conditions. It can be said,themfore, that moisture is the greatest enemy of all.

The acids that it produces, in combination with both

the metals and the refrigerant, cause damaging

COT-

rosion. While the corrosion may not form as rapidly

with R-12 as with some other refrigerants, the even-

tual formation is as damaging.

If the operating pressure and temperature in the

evaporator is reduced to the freezing point, moisture

in the refrigerant can collect at the orifice of the

expansion valve and freeze. This temporarily re-

stricts the flow of liquid causing erratic cooling.

As previously mentioned, moisture in excess of the

desiccant’s capacity can cause it to powder.

YOU SHOULD KNOW AND REMEMBER..That the inside of the refrigerat,ion system is com-

pletely sealed from the outside world. And if that

seal remains broken at any point

- the system will

soon be destroyed. That complete and positive seal-

ing of the entire system is vitally important and that

this sealed condition is absolutely necessary to retain

the chemicals and keep them in a pure and proper

condition.

That all parts of the refrigeration system are under

pressure at all times, whether operating or idle, and

that any leakage. points are continuously losing re-

frigerant and oil.

That the leakage of refrigerant can be so silent that

the complete charge may be lost without warning.

That refrigerant gas is heavier than air and will rap-

idly drop to the floor as it flows from a point of

leakage.

That the pressure in the system may momentarily

become as high as 400 lbs. per square inch, and that

under such pressure the molecules of refrigerant are

forced out through the smallest opening or pore.

That the compressor is continually giving up some

lubricating oil to the circulating refrigerant and de-

pends upon oil in the returning refrigerant for con-

tinuous replenishment. Any stoppage or major loss

of refrigerant will therefore be fatal to the compres-

SOT.That the extreme internal dryness of a properly proc-

essed system is a truly desert condition, with the

drying material in the receiver holding tightly on to

the tiny droplets of residual moisture.

Page 553 of 625

9B-44 1973 OPEL SERVICE MANUAL

Do not turn refrigerant drum upside down, as this

would allow liquid refrigerant to enter compressor

which may cause damage.

4. If line at center gauge fitting has not been purged

of air, loosen line at center fitting on gauge set and

crack valve on refrigerant drum to blow air from

line. Retighten line at center fitting and record exact

weight of refrigerant tank in water on the scales.

5. Open valve on refrigerant drum and both valves

on gauge set to allow refrigerant to flow into system.

Continue charging until the scales show that 2

Ibs.Opel 1900

- Manta and 2 l/4 lbs. GT, of refrigerant

have been transferred from refrigerant drum to sys-

tem.If full charge cannot be obtained, close both valves

on gauge set, start engine, and set temperature con-

trol knob to full cold position with blower in Max Hi.

Open low pressure valve on gauge set slowly and

leave open until full charge is added.

WARNING: Observe high pressure gauge while charg-

ing with compressor running. Shut

offengine ifpres-

sure exceeds 250 psi. A large fan placed in front

ol

the car wi// help reduce excessively high head pres-6. Close both valves on gauge set (high pressure valve

will already be closed if charging was completed by

running compressor) and close valve on refrigerant

drum.

If the engine was used to complete the charge into

the system, close valve on refrigerant drum to permit

compressor to draw any refrigerant left in the line

from the drum to the center fitting of the gauge set,

then close the low pressure valve on the gauge set.

7. Operate engine at 2000 RPM with temperature

control knob at full cold, blower speed in Max Hi.

After ten minutes of operation, observe appearance

of refrigerant in receiver-dehydrator. If bubbles are

observed, open low pressure gauge valve and valve

on refrigerant drum to allow more refrigerant to en-

ter system. Close valve when receiver-dehydrator

clears

up.If an air inlet temperature is below 70 degrees F.

when this check is made, bubbles may appear, even

though the proper amount of refrigerant is in the

system. Air inlet temperature must be 70 degrees F.

or above to make an accurate check.

8. When refrigerant has been installed, continue to

operate system and test for proper operation as ou-

tlined under “Operational Test”.

9. When satisfied that air conditioning system is op-

erating properly, stop engine, remove gauge set and

replace protective caps on compressor fittings.10. Using leak detector, check complete system for

leaks.Disposable Can Method

After having

depress&ed, repaired (if necessary)

and evacuated the refrigerant system, the system

may be charged as follows using refrigerant in dis-

posable cans:

1. Obtain three (3) 1

lb. cans or one 12 lb. can of

refrigerant.

2. If using 1 lb. cans, mount two (2) cans in J-6272-

02 (Multi-opener) or attach J-6271 (single-can

opener valve) on one can. If using the 12

lb. disposa-

ble can, attach J-23390 (disposable can control valve)

on can.WARNING: Make sure outlet valve on opener is

closed (clockwise) before installing opener.A. If the J-6272-02 multi-opener is used, raise lock-

ing lever, position three (3) cans of refrigerant and

force locking lever down to secure cans and at same

time puncture top of can to make it ready for charg-

ing.

B. If the J-6271 valve is used, back off the valve from

the can top retainer, slip the valve onto the can and

turn the valve into retainer until tight. DO NOT

open outlet valve during this operation, as turning

the valve into the retainer punctures top of can to

make it ready for charging.

3. Connect center flexible line of gauge set to fitting

on a can opener valve. If the line at center gauge

fitting has not been purged of air, loosen line at

center fitting on gauge set and “crack” valve at can

opener (for a second or two) to force air from the

line. Retighten line at center fitting.

4. Open valve at refrigerant source and at low and

high pressure valves on manifold gauge set. Leave

valve open at refrigerant source until all refrigerant

(when using 1 lb. can) has ‘entered the refrigeration

system or system is fully charged. Close valve on can.

A. If the system is charged using

1 lb. cans and the

J- 627 1 valve, disconnect valve from can. Leave valve

closed to flexible line to the center fitting of the

manifold gauge set. Install valve on a new and full

disposable can of refrigerant.

Page 554 of 625

REFRIGERANT COMPONENTS ALL MODELS9t3- 45

B. If system is charged using J-6272-02, close the

valve of opener after all cans are empty. Release the locking lever and discard the three (3) empty cans.

If this tool will be used to complete the charge with

additional cans to provide the required refrigerant

charge, leave the empty cans in position, locate one

full can and lock the lever into place. These empty

cans balance the assembly and prevent the loss of

refrigerant through the open “series” passage. Align

the pierced hole in the empty can with the punch in

the cover of the tool.

If the J-6271 valve for single cans is available, com-

plete charging as explained in 4a above.

5. Close high side valve on manifold gauge set,

WARNING: Prior to starting up engine, the high side

valve on the charging manifold must be closed due

to excessive pressure

bui/d-up which can result in

bursting of the container(s) causing serious injury. If

you are inexperienced in the use of this procedure, seek professional assistance.

6. Operate engine at 2000 RPM with temperature

control knob at full cold position and blower speed

on Max Hi. If air inlet temperature at the condenser

is below 70 degrees F. when this check is made,

bubbles may appear, even though the proper amount

of refrigerant is in the system. Air inlet temperature

must be 70 degrees F. or above to make an accurate

check.

7. When refrigerant has been installed, continue to

operate system and test for proper operation as ou-

tlined

under “Operational Test”.

8. When satisfied that the air conditioning system

is operating properly, stop engine, remove gauge set

and replace protective caps on suction and discharge

fittings.

from thegauge fitting to prevent damage-or injury to

personnel.

9. Using a leak detector, check complete system for

leaks.

Charging Station Method

INSTALLING J-8393-02

-

1. Be ceitain compressor hand shut-off valves to

gauge fittings are closed (counterclockwise).

2. Be certain all valves on charging station are

closed.

3. Connect high pressure gauge line to compressor

high pressure gauge fitting.

4. Turn high pressure hand shut-off valve one turn

clockwise, and high pressure control one turn coun-

terclockwise (open). Crack open low pressure con-

trol and allow refrigerant gas to hiss from low

pressure gauge line for three seconds, then connect

low pressure gauge line to low pressure gauge fitting

on compressor adapter fitting. (Place J-9459 adapter

on hose, then attach adapter to gauge fitting.)

FILLING CHARGING CYLINDER

1. Open Control valve on refrigerant container.

2. Open valve on bottom of charging cylinder, al-

lowing refrigerant to enter cylinder.

3. Bleed charging cylinder to valve (behind control

panel) only as required to allow refrigerant to enter

cylinder. When refrigerant reaches desired charge

level, close valve at bottom of charging cylinder and

be certain cylinder bleed valve is closed securely.

While filling the cylinder, it will be necessary to close

the bleed valve periodically to allow boiling to sub-

side so that refrigerant level in the charging cylinder

can be accurately read.

CHARGING THE SYSTEM USING J-8393-02

1. With charging station connected, as previously

described, remove low pressure gauge line at com-

pressor adapter fitting.

2. Crack open high and low pressure control valves

on station and allow refrigerant gas to purge from

system. Purge slowly enough so, that oil does not

escape from system along with refrigerant.

3. When refrigerant flow nearly stops, connect low

pressure gauge line to

compress& adapter fitting.

4. Turn on vacuum pump and open vacuum control

valve.

5. With system purged as

abovk, run pump until

26-28 inches of vacuum is obtained Continue to run

pump for 15 minutes after the system reaches 26-28

inches vacuum.

In all evacuating procedures, the specification of

26.

28 inches of mercury vacuum is used. These figures

are only attainable at or near sea level. For each 1000

feet above sea level where this operation is being

performed, the specifications should be lowered by 1

inch. For example, at 5000 feet elevation, only 21 to

23 inches vacuum can normally be obtained.

6. If 26-28 inches vacuum (corrected to sea level)

cannot be obtained, close vacuum: control valve and

Page 560 of 625

REFRIGERANT COMPONENTS ALL MODELSSB- 51

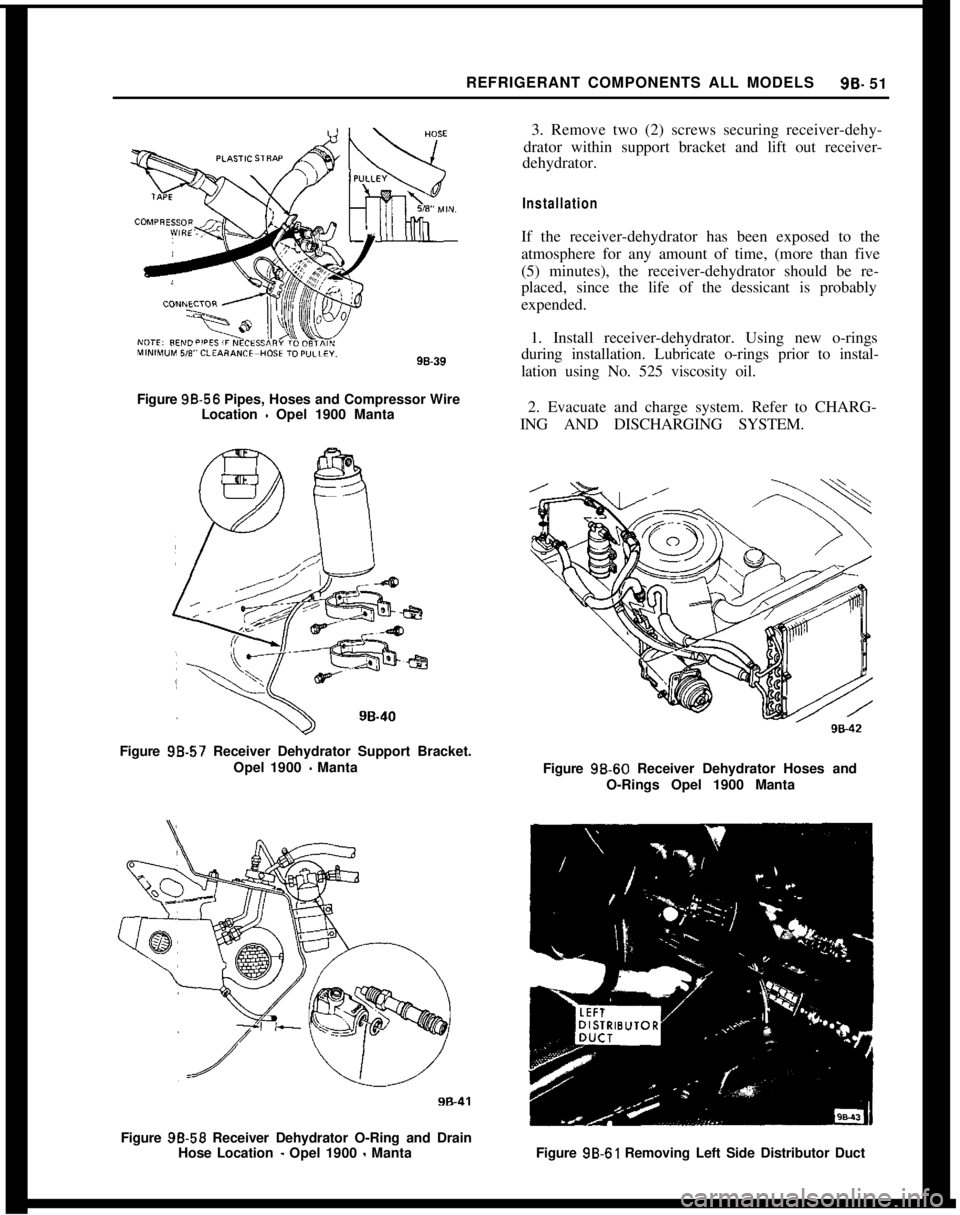

3. Remove two (2) screws securing receiver-dehy-

drator within support bracket and lift out receiver-

dehydrator.

InstallationIf the receiver-dehydrator has been exposed to the

atmosphere for any amount of time, (more than five

(5) minutes), the receiver-dehydrator should be re-

placed, since the life of the dessicant is probably

expended.

1. Install receiver-dehydrator. Using new o-rings

during installation. Lubricate o-rings prior to instal-

lation using No. 525 viscosity oil.

Figure 98.56 Pipes, Hoses and Compressor Wire

Location

- Opel 1900 Manta2. Evacuate and charge system. Refer to CHARG-

ING AND DISCHARGING SYSTEM.

Figure 98.57 Receiver Dehydrator Support Bracket.

Opel 1900

- Manta

Figure 98-59 Receiver Dehydrator O-Ring and Drain

Hose Location

- Opel 1900 - MantaFigure 9B-60 Receiver Dehydrator Hoses and

O-Rings Opel 1900 Manta

Figure 9B-61 Removing Left Side Distributor Duct

Page 564 of 625

REFRIGERANT COMPONENTS ALL MODELS99.55pipes and tape closed the open ends of refrigerant

lines, and also the open ends of the inlet and outlet

pipes of the condenser.

10. Remove two (2) top retaining screws.

Figure

9,S-73 Condenser Retaining Screws - Opel

1900

- Manta

11. Remove radiator grille and two (2) condenser to

body mounting screws. See Figure 98.74.

Figure 98-74 Condenser Assembly and Attachments.

Opel 1900

- Manta

12. Remove condenser.

Installation

If refrigerarit circuit or condenser has been exposed

to the atmosphere and moisture may be present in

the circuit, the system and/or component must beFigure 98-75 Condenser Assembly Mounting Brackets

Opel 1900 Manta

flushed prior to installation. Refer to FLUSHING

THE SYSTEM.

1. Install comjenser into car and install 2 condenser

to body mounting screws. See Figure 98-74. Install

radiator grill.

2. Install 2 top retaining screws.

3. Remove tape from the condenser pipes and re-

frigerant hoses and install hoses using new o-rings on

lines lubricated with No.

525 viscosity oil.

4. Evacuate system. Refer to EVACUATING SYS-

TEM.

5. While system is being evacuated, install radiator

into engine compartment and secure lower attaching

nut.

Figure 98.76 Clearance Between Lower Radiator

Tank and Fan Blades

- Opel 1900 Manta

6. On vehicles with automatic transmissions, fasten

Page 567 of 625

98-58 1973 OPEL SERVICE MANUAL

2. Discharge system. Refer to DISCHARGING

SYSTEM.

3. While system is discharging remove air cleaner

and loosen idler pulley and bracket assembly. See

Figure 98-80.

4. Remove bolt holding compressor adapter fitting

into rear head. Disengage from compressor and tape

closed openings in both lines and ports in rear head.

It is important to seal compressor ports to avoid a

loss of refrigeration oil and also to prevent foreign

material and moisture from entering compressor. See

Figure 9B-82.

5. Remove bolt and ground wire, unplug electrical

connector, and remove 2 rear compressor mounting

bolts. See Figure 98-82.

6. Remove 2 front compressor mounting bolts,

clutch drive belt, and lift out compressor. During

removal, maintain the compressor position so that

the sump is downward. Do not’rotate compressor

shaft. See Figure 9B-84.

Installation1. Install compressor into mounting brackets and

secure with 4 mounting bolts. See Figure

9B-84.2. Untape lines and ports, and install compressor

adapter fitting and bolt using new o-rings. See Figure

9B-82.3. Evacuate system. Refer to, EVACUATING

SYSTEM.

4. While system is being evacuated, install drive belt

and tighten idler pulley. See Figure

9B-80.5. Install bolt and ground wire and plug in electrical

connector. See Figure

9B-83.6. Install air cleaner and negative battery cable.

7. Charge system. Refer to, CHARGING SYS-

TEM.

REMOVAL AND INSTALLATION OF

RECEIVER.DEHYDRATOR

ASSEMBLY. GT

Removal1. Discharge system. Refer to DISCHARGING

SYSTEM.

2. Disconnect refrigerant lines to both ends of re-

ceiver-dehydrator and tape closed open ends of

re-

9862Figure 98.85 Refrigeration Hose Clamps Installation

GT

frigerant lines, and also the open

e:nds of the inlet and

outlet pipes of the receiver-dehydrator. See Figure

9B-86.Figure 98.86 Receiver-Dehydrator GT

3. Remove 2 screws securing receiver-dehydrator

and clamps to support bracket and lift out receiver

dehydrator. See Figure

9B-86.

Installation1. Install receiver-dehydrator using new o-rings

during installation. Lubricate o-rings prior to instal-

lation using No. 525 viscosity oil.

.

Page 568 of 625

REFRIGERANT COMPONENTS ALL MODELS9s. 59

2. If the receiver-dehydrator has been exposed to

the atmosphere for any amount of time, (more than

5 minutes), the receiver-dehydrator should be re-

placed, since the life of the dessicant is probably

expended.

3. Evacuate and charge system. Refer to CHARG-ING AND DISCHARGING SYSTEM.

REMOVAL AND INSTALLATION OF EVAPORATOR

AND EXPANSION VALVE. GTRemoval

1. Disconnect negative battery cable.

2. Discharge system. Refer to, DISCHARGING

SYSTEM.3. While system is discharging, remove attaching

screws and lift out luggage tray. See Figure

9B-87.Figure 98.88 Evaporator Cover Assembly and

Attaching Screws GT

Figure 98.87 Luggage Tray

4. Remove all evaporator cover screws and removecover. See Figure

9B-88.

5. Remove electrical plug connector from the resis-tor assembly and unplug blower motor connection

and remove ground wire. See Figure

9B-90.6. From underneath evaporator housing, discon-

nect two (2) drain hoses. See Figure

9B-91.

7. From under car remove 4 nuts securing

evapora-Figure 96.90 Electrical Connections, Ground Wire

GTtar mounting bracket to floor. See Figures

9B- 92

and

9B-93.8. Remove inlet and outlet pipes from evaporator

and tape closed the refrigerant lines and also the

open ends of the inlet and outlet pipes of the evapora-tor. See Figure

9B-94.